Beruflich Dokumente

Kultur Dokumente

ConocoPhillips Case Study

Hochgeladen von

abhishekatupesCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ConocoPhillips Case Study

Hochgeladen von

abhishekatupesCopyright:

Verfügbare Formate

Customer Profile

ConocoPhillips

Refining

Challenge: Provide accurate cost estimates with fewer staff to support a $1.4B budget for growth investments. Solution: Aspen Economic Evaluation software providing downstream estimating tools Benefits: Increases estimator productivity from $30M estimated/day to $80M estimated/day in two years. Reduces overruns to near zero Reduces variability in estimates from 35% to 12% Supports economic decision support with powerful database Reduces cost variability to <15% Increases capital project workload while keeping same staff levels Extends same tools to third parties for faster analysis of E&C bids Reduces project risks with better cost accuracy

Global Refiner Deploys Cost Estimation Solution to Accelerate Decision Making and Lower Costs

Standardized, systematic approach from AspenTech enables ConocoPhillips to aggressively complete $1.4B in capital projects, while reducing risk and doubling end-user productivity.

As one of the worlds leading integrated oil producers, operating 12 refineries in the U.S. and Canada with a throughput of 2.6 million barrels per day, ConocoPhillips is North Americas second largest refiner. To support its downstream operations, ConocoPhillips invests millions of dollars a year in refining capital projects, which can include maintenance, clean fuels upgrades, and growth investments. Completing these projects in a timely, efficient manner will help the company meet its operational goals and significantly improve the bottom line. Looking for a solution to enhance and speed up project decision making, ConocoPhillips adopted the Aspen Kbase capital cost estimation system for the team that handles all refinery project estimating. Since implementation in 2001, ConocoPhillips has not only increased estimating accuracy, but has also moved the business decision point forward in the design processensuring projects are completed much faster at significant savings. A statistical database enables the company to review and analyze post-project results for continuous process improvement.

By using Aspen Kbase on a systematic basis and tracking historical project cost performance, ConocoPhillips has greatly improved its ability to predict and manage capital costs. This has made the estimating function strategically valuable in the downstream capital investment decision process.

Jim Whiteside, ConocoPhillips Downstream

Support an Increase in Downstream Capital Projects

With market dynamics keeping refinery loads at over 90% capacity and regulatory pressures requiring clean fuels and emissions upgrades, ConocoPhillips faces a steady growth of downstream capital investment projects. ConocoPhillips philosophy is to employ a balanced approach in its downstream business to create shareholder value. The company adheres to three principles for each project: capital discipline, operational excellence and execution, and financial optimization. Thats why the estimating functionnow managed through Aspen Kbaseis so critical in examining the increasing volume of capital proposals, and providing actionable estimates earlier in the process.

About AspenTech

AspenTech is a leading provider of award-winning process optimization software and services. AspenTechs integrated aspenONE solutions enable manufacturers to reduce costs, increase capacity, and optimize operational performance end-to-end throughout the engineering, plant operations, and supply chain management processes, resulting in millions of dollars in cost savings. For more information, visit www.aspentech.com.

Standardized and Systematic Capital Cost Estimation

The Aspen Kbase solution not only provides a robust, viable capital cost estimation solution for downstream estimators, but also works with other project tracking tools to help ConocoPhillips closely monitor and analyze results long after the estimate is complete. The AspenTech solution provides systematic work processes, allowing ConocoPhillips to use consistent tools and collect results from projects for ongoing benchmarking. As such, the company can require E&C suppliers to use the same tools when bidding or working on projects.

Worldwide Headquarters

Aspen Technology, Inc. 200 Wheeler Road Burlington, MA 01803 phone: +1-781-221-6400 fax: +1-781-221-6410 info@aspentech.com

EMEA Headquarters

AspenTech Ltd. C1, Reading Intl Business Park Basingstoke Road Reading UK RG2 6DT phone: +44-(0)-1189-226400 fax: +44-(0)-1189-226401 ATE_info@aspentech.com

Standardized Work Processes for Reusable Designs

After adopting Aspen Kbase, ConocoPhillips has improved estimators productivity and project schedules. The company has built metrics into a statistical database resulting in decision support feedback and use of statistical analysis for enhanced economic decision making. Importantly, at the business level, Aspen Kbase estimating leads to early capital decisions on projects at the FEL 2 engineering stage.

APAC Headquarters

AspenTech - Shanghai 3rd Floor, North Wing Zhe Da Wang Xin Building 2966 Jin Ke Road Zhangjiang High-Tech Zone Pudong, Shanghai 201203, China phone: +86-21-5137-5000 fax: +86-21-5137-5100 apac_marketing@aspentech.com

2008 Aspen Technology, Inc. AspenTech, aspenONE, and the Aspen leaf logo are trademarks or registered trademarks of Aspen Technology, Inc. All rights reserved. 1394-0308

Das könnte Ihnen auch gefallen

- Response To RFPDokument8 SeitenResponse To RFPRohan JadhavNoch keine Bewertungen

- Hormone Replacement Therapy Real Concerns and FalsDokument13 SeitenHormone Replacement Therapy Real Concerns and FalsDxng 1Noch keine Bewertungen

- Game Audio - Tales of A Technical Sound Designer Volume 02Dokument154 SeitenGame Audio - Tales of A Technical Sound Designer Volume 02Joshua HuNoch keine Bewertungen

- Practice Problems For Modulus and Logarithm Section-I: FiitjeeDokument8 SeitenPractice Problems For Modulus and Logarithm Section-I: FiitjeePratham SharmaNoch keine Bewertungen

- RBL Financing (De Saint Gerand Electronic PEF Material Final Oct 2013)Dokument58 SeitenRBL Financing (De Saint Gerand Electronic PEF Material Final Oct 2013)abhishekatupesNoch keine Bewertungen

- Business Transformation Through TechnologyDokument20 SeitenBusiness Transformation Through TechnologyAmrik Singh100% (1)

- Engineering Manager ResumeDokument10 SeitenEngineering Manager ResumeJameel KhanNoch keine Bewertungen

- Michael R. Resume - ProductDokument2 SeitenMichael R. Resume - ProductMichael RobertsNoch keine Bewertungen

- Strategic Cost EstimationDokument35 SeitenStrategic Cost EstimationBrij PatwariNoch keine Bewertungen

- Problem SetsDokument69 SeitenProblem SetsAnnagrazia ArgentieriNoch keine Bewertungen

- Inclusions in Gross IncomeDokument2 SeitenInclusions in Gross Incomeloonie tunesNoch keine Bewertungen

- Key Performance Indicators: KPI Management ToolDokument4 SeitenKey Performance Indicators: KPI Management Tooljoaquin_guaco8038Noch keine Bewertungen

- Vice President Procurement Sourcing in USA Resume John GoebDokument2 SeitenVice President Procurement Sourcing in USA Resume John GoebJohnGoebNoch keine Bewertungen

- VP of Manufacturing or OperationsDokument4 SeitenVP of Manufacturing or Operationsapi-79310704Noch keine Bewertungen

- LOMA FLMI CoursesDokument4 SeitenLOMA FLMI CoursesCeleste Joy C. LinsanganNoch keine Bewertungen

- Director Project Management PMO in Washington D.C. Metro Resume Matthew HopwoodDokument3 SeitenDirector Project Management PMO in Washington D.C. Metro Resume Matthew HopwoodMatthew HopwoodNoch keine Bewertungen

- Aspen HYSYS BrochureDokument4 SeitenAspen HYSYS BrochureNabeel TahirNoch keine Bewertungen

- Apac 052416 Models Methods Data Behind ACCE V3Dokument40 SeitenApac 052416 Models Methods Data Behind ACCE V3kulaspiroNoch keine Bewertungen

- 2007 Coca Cola Enterprise SAP Business Planning and Consolidation NW Version 10 Implementation JourneyDokument18 Seiten2007 Coca Cola Enterprise SAP Business Planning and Consolidation NW Version 10 Implementation JourneyArpan MahajanNoch keine Bewertungen

- Materials Selection in Mechanical Design - EPDF - TipsDokument1 SeiteMaterials Selection in Mechanical Design - EPDF - TipsbannetNoch keine Bewertungen

- Application of Lean in Caterpillar IncDokument6 SeitenApplication of Lean in Caterpillar IncAyush GautamNoch keine Bewertungen

- Aspen PIMS DetailsDokument4 SeitenAspen PIMS DetailsJagan BoseNoch keine Bewertungen

- Project Manager or Implementation ManagerDokument5 SeitenProject Manager or Implementation Managerapi-121457406Noch keine Bewertungen

- Project Control Methods and Best Practices: Achieving Project SuccessVon EverandProject Control Methods and Best Practices: Achieving Project SuccessNoch keine Bewertungen

- New Python Basics AssignmentDokument5 SeitenNew Python Basics AssignmentRAHUL SONI0% (1)

- PMBOK Chapter 6 - CostDokument39 SeitenPMBOK Chapter 6 - CostlatehoursNoch keine Bewertungen

- Cost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsVon EverandCost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsNoch keine Bewertungen

- Libya EPSA IV Model E&P ContractDokument108 SeitenLibya EPSA IV Model E&P Contractabhishekatupes67% (3)

- Using Results Analysis To Get The Most Out of The PS ModuleDokument21 SeitenUsing Results Analysis To Get The Most Out of The PS Modulegokul198073% (11)

- GlobalDokument24 SeitenGloballaleye_olumideNoch keine Bewertungen

- Driving Forces Supply Chain ManagementDokument8 SeitenDriving Forces Supply Chain ManagementMuhammad Qasim Malik100% (1)

- Function Analysis System Technique DiagramDokument7 SeitenFunction Analysis System Technique DiagramTharayilJamesNoch keine Bewertungen

- Earned Value Project Management (Fourth Edition)Von EverandEarned Value Project Management (Fourth Edition)Bewertung: 1 von 5 Sternen1/5 (2)

- Results Analysis PDFDokument21 SeitenResults Analysis PDFsampath100% (3)

- Conoco Phillips 3251Dokument4 SeitenConoco Phillips 3251Anonymous 89mOzKNoch keine Bewertungen

- Mid-Size EPC Reduces Cost Estimating Time Up To 90% To Meet Tighter Schedules and BudgetsDokument2 SeitenMid-Size EPC Reduces Cost Estimating Time Up To 90% To Meet Tighter Schedules and BudgetsNaveen KamatNoch keine Bewertungen

- Aspen Economic Evaluation Family BrochureDokument6 SeitenAspen Economic Evaluation Family BrochureMazhar AslamNoch keine Bewertungen

- CV For Michael RobinsonDokument2 SeitenCV For Michael Robinsonapi-187601568Noch keine Bewertungen

- Assignment CompletedDokument4 SeitenAssignment CompletedRizwi PTINoch keine Bewertungen

- Continental Tire Success Story SCLDokument2 SeitenContinental Tire Success Story SCLBhanu NimraniNoch keine Bewertungen

- Carbon Credit Corporation: Measuring Sustainability With SAP® SoftwareDokument7 SeitenCarbon Credit Corporation: Measuring Sustainability With SAP® SoftwarehninoeNoch keine Bewertungen

- April 21 Nike Webinar FinalDokument45 SeitenApril 21 Nike Webinar FinalKarthik KadambiNoch keine Bewertungen

- Accountant's Role in The OrganizationDokument17 SeitenAccountant's Role in The OrganizationTapas TiwariNoch keine Bewertungen

- Bim - RipacDokument11 SeitenBim - RipacxnazmiexNoch keine Bewertungen

- VP IT Infrastructure Operations in San Francisco Bay CA Resume Pradeep KumarDokument4 SeitenVP IT Infrastructure Operations in San Francisco Bay CA Resume Pradeep KumarPradeepKumar2Noch keine Bewertungen

- 3 - MA - Case IDokument3 Seiten3 - MA - Case IDeepak KumarNoch keine Bewertungen

- EQNX Case Study HEMS 2112021215957910Dokument2 SeitenEQNX Case Study HEMS 2112021215957910Manish KumarNoch keine Bewertungen

- Amazing Chemicals - Case StudyDokument11 SeitenAmazing Chemicals - Case StudyKrishna HarshitaNoch keine Bewertungen

- Prateek Kurkanji: Work Force Management/OperationsDokument1 SeitePrateek Kurkanji: Work Force Management/OperationsShahbaz HasanNoch keine Bewertungen

- Abhinav Pratap Singh - Resume PDFDokument5 SeitenAbhinav Pratap Singh - Resume PDFgeneNoch keine Bewertungen

- Plagiarism Checker X Originality Report: Similarity Found: 3%Dokument8 SeitenPlagiarism Checker X Originality Report: Similarity Found: 3%Bicycle ThiefNoch keine Bewertungen

- DocumentDokument3 SeitenDocumentAshok U UmaprasadNoch keine Bewertungen

- I2 & Continental Tire Case StudyDokument4 SeitenI2 & Continental Tire Case StudyAniket RathodNoch keine Bewertungen

- Pricing and Estimating: B.Sravanthi Ced, KitswDokument25 SeitenPricing and Estimating: B.Sravanthi Ced, KitswKandagatla KamalNoch keine Bewertungen

- Bidding & Estimating: Click Here To View A Video Design OptimizationDokument2 SeitenBidding & Estimating: Click Here To View A Video Design OptimizationAdeniyi AleseNoch keine Bewertungen

- Aspentech Operational Insights: Emissions Management and Decision SupportDokument2 SeitenAspentech Operational Insights: Emissions Management and Decision SupportProcetradi MovilNoch keine Bewertungen

- Key Performance Indicators and BenchmarkingDokument12 SeitenKey Performance Indicators and BenchmarkingKhaled AbdelbakiNoch keine Bewertungen

- Repair & Renovation Services: Facilities OperationsDokument15 SeitenRepair & Renovation Services: Facilities OperationsFrancis Philippe Cruzana CariñoNoch keine Bewertungen

- IBM Oil - Cognos Performance Blueprint Offers Solutions For UpstreamDokument7 SeitenIBM Oil - Cognos Performance Blueprint Offers Solutions For UpstreamIBM Chemical and PetroleumNoch keine Bewertungen

- AspenTech Announces Availability of AspenONE V8 FINAL - For at - Com 12-10-2012Dokument3 SeitenAspenTech Announces Availability of AspenONE V8 FINAL - For at - Com 12-10-2012imoomexNoch keine Bewertungen

- Construction WorldDokument12 SeitenConstruction WorldlykniksNoch keine Bewertungen

- Business Service Overview:: Accenture Smart Building Solutions (ASBS)Dokument15 SeitenBusiness Service Overview:: Accenture Smart Building Solutions (ASBS)HandikaPutraNoch keine Bewertungen

- SAP Managed Services Project For A Netherlands Based Utility CompanyDokument3 SeitenSAP Managed Services Project For A Netherlands Based Utility CompanyAbdul RahoofNoch keine Bewertungen

- Coca-Cola Bottling Co. Consolidated Improves Project Cost ReportingDokument6 SeitenCoca-Cola Bottling Co. Consolidated Improves Project Cost Reportingjust_friendsNoch keine Bewertungen

- Sunil UDokument5 SeitenSunil USunil UndarNoch keine Bewertungen

- The Value of Early Analysis (Part 1) : by Gregory RothDokument4 SeitenThe Value of Early Analysis (Part 1) : by Gregory RothanandakoeNoch keine Bewertungen

- Evaluation of Capital ProjectsDokument3 SeitenEvaluation of Capital ProjectsashibhallauNoch keine Bewertungen

- CEL ConsultingDokument13 SeitenCEL ConsultingHuy TranNoch keine Bewertungen

- Book Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementVon EverandBook Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementNoch keine Bewertungen

- Resume-Vinit KhuranaDokument4 SeitenResume-Vinit KhuranaabhishekatupesNoch keine Bewertungen

- 2022.11.15 - CV MusabDokument2 Seiten2022.11.15 - CV MusababhishekatupesNoch keine Bewertungen

- ValuationDokument82 SeitenValuationabhishekatupesNoch keine Bewertungen

- SSC Jobs SSC CGL Recruitment Notification 2014Dokument40 SeitenSSC Jobs SSC CGL Recruitment Notification 2014Manavarthi RavitejNoch keine Bewertungen

- MBA (Full-Time) Add 2014 (Final)Dokument1 SeiteMBA (Full-Time) Add 2014 (Final)abhishekatupesNoch keine Bewertungen

- Woodside in LibyaDokument5 SeitenWoodside in LibyaabhishekatupesNoch keine Bewertungen

- Giignl The LNG Industry in 2012Dokument46 SeitenGiignl The LNG Industry in 2012abhishekatupesNoch keine Bewertungen

- Deloitte Upstream Oil and Gas AdvisoryDokument2 SeitenDeloitte Upstream Oil and Gas AdvisoryabhishekatupesNoch keine Bewertungen

- EPSAIVDokument14 SeitenEPSAIVabhishekatupesNoch keine Bewertungen

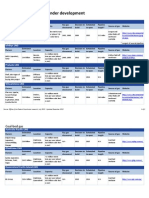

- Australia LNG Plants Under DevelopmentDokument2 SeitenAustralia LNG Plants Under DevelopmentabhishekatupesNoch keine Bewertungen

- North African Oil and Foreign Investment in Changing Market ConditionsDokument36 SeitenNorth African Oil and Foreign Investment in Changing Market ConditionsabhishekatupesNoch keine Bewertungen

- English ExerciseDokument2 SeitenEnglish ExercisePankhuri Agarwal100% (1)

- Bylaws of A Texas CorporationDokument34 SeitenBylaws of A Texas CorporationDiego AntoliniNoch keine Bewertungen

- Syllabus 9701 Chemistry AS: AS or A2 UnitsDokument4 SeitenSyllabus 9701 Chemistry AS: AS or A2 UnitsHubbak KhanNoch keine Bewertungen

- UTM Firewalls: AR3050S and AR4050SDokument8 SeitenUTM Firewalls: AR3050S and AR4050SChristian Javier Lopez DuranNoch keine Bewertungen

- Poster@IcepeDokument1 SeitePoster@IcepeAakash NawabNoch keine Bewertungen

- Kharrat Et Al., 2007 (Energy - Fuels)Dokument4 SeitenKharrat Et Al., 2007 (Energy - Fuels)Leticia SakaiNoch keine Bewertungen

- Zoomlion Gulf FZE Introduction: 1.1 ME Service Support 1.2 Construction CasesDokument13 SeitenZoomlion Gulf FZE Introduction: 1.1 ME Service Support 1.2 Construction CasesArk TradingNoch keine Bewertungen

- W1 - V1 MultipleWorksheets SolnDokument3 SeitenW1 - V1 MultipleWorksheets SolnAKHIL RAJ SNoch keine Bewertungen

- Veris Case StudyDokument2 SeitenVeris Case StudyPankaj GargNoch keine Bewertungen

- Where Business Happens Where Happens: SupportDokument19 SeitenWhere Business Happens Where Happens: SupportRahul RamtekkarNoch keine Bewertungen

- Topics For Oral PresentationDokument6 SeitenTopics For Oral PresentationMohd HyqalNoch keine Bewertungen

- Case Study Managed ServicesDokument2 SeitenCase Study Managed ServicesAshtangram jhaNoch keine Bewertungen

- ALA - Assignment 3 2Dokument2 SeitenALA - Assignment 3 2Ravi VedicNoch keine Bewertungen

- AOCS Ca 12-55 - 2009 - Phosphorus PDFDokument2 SeitenAOCS Ca 12-55 - 2009 - Phosphorus PDFGeorgianaNoch keine Bewertungen

- English Examination 1-Bdsi-XiDokument1 SeiteEnglish Examination 1-Bdsi-XiHarsuni Winarti100% (1)

- Meyer and Zack KM CycleDokument16 SeitenMeyer and Zack KM Cyclemohdasriomar84Noch keine Bewertungen

- English Literature Coursework Aqa GcseDokument6 SeitenEnglish Literature Coursework Aqa Gcsef5d17e05100% (2)

- Ansi Numerical CodeDokument6 SeitenAnsi Numerical Codekachra13Noch keine Bewertungen

- SrsDokument7 SeitenSrsRahul Malhotra50% (2)

- Analysis of Mozarts k.475Dokument2 SeitenAnalysis of Mozarts k.475ASPASIA FRAGKOUNoch keine Bewertungen

- 127 Bba-204Dokument3 Seiten127 Bba-204Ghanshyam SharmaNoch keine Bewertungen