Beruflich Dokumente

Kultur Dokumente

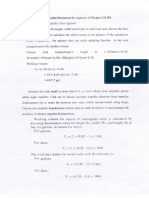

Fifth Wheel Load Calculation

Hochgeladen von

Anonymous 48jYxR1CCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fifth Wheel Load Calculation

Hochgeladen von

Anonymous 48jYxR1CCopyright:

Verfügbare Formate

Bodywork calculations 3

Table of content

BODYWORK CALCULATIONS ............................................2 PRINCIPLES OF CALCULATION ........................................3 OPTIMIZING LOAD ..............................................................6 EXAMPLE OF CALCULATION .............................................7 Example 1 4X2 Tractor with two axles ...........................7 Example 2 6X4 Tractor with three axles ........................9 Example 3 4X2 Crane behind cab ................................ 11 Example 4 6X2 Rear-mounted crane ...........................12 Example 5 4X2 Calculating length ...............................13 Example 6 6X2 Calculating centre of gravity ..............15 Example 7 6x2/4 Tractor ................................................16 Example 8 8x4 Centre of gravity calculation ................18 Example 9 8x4*4 Centre of gravity calculation ............19

Scania CV AB 2003

Bodywork calculations 3 BODYWORK CALCULATIONS

Scania CV AB 2003

Bodywork calculations 3

PRINCIPLES OF CALCULATION

The procedure for calculating a suitable platform length, payload and axle weight is based on a fewsimple rules.

The sum of the downward forces must always equal the sum of the upward forces. If a plank (assumed to be weightless) is placed on two supports and a 100 kg weight is positioned at the mid-point, the supports will each carry half of the weight, 50 kg each.

If the weight is positioned above one of the supports, this will be loaded with 100 kg and the other support will bear no load.

If the weight is placed on the outside of one of the supports, the plank will lift from the other support.

To prevent the plank from tipping, a weight of at least 20 kg must be placed over the first support. There is now equilibrium. In this case, the entire load will be carried by the second support.

Scania CV AB 2003

Bodywork calculations 3

This is popularly known as the lever principle. Replace one of the supports by a wheel and the other by a man lifting. If a weight is placed close to the man, he must lift a large part of the weight.

The closer the weight is moved towards the wheel, the less of the 100 kg weight must be lifted by the man.

However, if the weight is moved beyond the axis of the wheel, he must exert a downward force on the plank to prevent it from tilting upwards.

How does the weight supported by the man vary in relation to the position of the weight? The weight (load) is designated L (kg). The load (reaction force exerted on the man) is denoted F (kg). The distance from the wheel axis to the centre of gravity of the weight (load) is designated as lever H (mm). The distance between the loading points (wheel axis and man) is designated as A(mm).

Scania CV AB 2003

Bodywork calculations 3

In order to achieve equilibrium, the load (L) multiplied by its lever (H) must be equal to the force of reaction (F) multiplied by its lever, distance (A).

Axle weight and body calculations for trucks are based on this simple lever principle using the formula: Lx H = FxA

Load (L) x Lever (H) = Reaction (F) x Distance (A)

This equation may be rearranged in order to calculate load (L), reaction (F) or lever (H).

The wheel in the above example can be replaced by the front wheel of the truck and the man can be replaced by the rear wheel of the truck. The weight may be replaced by the truck body and load. The centre of gravity of the body and load are assumed to be at the mid-point of the platform. For the sake of simplicity we also use the unit (kg) for loads, i.e. forces.

Load (L) x Lever (H) = Reaction (F) x Distance (A) Load (L) = Reaction (F) x Distance (A) Lever (H)

Reaction (F) = Load (L) x Lever (H) Distance (A) Lever (H) = Reaction (F) x Distance (A) Load (L)

Scania CV AB 2003

Bodywork calculations 3 OPTIMIZING LOAD

All types of transport work using a truck require that the truck chassis be equipped with some type of bodywork. The intention of bodywork calculations is to optimize the chassis and the location of the bodywork in order to achieve maximum payload without exceeding maximum permissible axle weight and bogie weight, taking note of legal and technical limitations. This booklet deals with the main principles for bodywork calculations. Scania distributors and dealers have a PC-based calculation program for load/weight optimization and are able to offer assistance in bodywork calculation. Optimizing the load requires data on the weight and dimensions of the chassis. The distributor has access to chassis weights. In many countries, chassis weights are also available on the distributors website.

Example of PC calculation Front Chassis weight Additional weight Bodywork weight Weight 1-4 Bodywork equipment Unladen weight Load 0 Load 1-4 Weight of payload Unladen weight Weight of payload Gross train weight Maximum permissible weight Weight reserve 6445 0 1146 0 2135 9726 Rear Total 2585 9030 0 0 3404 4550 0 0 -135 2000 5854 15580

3885 11535 15420 0 0 0 3885 11535 15420 9726 5854 15580 3885 11535 15420 13611 17389 31000 14200 19000 32000 589 1611 1000

Weight on steered axles On steered front axles Slip limit Asphalt Slip limit Gravel roads

66% 43% 31% 18%

Scania CV AB 2003

Bodywork calculations 3

EXAMPLE OF CALCULATION

Example 1 4X2 Tractor with two axles

Calculation of front and rear axle weights (PA and PB) on a two-axle tractor with a kingpin load (L).

Applying the lever principle gives the following equation: FB = L x H A FB A L H =Kingpin load carried by the rear axle = Wheelbase = Kingpin load =Distance between front axle and fifth wheel

if:

A = 4200 mm L = 10000 kg H = 3600 mm

This gives the following distribution of load on the rear axle (FB). FB = 10000 x 3600 = 8571 kg 4200 Rear axle weight (PB) is the sum of load distribution on the rear axle (FB) and the trucks chassis weight on the rear axle (TB). PB = FB + TB

Scania CV AB 2003

Bodywork calculations 3

If chassis weight at the rear, TB = 4000 kg this gives a rear axle weight (PB) as follows: PB = 8571 + 4000 = 12571 kg

Load distribution on the front axle (FA) is calculated by subtracting the load distribution on the rear axle from the total load (L).

FA = L - FB Load distribution on the front axle (FA) in this example is as follows: FA = 10000 - 8571 = 1429 kg

Front axle weight (PA) is obtained in the same manner as the rear axle weight, i.e. the sum of load distribution on the front axle (FA) and the trucks chassis weight at the front (TA). PA = FA + TA

If chassis weight at the front, TA = 4500 kg this gives a front axle weight (PA) as follows: PA = 1429 + 4500 = 5929 kg

Scania CV AB 2003

Bodywork calculations 3

Example 2

6X4 Tractor with three axles

Calculation of the position of the fifth wheel (H) on a three-axle truck in order to achieve optimum use of front axle weight and bogie weight.

Applying the lever principle gives the following equation: H = FB x (A + B)

L

By subtracting the trucks chassis weight at the rear (TB) from the maximum permitted bogie weight, (PB) maximum permitted load on the bogie (FB) can be calculated. FB = PB - TB if: PB TB = = max. 20000 kg 5000 kg

where: H FB A B L

= Distance between front axle and kingpin = Maximum permitted load (kingpin) on bogie = Wheelbase = Distance to centre of gravity of bogie = Max. permitted load (kingpin)

This gives the following distribution of the load on the bogie (FB) FB = 20000 - 5000 = 15000 kg

The distance to the centre of gravity of the bogie (B) for the various chassis types is given in the main dimension drawings.

Scania CV AB 2003

Bodywork calculations 3

Maximum permitted load (L) is calculated by adding the max. permitted load on the bogie (FB) and the max. permitted load on the front axle (FA) L = FB + FA

The maximum permitted load on the front axle (FA) is calculated in the same manner as the max. permitted load on the bogie (FB) as follows: F A = P A - TA

if:

PA = 7000 kg TA = 5000 kg

this gives the following max. permitted load (L): FA = 7000 - 5000 = 2000 kg L = 15000 + 2000 = 17000 kg

if:

A = 4200 mm B = 675 mm (6x4)

this gives the following optimum placing of the fifth wheel.

H = 15000 x (4200 + 675) = 4300 mm 17000

In other words, in order to optimize the utilization of axle weights, the fifth wheel must be located 4300 mm from the front axle (100 mm behind the first driven axle). 10 Scania CV AB 2003

Bodywork calculations 3

Example 3

4X2 Crane behind cab

Equipment inside the wheelbase such as a crane behind the cab. If the truck is equipped with heavy optional equipment such as a crane behind the cab, the weight distribution of the crane on the front axle and rear axle must be calculated before the body calculations above can be carried out.

Applying the lever principle gives the following equation: KB = K x C A KB = Weight of crane carried by rear axle K = Total weight of crane C = Distance between front axle and centre of gravity of crane A = Wheelbase if: K = 1950 kg C = 802 mm A = 4300 mm

Crane weight on front axle (KA) will then be:

KA = K - KB KA = 1950 - 364 = 1586 kg

the rear axle (KB) will bear the following proportion of the total weight of the crane (K). KB = 1950 x 802 = 364 kg 4300

The weight of the crane on the front axle (KA) and rear axle (KB) are then added to the chassis weight of the truck at the front (TA) or rear (TB) in order to carry out further bodywork calculations. See example 5.

Scania CV AB 2003

11

Bodywork calculations 3

Example 4

6X2 Rear-mounted crane

Equipment outside the wheelbase such as a rearmounted crane. If the truck has heavy optional equipment such as a rear-mounted crane, the weight distribution of the crane on the front and rear axle must be calculated before carrying out the bodywork calculations above.

Applying the lever principle gives the following equation: KB = K x C (A+B) KB = Weight of crane carried by rear axle K = Total weight of crane C = Distance between front axle and centre of gravity of crane A = Wheelbase B = Distance to centre of gravity of bogie if: K C A B = 2500 kg = 7400 mm = 4600 mm = 612 mm (6x2)

The weight of the crane on the front axle (KA) will then be: KA = K - KB KA = 2500 - 3550 = -1050 kg

Note that KA is negative meaning that the front axle will be loaded with 1050 kg. Crane weight on the rear axle (KB) is added to the chassis weight of the truck at the rear (TB) and the reduced crane weight on the front axle (KA) subtracted from the chassis weight of the truck at the front (TA) in order to carry out further bodywork calculations.

the following proportion of the total weight (K) of the crane is supported by the rear axle (KB) KB = 2500 x 7400 = 3550 kg (4600+612) 12

Scania CV AB 2003

Bodywork calculations 3

Example 5

4X2 Calculating length

Calculation of body length. Same truck and equipment as in example 3.

Applying the lever principle gives the following equation: H = FB x A L The maximum permitted load on the rear axle (FB) is calculated by subtracting the trucks chassis weight rear (TB) and crane weight rear (KB) from the maximum permitted rear axle weight (PB). FB = PB - TB - KB if: PB = 10000 kg TB = 1780 kg KB = 364 kg (as example 3).

The maximum permitted load (L) is calculated by adding the maximum permitted load on the front axle (FA) to that on the rear axle (FB). L = FA + FB The maximum permitted load on the front axle (FA) is calculated in the same manner as the maximum permitted load on the rear axle (FB) i.e.: FA = PA - TA - KA if: PA = 6500 kg TA = 5000 kg KA = 1130 kg (as example 3)

this gives the following maximum permitted load on the rear axle. FB = 10000 - 1780 - 364 =7856 kg

this gives the following maximum permitted load (L): FA = 7500 - 4260 - 1586 = 1654 kg L = 1654 + 7856 = 9510 kg

Scania CV AB 2003

13

Bodywork calculations 3

In example 3, wheelbase (A) = 4300 mm. The distance between the front axle and the centre of gravity of the platform + load is thus as follows: H = 7856 x 4300 = 3552 mm 9510 i.e. the platform + the trucks centre of gravity must be located 3552 mm (H) behind the font axle or 4300 - 3552 = 748 mm (Y) in front of the rear axle to optimally utilise the maximum permissible axle weight. If the centre of gravity of the platform + load is assumed to be located at the mid-point of the platform, as in this example, platform length may then be calculated as below. The maximum length of the platform from the centre of gravity and forward is limited by the crane and its base, i.e, distance (D). X/2 cannot be less than: X/2 = H - D

Rear overhang (J) may be calculated as follows:

J=D+X-A

J = 1352 + 4400 - 4300 = 1452 mm

Comments: In this example we have calculated backwards by establishing D through the use of SCANIAs calculation program. This naturally makes it simpler and quicker to find a suitable vehicle. The result is a vehicle with weights and locations of crane and platform entirely optimized. The calculation program also makes it possible to gain some load capacity by choosing a front or rear axle with lower permissible weight capacity, if such a change is more optimal from a weight distribution perspective. The authorities in most countries will approve the vehicle even if the centre of gravity of the load is not at precisely the same location as that of the platform. In practice this has little or no significance. However, check the national regulations.

if D = 1352 mm, X/2 is: X/2 = 3552 - 1352 = 2200 mm Platform length is then: X = X/2 + X/2

X = 4400 mm

14

Scania CV AB 2003

Bodywork calculations 3

Example 6

6X2 Calculating centre of gravity

Calculation of the distance (E) between the mid-point of a given body (theoretical centre of gravity) and the centre of gravity in order to reach maximum axle weight.

Applying the lever principle gives the following equation: H = FB x (A + B) L H = Distance between front axle and centre of gravity of load for maximum axle weight utilization. FB = Maximum permitted load on bogie A = Wheelbase B = Distance to centre of gravity of bogie L = Maximum permitted load including bodywork if: FB A B L = = = = 12000 kg 5000 mm 553 mm (6 x 2) 14500 kg

this gives the following position of centre of gravity for maximum axle weight. H = 12000 x (5000 + 553) = 4595 mm 14500 If the body in this example is 8000 mm and the distance between the front axle and body is 650 mm, the distance (E) between the centre of gravity for maximum axle weight and the mid-point of the body (theoretical centre of gravity) is as follows: E = D + X/2 - H E = 650 + 4000 - 4595 = 55 mm Check with national regulations that this distance (E) is within the limits given.

For calculation of (L) and (FB), see earlier example.

Scania CV AB 2003

15

Bodywork calculations 3

Example 7

6x2/4 Tractor

Calculation of the position of the fifth wheel (H) on a threeaxle truck, with the tag axle in front of the driven axle, in order to achieve optimum use of front axle weight and bogie weight.

Applying the lever principle gives the following equation: H = FB x (A - B) L if: H = Distance between front axle and fifth wheel FB = Max. permitted load (kingpin) on bogie A = Wheelbase B = Distance to centre of gravity of bogie L = Max. permitted load (kingpin) The distance to the centre of gravity (B) of the bogie for the different types of chassis is given in the main dimension drawings.

By subtracting truck chassis weight at the rear (TB) from the maximum permitted bogie weight (PB), maximum permitted load on the bogie (FB) can be calculated. FB = PB - TB if: PB = max 20000 kg TB = 5000 kg

This gives the following distribution of load on the bogie (FB) FB = 20000 - 5000 = 15000 kg

16

Scania CV AB 2003

Bodywork calculations 3

Maximum permitted load (L) is calculated by adding the max. permitted load on the bogie (FB) and the maximum permitted load on the front axle (FA) L = FB + FA

The maximum permitted load on the front axle (FA) is calculated in the same manner as the max. permitted load on the bogie (FB) as follows: FA = PA - TA

if:

PA = 7000 kg TA = 5000 kg

this gives the following maximum permitted load (L): FA = 7000 - 5000 = 2000 kg L = 15000 + 2000 = 17000 kg

if:

A = 4100 mm B = 675 mm

this gives the following optimum location of the fifth wheel H = 15000 x (4100 - 675) = 3022 mm 17000 This means that in order to optimize the use of axle weight, the fifth wheel should be located 3022 mm from the front axle.

Scania CV AB 2003

17

Bodywork calculations 3

Example 8

8x4 Centre of gravity calculation

To calculate: Dimension (E), the distance between the centre of gravity of the platform and the optimum centre of gravity of the platform/load (H).

Target, laden truck Chassis weight Load + bodywork

A B C D FA FB L X = 5000 mm = 677,5 mm = 970 mm = 650 mm = 14 000 kg = 18 000 kg = 23 305 kg = 7 000 mm

Weight front Weight rear Weight tot. FA = 14 000 FB = 18 000 F tot = 32 000 - 5 865 PB = 8 135 - 2 830 PB = 15 170 - 8 695 L = 23 305

AT = Theoretical wh eelbase H = Optimal centre of gravity load/platform L = Maximum weight load + bodywork E = Distance between H and the centre of the bodywork PB = Load + bodywork load on

Remarks:

The distance (D) may be a minimum dimension, e.g. if a front cylinder is to fitted between the cab and bodywork. The chosen length of the bodywork (X) may be a dimension that the bodywork builder has chosen as standard. Deviating from this standard may mean paying a much higher price. The chosen wheelbase (A), 5000 mm, is very long for a tipper truck but for the sake of the calculation has no significance. From a stability perspective a shorter wheelbase would be preferable. But some countries require an even longer wheelbase to make it possible to load the vehicle to the maximum. Also check national regulations to make sure that the distance (E) is within permissible limits.

Calculation

AT = A + B C = 5000 + 677,5 - 970 = 4 707,5 mm

H=

AT x PB L

4707,5 x 15170 23305

= 3064 mm

E = X/2 + D C H = 3500 + 650 970 3064 = 116 mm Dimension (E), the distance between the practical and optimal values of H is = 116 mm. The bodywork should be 116 mm further forward towards the cab to achieve optimal load distribution.

18

Scania CV AB 2003

Bodywork calculations 3

Example 9

8x4*4 Centre of gravity calculation

To calculate: The optimal centre of gravity of the bodywork/ load should coincide with the mid-point of the bodywork. H should thus be equal to D + X/2 and E should be equal to 0.

Target, laden truck Chassis weight Load + bodywork

Weight front Weight rear Weight tot. FA = 7 100 FB = 24 000 F tot = 31 100 - 4 870 - 4 585 - 9 455 PA = 2 230 PB = 19 415 L = 21 645

A = 3350 mm B = 1256 mm FA = 7100 kg FB = 24000 kg L = 21645 kg X = 6200 mm AT = 4606 mm (as on main dimen sion drawing) PB = Load + bodywork load on rear axles

AT = Theoretical wheelbase H = Optimal centre of gravity load/platform L = Maximum weight for load + bodywork E = Distance between H and the centre of the bodywork X = Length of bodywork D = Dimension between front axle and front edge of bodywork

Calculation:

H= AT x PB = L 4606 x 19415 21645 = 4131 mm

Since the requirement is that the centre of gravity of the bodywork should be precisely above the centre of gravity of the load and bodywork, D is as follows: D = H X/2 = 4 131-3 350 = 1031 mm The distance between the front axle and bodywork is: D = 1031 mm och E = 0. Scania CV AB 2003 19

Das könnte Ihnen auch gefallen

- Calculating Commercial Vehicle Weight DistributionDokument8 SeitenCalculating Commercial Vehicle Weight DistributiondejejuniorNoch keine Bewertungen

- Dynamic Loading of A Forklift Truck Lifting InstallationDokument4 SeitenDynamic Loading of A Forklift Truck Lifting Installationmiroslav11Noch keine Bewertungen

- SCANIA Axle Load CalculationDokument19 SeitenSCANIA Axle Load CalculationGuillermo Cordero33% (3)

- Arcomet Self Erecting Tower Crane T33ADokument4 SeitenArcomet Self Erecting Tower Crane T33AviksofNoch keine Bewertungen

- Prinsip Electromagnetic BrakeDokument11 SeitenPrinsip Electromagnetic BrakeKiryaki FrancisNoch keine Bewertungen

- FEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneDokument6 SeitenFEA and Optimization of Telescopic Boom of Mobiles Hydraulic CraneAzmi Bin A MataliNoch keine Bewertungen

- DR As 1418.20-2014 Cranes Hoists and Winches Part20 TowTrucksDokument25 SeitenDR As 1418.20-2014 Cranes Hoists and Winches Part20 TowTrucksIan FlynnNoch keine Bewertungen

- As 1418.19-2007 Cranes Hoists and Winches Telescopic HandlersDokument7 SeitenAs 1418.19-2007 Cranes Hoists and Winches Telescopic HandlersSAI Global - APACNoch keine Bewertungen

- Slewing Bearings 1Dokument14 SeitenSlewing Bearings 1bennyfergusonNoch keine Bewertungen

- Crane Rail Selection: Calculation of Required Rail Head WidthDokument1 SeiteCrane Rail Selection: Calculation of Required Rail Head WidthMAHMOUD YOUNISNoch keine Bewertungen

- Tis 0012 Axle Loads and Weight Distribution Issue 1Dokument4 SeitenTis 0012 Axle Loads and Weight Distribution Issue 1bhukthaNoch keine Bewertungen

- Mathcad - Crane CalculationsDokument9 SeitenMathcad - Crane Calculationsapi-232034744Noch keine Bewertungen

- Zhao (2020) - Research On Jib Performance of Crane in Hoisting Wind GeneratorDokument9 SeitenZhao (2020) - Research On Jib Performance of Crane in Hoisting Wind GeneratorGogyNoch keine Bewertungen

- Sibre Crane Wheel SystemsDokument13 SeitenSibre Crane Wheel Systemsdotsy11Noch keine Bewertungen

- Lightweight SUV Frame Design DevelopmentDokument50 SeitenLightweight SUV Frame Design DevelopmentAltairEnlightenNoch keine Bewertungen

- 152 - HARDOX - 500 - UK - Data Sheet PDFDokument2 Seiten152 - HARDOX - 500 - UK - Data Sheet PDFneto-portoNoch keine Bewertungen

- FPS Bearing PDFDokument5 SeitenFPS Bearing PDFrohitgorasiaNoch keine Bewertungen

- Turning RadiusDokument28 SeitenTurning RadiusSean Pawit ChayanupatkulNoch keine Bewertungen

- TGN 08 Crane Rail Selection 2Dokument3 SeitenTGN 08 Crane Rail Selection 2Prasad PatilNoch keine Bewertungen

- Performance: East Technical University Ankara, 1994Dokument29 SeitenPerformance: East Technical University Ankara, 1994MaRCoS8666100% (1)

- BS 2573 Part 2Dokument24 SeitenBS 2573 Part 2Fenner Electromechanical100% (1)

- Heavy Equipment MechanicDokument2 SeitenHeavy Equipment Mechanicapi-77182490Noch keine Bewertungen

- Coel Catalogue 2006 1Dokument58 SeitenCoel Catalogue 2006 1Danilo MontesanoNoch keine Bewertungen

- Design of A Counterbalance Forklift Based On A Predictive Anti-Tip-Over ControllerDokument16 SeitenDesign of A Counterbalance Forklift Based On A Predictive Anti-Tip-Over ControllerHo Van RoiNoch keine Bewertungen

- Skidding System Data SheetDokument1 SeiteSkidding System Data Sheetm4l4ysiaNoch keine Bewertungen

- 320B All PDFDokument43 Seiten320B All PDFahmed_merzban9153Noch keine Bewertungen

- LECT-31 - Traction and Tractive ResistancesDokument18 SeitenLECT-31 - Traction and Tractive ResistancesMiran SheikhNoch keine Bewertungen

- Iso 8686 3 2018 en PDFDokument11 SeitenIso 8686 3 2018 en PDFjohn petersNoch keine Bewertungen

- Is 4573 1982Dokument45 SeitenIs 4573 1982pankaj100% (1)

- Paper Gondola WagonDokument2 SeitenPaper Gondola WagonrentizahariaNoch keine Bewertungen

- Crane Rating ChartsDokument48 SeitenCrane Rating Chartsjhoward2012npNoch keine Bewertungen

- Jib WindDokument156 SeitenJib WindBadanNoch keine Bewertungen

- TGN 11 Clip Spacing 09-12Dokument2 SeitenTGN 11 Clip Spacing 09-12kayakeras3335Noch keine Bewertungen

- SIBRE - General Catalogue Industrial BrakesDokument166 SeitenSIBRE - General Catalogue Industrial BrakesRaul FloresNoch keine Bewertungen

- Bulox Equipment CatalogDokument24 SeitenBulox Equipment CatalogIulian MurariuNoch keine Bewertungen

- Equilibrium Elevation.: FC (W V) / (G R)Dokument12 SeitenEquilibrium Elevation.: FC (W V) / (G R)BEN NARENDRANNoch keine Bewertungen

- Hoi Xe MyDokument81 SeitenHoi Xe MyĐứcNhậtNoch keine Bewertungen

- FEM Documentslist2008Dokument5 SeitenFEM Documentslist2008tantrihellyantiNoch keine Bewertungen

- Turntables Specification JostDokument6 SeitenTurntables Specification JostYãbeçk MâmNoch keine Bewertungen

- Telescopic Boom CranesDokument76 SeitenTelescopic Boom Cranestanjungkasri rayaNoch keine Bewertungen

- Crane Incident Handbook 4-27-20Dokument54 SeitenCrane Incident Handbook 4-27-20Nuragus HariyadiNoch keine Bewertungen

- DWP Calculation 1601139173Dokument18 SeitenDWP Calculation 1601139173Ashutosh KumarNoch keine Bewertungen

- 181-186 For Web PDFDokument6 Seiten181-186 For Web PDFdiego.peinado8856100% (1)

- Quality Audit Check Sheet For Wagon DepotDokument32 SeitenQuality Audit Check Sheet For Wagon Depotmukesh_singh_16100% (2)

- ABUS Overhead CranesDokument36 SeitenABUS Overhead CranesAya AlgalladNoch keine Bewertungen

- Shisham Props Technical Data SheetDokument1 SeiteShisham Props Technical Data SheetCatherine Fatima Mae LeynoNoch keine Bewertungen

- LEEA IP1 Step Notes 2 - LEEA - IP1 - 002 - 2012 v1.0000Dokument13 SeitenLEEA IP1 Step Notes 2 - LEEA - IP1 - 002 - 2012 v1.0000aymanNoch keine Bewertungen

- Designing of Cranes With StandardsDokument95 SeitenDesigning of Cranes With Standardsank_mehraNoch keine Bewertungen

- Universal Joint: Joint, or 'S Joint Is ADokument7 SeitenUniversal Joint: Joint, or 'S Joint Is APrashanth GopiNoch keine Bewertungen

- Train ResistancesDokument24 SeitenTrain ResistancesMahesh RamtekeNoch keine Bewertungen

- Effects of Wind On CranesDokument14 SeitenEffects of Wind On Cranesmike murdoc0% (1)

- Ic50 2018Dokument7 SeitenIc50 2018DahanTowerCraneNoch keine Bewertungen

- HydrospecDokument16 SeitenHydrospecg665013Noch keine Bewertungen

- BWM 0000660 06 PDFDokument19 SeitenBWM 0000660 06 PDFQasim SaleemNoch keine Bewertungen

- BasicDokument38 SeitenBasicVelmurugan SivaramanNoch keine Bewertungen

- Mass & Balance Q&ADokument109 SeitenMass & Balance Q&AAdwikaNoch keine Bewertungen

- Center Mass of Vehicle Au-29Dokument9 SeitenCenter Mass of Vehicle Au-29hamza najamNoch keine Bewertungen

- Wright CranesDokument13 SeitenWright Craneslandshark004100% (1)

- QDB 15 M&BDokument29 SeitenQDB 15 M&BKueh Chew Chai100% (8)

- Main Girder-FullDokument7 SeitenMain Girder-FullSatyajeet BeheraNoch keine Bewertungen

- 6 1 2 p1458 1473 Sya3000 - enDokument16 Seiten6 1 2 p1458 1473 Sya3000 - enMurali SambandanNoch keine Bewertungen

- American Traveling BlockDokument1 SeiteAmerican Traveling BlockAnonymous 48jYxR1CNoch keine Bewertungen

- M3036 Block 5861Dokument21 SeitenM3036 Block 5861Gregory StewartNoch keine Bewertungen

- MMX6 WebDokument2 SeitenMMX6 WebAnonymous 48jYxR1CNoch keine Bewertungen

- American Traveling Block PDFDokument1 SeiteAmerican Traveling Block PDFAnonymous 48jYxR1C100% (2)

- Hydril - GK Annular r2Dokument2 SeitenHydril - GK Annular r2Anonymous 48jYxR1CNoch keine Bewertungen

- Rong ShengDokument45 SeitenRong ShengAnonymous 48jYxR1C0% (1)

- Articulated Choke & Kill LinesDokument3 SeitenArticulated Choke & Kill LinesAnonymous 48jYxR1CNoch keine Bewertungen

- PumpDokument1 SeitePumpAnonymous 48jYxR1CNoch keine Bewertungen

- 1 Make Colliding Pattern of Device ClearDokument4 Seiten1 Make Colliding Pattern of Device ClearAnonymous 48jYxR1CNoch keine Bewertungen

- G:/Marketing/Public Data/Printed Materials/Advantage Booklet/Contractor Advantage Booklet - PDF Last Revision: Dec 1, 2009Dokument12 SeitenG:/Marketing/Public Data/Printed Materials/Advantage Booklet/Contractor Advantage Booklet - PDF Last Revision: Dec 1, 2009Anonymous 48jYxR1CNoch keine Bewertungen

- LS ManridersDokument8 SeitenLS ManridersAnonymous 48jYxR1CNoch keine Bewertungen

- Alloy Master LinksDokument1 SeiteAlloy Master LinksAnonymous 48jYxR1C0% (1)

- MISC006B Anchorage StrengthDokument2 SeitenMISC006B Anchorage StrengthAnonymous 48jYxR1CNoch keine Bewertungen

- Stepped Couplings OD355.6 - 1222: Large DiameterDokument1 SeiteStepped Couplings OD355.6 - 1222: Large DiameterAnonymous 48jYxR1CNoch keine Bewertungen

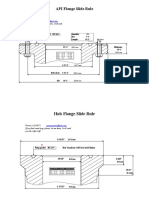

- Cameron Flange Slide RuleDokument1 SeiteCameron Flange Slide RuleAnonymous 48jYxR1C100% (1)

- Vedanta KesariDokument56 SeitenVedanta KesariAnonymous 48jYxR1CNoch keine Bewertungen

- ABRAuk Creusabro 4800Dokument3 SeitenABRAuk Creusabro 4800Anonymous 48jYxR1CNoch keine Bewertungen

- Woodco Lifting PlatesDokument1 SeiteWoodco Lifting PlatesAnonymous 48jYxR1CNoch keine Bewertungen

- API FlangeDokument3 SeitenAPI FlangeAnonymous 48jYxR1C100% (1)

- Cameron - DL-Annular BopDokument1 SeiteCameron - DL-Annular BopAnonymous 48jYxR1CNoch keine Bewertungen

- Calculation Statement For AgitatorDokument14 SeitenCalculation Statement For AgitatorAnonymous 48jYxR1CNoch keine Bewertungen

- Cameron - DL-Annular BopDokument1 SeiteCameron - DL-Annular BopAnonymous 48jYxR1C100% (1)

- Weights 6a FLGDokument10 SeitenWeights 6a FLGAnonymous 48jYxR1CNoch keine Bewertungen

- Cameron - DL-Annular BopDokument1 SeiteCameron - DL-Annular BopAnonymous 48jYxR1CNoch keine Bewertungen

- Cancer - Health in Your HandsDokument8 SeitenCancer - Health in Your HandsAnonymous 48jYxR1CNoch keine Bewertungen

- Zoology LAB Scheme of Work 2023 Hsslive HSSDokument7 SeitenZoology LAB Scheme of Work 2023 Hsslive HSSspookyvibee666Noch keine Bewertungen

- How To Spend An Hour A Day in Prayer - Matthew 26:40-41Dokument1 SeiteHow To Spend An Hour A Day in Prayer - Matthew 26:40-41Steve GainesNoch keine Bewertungen

- UVEX - Helmets & Eyewear 2009Dokument19 SeitenUVEX - Helmets & Eyewear 2009Ivica1977Noch keine Bewertungen

- David Sacks Resume February 16 2015Dokument1 SeiteDavid Sacks Resume February 16 2015api-279280948Noch keine Bewertungen

- AromatherapyDokument15 SeitenAromatherapymurrmurreNoch keine Bewertungen

- Important Points in SurveyingDokument4 SeitenImportant Points in SurveyingAnand BossNoch keine Bewertungen

- Cesars WayDokument20 SeitenCesars WayToni TursićNoch keine Bewertungen

- Po 4458 240111329Dokument6 SeitenPo 4458 240111329omanu79Noch keine Bewertungen

- British Airways Culture and StructureDokument29 SeitenBritish Airways Culture and Structure陆奕敏Noch keine Bewertungen

- Detailed Lesson Plan (DLP) Format: Learning Competency/iesDokument1 SeiteDetailed Lesson Plan (DLP) Format: Learning Competency/iesErma JalemNoch keine Bewertungen

- Attitude Scale For Mental IllnessDokument6 SeitenAttitude Scale For Mental IllnessSyed Faizan100% (7)

- Questionnaire OriginalDokument6 SeitenQuestionnaire OriginalJAGATHESANNoch keine Bewertungen

- Directorate of Technical Education, Maharashtra StateDokument47 SeitenDirectorate of Technical Education, Maharashtra StatePandurang GunjalNoch keine Bewertungen

- RTRT User GuideDokument324 SeitenRTRT User GuideAlae Khaoua100% (3)

- STRESS HealthDokument40 SeitenSTRESS HealthHajra KhanNoch keine Bewertungen

- Federal Public Service CommissionDokument2 SeitenFederal Public Service CommissionNasir LatifNoch keine Bewertungen

- Pamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFDokument9 SeitenPamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFNiKhil GuPtaNoch keine Bewertungen

- Complete DaikinDokument11 SeitenComplete DaikinAGNIDEEP BAIDYANoch keine Bewertungen

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Dokument28 Seiten2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValenteNoch keine Bewertungen

- Livro Spectrochemical AnalysisDokument9 SeitenLivro Spectrochemical AnalysisRicardo PossebonNoch keine Bewertungen

- Learning Theories Behaviourism, Cognitivism, Social ConstructivismDokument39 SeitenLearning Theories Behaviourism, Cognitivism, Social ConstructivismJuan Miguel100% (3)

- 5024Dokument2 Seiten5024Luis JesusNoch keine Bewertungen

- HLA HART Concept of LawDokument19 SeitenHLA HART Concept of LawHarneet KaurNoch keine Bewertungen

- FacebookDokument2 SeitenFacebookAbhijeet SingareNoch keine Bewertungen

- Malnutrition Case StudyDokument3 SeitenMalnutrition Case Studyapi-622273373Noch keine Bewertungen

- Self-Actualization in Robert Luketic'S: Legally Blonde: A HumanisticDokument10 SeitenSelf-Actualization in Robert Luketic'S: Legally Blonde: A HumanisticAyeshia FréyNoch keine Bewertungen

- TheBigBookOfTeamCulture PDFDokument231 SeitenTheBigBookOfTeamCulture PDFavarus100% (1)

- A B&C - List of Residents - VKRWA 12Dokument10 SeitenA B&C - List of Residents - VKRWA 12blr.visheshNoch keine Bewertungen

- 2 MercaptoEthanolDokument8 Seiten2 MercaptoEthanolMuhamad ZakyNoch keine Bewertungen

- California Academy For Lilminius (Cal) : Lesson PlanDokument4 SeitenCalifornia Academy For Lilminius (Cal) : Lesson Plandarryl franciscoNoch keine Bewertungen

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (1)

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionVon EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionNoch keine Bewertungen

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (54)

- Automotive Wiring and Electrical SystemsVon EverandAutomotive Wiring and Electrical SystemsBewertung: 4.5 von 5 Sternen4.5/5 (3)

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsVon EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsBewertung: 5 von 5 Sternen5/5 (4)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsVon EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsBewertung: 4.5 von 5 Sternen4.5/5 (17)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionVon EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionBewertung: 5 von 5 Sternen5/5 (2)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsVon EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNoch keine Bewertungen

- Common Rail Fuel Injection Technology in Diesel EnginesVon EverandCommon Rail Fuel Injection Technology in Diesel EnginesNoch keine Bewertungen

- Classic Car Museum Guide: Motor Cars, Motorcycles & MachineryVon EverandClassic Car Museum Guide: Motor Cars, Motorcycles & MachineryNoch keine Bewertungen

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingVon EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingBewertung: 4.5 von 5 Sternen4.5/5 (9)

- Why We Drive: Toward a Philosophy of the Open RoadVon EverandWhy We Drive: Toward a Philosophy of the Open RoadBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Automotive Electronic Diagnostics (Course 1)Von EverandAutomotive Electronic Diagnostics (Course 1)Bewertung: 5 von 5 Sternen5/5 (6)

- High-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionVon EverandHigh-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionNoch keine Bewertungen

- Troubleshooting and Repair of Diesel EnginesVon EverandTroubleshooting and Repair of Diesel EnginesBewertung: 1.5 von 5 Sternen1.5/5 (2)

- The Little Black Book of Motorcycle WisdomVon EverandThe Little Black Book of Motorcycle WisdomBewertung: 4.5 von 5 Sternen4.5/5 (6)

- How to Drive: Real World Instruction and Advice from Hollywood's Top DriverVon EverandHow to Drive: Real World Instruction and Advice from Hollywood's Top DriverBewertung: 4 von 5 Sternen4/5 (17)

- Maintenance Excellence: Principles, Practices, and Future TrendsVon EverandMaintenance Excellence: Principles, Practices, and Future TrendsNoch keine Bewertungen

- Automotive Scan Tool PID DiagnosticsVon EverandAutomotive Scan Tool PID DiagnosticsBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Competition Engine Building: Advanced Engine Design and Assembly TechniquesVon EverandCompetition Engine Building: Advanced Engine Design and Assembly TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (7)

- Trucking Business Startup: Build a Long-Term, Highly Profitable Trucking Company From Scratch in Just 30 Days Using Up-to-Date Expert Business Success SecretsVon EverandTrucking Business Startup: Build a Long-Term, Highly Profitable Trucking Company From Scratch in Just 30 Days Using Up-to-Date Expert Business Success SecretsBewertung: 5 von 5 Sternen5/5 (2)