Beruflich Dokumente

Kultur Dokumente

Delhi IUTAM Symp

Hochgeladen von

hieuhuech1Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Delhi IUTAM Symp

Hochgeladen von

hieuhuech1Copyright:

Verfügbare Formate

Applications and Research Topics for Active Magnetic Bearings

Gerhard Schweitzer ETH Zurich SWITZERLAND www.mcgs.ch e-mail: g.schweitzer@ggaweb.ch

Abstract More than thirty years of research and application experience have lead to active magnetic bearings (AMB), which allow unique applications for rotating machinery with excellent performance. The paper will briey discuss the state of art by giving historic examples and actual industrial applications. The main part is devoted to recent research topics, as a challenge to young researchers in rotor dynamics, mechatronics design and control. As an outlook, novel applications for nuclear and underwater environment, and for a superconductive bearing are addressed. Key words: magnetic bearings, active magnetic bearings, research topics, rotor dynamics

1 Introduction

Magnetic bearings offer a novel way of solving classical problems of rotor dynamics by suspending a spinning rotor with no contact, wear and lubrication, and controlling its dynamic behavior. In a general sense such an Active Magnetic Bearing AMB is a typical mechatronics product. Figure 1 presents the main components and explains the function of a simple bearing for suspending a rotor just in one direction. The suspension of a full rotor of course needs several magnets, which are connected to one another by a multivariable controller. The built-in software determines its main characteristics, which allows to control the dynamics. Thus, the control law of the feedback is responsible for the stability of the hovering state as well as the stiffness and the damping of such a suspension. Stiffness and damping can be varied widely within physical limits, and can be adjusted to technical requirements. They can also be changed during operation. Theory, design and application are detailed in [13], which is the reference to several gures of this survey and to further research

Proc. IUTAM-Symp. on Emerging Trends in Rotor Dynamics, March 23-26, 2009, Indian Institute of Technology, Delhi, India. Springer-Verlag

Gerhard Schweitzer

topics as well. Standards and guidelines on practical issues are given in [1]. After a brief glance on history the paper shows examples of recent industrial applications for turbomachinery and ywheels. It concentrates on actual research topics such as high speed issues, control of elastic rotors, touch-down dynamics, and the potential of using AMB as a key element for smart rotating machinery. An outlook on future applications, such as in nuclear and underwater environments, concludes the survey.

Gap Sensor ElectroMagnet Rotor MicroProcessor Control

W

Power Amplifier

Fig. 1 Principle of the actively controlled magnetic bearing: a gap sensor measures the displacement of the rotor from its reference position, a microprocessor derives a control signal from the measurement, a power amplier transforms this signal into a control current, and this current generates the magnetic eld forces within the actuating electromagnet in such a way that the rotor remains in its hovering position.

2 A Glance on History

First investigations on the physics of suspending a body freely by magnetic eld forces go back to Earnshaw (1842, [4]) and Braunbek (1939, [3]). A patent of Kemper (1937, [9]) showed the potential of AMB for magnetically levitated vehicles, and the experiments of Beams demonstrated a spectacular high speed application, where mm-sized steel balls were rotated freely with up to 300 kHz until they burst [2]. First industrial-like applications of AMB were initiated by Habermann [8] for aerospace momentum wheels. The potential for the active control of rotor dynamics was shown in 1974, see Fig. 2. The interest in AMB grew with the implementation of digital control with microprocessors [15], emphasizing the role of software as a prominent element within the machine, eventually leading to the concept of smart machines [6], Sect. 4. The industrialization, about 20 years ago, came with

Applications and Research Topics for Magnetic Bearings

Fig. 2 Active damping: vibration control of a highspeed rotor by AMB was demonstrated in theory and experiment for a multibody centrifuge [12]. The lateral displacements of the rotor elements are measured in some selected locations, the signals are used to derive a control signal for generating suitable damping forces, which act on a specic rotor. In such a way it is possible to cross various bending resonances, and to extend the operational speed beyond the initial stability limit caused by internal damping effects.

the availability of design tools for modeling rotor dynamics and control, and with the advances of hardware for power electronics.

3 Industrial Applications

The state of art in industrial applications will be shown by a few typical examples, Figs. 2 to 6. The description of the examples is given in the captions. The actual emphasis is on turbo-machinery, but of course, there are other promising areas as well, such as machine tools, high-speed motors and generators, ywheels, momentum wheels, or centrifuges. The main features are not only high speed, high power density, or the control of rotor dynamics. Other features, such as the absence of contamination by lubrication or mechanical wear, low energy consumption, and low maintenance costs are prevailing now. Furthermore, the use of AMB as a key to smart machinery allows the integration of the machine into the control of a whole production process and to manage safety and maintenance issues.

Gerhard Schweitzer

Fig. 3 Turbo-blower: cooling gas compressor (CO2 ) for a power laser, cutting metal sheets up to 25 mm. The laser needs uncontaminated gas. The speed is 54000 rpm, the rotor mass 3.6 kg, the motor power 12 kW, the radial bearing 48 mm in diameter, the bearing force 230 N (courtesy TRUMPF/MECOS).

Fig. 4 Pipeline compressor HOFIM for natural gas: integration of direct drive and magnetic bearing in the turbomachine, 6 MW, 9000 rpm (courtesy MAN Turbo/S2M).

Applications and Research Topics for Magnetic Bearings

Fig. 5 Gas-turbine/Generator for power generation: 4 radial bearings and 1 thrust bearing, 6010 rpm, 9000 kW, bearing diameter 400 mm (courtesy S2M).

Fig. 6 Flywheel [11]: the 140 kW energy storage ywheel has been developed to provide 15 seconds of ride-through power and UPS service in conjunction with a diesel generator set. The ywheel operates in a vacuum. In the cabinet the ywheel is on the lower left, the magnetic bearing controller is at upper middle, motor/generator and system controller on upper left, and motor/generator power electronics on the right. The right gure shows the cross-section of the ywheel: total energy storage 1.25 kWh at 36000 rpm for delivery of 140 kW for 15 s (0.58 kWh), ywheel rotor mass 109 kg. The ywheel has a steel hub, a 2-pole brushless DC motor/generator, and permanent magnet biased magnetic bearings (courtesy CALNETIX).

Gerhard Schweitzer

4 Research Topics

This survey will focus on 5 research topics, which actually appear to be most challenging, and which are illustrated in exemplary gures: High-speed Rotors In industrial applications the speed usually is limited not by the bearings themselves, but by the mechanical design of the motor drive, Fig. 7. Critical elements are the usually complex structure of the motor/generator part and the laminated bushes on the rotor with their shrink ts, under the magnetic bearings. Research shows that rotor speeds of up to 340 m/s in the bearing area can be reached with iron sheets from amorphous metal (metallic glass), having good magnetic and mechanical properties. For high speeds permanent magnet synchronous drives are used, where the rotor is wound with carbon bres, allowing speeds of about 300 m/s. As the cooling of the rotor, in particular in vacuum applications, is limited, high efciency of the drives and optimized thermal design is essential.

Fig. 7 Examples for the maximal diameter of the (asynchronous) motor drive in function of the rotor speed, which has been achieved in various conventional AMB applications. The (x) indicates a rotor broken at 178 m/s. The circumferential speed is a measure for the centrifugal load and leads to specic requirements on design and material.

Control of Elastic Rotors There are two reasons why exible systems present more of a challenge to the control system designer than does a rigid rotor. The rst is the simple matter that a exible rotor has a much wider mechanical bandwidth than does a rigid rotor. This means that the mechanical response to high frequency forcing is much larger for a exible rotor than for a rigid rotor and, as a result, the dynamic behavior of the feedback controller at high frequencies is much more important for exible rotors than for rigid rotors. The second reason is that, when the sensors and actuators are not collocated axially along the rotor, then it is always true that at least one undamped exible mode shape will exhibit a node between a sensoractuator pair. If this mode has a frequency within the bandwidth of the controller, then it poses special dynamics problems for the system. Both of these issues must be attended to either explicitly or implicitly in the design of an AMB controller for a exible rotor (cited from Maslen in [13]). Figures 8 and 9 show a simple example. For a real elastic rotor, on an elastic foundation, with several actuators and sensors,

Applications and Research Topics for Magnetic Bearings

Fig. 8 A pinned, exible beam controlled at the free end by an active magnetic bearing. Sensor and actuator are not collocated (courtesy Maslen).

SUREOHP QRGH DFWXDWRU ORFDWLRQ VHQVRU ORFDWLRQ

SUREOHP QRGH

SRVLWLRQ FP

PRGH QXPEHU

Fig. 9 Modeshapes of the exible beam of Fig. 8. The mode numbers 3 and 8 show that the displacements measured at the sensor location are out of phase with the ones at the actuator location, causing stability problems. For this simple single input/single output control, compensation of the phase lag can be achieved classically. For real rotors more advanced concepts are necessary (courtesy Maslen)

a multiple input/multiple output control has to take into account uncertainties, and it has to be robust. Touch-down Dynamics Contact between a rotor and a stator can lead to violent vibrations. As a back-up, in order to avoid potential damage, AMB supported rotors are equipped with touch-down bearings. These are an additional set of conventional bearings, and the rotor will only come into touch with them in extraordinary situations. These bearings should be able to support the rotor for a limited time period until the normal operating mode can be recovered or until the rotor can be run down safely. Dynamics of the touch-down are inherently nonlinear, with strong dependence on initial conditions, and with chaotic phases, Fig. 10. The backward whirl is the most dangerous one, generating very high contact forces. The optimal design of retainer bearings still relies mostly on experience, and a systematic, generally accepted design procedure has yet to be developed. Open research questions include the choice of material, the physical insight into high-speed contacts, i.e. for contact speeds above 200 m/s, the running down through critical speeds in retainer bearings, and control aspects in critical contact situations.

Gerhard Schweitzer

Fig. 10 Left: Variables for describing the touch-down dynamics of the rotor within the stator: , air gap , mass of the rotor m, normal force FN and friction force , whirl velocity rotor speed FN . Right: motion of the rotor center within a circle with the radius of the airgap (0.3 mm). The backward whirl is initiated by a drop down of the rotor, [7].

Smart Machines Machines can be termed smart when their internal capability of sensing, actuating and information processing is used in an extensive way. This leads to better functionality with features such as self-calibration, self-diagnostics, self-tuning, self-corrections, and eventually, it leads to less maintenance and higher safety. The smart machine in Fig. 11 consists of three main parts. One is the Actual Mechatronic System, the real machine with its process, sensors, actuators and the controller. The second part is the Mechatronic System Model, a software representation of the real machine, built up by using identication techniques. The model, or a part of it, will be used for designing, modifying or reconguring the control of the real machine. The third part describes the Smart Machine Management. It indicates the additional functions that can be incorporated into the system by making smart use of the available information. Figure 12 shows the application of the smart machine concept to an AMB system, which has been built as a test rig for developing self-tuning procedures for its basic control loop. The potential of AMB/rotor systems to become fault-tolerant is seen as a general feature of smart machinery, contributing to the already very impressive, but still growing, safety and reliability features of AMBs. Advanced Applications Advanced applications are a challenge for actual AMB research, promising novel and attractive solutions. Examples are given in Fig. 13 for a nuclear power plant, and in Fig. 14 for the use of high temperature superconductors. AMBs in aero-engines would lead to the futuristic all-electric, or rather oil-free, airplane [5]. Related research problems on high temperature materials are addressed and referenced in [13]. For the deep-sea exploration of natural gas, compressors will be needed that work autonomously and with minimal maintenance, and AMB equipped machinery is offering such performance [14].

Applications and Research Topics for Magnetic Bearings

Human Operator

q m

Correction

Prognosis

Diagnosis

Data Center

Smart Machine Management

Digital Controller Actuator l Process l Sensor

Mechatronic System Model Digital Controller Actuator Process Sensor

Actual Mechatronic System

Fig. 11 Structure of a smart machine

Fig. 12 Rotor in AMB with additional smart machine modules for diagnosis and correction

5 Conclusions

The survey shows, after a brief glance on history and trends, the state of the art for industrial applications of active magnetic bearings in rotating machinery. Main areas are turbo-machinery, most often coupled to directly driven motor/generator units. The advantages are, next to vibration control and high power density, the

10

Gerhard Schweitzer

Fig. 13 Schematic crosssection of a turbo-generator for a nuclear power plant, the rst pebble-bed high temperature gas-cooled test reactor with the gas turbine in the direct cycle (HTR-10GT, under construction, Chinese government key project): 6 MW, 15000 rpm, vertical rotor axis, 4 radial bearings, 2 axial bearings, length of turbine 3.5 m, mass of turbine 1000 kg. (photo courtesy Institute of Nuclear and Novel Energy Technology INET, Tsinghua University, Beijing, [16]).

Fig. 14 Test rig for a superconductive bearing designed for a 4 MVA HTS synchronous generator, bearing capacity 500 kg, maximum speed 4500 rpm. In the temperature range below 60 K the bearing capacity remains almost constant. The bearing, initially cooled down to 28 K, can still be operated for additional 2 hours without cooling (photo courtesy SIEMENS, [10]).

Applications and Research Topics for Magnetic Bearings

11

absence of contamination by lubrication and mechanical wear, low costs for energy and maintenance, and high lifetime. Five research topics are addressed and illustrated by examples: high-speed rotors, the control of elastic rotors, touch-down dynamics, the smart machine concept, and advanced applications. These include applications of AMB for nuclear power generation, superconductive bearings, aeroengines, and underwater compressors for natural gas exploration.

References

1. ISO Standard 14839. Mechanical Vibrations - Vibrations of rotating machinery equipped with active magnetic bearings - Part 1: Vocabulary, Part 2: Evalution of vibration, Part 3: Evaluation of stability margin, Part 4: Technical guidelines, system design (Draft), 2002/2006. 2. J.W. Beams. High rotation speeds. J. Applied Physics, 8:795806, 1937. 3. W. Braunbek. Frei schwebende K orper im elektrischen und magnetischen Feld. Z. Phys., 112:753763, 1939. 4. S. Earnshaw. On the nature of the molecular forces which regulate the constitution of the lumiferous ether. Trans. Camb. Phil. Soc., 7, Part I:97112, 1842. 5. D. Ewins and R. Nordmann et al. Magnetic bearings for smart aero-engines (MAGFLY). Final Report EC GROWTH Research Project G4RD-CT-2001-00625, Europ. Commun., 2006. 6. D. Ewins, R. Nordmann, G. Schweitzer, and A. Traxler et al. Improved Machinery Performance Using Active Control Technology (IMPACT). Final Report, BRITE/EURAM Research Project BRPR-CT97-0544, Europ. Commun., 2001. 7. M. Fumagalli. Modelling and measurement analysis of the contact interaction between a high speed rotor and its stator. PhD thesis, ETH Zurich No 12509, 1997. 8. H. Habermann and G. Liard. Le palier magn etique active: un principe r evolutionaire. SKF Rev. Roulements Nr. 192, 1977. 9. H. Kemper. Overhead suspension railway with wheel-less vehicles employing magnetic suspension from iron rails. Germ. Pat. Nos. 643316 and 644302, 1937. 10. P. Kummeth, W. Nick, and HW. Neum uller. Development of superconducting bearings for industrial application. In H. Bleuler and G. Genta, editors, Proc. 10th Internat. Symp. on Magnetic Bearings, page Keynote, Martigny, Switzerland, Aug. 2006. 11. P. Mc Mullen, V. Vuong, and L. Hawkins. Flywheel energy storage system with active magnetic bearings and hybrid backup bearings. In H. Bleuler and G. Genta, editors, Proc. 10th Internat. Symp. on Magnetic Bearings, Martigny, Switzerland, Aug. 2006. 12. G. Schweitzer. Stabilization of self-excited rotor vibrations by an active damper. In F.I. Niordson, editor, Proc. IUTAM Symp. on Dynamics of Rotors, Lyngby, 1974. Springer-Berlin. 13. G. Schweitzer and E.H. Maslen, editors. (contributors: H. Bleuler, M. Cole, P. Keogh, R. Larsonneur, E.H. Maslen, R. Nordmann, Y. Okada, G. Schweitzer, and A. Traxler). Magnetic Bearings - Theory, Design and Application to Rotating Machinery. Springer-Verlag, 2009. 14. H. Skofteland and K.O. Stinessen. Method and apparatus for protection of compressor modules against inux of contaminated gas (WO/2008/002148). Patent, Internat. Appl. No. PCT/NO2007/000222, 20.06.2007. 15. A. Traxler. Eigenschaften und Auslegung von ber uhrungsfreien elektromagnetischen Lagern. PhD thesis, ETH Zurich No 7851, 1985. 16. Suyan YU, Guojun YANG, Lei SHI, and Yang XU. Application and research of the active magnetic bearing in the nuclear power plant of high temperature reactor. In H. Bleuler and G. Genta, editors, Proc. 10th Internat. Symp. on Magnetic Bearings, page Keynote, Martigny, Switzerland, Aug. 2006.

Das könnte Ihnen auch gefallen

- Application of Permanent Magnet Bias Magnetic Bearings To An Energy Storage FlywheelDokument15 SeitenApplication of Permanent Magnet Bias Magnetic Bearings To An Energy Storage FlywheelmivanoNoch keine Bewertungen

- Application of Permanent Magnet Bias Magnetic Bearings To An Energy Storage FlywheelDokument15 SeitenApplication of Permanent Magnet Bias Magnetic Bearings To An Energy Storage FlywheelcoolcoliNoch keine Bewertungen

- Fig. 10.2 Types of ControllersDokument30 SeitenFig. 10.2 Types of Controllerssum8c88Noch keine Bewertungen

- The Active Magnetic BearingDokument6 SeitenThe Active Magnetic BearingdhudhiNoch keine Bewertungen

- Magnetic BearingDokument5 SeitenMagnetic BearingKarthiLoganNoch keine Bewertungen

- Mechatronics in Rotating MachineryDokument16 SeitenMechatronics in Rotating MachineryPiotr PietrzakNoch keine Bewertungen

- Rotary-Axial Spindles For Ultra-Precision MachiningDokument4 SeitenRotary-Axial Spindles For Ultra-Precision MachiningphuongdxNoch keine Bewertungen

- Turbomolecular Pumps On Conical Active Magnetic Bearings PDFDokument13 SeitenTurbomolecular Pumps On Conical Active Magnetic Bearings PDFVu MinhNoch keine Bewertungen

- Design and Experiments of The Active Magnetic Bearing System For The Htr-10Dokument16 SeitenDesign and Experiments of The Active Magnetic Bearing System For The Htr-10andy131078Noch keine Bewertungen

- Torsional Vibration of Turbomachinery - Duncan N. Walker PDFDokument136 SeitenTorsional Vibration of Turbomachinery - Duncan N. Walker PDFkolle_sdestefa100% (1)

- 1.1 Torsional Vibration: Torsional Vibration Involves Angular Oscillations of The Rotors of ADokument6 Seiten1.1 Torsional Vibration: Torsional Vibration Involves Angular Oscillations of The Rotors of ASç-č AbabiiNoch keine Bewertungen

- Rotordynamic Design Considerations For A 23 MW Compressor With Magnetic BearingsDokument15 SeitenRotordynamic Design Considerations For A 23 MW Compressor With Magnetic Bearingsmghgol100% (1)

- Machine Tool Spindle UnitsDokument22 SeitenMachine Tool Spindle UnitsMaricel Cearmel100% (2)

- Rotor Dynamics of Aircraft Gas Turbine EnginesDokument5 SeitenRotor Dynamics of Aircraft Gas Turbine EnginesfengrotorNoch keine Bewertungen

- ISME Paper On Shaft ScalingDokument13 SeitenISME Paper On Shaft Scalingbala_aeroNoch keine Bewertungen

- 14wa Kor SaDokument20 Seiten14wa Kor SaVulebg VukoicNoch keine Bewertungen

- Analytical and Experimental Investigation of A Low Torque, Ultra-High Speed Drive SystemDokument7 SeitenAnalytical and Experimental Investigation of A Low Torque, Ultra-High Speed Drive SystemJerry HalibasNoch keine Bewertungen

- Synchrony AMB WhitePaper 2014Dokument10 SeitenSynchrony AMB WhitePaper 2014Saurabh SharmaNoch keine Bewertungen

- A 300 000-r Min Magnetically Levitated Reaction Wheel DemonstratorDokument4 SeitenA 300 000-r Min Magnetically Levitated Reaction Wheel DemonstratorxrovljolscjvmiszchNoch keine Bewertungen

- Active Magnetic Bearings For Frictionless Rotating Machineries by Joga Dharma SetiawanDokument6 SeitenActive Magnetic Bearings For Frictionless Rotating Machineries by Joga Dharma SetiawanNikkizGogasNoch keine Bewertungen

- Research Article: Dynamic Characteristics of Air Cycle Machine Rotor SystemDokument17 SeitenResearch Article: Dynamic Characteristics of Air Cycle Machine Rotor SystemEmandi RajeshNoch keine Bewertungen

- University of Nottingham School of Mechanical, Materials, Manufacturing Engineering and Management Advanced Dynamics of Machines (H3 C ADM)Dokument3 SeitenUniversity of Nottingham School of Mechanical, Materials, Manufacturing Engineering and Management Advanced Dynamics of Machines (H3 C ADM)Jessica SandersNoch keine Bewertungen

- 2023-Rafal-Analysis of A Segmented Axial Active Magnetic Bearing For Multi-MWDokument11 Seiten2023-Rafal-Analysis of A Segmented Axial Active Magnetic Bearing For Multi-MWAlex CooperNoch keine Bewertungen

- Active Magnetic Bearings For Machining ApplicationsDokument7 SeitenActive Magnetic Bearings For Machining ApplicationsMustafa Tajkhan100% (1)

- 492 FerreiraDokument6 Seiten492 FerreiraRonald LiemNoch keine Bewertungen

- Rotordynamic Analysis of The AM600 Turbine-Generator ShaftlineDokument20 SeitenRotordynamic Analysis of The AM600 Turbine-Generator ShaftlineJarot PrakosoNoch keine Bewertungen

- Machine Tool Feed DrivesDokument18 SeitenMachine Tool Feed DrivesDoris ParaschivNoch keine Bewertungen

- Paper Marnetic2013Dokument14 SeitenPaper Marnetic2013Renan SiqueiraNoch keine Bewertungen

- Hydrodynamic Effects On Modeling and Control of A High Temperature Active Magnetic Bearing Pump With A Canned RotorDokument11 SeitenHydrodynamic Effects On Modeling and Control of A High Temperature Active Magnetic Bearing Pump With A Canned RotorVu MinhNoch keine Bewertungen

- Basics of Rotor and Structural VibrationDokument23 SeitenBasics of Rotor and Structural VibrationdiegovalenzuelaNoch keine Bewertungen

- Design and Development of Gap SensorDokument14 SeitenDesign and Development of Gap SensorJagannath Prasad SahooNoch keine Bewertungen

- Massachusetts Institute of Technology: 2.1 Surface Magnet MachinesDokument32 SeitenMassachusetts Institute of Technology: 2.1 Surface Magnet MachinesEgyptman JanNoch keine Bewertungen

- Paper Rotor DynamicsDokument12 SeitenPaper Rotor DynamicsTony HeNoch keine Bewertungen

- Foc Vs DTC Ieee FormatDokument17 SeitenFoc Vs DTC Ieee Formatmamado hackNoch keine Bewertungen

- 2003 Design of A New Axial Flux Permanent Magnet Generator For Hybrid Electric VehiclesDokument5 Seiten2003 Design of A New Axial Flux Permanent Magnet Generator For Hybrid Electric VehiclesFazal Karim MahsudNoch keine Bewertungen

- Rotor IntroductionDokument3 SeitenRotor IntroductionJohn ByersNoch keine Bewertungen

- Article Vilebrequin F8L413Dokument12 SeitenArticle Vilebrequin F8L413Maarten BaanNoch keine Bewertungen

- Study and Fabrication of Electromagnetic PDFDokument23 SeitenStudy and Fabrication of Electromagnetic PDFBhati Rdx SurajNoch keine Bewertungen

- Dynamics of A Hydropower Generator Subjected To Unbalanced Magnetic PullDokument13 SeitenDynamics of A Hydropower Generator Subjected To Unbalanced Magnetic PullPaulo GomesNoch keine Bewertungen

- A Seminar Report On Active Magnetic BearingDokument22 SeitenA Seminar Report On Active Magnetic BearingYusuf KhansNoch keine Bewertungen

- Ismb 7Dokument6 SeitenIsmb 7Kadhigo YusufNoch keine Bewertungen

- MIT - Permanent Magnet Brushless DC MotorsDokument32 SeitenMIT - Permanent Magnet Brushless DC Motorsslysoft.20009951Noch keine Bewertungen

- Influence of Elastic Foundation Structures On The Rotor DynamicsDokument8 SeitenInfluence of Elastic Foundation Structures On The Rotor DynamicsVodanh Tieutot100% (1)

- Construction: 3. Working Principle 5 .Engagement Time 6. Burnihing 7. TorqueDokument17 SeitenConstruction: 3. Working Principle 5 .Engagement Time 6. Burnihing 7. TorqueSkive FabsysNoch keine Bewertungen

- Experimental Evaluation of A New Braking System For Use in Passive Haptic DisplaysDokument5 SeitenExperimental Evaluation of A New Braking System For Use in Passive Haptic Displaysfahrgeruste3961Noch keine Bewertungen

- Design and Shop Testing of A 165KW Cryogenic Expander Generator On Magnetic BearingsDokument6 SeitenDesign and Shop Testing of A 165KW Cryogenic Expander Generator On Magnetic BearingsCalnetix TechnologiesNoch keine Bewertungen

- Chuan Doan He Banh RangDokument14 SeitenChuan Doan He Banh RangAlexander VovaNoch keine Bewertungen

- IRJET V6I5165rahularghodeDokument5 SeitenIRJET V6I5165rahularghodeSebin MathewNoch keine Bewertungen

- Design and Implementation of A Controllable ModelDokument11 SeitenDesign and Implementation of A Controllable ModelNour3' 'Noch keine Bewertungen

- Bearingless Motor Technology For Industrial and Transportation ApplicationsDokument8 SeitenBearingless Motor Technology For Industrial and Transportation Applicationsalstn7906Noch keine Bewertungen

- Design of Damper To Protect The Field Coil of An HTS Synchronous MotorDokument4 SeitenDesign of Damper To Protect The Field Coil of An HTS Synchronous Motorgurunathan14Noch keine Bewertungen

- Magnetic BrakeDokument10 SeitenMagnetic BrakeIgnacio Rifo NochezNoch keine Bewertungen

- Magnetic Bearings Theory and ApplicationsDokument140 SeitenMagnetic Bearings Theory and ApplicationsYüksel Kurtalan100% (2)

- Gear Units in Cpi PlantsDokument4 SeitenGear Units in Cpi PlantsafsuarezcoNoch keine Bewertungen

- Study of a reluctance magnetic gearbox for energy storage system applicationVon EverandStudy of a reluctance magnetic gearbox for energy storage system applicationBewertung: 1 von 5 Sternen1/5 (1)

- Piezoelectric Actuators: Vector Control Method: Basic, Modeling and Mechatronic Design of Ultrasonic DevicesVon EverandPiezoelectric Actuators: Vector Control Method: Basic, Modeling and Mechatronic Design of Ultrasonic DevicesNoch keine Bewertungen

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideVon EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideBewertung: 4 von 5 Sternen4/5 (8)

- 2SP0115T Control IGBT ManualDokument21 Seiten2SP0115T Control IGBT Manualhieuhuech1Noch keine Bewertungen

- Tektronix A6303 070390504Dokument34 SeitenTektronix A6303 070390504hieuhuech1Noch keine Bewertungen

- Real-Time Interface Dspace DSDokument12 SeitenReal-Time Interface Dspace DShieuhuech1Noch keine Bewertungen

- Advantest r6441 DMM User ManualDokument263 SeitenAdvantest r6441 DMM User Manualhieuhuech1Noch keine Bewertungen

- TDS7000 SeriesDokument254 SeitenTDS7000 Serieshieuhuech1Noch keine Bewertungen

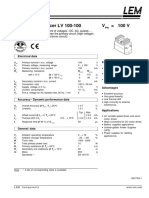

- Lem Voltage 100-500Dokument2 SeitenLem Voltage 100-500hieuhuech1Noch keine Bewertungen

- Simulation Study On Speed Control of Permanent Magnet Direct-Driven System For Mining ScraperDokument11 SeitenSimulation Study On Speed Control of Permanent Magnet Direct-Driven System For Mining Scraperhieuhuech1Noch keine Bewertungen

- Sanwa pc500Dokument42 SeitenSanwa pc500hieuhuech1Noch keine Bewertungen

- Msp-Exp430G2 Launchpad Workshop: - Meet The Launchpad - Lab 1: Blink Launchpad LedsDokument16 SeitenMsp-Exp430G2 Launchpad Workshop: - Meet The Launchpad - Lab 1: Blink Launchpad Ledshieuhuech1Noch keine Bewertungen

- Stator Flux and Speed - HADokument6 SeitenStator Flux and Speed - HAhieuhuech1Noch keine Bewertungen

- Fod8316 108263Dokument30 SeitenFod8316 108263hieuhuech1Noch keine Bewertungen

- Ansys Chu y Chicago Modeling and Simulation of Brushless DC Motor Drive SystemDokument25 SeitenAnsys Chu y Chicago Modeling and Simulation of Brushless DC Motor Drive Systemhieuhuech1Noch keine Bewertungen

- Design of A Microcontroller-Based Circuit For Software ProtectionDokument6 SeitenDesign of A Microcontroller-Based Circuit For Software Protectionhieuhuech1Noch keine Bewertungen

- Nonlinear Model of Permanent-Magnet Synchronous MotorsDokument8 SeitenNonlinear Model of Permanent-Magnet Synchronous Motorshieuhuech1Noch keine Bewertungen

- Sensorless Foc of PMSM Chu YDokument42 SeitenSensorless Foc of PMSM Chu Yhieuhuech1Noch keine Bewertungen

- Speed Control Design of A PMSM Based On Functional Model Predictive ApproachDokument15 SeitenSpeed Control Design of A PMSM Based On Functional Model Predictive Approachhieuhuech1Noch keine Bewertungen