Beruflich Dokumente

Kultur Dokumente

CH 6

Hochgeladen von

Vikas UpadhyayOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CH 6

Hochgeladen von

Vikas UpadhyayCopyright:

Verfügbare Formate

Chapter 6 INTRODUCTION: MCB and UPS

6.1 Fuse, MCB and their Requirement

Fuse is a safety device that protects the circuit from excess current. Fuse is a piece of wire sized to melt when current more than specific amount passes through it. It melts and opens the circuit. Fuses are rated in amperes, a measurement of electrical current flow. Higher the amperage rating, more current can flow through the fuse before it blows. Types of Fuses Plug Fuse These fuses are Semi-enclosed and re-wirable fuses. These can be rewired with fuse wire. Most buildings use these fuses for wall outlets and lighting. These fuses also dont hold many amps typically less than 15.

Fig 6.1.

Plug fuse

Cartridge Fuses These fuses are typically cylindrical in appearance, although they can be different lengths depending on the electricity needs. These fuses are capable of handling larger electricity currents and are used in a variety of circuits. Most cartridge fuses are rated up to 500 volts. While plug fuses only hold 15 or less amps, a cartridge fuse will hold up to 600 amps of electricity.

Fig 6.2.

Types of fuses

Basic Concepts of Electronics and Electrical The difference between a cartridge and plug fuse is the amount of time taken to melt the fuses metal element. Fuses that are time delayed are commonly referred to as slow blow fuses, take longer to melt. These type of fuses are less likely to trip due to momentary electricity overloads. For example, while turning on a high energy lamp the slow blow fuse wont blow from the initial excess of electricity. MCB (Miniature Circuit Breaker) A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overload or short circuit. Its basic function is to detect a fault condition and interrupt current flow. Unlike a fuse, which operates once and then must be replaced, a circuit breaker can be reset (either manually or automatically) to resume. There are three main types of MCBs: 1. Type B trips between 3 and 5 times full load current. 2. Type C trips between 5 and 10 times full load current. 3. Type D trips between 10 and 20 times full load current.

Fig 6.3.

Different types of MCBs

Fuse/MCB Selection While selecting the correct MCB or fuse for usage, its role in both over-current protection, and shortcircuit protection has to be considered. Basic principles underlying are as follows. Nominal current rule: The nominal current of the fuse/MCB must be less than the current rating of the cable it is protecting. For example, a 32-amp MCB is suitable for a current of 30 amps in a 35-amp cable circuit. Tripping rule: A current of 1.45 times the nominal current must cause the device to trip in less than 1 hour. All modern devices meet this requirement except re-wirable fuses. These fuses normally require about twice the nominal current to blow them in one hour. Disconnection time rule: In a short-circuit condition; the fuse/MCB must trip in less than a specified short time. Double Pole MCB (The main switch): Double Pole MCB allows turning off and on the electric supply to home because this is the main operating switch to control electric supply. Immediately switch off the main switch in emergency i.e. in electric shock, fire or while working on main board. Multiple mains switch also can be used if there is more supply unit. Fig 6.4. Double pole MCB

NIELIT, Chandigarh Centre

Basic Concepts of Electronics and Electrical Circuit Breakers Circuit breaker is a device which switches off and on electric supply at normal and abnormal condition. These are automatic protection devices in the Main switch board or fuse-box that switch off a circuit if they detect a fault. The size of the fuse and Circuit Breaker are similar, but it gives more and more protection. If it trips, its can be reset.

Fig 6.5. Circuit Breaker

6.2

Earthing

Need of earthing: A wire coming from the ground 2.5 to 3.0 meter deep from an electrode /a metal plate is called earthing. The earth potential is always taken as zero for all practical purposes. The electrical apparatus or machines when connected with earth attain zero potential and are said to earthed. Earthing is needed for following purposes: 1. To save human life from danger or shock or death, if any apparatus this becomes leaky. 2. To protect large building from atmospheric lighting. 3. To protect all machines fed from over head lines from lightening arresters. There are two types of earthing: 1. Plate earthing. 2. Pipe earthing. Plate earthing: In the plat earthing, looping earth wire is bolted tightly with the earth plate, which is made up of copper 60cm x 60cm x 5mm and placed 3 meter in the ground. Copper plates are found to be most effective earth electrodes and are not affected by soil moisture. They do not get rusted. But as its metallic value is very high, galvanized iron plates are preferred and usually used for normal work. The plate is kept with its face vertical and is so arranged that it is placed in an alternate layer of coke and salt for a minimum thickness of 15cm. The coke and salt decreases the earth resistance. It is to be taken care that plate, nut, bolt and wire must be of same metal (either galvanized iron or copper). Usually the earth wire is drawn through a GI pipe fitted with a funnel on the top through which salty water is poured in the pit of the earth plate time to time. In summer session when the moisture of the soil will decrease to a large extent. This increases the earth resistance. The conductivity (earthing efficiency) increases with increase of plate size and depth of embedding. It is only disadvantage that conductivity of

NIELIT, Chandigarh Centre

Basic Concepts of Electronics and Electrical earth wire with the plate below the earth cannot be seen physically; hence it is misleading and some time result in heavy loss in case of fault.

Fig. 6.6: Schematic of Buried Copper Plate Picture

Fig. 6.7: Buried Copper Plate Picture

Fig. 6.8: Earthing plate interconnection

NIELIT, Chandigarh Centre

Basic Concepts of Electronics and Electrical Pipe earthing: In this system of earthing a GI pipe of 38mm diameter and 2meter length is kept vertically in ground to work as an electrode but depth depends upon the soil conduction. There is no hard and fast rule for this. The earth wire is fastened on the top section of pipe with nut and bolts. The pit area is filled with salt and coal mixture for improving the soil condition and efficiency of the earthing system. The contact surface area of GI pipe with the soil is more in comparison to the plate because of its circular section and hence can take up heavy leakage current for the same electrode size. The earth wire connection can be check up as the connection wire is above the ground level. It is an advantage over the plate type earthing. Advantage of Earthing: Earthing to equipments and apparatus provides effective safeguard against injury and death. Earthing saves the human life from danger or shock or death if any apparatus which becomes leaky. Earthing provides safety to the large building from atmospheric lighting. Earthing provide safety to all machines fed from over head lines from lightening arresters. Earthing provide very low resistance to the flow of heavy current to a circuit. Earthing to equipments and apparatus provides effective safeguard against injury and death. 6.2(b) Continuity and Resistance Test of earth All appliances are subject to this particular test, which ensures that there is a satisfactory connection between the Earth pin in a plug and the case of the appliance. The earthing of an appliance means it is safer to use because the chance of electrical shock is reduced, and combining these together with standard insulative properties enhances the safety of an appliance even further. This particular test is also referred to as an Earth Bond or Earth Resistance test, but they all measure the same thing. There are generally two types of earth bond test current used. Low current which is generally in the range of 100 to 200 milliamps. High test currents in the range of 10 amps or 25 amps. The earth bond test passes a test current along the earth cable from the pin of the plug to the bodywork of the appliance. The appliance tester then measures the resistance of that connection. If the connection is rusty, or corroded then the earth resistance reading will increase. To perform an earth continuity test, the appliances mains plug must be inserted into testing device and a test lead must be connected to a suitable earth point on the appliance. In order to pass the test, the reading from the tester should show that the resistance that has been measured is less than 0.1 + the resistance of the supply cable. Physical nature of the earth resistance: The understanding of the earth resistance physical nature will help us to evaluate the conditions to be fulfilled in order to get its correct measurement. According to its definition, resistors have two terminals and its resistance is defined as the quotient of the voltage applied on those terminals and the current circulating between them as a consequence of that voltage. The value of the resistance depends on the type of material (resistivity) and its physical dimensions (area and length of the resistive element). In the earth resistance, only one of the terminals is evident that is a electrically accessible part of a buried electrode in the earth resistance. And the second terminal is any other point of the earth. The idea is that outside the earth volume next to a buried electrode, through which a current is injected, all the planet volume is equipotential related to that current. Any point of that equipotential volume can be considered as the second electrode of the earth resistance.

NIELIT, Chandigarh Centre

Basic Concepts of Electronics and Electrical Testing earth electrodes The earth electrode, where used, is the means of making contact with the general mass of earth. Thus it must be tested to ensure that good contact is made. There are several methods for measurement of the earth electrode resistance. In all cases, the electrode must be disconnected from the earthing system of the installation before the tests commence. Using an earth fault loop impedance tester The tester is connected between the phase at the origin of the installation and the earth electrode under test.The test is then carried out, the result being taken as the electrode resistance although the resistance of the protective system from the origin of the installation to the furthest paint of the installation must be added to it before its use to verify that the 50 V level is not exceeded. The protective system resistance is likely to be negligible by comparison with the permissible electrode resistance.

Fig. 6.9: Wiring for MCB and Cutout

NIELIT, Chandigarh Centre

Basic Concepts of Electronics and Electrical It is most important to ensure that earthing leads and equipotential bonds are reconnected to the earth electrode when testing is completed 6.2 Switch, Junction and Outlet boxes

An electrical junction box is a container for electrical connections, usually intended to conceal them from sight and deter tampering. A small metal or plastic junction box may form part of an electrical conduit wiring system in a building, or may be buried in the plaster of a wall, concealed behind an access panel or cast into concrete with only the lid showing. It sometimes includes terminals for joining wires. A similar container used for joining wires to electrical switches or sockets is called a pattress.

Fig. 6.10: Junction Box

Fig. 6.11: Junction Box Wiring There are varieties for plastic and metal boxes. These boxes are in different shape and sizes such as, round, square and octagonal boxes. And they come in depths ranging from 1/2" to over 3" deep. Then there are boxes with no back that serve as depth extenders and covers with cut-outs for various uses. Electrical wall and ceiling boxes can be used in many ways, such as: Join or splice wires together in circuits Mount and house connections for a lamp fixture to a wall or ceiling Mount and house connections for a ceiling fan. Mount recessed in a wall or ceiling or surface mounted NIELIT, Chandigarh Centre

7

Basic Concepts of Electronics and Electrical 6.4 Wiring and Testing 6.4.a. Inverter Wiring and Testing Always connect the inverter to a three pin, three-wire grounding mains socket. The socket must be connected to appropriate branch protection (fuse / circuit-breaker). To switch off the inverter output in emergency, use inverter RESET switch on the Front panel, also disconnect the mains cord. Avoid installing the inverter in open, excessively humid places or where there is possibility of water. Care must be taken to ensure that the inverter is kept away from heat-emitting appliances such as a heater, blower, oven etc. The unit must also be placed in a manner that it avoids exposure to direct sunlight. The place of the installation should be well ventilated and easily accessible for servicing. Foreign objects and water must not enter the inverter. Always ensure that no objects containing a liquid are kept near the unit (Inverter). Keep away from reach of children. Installation procedure: Identify the points, which are to be connected to the inverter. Ensure the appliances, which are to be provided with backup; do not exceed the capacity of the inverter. Consider the best suited position for the inverter installation as per all the necessary precautions. a. Mobile installation/connection With your battery bank connected the inverter, the input terminal is plugged into 15 Amp socket. An adaptor/extension is then plugged into the output terminal and appliances can then be connected to the adaptor/extension.

To various household circuits connected only to utility power To various householdcircuits connected both utility & inverter

Fig. 6.12: Mobile Wiring Mobile Interconnection b. Distribution Board (DB) installation/connection With the battery bank connected to the inverter, the input terminal is connected to the Mains power in the Distribution Boards (DB). The output terminal is connected to the relevant Miniature Circuit Breakers (MCBs) within the DB in which inverter to run. These MCBs can be separated.

NIELIT, Chandigarh Centre

Basic Concepts of Electronics and Electrical

To various household circuits connected only to utility power

To various household circuits connected inverter Fig. 6.13: Installation of Inverter 6.4.b. UPS Wiring and Testing Purpose This wiring circuit diagram is design for when one want to give supply to particular rooms in the home or office in the building in case of failing the power supply. And power supply is needed continuously to the appliances (laptop, computer etc) in that specific rooms or office in case of low wattage UPS or single battery or in case of when generator system is not available. How to do this wiring in Home First of all, remove those Live (Phase) wires from the main distribution board (from the circuit breaker) of those particular Rooms (As shown in Figure) if one wants to give automatic supply (in both cases from Battery and Power House without any interrupt or disturbance). Suppose it is needed to connect only these two rooms with this system as shown in figure. Then connect these two live (phase) wires at the end as shown in figure. Now do the same wiring (Connect UPS, Battery, Home appliances etc) as shown in figure. both utility &

Fig. 6.14: UPS Wiring Interconnection NIELIT, Chandigarh Centre

9

Basic Concepts of Electronics and Electrical

PRACTICAL COMPETENCY

6.1 (A) AIM: Testing and wiring of MCBs and fuses. Testing of MCBs.

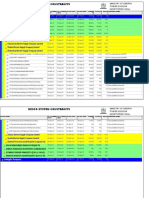

APPARATUS: Multimeter, screwdriver set. Theory & Procedure Open the electrical box which contains the circuit breaker panel The switches are marked with the parts of the house to which they are connected. Before testing the circuit breaker, all the home appliances should be turned off and then unplugged. It prevents a short circuit which might result from an increase in the voltage. The multimeter is to be set to the position 'Volts AC'. Use two probes of multimeter, the first one to touch the terminal screw of MCB and the other one for the ground. If there is no indication in multimeter the MCB is bad, if there is indication then MCB is good. MCB can be tested for load also. For testing of load of MCB , disconnect the one end of the cable and connect it with the meter in series and other end of the meter with MCB. Verify the rated current of MCB with the reading of meter. (B) AIM: Testing of Fuse APPARATUS: Multimeter. Theory & Procedure Switch off the power supply of the equipment for which fuse is to be tested. Use analog/digital multimeter check the fuse. Select the multimeter in lowest ohms range(X1). Touch the probes of multimeter to both end of the fuse. The fuse can be checked while it still in circuit. If meter reading is Zero ohms or it continuity then fuse is working. If meter reading is not Zero ohms or it does not show continuity then fuse is not working. For fuse replacement, use only the fuse for same current ratings. 6.2 AIM: Find the total load and select a suitable UPS/Inverter(rating factor) for home use

Calculating Power Requirements The power required by a component is commonly called in either Watts (W) or Volt Amps (VA). The Watt and VA levels differ (the VA rating will always be equal to or higher than the W rating). The ratio of W to VA is called the Power Factor. In a resistive load such as a heater or a toaster, Watts and VA numbers are the same. Some devices will use a Power Factor Corrected power supply. These units will have a Power Factor almost equal to one (~0.99). These components typically include servers, hubs and storage systems. This means that a 1000VA rated component will have a 990W load. The capacity of UPS systems is given in Volt Amps. If the power consumption is not stated in Watts or VA, then check for the current consumption in amps (A). Multiply Amps by Input Volts to obtain the power consumption in VA. For example if a machine has a stated current consumption of 1.5A at 230V then power consumption will be 230 x 1.5 = 345VA. Once it is calculated and specified, select a UPS that will properly handle a particular load. To increase the battery runtime/backup additional batteries has to be added. NIELIT, Chandigarh Centre

10

Basic Concepts of Electronics and Electrical Lets take another example: We have four computers that need to be given a UPS backup. Then if, one computer consumes 350 VA, then total power will be 350* 4 = 1400 VA. So the UPS needed will be of more than 1400VA . UPS is available in 500VA , 1000VA, 2000VA and so on. Hence UPS rated with 2000VA (2KVA) will be suitable . 6.3 AIM : Installation of UPS/Inverter.

Procedure: First of all the circuit/load to be connected on UPS/Inverter is to be identified and calculated UPS/Inverter rating Disconnect the Live(Phase) wires from the main distribution board of those particular circuits. Then connect these two Live wires at the end as shown in the figure.

Live wire to different desired circuits to be connected

Fig 6.15. Wire connections with UPS

on UPS

Fig. 6.15: Wire Connections with UPS

NIELIT, Chandigarh Centre

11

Das könnte Ihnen auch gefallen

- Services 2 Reading MaterialDokument16 SeitenServices 2 Reading MaterialDhyey VaraNoch keine Bewertungen

- Lightning ProtectionDokument15 SeitenLightning ProtectionEnglish words BY Utkarsh johriNoch keine Bewertungen

- Mcbs or Miniature Circuit Breakers Are Electromechanical Devices Which ProtectDokument9 SeitenMcbs or Miniature Circuit Breakers Are Electromechanical Devices Which ProtectDivyansh GuptaNoch keine Bewertungen

- Electrical InstallationsDokument48 SeitenElectrical InstallationsSyed Muzammil AliNoch keine Bewertungen

- Topic 3 - Current ProtectionDokument20 SeitenTopic 3 - Current ProtectionVictorNoch keine Bewertungen

- Study of Power Supply & Safety DevicesDokument27 SeitenStudy of Power Supply & Safety DevicesMueen FaisalNoch keine Bewertungen

- Lab ManualDokument96 SeitenLab ManualASWANI RAJAN50% (2)

- Lastactivity NapiliDokument10 SeitenLastactivity NapiliMArk BarenoNoch keine Bewertungen

- BEE Unit-5 Notes Basic Electrical InstallationDokument22 SeitenBEE Unit-5 Notes Basic Electrical InstallationTapendra Tailor100% (10)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- Electrical System Design NotesDokument15 SeitenElectrical System Design Notesdilja aravindan100% (1)

- InstallationDokument45 SeitenInstallationshaadi220622Noch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Protective DevicesDokument7 SeitenProtective Devicesbolt sparkNoch keine Bewertungen

- Topic: Electrical Protective EquipmentDokument17 SeitenTopic: Electrical Protective EquipmentAnanjay ChawlaNoch keine Bewertungen

- Training Report of Grid Substation: Presented byDokument11 SeitenTraining Report of Grid Substation: Presented byତୁଷାର ମିଶ୍ର100% (1)

- 5th UnitDokument6 Seiten5th UnitAbhishek MishraNoch keine Bewertungen

- Electrical Installation: The Most Common Types of Faults in Domestic Systems AreDokument23 SeitenElectrical Installation: The Most Common Types of Faults in Domestic Systems Arekrishnareddy_chintala100% (1)

- Unit-Ii MCB and ElcbDokument26 SeitenUnit-Ii MCB and ElcbArshad MohammedNoch keine Bewertungen

- Earthing & Protective DevicesDokument26 SeitenEarthing & Protective DevicesShreeja mayyaNoch keine Bewertungen

- Protective Device A SwtichgearDokument24 SeitenProtective Device A SwtichgearVarun Ghagare 03Noch keine Bewertungen

- Earthing Myths and FactsDokument67 SeitenEarthing Myths and FactsPramode MishraNoch keine Bewertungen

- Ecm216 Building Services Bab 1.5 CableDokument3 SeitenEcm216 Building Services Bab 1.5 CableAZUAN BIN AHMAD FAUZI100% (1)

- House WiringDokument9 SeitenHouse WiringhassjayawardanaNoch keine Bewertungen

- House Wiring MCB MAVDokument7 SeitenHouse Wiring MCB MAVP. ChaudhuriNoch keine Bewertungen

- Overhead Line Maint.Dokument12 SeitenOverhead Line Maint.Srikanth VsrNoch keine Bewertungen

- 1 Three Phase Power Measurement, Electrical Safety - Fuses and Earthing, Residential WiringDokument49 Seiten1 Three Phase Power Measurement, Electrical Safety - Fuses and Earthing, Residential WiringUtkarsh ShuklaNoch keine Bewertungen

- EEC Unit VIDokument8 SeitenEEC Unit VITushar Shinde100% (2)

- Presented ByDokument19 SeitenPresented ByNgocHoanTranNoch keine Bewertungen

- EarthingDokument43 SeitenEarthingabinash pradhanNoch keine Bewertungen

- Seminar Report On Ultra ConductorDokument18 SeitenSeminar Report On Ultra ConductorNavneet Singh100% (1)

- BEE Assignment Unit 4Dokument13 SeitenBEE Assignment Unit 4Abhishek RaoNoch keine Bewertungen

- Module-5 (Electrical Installation) - INSDokument21 SeitenModule-5 (Electrical Installation) - INSGemechu TayeNoch keine Bewertungen

- EarthingDokument43 SeitenEarthingajeetgaur30100% (1)

- Group 3 - Types of Fuses and MCBDokument13 SeitenGroup 3 - Types of Fuses and MCBJordan Dator MontemayorNoch keine Bewertungen

- Practical ElectricityDokument10 SeitenPractical Electricityanwar9602020Noch keine Bewertungen

- Installing Electrical Protective Devices For Distribution, Power, Lightning Protection and Grounding SystemsDokument23 SeitenInstalling Electrical Protective Devices For Distribution, Power, Lightning Protection and Grounding SystemsYamut Si ako67% (6)

- School of Electrical Engineering Lab RecordDokument9 SeitenSchool of Electrical Engineering Lab RecordSudesha BasuNoch keine Bewertungen

- ECM346 1.2.3 Function of Protection Devices HBI 02Dokument50 SeitenECM346 1.2.3 Function of Protection Devices HBI 02Tiffany's LoveNoch keine Bewertungen

- EHV Sheath Earthing SystemDokument9 SeitenEHV Sheath Earthing SystemZul FadzlyNoch keine Bewertungen

- Circuit Breakers: Carla Cristine Pillejera Bet-Mect3ADokument25 SeitenCircuit Breakers: Carla Cristine Pillejera Bet-Mect3Akanye eastNoch keine Bewertungen

- 1435028754370-Earthing GSDokument89 Seiten1435028754370-Earthing GSprembiharisaranNoch keine Bewertungen

- Household Circuits - STD 10Dokument5 SeitenHousehold Circuits - STD 10yashwantnayak61Noch keine Bewertungen

- 6.0 Electrical InstallationsDokument8 Seiten6.0 Electrical Installationsdh25881Noch keine Bewertungen

- EE101 6 Electrical InstallationsDokument8 SeitenEE101 6 Electrical InstallationsKasun WerangaNoch keine Bewertungen

- Electric Circuit Breaker & IsolatorDokument6 SeitenElectric Circuit Breaker & IsolatorRik RkNoch keine Bewertungen

- EHVHV Cable Sheath EarthingDokument12 SeitenEHVHV Cable Sheath EarthingHimdad Tahir100% (1)

- Simple House Wiring With MCB or Fuse Project: Wire (Or Positive), and AnotherDokument6 SeitenSimple House Wiring With MCB or Fuse Project: Wire (Or Positive), and AnotherP. ChaudhuriNoch keine Bewertungen

- SUN ReportDokument10 SeitenSUN Reportpratham sutharNoch keine Bewertungen

- Safety Switch and Disconnecting MeansDokument16 SeitenSafety Switch and Disconnecting MeansKerwin James AustriaNoch keine Bewertungen

- Electrical InstallationsDokument28 SeitenElectrical InstallationsAshutoshNoch keine Bewertungen

- Grounding and Bonding 101 : Mark Kleine - N5HZR - BICSI Trained InstructorDokument37 SeitenGrounding and Bonding 101 : Mark Kleine - N5HZR - BICSI Trained Instructorchibssa alemayehuNoch keine Bewertungen

- Chapter-1 Power DistributionDokument43 SeitenChapter-1 Power Distributionrajendra88Noch keine Bewertungen

- Shakir Seminar Report On Ultra ConductorsDokument18 SeitenShakir Seminar Report On Ultra ConductorsMeer ShakirNoch keine Bewertungen

- Basics of SubstationDokument53 SeitenBasics of Substationraza239Noch keine Bewertungen

- Nvent ERICO Grounding MythsDokument9 SeitenNvent ERICO Grounding MythsMahmoud GwailyNoch keine Bewertungen

- HV Cable Sheath EarthingDokument15 SeitenHV Cable Sheath EarthingjuliancansenNoch keine Bewertungen

- Mini Project On: Drinking Water AlarmDokument37 SeitenMini Project On: Drinking Water Alarmsubinsudhee12380% (5)

- Presentation of Technical TrainingDokument91 SeitenPresentation of Technical TrainingChander MohanNoch keine Bewertungen

- Lab # 1 Electrical Safety and PrecautionDokument14 SeitenLab # 1 Electrical Safety and PrecautionNoumanShabbirNoch keine Bewertungen

- Behavsci 04 00423 PDFDokument14 SeitenBehavsci 04 00423 PDFArturo Eduardo Villalpando FloresNoch keine Bewertungen

- RandomDokument14 SeitenRandomVikas UpadhyayNoch keine Bewertungen

- A Machine Learning Based Approach For Mapping PersDokument7 SeitenA Machine Learning Based Approach For Mapping PersVikas UpadhyayNoch keine Bewertungen

- IOT - Training From Si2ChipDokument1 SeiteIOT - Training From Si2ChipVikas UpadhyayNoch keine Bewertungen

- "Miniaturization, Power Optimization, Performance and Reliability Trade-Off in RF Based Embedded System Design": Onboard As Case StudyDokument1 Seite"Miniaturization, Power Optimization, Performance and Reliability Trade-Off in RF Based Embedded System Design": Onboard As Case StudyVikas UpadhyayNoch keine Bewertungen

- PCB Design PDFDokument28 SeitenPCB Design PDFVikas UpadhyayNoch keine Bewertungen

- PCB Design PDFDokument28 SeitenPCB Design PDFVikas UpadhyayNoch keine Bewertungen

- ARM ARM Microprocessor Basics Microprocessor Basics: Introduction To ARM Processor Introduction To ARM ProcessorDokument0 SeitenARM ARM Microprocessor Basics Microprocessor Basics: Introduction To ARM Processor Introduction To ARM ProcessorVikas UpadhyayNoch keine Bewertungen

- VLSIDokument7 SeitenVLSIVikas UpadhyayNoch keine Bewertungen

- Testing of Continuity in Switches and LoadDokument7 SeitenTesting of Continuity in Switches and LoadVikas UpadhyayNoch keine Bewertungen

- CH 1 PDFDokument25 SeitenCH 1 PDFVikas UpadhyayNoch keine Bewertungen

- Chapter 3Dokument10 SeitenChapter 3Vikas UpadhyayNoch keine Bewertungen

- Optical Amplifier TheoryDokument24 SeitenOptical Amplifier Theoryナス サンNoch keine Bewertungen

- Vikas ProjectDokument67 SeitenVikas ProjectVikas UpadhyayNoch keine Bewertungen

- White LED Driver Circuits For Off-Line Applications Using Standard PWM ControllersDokument13 SeitenWhite LED Driver Circuits For Off-Line Applications Using Standard PWM ControllersVikas UpadhyayNoch keine Bewertungen

- Radar NotesDokument97 SeitenRadar Notessrikanth497100% (2)

- Irodov. Basic Laws of ElectromagnetismDokument316 SeitenIrodov. Basic Laws of ElectromagnetismDiego AntonioNoch keine Bewertungen

- Toshiba TransformerDokument28 SeitenToshiba Transformeryeoj_arom100% (3)

- MIT2 Shapiro 3.05 - SoluDokument4 SeitenMIT2 Shapiro 3.05 - SoluDouglas LimaNoch keine Bewertungen

- HESCODokument2 SeitenHESCOAli Assad MirNoch keine Bewertungen

- Energy Performance of Stationary-Rack, Door-Type Commercial Dishwashing MachinesDokument19 SeitenEnergy Performance of Stationary-Rack, Door-Type Commercial Dishwashing MachinesRed RedNoch keine Bewertungen

- Direct Ray EPEX Omniflex IV System Service ManualDokument13 SeitenDirect Ray EPEX Omniflex IV System Service ManualNahomi espinozaNoch keine Bewertungen

- Machine Lab 1Dokument9 SeitenMachine Lab 1مالك المجيديNoch keine Bewertungen

- Microwave Oven: Service ManualDokument33 SeitenMicrowave Oven: Service ManualCesar Calderon GrNoch keine Bewertungen

- Effect of PCM On Temperature Fluctuation During The Door Opening of A Household RefrigeratorDokument22 SeitenEffect of PCM On Temperature Fluctuation During The Door Opening of A Household RefrigeratorWalton Science Research LabNoch keine Bewertungen

- Physics 121: Electricity & Magnetism - Lecture 3 Electric FieldDokument22 SeitenPhysics 121: Electricity & Magnetism - Lecture 3 Electric FieldDilini WijesinghNoch keine Bewertungen

- ResonanceDokument48 SeitenResonancePrakash Nik79% (92)

- Course Work O1Dokument4 SeitenCourse Work O1zaianzNoch keine Bewertungen

- Accu Icr18650 2.2 PDFDokument8 SeitenAccu Icr18650 2.2 PDFNaciu CatalinNoch keine Bewertungen

- Using The Mobile Substations in 132Kv Network and Studying Their Effects On The Losses of NetworkDokument4 SeitenUsing The Mobile Substations in 132Kv Network and Studying Their Effects On The Losses of NetworkSudhir RavipudiNoch keine Bewertungen

- Manual Usuario Balanza healtOMeter 500KLDokument16 SeitenManual Usuario Balanza healtOMeter 500KLararmijosNoch keine Bewertungen

- ASTM D2583 Standard Testing Method of Measuring Hardness by Barcol Hardness MethodDokument8 SeitenASTM D2583 Standard Testing Method of Measuring Hardness by Barcol Hardness MethodHASSAN WASEEMNoch keine Bewertungen

- Richtekusainc Rt906950gb Datasheets 6616Dokument15 SeitenRichtekusainc Rt906950gb Datasheets 6616JayR VillaNoch keine Bewertungen

- Molar Volumes of Hydrogen Gas LabDokument4 SeitenMolar Volumes of Hydrogen Gas LabHannah Lee100% (3)

- Control of Vibration and Resonance in Aero Engines and Rotating Machinery - An OverviewDokument7 SeitenControl of Vibration and Resonance in Aero Engines and Rotating Machinery - An OverviewpeaceshadyNoch keine Bewertungen

- TD RWG Ewg Poti enDokument3 SeitenTD RWG Ewg Poti enJanko PekoljNoch keine Bewertungen

- Speed of Sound Bubbly LiquidsDokument8 SeitenSpeed of Sound Bubbly LiquidsAndrew FahimNoch keine Bewertungen

- Solar Radiation GeometryDokument62 SeitenSolar Radiation GeometrySai ReddyNoch keine Bewertungen

- Nlewis65 204 208 Classroom Winnick 29 No 3 Summer 1995 CeeDokument5 SeitenNlewis65 204 208 Classroom Winnick 29 No 3 Summer 1995 CeeFerdz RmrzNoch keine Bewertungen

- Capacitance Multiple Choice QuestionsDokument4 SeitenCapacitance Multiple Choice QuestionsRupak MandalNoch keine Bewertungen

- 100-9 0Dokument104 Seiten100-9 0jhierryNoch keine Bewertungen

- Work Book Physics Grade 11&12Dokument33 SeitenWork Book Physics Grade 11&12Yonatan Tolosa100% (2)

- Multiphase Systems - Part IDokument20 SeitenMultiphase Systems - Part I랄뚜기Noch keine Bewertungen

- Heat Capacity CP CO2 As A Function of Temper 2016 PDFDokument140 SeitenHeat Capacity CP CO2 As A Function of Temper 2016 PDFRubén100% (1)

- DSLSBillDokument1 SeiteDSLSBillSandeep ParasharNoch keine Bewertungen

- Olympic Tunnel Presentation PGH 3Dokument67 SeitenOlympic Tunnel Presentation PGH 3Sivagnana SundaramNoch keine Bewertungen