Beruflich Dokumente

Kultur Dokumente

Victaulic JT 06.01

Hochgeladen von

nrd9771Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Victaulic JT 06.01

Hochgeladen von

nrd9771Copyright:

Verfügbare Formate

R

IPS CARBON STEEL PIPE GROOVED SYSTEM

VICTAULIC

IS AN ISO 9001 CERTIFIED COMPANY

REGISTERED TRADEMARK OF VICTAULIC COPYRIGHT 2003 VICTAULIC PRINTED IN U.S.A. 1686 REV B

06.01

Vi ctaul i c Company of Ameri ca Phone: 1- 800- PICK- VIC (1- 800- 742- 5842) Fax: 610- 250- 8817 e- mai l :pi ckvi c@vi ctaul i c.com

Vi ctaul i c Company of Canada Phone: 905- 884- 7444 Fax: 905- 884- 9774 e- mai l : vi ccanada@vi ctaul i c.com

Vi ctaul i c Europe Phone:32- 9- 381- 1500 Fax: 32- 9- 380- 4438 e- mai l : vi ceuro@vi ctaul i c.be

Vi ctaul i c Ameri ca Lati na Phone: 610- 559- 3300 Fax: 610- 559- 3608 e- mai l : vi cal @vi ctaul i c.com

Vi ctaul i c Asi a Paci fi c Phone: 65- 6235- 3035 Fax: 65- 6235- 0535 e- mai l : vi cap@vi ctaul i c.com

Grooved Piping System

The only system that provides the option of rigidity or exibility

PRODUCT DESCRIPTION

Gasket

Housing

Bolt/Nut

Groove

Installed cost

savings from

10% to 30%

M inimal equipment investment

Fast assembly in tight places

Clean system. . . no pipe dope

or welding slag to contaminate

pipes Costs are more

predictable. . . estimates more

accurate

Each joint

is a union

Removal of two couplings

permits removal of pipe section

for cleaning or servicing Easy

future add-on, change or

renovation of pipe to distribute

internal wear from abrasives or

slurries

WARNING: Depressurize and

drain the piping system before

attempting to install, remove,

or adjust any Victaulic piping

products.

Proven joint

reliability

Full circumferential

engagement of housing into

groove provides end pull

strength Couplings available

for working pressures to 2, 500

psi ( 17, 235 kPa) . . . vacuum

services to 29.9" Hg

For roll or cut

grooved pipe

Victaulic tools permit roll

grooving standard steel pipe up

to 42" ( 1050 mm) in 0.375" ( 9, 5

mm) wall thicknesses

Couplings fit either roll or cut

grooved pipe Roll grooving

permits use on pipe from

Schedule 5 to Schedule 40

Pipe of different wall thickness

and material can be connected

directly and intermixed

Exaggerated for clarity

Exaggerated for clarity

Roll Grooved

Cut Grooved

The Victaulic grooved piping system is the most versatile, economical

and reliable piping system available. I t is up to three times faster to

install than welding, easier and more reliable than threading or flanging,

resulting in lowest total installed cost.

The system is designed for roll grooved or cut grooved standard pipe or

roll grooved light wall pipe. Pipe end preparation is fast and easy either

in the shop or on the job site with a variety of Victaulic grooving tools

available.

I n addition to speed and ease of assembly, the Victaulic system offers

varied mechanical benefits to the designer, installer and owner. With the

introduction of Zero-Flex

and FireLock

rigid couplings, the option of

flexibility or rigidity adds to the design versatility. Flexible and rigid

couplings can be incorporated as needed in any system to take full

advantage of the characteristics of each.

2 G rooved Piping System

06.01

RIGID SYSTEMS

Zero-Flex Style 07, FireLock Style 005 and Transition Style 307 Rigid Couplings have a unique, patented

angle pad design which constricts the housing keys into the groove around the full circumference to grip

the pipe rigidly. The housings slide on the angled pads rather than mating squarely.

This sliding adjustment also forces the key sections into opposed contact on the inside and the outside

groove edges, pushing the joint to its maximum pipe end separation ( see chart below) during assembly.

These rigid couplings provide a rigid joint allowing no expansion/contraction or linear movement.

Couplings will push the pipe ends to their maximum allowable separation which must be considered

during assembly.

Rigid couplings ( Styles 07, 005, 89, 489, 307, HP-70, 741 and others) create a rigid joint, useful for risers,

mechanical rooms and other areas where flexibility is not desired. Zero-Flex Style 07 and FireLock Style

005 couplings are designed to provide rigidity to permit hanging to ASM E B31.1 Power Piping Code,

ASM E B31.9 Building Services Piping Code and NFPA 13 Sprinkler Systems.

RIGID COUPLING PERFORMANCE

(Angle Bolt Pad Design)

Pipe Size

Allowable

Pipe End Sep.

Inches/mm

Pipe Size

Allowable

Pipe End Sep.

Inches/mm

Nominal

\Diameter

Inches/mm

Actual

Outside Diameter

Inches/mm

Nominal

Diameter

Inches/mm

Actual

Outside Diameter

Inches/mm

3

/

4

1.050 0.05 5 5.563 0.16

20 26, 7 1, 2 125 141, 3 4, 1

1 1.315 0.05

159, 0 mm

6.250 0.16

25 33, 7 1, 2 159, 0 4, 1

1

1

/

4

1.660 0.05

165, 1 mm

6.500 0.16

32 42, 4 1, 2 165, 1 4, 1

1

1

/

2

1.900 0.05 6 6.625 0.16

40 48, 3 1, 2 150 168, 3 4, 1

2 2.375 0.07 8 8.625 0.19

50 60, 3 1, 7 200 219, 1 4, 8

2

1

/

2

2.875 0.07 10 10.750 0.13

65 73, 0 1, 7 250 273, 0 3, 3

76, 1 mm

3.000 0.07 12 12.750 0.13

76, 1 1, 7 300 323, 9 3, 3

3 3.500 0.07 14 14.000 0.13

80 88, 9 1, 7 350 355, 6 3, 3

4 4.500 0.16 16 16.000 0.13

100 114, 3 4, 1 400 406, 4 3, 3

108, 0 mm

4.250 0.16 18 18.000 0.13

108, 0 4, 1 450 457, 0 3, 3

133, 0 mm

5.250 0.16 20 20.000 0.13

133, 0 4, 1 500 508, 0 3, 3

139, 7 mm

5.500 0.16 24 24.000 0.09

139, 7 4, 1 600 610, 0 2, 3

Provides rigidity

Zero-Flex Style 07 and

FireLock Style 005 unique

( patented) angled-pad design

adjusts to standard pipe

tolerances Provides positive

clamping of the pipe to resist

flexural and torsional loads

Support and hanging

requirements correspond to

ASM E B31.1 Power Piping

Code, ASM E B31.9 Building

Services Code and NFPA 13

Sprinkler Systems

Easy swing-over

assembly

Bolt-pad design permits

assembly by removing one nut/

bolt and scissoring housing over

gasket Reduces the number of

components to handle during

assembly Speeds and eases

installation

06.01

G rooved Piping System 3

FLEXIBLE SYSTEMS

Flexible grooved-type couplings ( such as Styles 77, 75, 72, 750, 78 and 791) allow controlled angular,

linear and rotational movement at each joint to accommodate expansion, contraction, setting, vibration,

noise and other piping system movement. These features provide advantages in designing piping

systems but must be considered when determining hanger and support spacing and location.

Victaulic couplings offer superior vibration attenuation characteristics to both flexible metal and

elastomeric flexible arch-type connectors. I ndependent vibration testing data ( request Section 26.04)

verifies that three Victaulic couplings in close proximity to a vibration source ( pump, equipment, etc.)

provide superior vibration attenuation in piping systems.

Both type couplings offer installed cost savings from 10 to 30% and higher, plus the convenience of a

union at every joint and the proven pressure-responsive C shaped Victaulic gasket. Both type products

fit into standard roll or cut grooved pipe and provide the security of full circumferential engagement of the

coupling housing into the groove for high pressure and end load service.

FLEXIBLE COUPLING PERFORMANCE

Pipe Size

Allow. Pipe

End Sep.

In./mm

Deect. Fr. C

L

Pipe Size

Allow. Pipe

End Sep.

In./mm

Deect. Fr. C

L

Pipe Size

Allow. Pipe

End Sep.

In./mm

Deect. Fr. C

L

Nominal

Diameter

In./mm

Actual

Outside

Dia.

In./mm

Degrees

per

Cplg.

Pipe

In./ft.

mm/m

Nominal

Diameter

In./mm

Actual

Outside

Dia.

In./mm

Degrees

per

Cplg.

Pipe

In./ft.

mm/m

Nominal

Diameter

In./mm

Actual

Outside

Dia.

In./mm

Degrees

per

Cplg.

Pipe

In./ft.

mm/m

3

/

4

1.050 0 - 0.06

3 24

0.72 4

1

/

2

5.000 0 - 0.13

1 26

0.25 10 10.750 0 - 0.13

0 40

0.14

20 26, 7 0 - 1, 6 60 120 127, 0 0 - 3, 2 21 250 273, 0 0 - 3, 2 12

1 1.315 0 - 0.06

2 43

0.57

133, 0 mm

5.250 0 - 0.13

1 21

0.28

304, 8 mm

12.000 0 - 0.13

0 36

0.13

25 33, 7 0 - 1, 6 48 133, 0 0 - 3, 2 23 304, 8 0 - 3, 2 11

1

1

/

4

1.660 0 - 0.06

2 10

0.45

139, 7 mm

5.500 0 - 0.13

1 18

0.28 12 12.750 0 - 0.13

0 34

0.12

32 42, 4 0 - 1, 6 38 139, 7 0 - 3, 2 23 300 323, 9 0 - 3, 2 10

1

1

/

2

1.900 0 - 0.06

1 56

0.40 5 5.563 0 - 0.13

1 18

0.27 14 14.000 0 - 0.13

0 31

0.11

40 48, 3 0 - 1, 6 33 125 141, 3 0 - 3, 2 22 350 355, 6 0 - 3, 2 9

2 2.375 0 - 0.06

1 31

0.32

152, 4 mm

6.000 0 - 0.13

1 12

0.21 15 15.000 0 - 0.13

0 29

0.10

50 60, 3 0 - 1, 6 27 152, 4 0 - 3, 2 17 375 381, 0 0 - 3, 2 8

2

1

/

2

2.875 0 - 0.06

1 15

0.26

159, 0 mm

6.250 0 - 0.13

1 9

0.24 16 16.000 0 - 0.13

0 27

0.10

65 73, 0 0 - 1, 6 22 159, 0 0 - 3, 2 20 400 406, 4 0 - 3, 2 8

76, 1 mm.

3.000 0 - 0.06

1 12

0.26

165, 1 mm

6.500 0 - 0.13

1 6

0.23 18 18.000 0 - 0.13

0 24

0.08

76, 1 0 - 1, 6 22 165, 1 0 - 3, 2 19 450 457, 0 0 - 3, 2 7

3 3.500 0 - 0.06

1 2

0.22 6 6.625 0 - 0.13

1 5

0.23 20 20.000 0 - 0.13

0 22

0.08

80 88, 9 0 - 1, 6 18 150 168, 3 0 - 3, 2 19 500 508, 0 0 - 3, 2 7

3

1

/

2

4.000 0 - 0.06

0 54

0.19

203, 2 mm

8.000 0 - 0.13

0 54

0.16 22 22.000 0 - 0.13

0 19

0.07

90 101, 6 0 - 1, 6 16 203, 2 0 - 3, 2 13 550 559, 0 0 - 3, 2 6

4 4.500 0 - 0.13

1 36

0.34 8 8.625 0 - 0.13

0 50

0.18 24 24.000 0 - 0.13

0 18

0.07

100 114, 3 0 - 3, 2 28 200 219, 1 0 - 3, 2 15 600 610, 0 0 - 3, 2 6

108, 0 mm

4.250 0 - 0.13

1 41

0.35

254, 0 mm

10.000 0 - 0.13

0 43

0.15

108, 0 0 - 3, 2 29 254, 0 0 - 3, 2 13

Refer to notes on page 4.

NO TE: These values are based on standard roll grooved pipe. Figures for standard cut grooved pipe may be doubled. See notes on page 4.

Minimizesnoise and

vibration

transmission

I solates noise and vibration

Resilient gasket helps absorb

noise and vibration Permits

elimination of noise suppression

devices Provides superior

vibration attenuation better than

flexible metal or elastomeric

arch-type connectors ( refer to

26.04)

Provides

expansion and

contraction

Up to 0.250" ( 6, 35 mm) linear

movement at each joint

M inimizes or eliminates costly

expansion joints and loops ( refer

to 26.02)

Minimizes

system

stresses

Flexible joints provide virtually

a stress free system ( refer to

26.03) Reduces or eliminates

stresses from settlement of

buried pipe Absorbs

temporary stresses induced by

seismic tremors ( refer to 26.05)

Contraction

Expansion

Deflection

4 G rooved Piping System

06.01

COUPLING MAXIMUM WORKING PRESSURE

(Standard Wall Steel Pipe)

Pipe Size

Pipe

Wall

Thick.

Sched.

Coupling Style Working Pressure PSI/kPa

Nominal

Diameter

In./mm

Actual

Outside

Dia.

In./mm

Style 07

Rigid

Style 005

Rigid

Style 77

Flexible

Style 75

Flexible

Style 78

Snap-Joint

Style 791

Boltless

Style 741

Flange Adpt.

Style 743

Flange Adpt.

HP-70

Rigid

HP-70ES

EndSeal

Style 72

Outlet

Style 750

Reducing

3

/

4

1.050

40

1000

20 26, 7 6900

1 1.315

40

750 1000 300

25 33, 7 5175 6900 2065

1

1

/

4

1.660

40

750 350 1000 300

32 42, 4 5175 2410 6900 2065

1

1

/

2

1.900

40

750 350 1000 500 300 500

40 48, 3 5175 2410 6900 3450 2065 3450

2 2.375

40

750 350 1000 500 300 700 300 720 1000 2500 500 350

50 60, 3 5175 2410 6900 3450 2065 4825 2065 4965 6900 17235 3450 2410

2

1

/

2

2.875

40

750 350 1000 500 300 700 300 720 1000 2500 500 350

65 73, 0 5175 2410 6900 3450 2065 4825 2065 4965 6900 17235 3450 2410

76, 1 mm

3.000

40

750 350 1000 500 350

76, 1 5175 2410 6900 3450 2410

3 3.500

40

750 350 1000 500 300 700 300 720 1000 2500 500 350

80 88, 9 5175 2410 6900 3450 2065 4825 2065 4965 6900 17235 3450 2410

3

1

/

2

4.000

40

1000 500

90 101, 6 6900 3450

4 4.500

40

750 350 1000 500 300 700 300 720 1000 2500 500 350

100 114, 3 5175 2410 6900 3450 2065 4825 2065 4965 6900 17235 3450 2410

108, 0 mm

4.250

40

750 300 1000 450

108, 0 5175 2065 6900 3100

4

1

/

2

5.000

40

450

120 127, 0 3100

133, 0 mm

5.250

40

700 300 1000 450

133, 0 4825 2065 6900 3100

139, 7 mm

5.500

40

700 300 1000 450

139, 7 4825 2065 6900 3100

5 5.563

40

700 300 1000 450 300 700 300 720 350

125 141, 3 4825 2065 6900 3100 2065 4825 2065 4965 2410

159, 0 mm

6.250

40

700 300 1000 450

159, 0 4825 2065 6900 3100

165, 1 mm

6.500

40

700 300 1000 450 300 350

165, 1 4825 2065 6900 3100 2065 2410

6 6.625

40

700 300 1000 450 300 600 300 720 1000 2000 400 350

150 168, 3 4825 2065 6900 3100 2065 4135 2065 4965 6900 13790 2750 2410

8 8.625

40

600 300 800 450 300 500 300 720 800 1500 350

200 219, 1 4130 2065 5500 3100 2065 3450 2065 4965 5500 10350 2410

10 10.750

40

500 800 300 720 800 1250

250 273, 0 3450 5500 2065 4965 5500 8625

12 12.750

30

400 800 300 720 800 1250

300 323, 9 2750 5500 2065 4965 5500 8625

14 14.000

30

250 300 300 600

350 355, 6 1725 2065 2065 4135

15 15.000

0.375

300

375 381, 0 2065

16 16.000

30

250 300 300 600

400 406, 4 1725 2065 2065 4135

18 18.000

STD

250 300 300

450 457, 0 1725 2065 2065

20 20.000

20

250 300 300

500 508, 0 1725 2065 2065

22 22.000

20

300

550 559, 0 2065

24 24.000

20

250 250 300

600 610, 0 1725 1725 2065

NOTES

* Working Pressure and End Load are total, from all internal and external loads, based on standard weight ( ANSI ) steel pipe, standard roll or cut grooved in accordance with

Victaulic specifications. Contact Victaulic for performance on other pipe.

WARNI NG : FO R O NE TI M E FI ELD TEST O NLY, the M aximum Joint Working Pressure may be increased to 1

1

/2 times the figures shown.

Allowable Pipe End Separation and Deflection figures show the maximum nominal range of movement available at each joint for standard roll grooved pipe.

Figures for standard cut grooved pipe may be doubled. These figures are maximums; for design and installation purposes these figures should be reduced by: 50% for

3

/4 -

3

1

/2" ( 20 - 90 mm) ; 25% for 4" ( 100 mm) and larger.

Number of bolts required equals number of housing segments.

M etric thread size bolts are available ( color coded gold) for all coupling sizes upon request. Contact Victaulic for details.

WARNI NG : Depressurize and drain the piping system before attempting to install, remove, or adjust any Victaulic piping products.

This product shall be manufactured by Victaulic Company. All products shall be installed in accordance with current Victaulic installation/assembly instructions.

Victaulic reserves the right to change product specifications, designs and standard equipment without notice and without incurring obligations.

Das könnte Ihnen auch gefallen

- Slug Flow: (Sample Model: Slug - Dat)Dokument7 SeitenSlug Flow: (Sample Model: Slug - Dat)nrd9771Noch keine Bewertungen

- Section Viii Div 1 Div 2 Div ComparisonDokument2 SeitenSection Viii Div 1 Div 2 Div Comparisonapparaokr100% (5)

- DK598X_book_Accelerated_AgingDokument10 SeitenDK598X_book_Accelerated_Agingnrd9771Noch keine Bewertungen

- Reliability Over TimeDokument27 SeitenReliability Over Timenrd9771Noch keine Bewertungen

- Tape Coating 2Dokument7 SeitenTape Coating 2nrd9771Noch keine Bewertungen

- DK598X - Book - FM Page 1 Monday, January 24, 2005 11:11 PMDokument6 SeitenDK598X - Book - FM Page 1 Monday, January 24, 2005 11:11 PMnrd9771Noch keine Bewertungen

- Ncode Designlife Brochure PDFDokument4 SeitenNcode Designlife Brochure PDFnrd9771Noch keine Bewertungen

- Nonparametric Statistical Methods for Reliability AnalysisDokument30 SeitenNonparametric Statistical Methods for Reliability Analysisnrd9771Noch keine Bewertungen

- b15906 6Dokument21 Seitenb15906 6nrd9771Noch keine Bewertungen

- b15906 4Dokument18 Seitenb15906 4nrd9771Noch keine Bewertungen

- Polyken 2019 PrimerDokument5 SeitenPolyken 2019 Primernrd9771Noch keine Bewertungen

- Stellite PropertiesDokument2 SeitenStellite Propertiesnrd9771Noch keine Bewertungen

- System Structures: Defn. 2.1 ReliabilityDokument20 SeitenSystem Structures: Defn. 2.1 Reliabilitynrd9771Noch keine Bewertungen

- Ncode Designlife Brochure PDFDokument4 SeitenNcode Designlife Brochure PDFnrd9771Noch keine Bewertungen

- b15906 1Dokument21 Seitenb15906 1nrd9771Noch keine Bewertungen

- Ductile IronDokument7 SeitenDuctile Ironnrd9771Noch keine Bewertungen

- Teadit - Solid Metallic GasketsDokument1 SeiteTeadit - Solid Metallic Gasketsnrd9771Noch keine Bewertungen

- Hot Service SpecsDokument3 SeitenHot Service Specsnrd9771Noch keine Bewertungen

- WSA 113 RC Pipe With Flexible TPL Issue 1Dokument31 SeitenWSA 113 RC Pipe With Flexible TPL Issue 1NikeNoch keine Bewertungen

- Al BR ProfileDokument1 SeiteAl BR Profilenrd9771Noch keine Bewertungen

- Hose Air & Water GP300Dokument1 SeiteHose Air & Water GP300nrd9771Noch keine Bewertungen

- 061110170425preview - CP 27-1999 Amd1Dokument6 Seiten061110170425preview - CP 27-1999 Amd1nrd9771Noch keine Bewertungen

- Al BR ProfileDokument1 SeiteAl BR Profilenrd9771Noch keine Bewertungen

- Rosen Intel PigsDokument1 SeiteRosen Intel Pigsnrd9771Noch keine Bewertungen

- Tape Coating 2Dokument7 SeitenTape Coating 2nrd9771Noch keine Bewertungen

- Ductile IronDokument7 SeitenDuctile Ironnrd9771Noch keine Bewertungen

- Ductile IronDokument7 SeitenDuctile Ironnrd9771Noch keine Bewertungen

- Impact Test For CS MaterialDokument1 SeiteImpact Test For CS Materialnrd9771Noch keine Bewertungen

- Field Installed Flanges Ss 202Dokument1 SeiteField Installed Flanges Ss 202nrd9771Noch keine Bewertungen

- Flow LinesDokument1 SeiteFlow Linesnrd9771Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Data Sheet For Chilled Water Pump (Primary) For Air Cooled ChillerDokument2 SeitenData Sheet For Chilled Water Pump (Primary) For Air Cooled ChillerHemanti SharmaNoch keine Bewertungen

- Increase of Wear Resistance of The Drill Pipe Thread Connection by Electromechanical Surface HardeningDokument5 SeitenIncrease of Wear Resistance of The Drill Pipe Thread Connection by Electromechanical Surface HardeningQuality controllerNoch keine Bewertungen

- Tyre-Flex Coupling DeatilsDokument19 SeitenTyre-Flex Coupling DeatilsDnyanesh BhaleraoNoch keine Bewertungen

- 2011 Boiler Feed Pumps Thermosolar Conference V3 PDFDokument27 Seiten2011 Boiler Feed Pumps Thermosolar Conference V3 PDFjrri16Noch keine Bewertungen

- Alignment LEBW4975 06Dokument32 SeitenAlignment LEBW4975 06dfheardNoch keine Bewertungen

- Robot Arm Assembly Drives Multiple AxesDokument9 SeitenRobot Arm Assembly Drives Multiple AxesBillel LouniciNoch keine Bewertungen

- Oil and Gas Plant Procedure & Question and Answers GuideDokument35 SeitenOil and Gas Plant Procedure & Question and Answers GuideUsama ArifNoch keine Bewertungen

- 4600en 0119fleDokument40 Seiten4600en 0119fledeni jakaNoch keine Bewertungen

- Dme I Unit 1 To 6 - MCQDokument30 SeitenDme I Unit 1 To 6 - MCQSAURAV KOULNoch keine Bewertungen

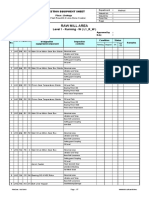

- Lhoknga Plant Raw-Mill Inspection Equipment SheetDokument7 SeitenLhoknga Plant Raw-Mill Inspection Equipment SheetTeuku AlkhaitamiNoch keine Bewertungen

- ESPECIFICACIÓNDokument24 SeitenESPECIFICACIÓNaecf_13Noch keine Bewertungen

- REAR FINAL DRIVE ASSEMBLY GUIDEDokument36 SeitenREAR FINAL DRIVE ASSEMBLY GUIDESonia GarciaNoch keine Bewertungen

- Rotodynamic Analysis & Optimization Study of BearingDokument10 SeitenRotodynamic Analysis & Optimization Study of BearingGaurav JogiNoch keine Bewertungen

- Catalogo de SELECCIÓN CARDANDokument36 SeitenCatalogo de SELECCIÓN CARDANTony CasillaNoch keine Bewertungen

- Gearboxes: Gearbox ApplicationDokument8 SeitenGearboxes: Gearbox Applicationrizviabbas2012Noch keine Bewertungen

- Selection Guide Dimensional Data Overview and Performance DataDokument4 SeitenSelection Guide Dimensional Data Overview and Performance Data3568Noch keine Bewertungen

- Model AG25 ProcessDokument11 SeitenModel AG25 Processasrul fatahNoch keine Bewertungen

- Design and Analysis of Kinematic Couplings For Modular MachiDokument264 SeitenDesign and Analysis of Kinematic Couplings For Modular MachigheinbaNoch keine Bewertungen

- CP200 pump installation manualDokument45 SeitenCP200 pump installation manualjacklyn ade putraNoch keine Bewertungen

- 1-Instruction Manual Cyclone Unit HCC CE-En REV1!22!11-10Dokument10 Seiten1-Instruction Manual Cyclone Unit HCC CE-En REV1!22!11-10Oscar CañeteNoch keine Bewertungen

- UNIT 2 Design of Shafts, Keys and CouplingsDokument6 SeitenUNIT 2 Design of Shafts, Keys and Couplingsrahul dNoch keine Bewertungen

- 02 Tooth Gear Coupling BoWexDokument20 Seiten02 Tooth Gear Coupling BoWexTeddy NsNoch keine Bewertungen

- Mastertech1 PDFDokument4 SeitenMastertech1 PDFDiego AlejandroNoch keine Bewertungen

- Amerifle Diaphragm Coupling CatalogueDokument24 SeitenAmerifle Diaphragm Coupling CatalogueratapornNoch keine Bewertungen

- Screw Conveyor Engineering GuideDokument44 SeitenScrew Conveyor Engineering Guideaxl1100% (2)

- 4.2a - Dinamic Oil - Planetary Gearboxes - Installation Operation ManualDokument59 Seiten4.2a - Dinamic Oil - Planetary Gearboxes - Installation Operation Manualphuocloi82Noch keine Bewertungen

- Transfer Case Removal and Installation Guide: Item DescriptionDokument4 SeitenTransfer Case Removal and Installation Guide: Item DescriptionMarco Equipment Sales LLCNoch keine Bewertungen

- Grinnell DNV Certificate PDFDokument3 SeitenGrinnell DNV Certificate PDFAna Carolina SantosNoch keine Bewertungen

- External CatchDokument1 SeiteExternal CatchMicNoch keine Bewertungen

- Operating Limits Up To 1800 m3/h And 140 mCEDokument50 SeitenOperating Limits Up To 1800 m3/h And 140 mCEarielbankiNoch keine Bewertungen