Beruflich Dokumente

Kultur Dokumente

Tidsdiskret Pid Reg

Hochgeladen von

Lucian GomoescuOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tidsdiskret Pid Reg

Hochgeladen von

Lucian GomoescuCopyright:

Verfügbare Formate

19

3.4

3.4.1

Discretizing a PID controller

Computer based control loop

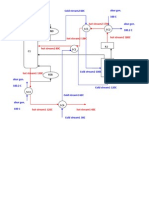

Figure 3.2 shows a control loop where controller is implemented in a computer. The computer registers the process measurement signal via an AD converter (from analog to digital). The AD converter produces a numerical value which represents the measurement. As indicated in the block diagram this value may also be scaled, for example from volts to percent. The resulting digital signal, y(tk ), is used in the control function, which is in the form of a computer algorithm or program calculating the value of the control signal, u(tk ).

r( tk ) e(t k) u( tk ) u(t ) y(t )

tk =kh h y( tk) r (tk )

tk e(t k ) Discrete-time u(tk ) PID controller y( tk )

tk

Scaling and DA-converter with signal holding

t v u( t) Process y

AD-converter and scaling

tk

Sampling

Measured y( t) t Sensor

Figure 3.2: Control loop where the controller function is implemented in a computer The control signal is scaled, for example from percent to milliamperes, and sent to the DA converter (from digital to analog) where it is held constant during the present time step. Consequently the control signal becomes a staircase signal. The time step or the sampling interval, h [s], is usually small compared to the time constant of the actuator (e.g. a valve) so the actuator does not feel the staircase form of the control signal. A typical value of h in commercial controllers is 0.1 s.

20

3.4.2

Development of discrete-time PID controller

The starting point of deriving the discrete-time PID controller is the continuous-time PID (proportional + integral + derivate) controller: Z Kp t e d + Kp Td e f (t) (3.19) u(t) = Kp e(t) + Ti 0 where u is the controller output (the control variable), e is the control error: e(t) = r(t) y (t) (3.20) where r is the reference or setpoint, and y is the process measurement. ef is the ltered control error. It is the output of the following lowpass lter: ef (s) = 1 e(s) Tf s + 1 (3.21)

where Tf is the lter time-constant, which is typically selected as Tf = aTd where typically a = 0.1. We will now derive a discrete-time formula for u(tk ), the value of the control signal for the present time step. The discretization can be performed in a number of ways. Probably the simplest way is as follows: Dierentiating both sides of (3.19) gives2 u (t) = Kp e (t) + Kp e(t) + Kp Td e f (t) Ti (3.23) (3.22)

Applying the Backward dierentiation method (3.2) to u , e , and e f gives e f (tk ) e f (tk1 ) u(tk ) u(tk1 ) e(tk ) e(tk1 ) Kp = Kp + e(tk ) + Kp Td h h Ti h (3.24) f (tk1 ) in Applying the Backward dierentiation method on e f (tk ) and e (3.24) gives u(tk ) u(tk1 ) h = Kp e(tk ) e(tk1 ) h Kp + e(tk ) Ti

ef (tk )ef (tk1 ) h

(3.25) (3.26) h

ef (tk1 )ef (tk2 ) h

+Kp Td

2

(3.27)

The time derivative of an integral is the integrand.

21 Solving for u(tk ) nally gives the discrete-time PID controller: u(tk ) = u(tk1 ) + Kp [e(tk ) e(tk1 )] + + Kp h e(tk ) Ti (3.28) (3.29)

Kp Td [ef (tk ) 2ef (tk1 ) + ef (tk2 )] h

The discrete version of the lter (3.21) can be derived as described in Section 3.3. The discrete-time PID controller algorithm (3.28) is denoted the absolute or positional algorithm. Automation devices typically implements the incremental or velocity algorithm. because it has some benets. The incremental algorithm is based on splitting the calculation of the control value into two steps: 1. First the incremental control value u(tk ) is calculated. 2. Then the total or absolute control value is calculated with u(tk ) = u(tk1 ) + u(tk1 ). Thus, the incremental PID algorithm is u(tk ) = Kp [e(tk ) e(tk1 )] + + Kp h e(tk ) Ti (3.30) (3.31) (3.32)

Kp Td [ef (tk ) 2ef (tk1 ) + ef (tk2 )] h u(tk ) = u(tk1 ) + u(tk )

The summation (3.32) implements the (numerical) integral action of the PID controller. The incremental PID control function is particularly useful if the actuator is controlled by an incremental signal. A step-motor is such an actuator. The motor itself implements the numerical integration (3.32). It is (only) u(tk ) that is sent to the motor.

3.4.3

Some practical features of the PID controller

A practical PID controller must have certain features to be functional: Integrator anti windup: Large excitations of the control system, typically large disturbances or large setpoint changes, may cause the

22 control signal to reach its maximum or minimum limits with the control error being dierent from zero. The summation in (3.32), which is actually a numerical integration, will then cause u to increase (or descrease) steadily this is denoted integral windup so that u may get a very high (or low) value. When the excitations are back to normal values, it may take a very long time before the large value of u is integrated back to a normal value (i.e. within 0 100%), causing the process output to deviate largely from the setpoint. Preventing the windup is (not surprisingly) denoted anti windup, and it can realized as follows: 1. Calculate an intermediate value of the control variable u(tk ) according to (3.32), but do not send this value to the DA (Digital-to-Analog) converter. 2. Check if this intermediate value is greater than the maximum value umax (typically 100%) or less than the minimum value umin (typically 0%). If it exceeds one of these limits, set u(tk ) in (3.32) to zero. 3. Write u(tk ) to the DA converter.

Bumpless transfer: Suppose the controller is switched from automatic to manual mode, or from manual to automatic mode (this will happen during maintenance, for example). The transfer between modes should be bumpless, ideally. Bumpless transfer can be realized as follows: Bumpless transfer from automatic to manual mode: In manual mode it is the manual (or nominal) control signal u0 that controls the process. We assume here that the control signal u(tk ) in (3.32) has a proper value, say ugood , so that the control error is small, immediately before the switch to manual mode. To implement bumpless transfer, set u0 equal to ugood at the switching moment. Bumpless transfer from manual to automatic mode: While the controller is in manual mode, u(tk ) in (3.32) is set (forced) to zero, and both u(tk ) and u(tk1 ) are set to u0 , the manual control value (which may be changed during the manual mode, of course). After the switching from manual to automatic mode allow u(tk ) to be calculated according to (3.30) (hence, do not force u(tk ) to be zero any longer).

23

3.4.4

Selecting the sampling time of the control system

The DA converter (digital to analog) which is always between the discrete-time control function and the continuous-time process to be controlled, implements holding of the calculated control signal during the time-step (sampling interval). This holding implies that the control signal is time delayed approximately h/2, see Figure 3.3. The delay inuences the

Original discrete-time signal The signal held fixed

h/2

The original signal time-delayed h /2 = average stair-formed signal

Figure 3.3: The DA-converter holds the calculated control signal throyghout the sampling interval, thereby introducing an approximate time-delay of h/2. stability of the control loop. Suppose we have tuned a continuous-time PID controller, and apply these PID parameters on a discrete-time PID controller. Then the control loop will get reduced stability because of the approximate delay of h/2. As a rule of thumb (this can be conrmed from a frequency response based analysis), the stability reduction is small and tolerable if the time delay is less than one tenth of the response-time of the control system as it would have been with a continuous-time controller or a controller having very small sampling time: Tr h 2 10 which gives Tr (3.34) 5 The response time is here the 63% rise time which can be read o from the setpoint step response. For a system the having dominating time constant T , the response-time is approximately equal to this time constant. h (3.33)

Das könnte Ihnen auch gefallen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsVon EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNoch keine Bewertungen

- Construction Management Plan TemplateDokument15 SeitenConstruction Management Plan TemplatePrasad Ghorpade100% (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- 2 - SmartPlant Foundation PDFDokument22 Seiten2 - SmartPlant Foundation PDFLucian GomoescuNoch keine Bewertungen

- Digital Signal Processing Using the ARM Cortex M4Von EverandDigital Signal Processing Using the ARM Cortex M4Bewertung: 1 von 5 Sternen1/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Stone ColumnDokument116 SeitenStone ColumnNur Farhana Ahmad Fuad100% (1)

- Chapter 2 Discrete Data Control SystemsDokument78 SeitenChapter 2 Discrete Data Control SystemsAmruth ThelkarNoch keine Bewertungen

- Presentation For ControllerDokument42 SeitenPresentation For ControllerAlakshendra JohariNoch keine Bewertungen

- Injection Machine RobotDokument89 SeitenInjection Machine Robotphild2na250% (2)

- Reflection EssayDokument3 SeitenReflection Essayapi-451553720Noch keine Bewertungen

- Yaskawa Product CatalogDokument417 SeitenYaskawa Product CatalogSeby Andrei100% (1)

- Control of DC Motor Using Different Control StrategiesVon EverandControl of DC Motor Using Different Control StrategiesNoch keine Bewertungen

- Pid Control ch8 PDFDokument22 SeitenPid Control ch8 PDFGholamreza IlkhaniNoch keine Bewertungen

- Jump in A Teachers BookDokument129 SeitenJump in A Teachers BookShei QuinterosNoch keine Bewertungen

- Teknik Kendali Digital PDFDokument230 SeitenTeknik Kendali Digital PDFWahyu Juliarto100% (3)

- Algoritmo Velocidade PDFDokument11 SeitenAlgoritmo Velocidade PDFPaulo César RibeiroNoch keine Bewertungen

- Control System-Ii Lab File: Bachelor of Engineering (Division of Instrumentation & ControlDokument41 SeitenControl System-Ii Lab File: Bachelor of Engineering (Division of Instrumentation & ControlParas SinghNoch keine Bewertungen

- Experiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETDokument18 SeitenExperiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETMd Abid AfridiNoch keine Bewertungen

- Signal Processing in Digital ControlDokument40 SeitenSignal Processing in Digital ControlSaiRoopa GaliveetiNoch keine Bewertungen

- Augmented UKFDokument6 SeitenAugmented UKFJang-Seong ParkNoch keine Bewertungen

- Project Based Learning IcsDokument14 SeitenProject Based Learning IcsAvinash YadavNoch keine Bewertungen

- Application Note AN2208: Universal PID-ThermoregulatorDokument17 SeitenApplication Note AN2208: Universal PID-ThermoregulatorJ Daniel PichardoNoch keine Bewertungen

- Sampling and Sampled-Data SystemsDokument20 SeitenSampling and Sampled-Data SystemsAmit KumarNoch keine Bewertungen

- Introduction To PID Control: Lab-808: Power Electronic Systems & Chips Lab., NCTU, TaiwanDokument32 SeitenIntroduction To PID Control: Lab-808: Power Electronic Systems & Chips Lab., NCTU, TaiwandaswkNoch keine Bewertungen

- Discrete Systems Z TransfrmDokument5 SeitenDiscrete Systems Z TransfrmAlie FavourNoch keine Bewertungen

- O.dyer PIDDokument205 SeitenO.dyer PIDHemaNoch keine Bewertungen

- PID ControllerDokument5 SeitenPID ControllerIcarus CanNoch keine Bewertungen

- Pid PostDokument33 SeitenPid PostosamahNoch keine Bewertungen

- InTech-Pid Control TheoryDokument17 SeitenInTech-Pid Control TheoryAbner BezerraNoch keine Bewertungen

- Jane - W - S - Liu - Real - Time - SystemsDokument409 SeitenJane - W - S - Liu - Real - Time - Systemssltan_1200100% (2)

- Industrial Emulator Manual Chapter 4 Thru 6Dokument37 SeitenIndustrial Emulator Manual Chapter 4 Thru 6Jake DaytonNoch keine Bewertungen

- CHE3162.Lecture8 Feedback PIDDokument33 SeitenCHE3162.Lecture8 Feedback PIDPhan NeeNoch keine Bewertungen

- Analog - Digital - PC Based - PidDokument18 SeitenAnalog - Digital - PC Based - PidAAYUSH KUMARNoch keine Bewertungen

- Dieu TocDokument20 SeitenDieu TocladoiblNoch keine Bewertungen

- Pid Control 15 1 2007Dokument69 SeitenPid Control 15 1 2007Chang Chee HongNoch keine Bewertungen

- Introduction To Discrete Control SystemDokument34 SeitenIntroduction To Discrete Control SystemArif HassanNoch keine Bewertungen

- Feedback Controllers: Figure 8.1 Schematic Diagram For A Stirred-Tank Blending SystemDokument18 SeitenFeedback Controllers: Figure 8.1 Schematic Diagram For A Stirred-Tank Blending Systeml7aniNoch keine Bewertungen

- Robust Tuning Procedures of Dead-Time Compensating ControllersDokument28 SeitenRobust Tuning Procedures of Dead-Time Compensating ControllersNadir ZubovićNoch keine Bewertungen

- CHAPTER 1: Introduction To Discrete-Time Control Systems Digital Control SystemsDokument6 SeitenCHAPTER 1: Introduction To Discrete-Time Control Systems Digital Control SystemsIzzat AzmanNoch keine Bewertungen

- Discrete Controller: DesignDokument43 SeitenDiscrete Controller: DesignArif HassanNoch keine Bewertungen

- Digital Control System PDFDokument0 SeitenDigital Control System PDFwww.bhawesh.com.np100% (1)

- Finn Haugen. Telemark University College National Instruments ConfidentialDokument27 SeitenFinn Haugen. Telemark University College National Instruments ConfidentialtriplbingaziNoch keine Bewertungen

- PID Controller: Figure 1: A Crude Example For A RegulationDokument5 SeitenPID Controller: Figure 1: A Crude Example For A RegulationAndres EspinosaNoch keine Bewertungen

- CHAPTER 1: Introduction To Discrete-Time Control Systems Digital Control SystemsDokument6 SeitenCHAPTER 1: Introduction To Discrete-Time Control Systems Digital Control SystemsIzzat AzmanNoch keine Bewertungen

- ME 5659 Scribed NotesDokument8 SeitenME 5659 Scribed NotesMayur BhiseNoch keine Bewertungen

- Chapter 2 Discrete Data Control SystemsDokument70 SeitenChapter 2 Discrete Data Control SystemsAmruth Thelkar67% (3)

- Digital Control Systems: Lecture NotesDokument61 SeitenDigital Control Systems: Lecture NotesHari Pavan0391Noch keine Bewertungen

- Weekly PP PDFDokument11 SeitenWeekly PP PDFDanielHaileNoch keine Bewertungen

- Chapter 22 General Purpose PID ControlDokument10 SeitenChapter 22 General Purpose PID ControlEduardo AlvearNoch keine Bewertungen

- Chapter 22Dokument9 SeitenChapter 22lotex77Noch keine Bewertungen

- Feedback Controllers: Figure. Schematic Diagram For A Stirred-Tank Blending SystemDokument24 SeitenFeedback Controllers: Figure. Schematic Diagram For A Stirred-Tank Blending SystemRama ChilpuriNoch keine Bewertungen

- PID Control TheoryDokument17 SeitenPID Control TheoryManuel Santos MNoch keine Bewertungen

- Experiment 10Dokument2 SeitenExperiment 10kalidindi chandrasekharNoch keine Bewertungen

- Repetitive ControlDokument22 SeitenRepetitive ControlShri KulkarniNoch keine Bewertungen

- Sampling and Sampled-Data SystemsDokument20 SeitenSampling and Sampled-Data Systemsvineetverma0698Noch keine Bewertungen

- Submitted by Vikrant Rana CH-6276Dokument30 SeitenSubmitted by Vikrant Rana CH-6276vcoolkrazyNoch keine Bewertungen

- Fundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsVon EverandFundamentals of Electronics 3: Discrete-time Signals and Systems, and Quantized Level SystemsNoch keine Bewertungen

- Nonlinear Control Feedback Linearization Sliding Mode ControlVon EverandNonlinear Control Feedback Linearization Sliding Mode ControlNoch keine Bewertungen

- Analog Automation and Digital Feedback Control TechniquesVon EverandAnalog Automation and Digital Feedback Control TechniquesNoch keine Bewertungen

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorVon EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNoch keine Bewertungen

- Ma TaDokument1 SeiteMa TaLucian GomoescuNoch keine Bewertungen

- Ma TaDokument1 SeiteMa TaLucian GomoescuNoch keine Bewertungen

- Manualeng PDFDokument39 SeitenManualeng PDFLucian GomoescuNoch keine Bewertungen

- Tomov R20Dokument10 SeitenTomov R20Lucian GomoescuNoch keine Bewertungen

- Schema Integrata TermicDokument1 SeiteSchema Integrata TermicLucian GomoescuNoch keine Bewertungen

- Notes On Guenter Lee PDEs PDFDokument168 SeitenNotes On Guenter Lee PDEs PDF123chessNoch keine Bewertungen

- Method Statement For FDTDokument7 SeitenMethod Statement For FDTMs UndergroundNoch keine Bewertungen

- Forum Fall 10Dokument1 SeiteForum Fall 10Benjamin JefferiesNoch keine Bewertungen

- NOLS 2014 Fall Catalog PDFDokument60 SeitenNOLS 2014 Fall Catalog PDFcoldflame81Noch keine Bewertungen

- NBA AwarenessDokument39 SeitenNBA AwarenessRaja SekarNoch keine Bewertungen

- WSDL Versioning Best PracticesDokument6 SeitenWSDL Versioning Best Practiceshithamg6152Noch keine Bewertungen

- S6a S13 GX RX InterfacesDokument4 SeitenS6a S13 GX RX Interfacessyedsajjad68Noch keine Bewertungen

- Is Euclidean Zoning The New Pig in The Parlor?: The Coming of Age of Form-Based Zoning (Damon Orobona)Dokument19 SeitenIs Euclidean Zoning The New Pig in The Parlor?: The Coming of Age of Form-Based Zoning (Damon Orobona)Damon Orobona100% (1)

- EI in NegotiationsDokument22 SeitenEI in NegotiationspranajiNoch keine Bewertungen

- Sentence Cont. ExerciseDokument6 SeitenSentence Cont. ExerciseKim Thy Trần PhạmNoch keine Bewertungen

- Mexico For Sale. Rafael GuerreroDokument12 SeitenMexico For Sale. Rafael GuerreroGabriela Durán ValisNoch keine Bewertungen

- Advanced Signal Multi-ScannerDokument8 SeitenAdvanced Signal Multi-ScannerneerajupmanyuNoch keine Bewertungen

- The Peripatetic Observer 2003Dokument10 SeitenThe Peripatetic Observer 2003SUNY Geneseo Department of EnglishNoch keine Bewertungen

- Baird, A. Experimental and Numerical Study of U-Shape Flexural Plate.Dokument9 SeitenBaird, A. Experimental and Numerical Study of U-Shape Flexural Plate.Susana Quevedo ReyNoch keine Bewertungen

- Botbee IntegrationDokument16 SeitenBotbee IntegrationAnuj VikalNoch keine Bewertungen

- MAX31865 RTD-to-Digital Converter: General Description FeaturesDokument25 SeitenMAX31865 RTD-to-Digital Converter: General Description FeaturespaKoSTe1Noch keine Bewertungen

- Eng 105 S 17 Review RubricDokument1 SeiteEng 105 S 17 Review Rubricapi-352956220Noch keine Bewertungen

- Sample PREP-31 Standard Sample Preparation Package For Rock and Drill SamplesDokument1 SeiteSample PREP-31 Standard Sample Preparation Package For Rock and Drill SampleshNoch keine Bewertungen

- Types of Evidence DLPDokument9 SeitenTypes of Evidence DLPMary Joy IgnacioNoch keine Bewertungen

- Matter Week 6Dokument4 SeitenMatter Week 6api-316479601Noch keine Bewertungen

- Medical Technology ScheduleDokument2 SeitenMedical Technology ScheduleCara Veronica MendozaNoch keine Bewertungen

- A Brief Tutorial On Interval Type-2 Fuzzy Sets and SystemsDokument10 SeitenA Brief Tutorial On Interval Type-2 Fuzzy Sets and SystemstarekeeeNoch keine Bewertungen

- Add-On Effect of Brahmi in The Management of SchizophreniaDokument3 SeitenAdd-On Effect of Brahmi in The Management of SchizophreniaNAITIKNoch keine Bewertungen

- Perkembangan Kurikulum USADokument25 SeitenPerkembangan Kurikulum USAFadhlah SenifotoNoch keine Bewertungen