Beruflich Dokumente

Kultur Dokumente

Pumps in Series and Parallel

Hochgeladen von

Suhadahafiza ShafieeCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pumps in Series and Parallel

Hochgeladen von

Suhadahafiza ShafieeCopyright:

Verfügbare Formate

INTRODUCTION

Pumps are used to transfer fluid in a system, either at the same elevation or to a new height.

The needed flow rate depends on the height to which the fluid is pumped. Each pump has a head-

discharge relationship that is inversely proportional (i.e., if a higher flow rate is needed, then less head

or pressure will be produced by the pump, and vice versa). This head-discharge relationship, also

known as the pump characteristic curve, is provided by the pump manufacturer.

Two pumps (or typically more in practice) can be combined in series to increase the height to

which the fluid can be pumped at a given flow rate, or combined in parallel to increase the flow rate

associated with a given value of head. In theory, if two pumps are combined in series, the pumping

system will produce twice the head for a given flow rate. Similarly, if two pumps are combined in

parallel, the pumping system is expected to have twice the flow rate of single pump for a given head.

OBJECTIVES

1. To demonstrate pump performance when connected in series and parallel

2. To show shut off point of pump in series and parallel

3. To analyse pump network for pipelines operating under pressure

4. To estimate power requirement for a pump as a function of its throughput, pressure increase

and efficiency

PROCEDURE

1. The equipment was set up by following some basic procedures.

2. The main power supply is switched on.

3. The appropriate pump was select and the following valve position is checked.

Pump Operation Running Pump Open Valve Close Valve

Single Pump 1, P1 1, 3 2, 3

Serial Both Pump, P1 & p2 1, 4 2, 4

Parallel Both Pump, P1 & p2 1, 2, 4 3

4. Valve V5 (as a variable parameter) is slowly opened until the flow rate reaches to a certain

level that is needed by the operation of the pump.

5. The pressure reading on the pressure indicator is observed. Flow rate and pressure is recorded

when the stable condition is achieved.

6. The observation is repeated by increasing the flow rate until reaches to a certain maximum

level that is needed by the operation of the pump.

7. The pump is turned off. Valve V5 is ensured that it is in fully close position. The main power

supply is switched off.

Pump Operation Volume Flow Rate (L/min)

Single 20 40 60 80 90

Serial 20 40 60 80 90

Parallel 40 80 120 160 180

DISCUSSION

The objective of this laboratory experiment is to measure and compare the performance of a

single centrifugal pump to that of two pumps in parallel and series configurations.

THEORY

By ssuming steady, uniform, incompressible flow between the inlet and outlet sections of a

piping system containing a pump, the energy conservation equation can be used to illustrate the

relationship between kinetic and potential energy of the fluid:

T

l P 1

2

1 1

2

2

2 2

H H z

g 2

V

g

p

z

g 2

V

g

p

=

|

|

.

|

\

|

+ +

|

|

.

|

\

|

+ +

(1)

where the subscripts 1 and 2 refer to inlet and exit sections, respectively [1]. H

p

is the 'head' produced

by a pump (in meters); H

l_T

represents energy losses (in meters) from friction, turbulence, fittings,

etc.; p is the static pressure (in Pa); is the fluid density (in kg/m

3

); g is the gravitational constant (in

meters/sec

2

); V is the fluid velocity (in meters/sec); and z is the elevation of the measurement point (in

meters). For this laboratory, the minor head losses, H

l_T

, may be neglected.

One important aspect of pump performance is the pressure, or head, that the pump can produce as a

function of flow rate. Generally, the higher the flow rate, the lower the head that the pump can

contribute. A parabola is often used to fit this performance data:

2

0

AQ H H

p

= (2)

where Q is the volumetric flow rate, A is a constant determined empirically from the data, and H

0

is

the head delivered at zero flow rate.

For the two pumps in series, the flow Q through the first pump must equal the flow through the next,

but each pump adds pressure head. For nominally identical pumps the total head added is

( )

2

0

2 AQ H H

series

= . (3)

For identical pumps in parallel, the pressures at the two inlets and outlets are identical and the

maximum head the two pumps can deliver is no greater than that of one pump. The flow rate,

however, is doubled for two identical pumps in parallel:

H

parallel

= H

0

A

Q

2

|

\

|

.

|

2

(4)

In practice, these performance curves will not be met because of losses in piping systems and non-

identical pumps.

An important objective when selecting a pump for an engineering system is maximizing the efficiency

for the desired flow conditions. For a pump, the efficiency is defined as

h = P

o

/P

i

(5)

where P

o

is the power output from the pump (in Watts), and P

i

is the power imparted to the fluid from

the pump (in Watts). Output power is determined experimentally with the following equation

P

o

= g*Q*H

p

.

(6)

The input power to the pump is the output power from the motor. Pi varies as a function of flow rate.

The purpose to connect pump in series and parallel is to extend the total pump performance in

a system. The shutoff pressure is the maximum pressure a pump will develop under zero-flow

conditions, which reflects a fully blocked outlet.

Pumps combined in parallel can increase the flow twice for the same given head. In practice,

this would be done if a pump provides the right head, but provides small flow. Parallel arrangement

is also used if the demand of flow is different. One pump can be used at lower flow than the second

pump. The advantage of arranging pumps in parallel is the redundancy in case failure occurs. On the

other hand, applying pumps arrangement into series can twice increase the head. In practice, this

would be done if the pump provides the right flow rate, but small head. When pumps are connected in

series or parallel, the power input to the pump increases. The effect of increasing motor speed can be

estimated using the similarity rules.

The operating point of the pump is at the point where the head of the pump is the same as the

pipe resistance. The operating point is the intersection of the pump characteristic curve and the pipe

system characteristic curve. The most common reason for choosing parallel pumps is because you

want to have a spare in case the single operating pump fails. Pumps in series are generally not

advised. This is because the maximum shutoff head of pumps in series is additive, and will result in

higher design pressures in the downstream piping/equipment.

Generally in pumps increasing the flow rate will decrease the provided head. The efficiency

of the pumps was not calculated due to lack of givens (input power)

CONCLUSIONS

Thanks to Allah The Almighty for His blessing, we manage to finish up the experiment and

the reports in the given time. Because of Him we are able to achieve the objectives of this experiment.

In a series arrangement, each pump handles the same flow rate, but the total head produced by the

combination of pumps will be additive. For pumps configured in parallel, the flow rate Q is split

between the pumps at the inlet into Q

1

and Q

2.

The commonality of head across parallel pumps is the

most important feature of pumps installed in parallel. If the pump heads are not matched, pumps in

parallel will not function properly.

REFERENCES

- White, Frank M. Fluid Mechanics; 3rd Edition, McGraw Hill; 1994

- http://www.cheresources.com/invision/blog/4/entry-322-multiple-centrifugal-

pumps-in-series-and-parallel/

- Lab Manual, Fluid Mechanis.

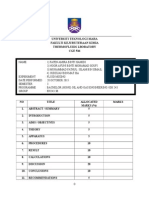

INTERNATIONAL ISLAMIC UNIVERSITY MALAYSIA

FLUID MECHANICS

BTE 2222

EXPERIMENT 2

PUMPS IN SERIES AND PARALLEL

15 / 11 / 2013

SUHADAHAFIZA BINTI SHAFIEE 1123746

GROUP MEMBERS : -

SINGLE

SERIAL

0

2

4

6

8

10

12

1 2 3 4 5

p

r

e

s

s

u

r

e

flow rate

Pressure different vs. Flow rate

0

2

4

6

8

10

12

14

20 40 60 80 90

p

r

e

s

s

u

r

e

flow rate

Pressure different vs. Flow rate

PARALLEL

0

2

4

6

8

10

12

40 80 120 160 180

p

r

e

s

s

u

r

e

flow rate

Pressure different vs. Flow rate

Das könnte Ihnen auch gefallen

- Series and Parallel PumpDokument15 SeitenSeries and Parallel PumpbandarNoch keine Bewertungen

- Lab 1 Series Parallel PumpsDokument16 SeitenLab 1 Series Parallel PumpsSasys Rgl100% (11)

- Fluid Pump Report 2013Dokument33 SeitenFluid Pump Report 2013M Shahrul Izuan100% (1)

- Lab 3-Pumps in Series and ParallelDokument6 SeitenLab 3-Pumps in Series and ParallelIrfan Ismail100% (1)

- Lab3E6 - Series and Parallel Pump PDFDokument13 SeitenLab3E6 - Series and Parallel Pump PDFShimal De Silva50% (2)

- 5 Parallel and Series Pump Operation 5Dokument15 Seiten5 Parallel and Series Pump Operation 5Omar AhmedNoch keine Bewertungen

- Series and ParallelDokument23 SeitenSeries and ParallelErvz Mission100% (2)

- Lab3E8 - Series and Parallel PumpDokument8 SeitenLab3E8 - Series and Parallel PumpRaied Basam0% (1)

- Fluid Lab - Pump in Parallel and SeriesDokument8 SeitenFluid Lab - Pump in Parallel and SeriesYukiYukina100% (2)

- Series and Parallel Operation of Centrifugal PumpsDokument12 SeitenSeries and Parallel Operation of Centrifugal PumpsdatonizamNoch keine Bewertungen

- Experiment 12: Series and Parallel Pumps Introduction To The EquipmentDokument8 SeitenExperiment 12: Series and Parallel Pumps Introduction To The Equipmentwaleed ahmadNoch keine Bewertungen

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideVon EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideBewertung: 5 von 5 Sternen5/5 (1)

- Series & Parallel PumpDokument14 SeitenSeries & Parallel PumpDivaan Raj Karunakaran100% (3)

- Experiment On Performance of Centrifugal PumpDokument7 SeitenExperiment On Performance of Centrifugal PumpSyfNoch keine Bewertungen

- Pump Curve Lab ReportDokument19 SeitenPump Curve Lab ReportNang Truong0% (1)

- Experiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Dokument11 SeitenExperiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Safi Ullah WarraichNoch keine Bewertungen

- Basic Theory of PumpDokument19 SeitenBasic Theory of PumpJoon Eeo100% (4)

- Efficiency of The Centrifugal Pump-Lab ReportDokument12 SeitenEfficiency of The Centrifugal Pump-Lab ReportEbutalib Allahverdiyev71% (14)

- Experiment 5 Series and Parallel PumpDokument20 SeitenExperiment 5 Series and Parallel Pumpgongweejie9333% (3)

- Lab 8-Centrifugal Pump Experiment-MethodDokument17 SeitenLab 8-Centrifugal Pump Experiment-MethodKarla PerezNoch keine Bewertungen

- Experiment 5 - Series Parallel Centrifugal PumpDokument15 SeitenExperiment 5 - Series Parallel Centrifugal PumpEiyra Nadia33% (3)

- Cooling Tower LabDokument33 SeitenCooling Tower Labkeckstand100% (2)

- Performance Characteristic of Centrifugal PumpDokument30 SeitenPerformance Characteristic of Centrifugal PumpRam Krishna Singh91% (22)

- Thermofluids Lab: Fluid MixingDokument25 SeitenThermofluids Lab: Fluid Mixingfatenamira50% (2)

- Experiment Multi Pump Test RigDokument55 SeitenExperiment Multi Pump Test RigSurendran Balakrishnan88% (16)

- Centrifugal Pump FullDokument25 SeitenCentrifugal Pump FullMohamad FaizNoch keine Bewertungen

- Centrifugal PumpsDokument20 SeitenCentrifugal PumpsPiccollo640780% (5)

- Performance PumpDokument13 SeitenPerformance PumpPutera AshrafNoch keine Bewertungen

- Experiment No. 1 Hydraulic RamDokument13 SeitenExperiment No. 1 Hydraulic RamAlex Luminarias67% (6)

- Experiment 3Dokument3 SeitenExperiment 3MaisarahNoch keine Bewertungen

- Centrifugal Pump Lab ReportDokument16 SeitenCentrifugal Pump Lab Reportapi-31051928380% (5)

- Performance and Benefits of PumpsDokument16 SeitenPerformance and Benefits of PumpsKirstie CruzadaNoch keine Bewertungen

- Series and Parallel PumpsDokument8 SeitenSeries and Parallel PumpsLanyoong67% (3)

- Performance Characteristics of Centrifugal PumpsDokument7 SeitenPerformance Characteristics of Centrifugal PumpsNiroshan Susith Punchihewa100% (1)

- Lab Report Performance Characteristics of Centrifugal PumpDokument10 SeitenLab Report Performance Characteristics of Centrifugal PumpRam Krishna Singh85% (33)

- Exp 2 Friction LossesDokument15 SeitenExp 2 Friction LossesDonna Mae Ramos Galaez0% (1)

- Bernoulli's Theorem DemonstrationDokument17 SeitenBernoulli's Theorem DemonstrationjjNoch keine Bewertungen

- Fluid Mixing ExpDokument9 SeitenFluid Mixing ExpNawal DaBombNoch keine Bewertungen

- Head Loss Due To Pipe FittingDokument6 SeitenHead Loss Due To Pipe Fittingmhk00133% (3)

- Multi Pump 2Dokument13 SeitenMulti Pump 2Dayu Zaty50% (4)

- Experiment 7-Pump Performance - Single PumpDokument12 SeitenExperiment 7-Pump Performance - Single PumpVasanthan Rao0% (1)

- MEC2404 Frictional Flow in Pipe Lab RepoDokument10 SeitenMEC2404 Frictional Flow in Pipe Lab Repoatik100% (1)

- Flow Measurement Lab5Dokument18 SeitenFlow Measurement Lab5Jérôme J. JeitanyNoch keine Bewertungen

- Centrifugal LabDokument40 SeitenCentrifugal LabSalim Bran100% (1)

- Series and Parallel PumpsDokument11 SeitenSeries and Parallel PumpsKevin Devastian100% (1)

- Report Multi PumpDokument12 SeitenReport Multi PumpMuhammad Hafiz75% (4)

- Centrifugal Pump.......... Very ImpDokument22 SeitenCentrifugal Pump.......... Very Impavi07me4uNoch keine Bewertungen

- Energy Losses in Bends and FittingsDokument11 SeitenEnergy Losses in Bends and FittingsQuenneBelocura100% (1)

- Lab 2-Water Cooling TowerDokument31 SeitenLab 2-Water Cooling Towerriniz92100% (4)

- Series & Parallel Pump TestDokument22 SeitenSeries & Parallel Pump TestIkhwan Z.100% (23)

- Pumps in Parallel PDFDokument10 SeitenPumps in Parallel PDFZezo HassanNoch keine Bewertungen

- Lab 3-Pumps in Series and ParallelDokument5 SeitenLab 3-Pumps in Series and ParallelnidhalsaadaNoch keine Bewertungen

- Title: Figure 1: Categories of Centrifugal PumpDokument7 SeitenTitle: Figure 1: Categories of Centrifugal PumpHaziq Pazli100% (1)

- Objective of PumpsDokument6 SeitenObjective of PumpsTomide OlasupoNoch keine Bewertungen

- Pump Performance - Double PumpsDokument8 SeitenPump Performance - Double PumpsAshNoch keine Bewertungen

- ERT 205 Lab 5Dokument14 SeitenERT 205 Lab 5Ang Kien HauNoch keine Bewertungen

- What Is Characteristic CurveDokument7 SeitenWhat Is Characteristic Curvehafiz hassanNoch keine Bewertungen

- Arranging Dissimilar Centrifugal Pumps in Series and ParallelDokument8 SeitenArranging Dissimilar Centrifugal Pumps in Series and ParallelPujo BagusNoch keine Bewertungen

- Pump Curve Final ReportDokument5 SeitenPump Curve Final ReportRokaya KhalilyNoch keine Bewertungen

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesVon EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesBewertung: 5 von 5 Sternen5/5 (1)

- BTE 4417 Assignment 2 SEM 2, 2014/15Dokument2 SeitenBTE 4417 Assignment 2 SEM 2, 2014/15Suhadahafiza ShafieeNoch keine Bewertungen

- Codes of EthicsDokument20 SeitenCodes of EthicsSuhadahafiza ShafieeNoch keine Bewertungen

- Investment and BEP AnalysisDokument31 SeitenInvestment and BEP AnalysisSuhadahafiza ShafieeNoch keine Bewertungen

- Evaporation CalculationsDokument33 SeitenEvaporation CalculationsSuhadahafiza ShafieeNoch keine Bewertungen

- Tutorial 2 Heat Transfer Answer Bmm3513 Sem 1-12-13Dokument2 SeitenTutorial 2 Heat Transfer Answer Bmm3513 Sem 1-12-13Suhadahafiza Shafiee100% (1)

- Moody DiagramDokument6 SeitenMoody DiagramBelen CabalunaNoch keine Bewertungen

- 01 Hydraulics & Geotechnical Engineering 1 PDFDokument6 Seiten01 Hydraulics & Geotechnical Engineering 1 PDFKate AdvinculaNoch keine Bewertungen

- Justin Matthew Guzman - Activity No. 8 and 9 SubmissionDokument9 SeitenJustin Matthew Guzman - Activity No. 8 and 9 SubmissionJustin D. GuzmanNoch keine Bewertungen

- Machine Design SpringsDokument4 SeitenMachine Design Springscoc boyNoch keine Bewertungen

- Walker and Mayes - SPE-4975-PADokument8 SeitenWalker and Mayes - SPE-4975-PALogan LumNoch keine Bewertungen

- Electrostatics MCQDokument5 SeitenElectrostatics MCQMohan Raj100% (1)

- MCE321 - Introduction To Tribology Lecture NoteDokument9 SeitenMCE321 - Introduction To Tribology Lecture NoteEzekielNoch keine Bewertungen

- PSAD-PreBoardExam02 ManilaRoundDokument10 SeitenPSAD-PreBoardExam02 ManilaRoundSharmaine FajutaganaNoch keine Bewertungen

- Course Code: 19ASC303A Course Title: Aerodynamics - 2 (Fundamentals of Compressible Flow) Assignment # 6Dokument5 SeitenCourse Code: 19ASC303A Course Title: Aerodynamics - 2 (Fundamentals of Compressible Flow) Assignment # 6RD412Noch keine Bewertungen

- 1.1 General: Means So Much Affected As Those Whose Foundations Did Not Reach The Bottom of The Soil"Dokument54 Seiten1.1 General: Means So Much Affected As Those Whose Foundations Did Not Reach The Bottom of The Soil"Sai GnanadeepNoch keine Bewertungen

- CivilFEM Theory ManualDokument1.589 SeitenCivilFEM Theory ManualRoberto Pérez100% (1)

- Thermo-Fatigue Life Evaluation of Snagcu Solder Joints in Flip Chip AssembliesDokument7 SeitenThermo-Fatigue Life Evaluation of Snagcu Solder Joints in Flip Chip AssembliesDurgesh KhannaNoch keine Bewertungen

- D5407 PDFDokument6 SeitenD5407 PDFZamir Danilo Morera ForeroNoch keine Bewertungen

- EM Dis CH 4 Part 5Dokument24 SeitenEM Dis CH 4 Part 5Fawzi Al-TawilNoch keine Bewertungen

- Hydrodynamic Transverse Loads On Ships in Deep and Shallow WaterDokument25 SeitenHydrodynamic Transverse Loads On Ships in Deep and Shallow WaterJason SmithNoch keine Bewertungen

- DME QB All UnitsDokument11 SeitenDME QB All UnitsPrakash ThangavelNoch keine Bewertungen

- Robin in DuDokument8 SeitenRobin in DuRobin George RejiNoch keine Bewertungen

- Structural Stability CourseDokument196 SeitenStructural Stability CourseBrillVerdeNoch keine Bewertungen

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDokument9 SeitenDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- HSSRPTR - Focus Point Plus One Physics - Part 1 Chapter 1-8Dokument86 SeitenHSSRPTR - Focus Point Plus One Physics - Part 1 Chapter 1-8AswithNoch keine Bewertungen

- Section 10.2 Path Independence of Line IntegralDokument23 SeitenSection 10.2 Path Independence of Line IntegralKrishna ChaituNoch keine Bewertungen

- The Lift Force On A Spherical Body in A Rotational FlowDokument20 SeitenThe Lift Force On A Spherical Body in A Rotational FlowARUN KRISHNA B J am21d400Noch keine Bewertungen

- A Code of Practice For The Determination of Cyclic Stress-StrainDokument22 SeitenA Code of Practice For The Determination of Cyclic Stress-StrainDeivyson AugustoNoch keine Bewertungen

- Design and Analysis of Three Rotor Rotary EngineDokument10 SeitenDesign and Analysis of Three Rotor Rotary EngineIRJMETS JOURNALNoch keine Bewertungen

- JNTUK-DAP-Course Structure and Syllabus-B.tech (Petroleum Engineering) - II YEAR.R10 StudentsDokument31 SeitenJNTUK-DAP-Course Structure and Syllabus-B.tech (Petroleum Engineering) - II YEAR.R10 StudentsMohsin KhanNoch keine Bewertungen

- Aqa Mam1 W QP Jan04Dokument5 SeitenAqa Mam1 W QP Jan04jfarrell_ie5767Noch keine Bewertungen

- Stress - Analysis - Report - Optimized - Muhammad - H Adi: Simulation:1Dokument12 SeitenStress - Analysis - Report - Optimized - Muhammad - H Adi: Simulation:1Febrian SyahputraNoch keine Bewertungen

- Properties Measurement PVT ManuscriptDokument5 SeitenProperties Measurement PVT ManuscriptAtqh AzmnNoch keine Bewertungen

- Mastering Mixing FundamentalsDokument82 SeitenMastering Mixing FundamentalsArturo K. Cabras Jr.Noch keine Bewertungen

- Mass Moment of Inertia-Test1Dokument2 SeitenMass Moment of Inertia-Test1VisitOn.T.witte.rNoch keine Bewertungen