Beruflich Dokumente

Kultur Dokumente

Philippine Furniture Sector Profile

Hochgeladen von

Arangkada PhilippinesCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Philippine Furniture Sector Profile

Hochgeladen von

Arangkada PhilippinesCopyright:

Verfügbare Formate

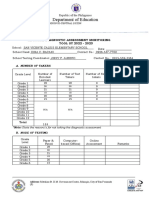

FURNITURE SECTOR PROFILE A.

Vision, Goals and Targets Strategic Vision for the Industry The Philippines to be the global design hub for products using sustainable materials Goals of the industry Product Development To have access to market in which the government has to institutionalize a budget to support trends gathering, forecasting and sharing. To upgrade design education through early introduction of design awareness appreciation and information and training assistance for design students and professional designers and manufacturers. To establish sustainable and environment-friendly raw materials and establish supply hubs for semi process and raw materials from local and imported sources. Advocacy To build the group to be a strong force with a unified voice. Build the group to strongly influence all appropriate sectors Build support infrastructure to continue the gains. Marketing To make the Philippine furniture top of mind in Asia. To sell to traditional markets. Simplify marketing strategy to align furniture design to customer needs in local, glocal and global. Capacity Building To have a sustainable supply of raw materials To provide readily available skilled manpower to the industry. To ensure availability of advanced and cost-effective technologies machineries/equipment and production processes. B. State of the Industry Structure of the Industry Manufactured products may be classified into two broad categories: 1) leg items which include chairs, tables, beds, headboards and settees; and 2) case goods such as cabinets, desks, wardrobe cases, chest of drawers, dressers and kitchen storage units. In terms of materials, products have branched out from rattan and buri wood to metal, stonecraft, bamboo and plastic. New forms also emerged with two or more materials and in combination with grasses (seagrass), shells, coconut lumber, shells and leather. Skills/ processes done on the local industry include weaving, wood carving, marquetry, laminating wooden carcasses with rattan and wicker, leather, fossilized stone, and inlaying shells, coconut shells, animal bone or horn. Product lines include low-end furniture to medium and high-end lines. Filipino furniture firms have likewise expanded their capabilities to include production of contract furniture. They have started to be recognized as a preferred source of furniture for hotels, restaurants, offices and other public institutions. Moreover, the industry relies heavily on locally procured raw materials such as wood (which represents 40% of the total furniture produced in the country); rattan, bamboo, buri and other forest-based or agricultural materials (which account for another 40%); metal, stone, plastic, and a combination of these materials (mixed media). There are two (2) business support organizations for Furniture: Chamber of Furniture Industries of the Philippines (CFIP) and the Cebu Furniture Industries Foundation (CFIF). The industry is linked with various government agencies in the research and sourcing of raw materials particularly with the following:

Department of Science and Technology (DOST) and affiliated agencies Department of Environment and National Resources (DENR) Department of Trade and Industry (DTI) and affiliated agencies Landscape of the Industry Majority of the manufacturers in the Philippine Furniture industry is utilizing basic Furniture technology directed towards small volume orders and not for mass production. Strength of the industry remains in manual labor with good artisanship and craftsmanship applied in modern designs. Innovation in the use of indigenous materials is initiated by the private sector in partnership with local designers as well as the Design Center of the Philippines. Rattan furniture companies are well-equipped with the machinery and equipment necessary for efficient production. Among these are straightening machine, splitting machine, sizing machine, crosscut saw, surfacer, thicknesser, sander, pneumatic jig, and finishing booth. Semi-mechanized production is the norm in wooden furniture manufacturing. Most factories are equipped with cut saw or radial saw, jointer-planer, thicknesser, planer, table saw, band saw, shaper, router, drill press, universal and wide belt sander, boring machine, hot press and multiple boring machines. Aware of the growing need to improve their productivity and competitiveness, majority of furniture firms are investing in technology to streamline their production. Suppliers of raw materials are basically located in Quezon, Iligan, Davao, Bicol, Bohol, Butuan, Tuguegarao, etc. Some manufacturers are already importing wood materials due to the problem in the sourcing of wood in the Philippines. The following are involved in the supply chain of the industry: 1. 2. 3. 4. 5. 6. 7. 8. 9. Gatherers of raw materials Enablers Traders/Middlemen Consolidators Retail Shops/Distributors Lending Institutions Banking Institutions Buying Agents Exporters

Capacity and Market of the Industry Plant capacities of furniture firms have been gradually increasing since their early beginnings up to the present. At present, however, majority of manufacturers have reported unutilized capacities which can accommodate demanding requirements of overseas clients. Several companies also have an established a network of subcontractors who can fill the demand during peak seasons.

ASEAN Furniture Production 2010 Country Malaysia Indonesia Thailand Vietnam Total Furniture Production $3.6B $2.7B $2.4B $5.0B Total Furniture Exports $2.6B $1.9B $1.2B $3.3B $ 227M Local Sales $1.0B $0.8 B $1.2 B $1.7 B $ 647M Total Population 27 million 230 Million 67 Million 87 Million 91 Million

Philippines $ 874M Source: Roadmap submitted by CFIP

Performance of the Industry

2006 Furniture 274.12 Furnishings 21.33 Others 47,114.65 Total Export 47,410.11 (Value in US$ Million) 2007 240.32 20.29 50,205.10 50,465.72 2008 219.73 20.43 48,837.37 49,077.54 2009 137.19 11.61 38,287.00 38,435.80 2010 150.75 18.82 51,327.93 51,497.51 2011 161.36 23.22 48,120.34 48,304.92 2012 159.59 27.71 51,912.21 52,099.52 Jan to Nov 2013 203.67 27.84 49,147.31 49,378.83

Source: National Statistics Office, processed by BETP

KEY EXPORT SECTOR

2010 ACTUAL EXPORTS US$ Million 427

2010 GRWTH vs. AVG 3 YRS % -19

INDIC. MARKET SIZE US$ Million 469,000

MKT SHARE % 0.09

MKT GRWTH % 7

LVA %

LVA AMT. AT 2010 ACTUAL EXPORTS US$ Million 342

ESTIMATED NO. OF WORKERS

8. HOMESTYLE

80

2,100,000

Raw Data Sources: BETP for Merchandize Exports; BSP for Services as processed by BETP Benchmark Average 3 years cover 2006-2008 "normal" market conditions; Lifted from the presentation of DED Emma Mijares during Roadmapping workshop of Furniture industry

Challenges Faced by the Industry Technical Forest Stewardship Council - Chain of Custody (FSC CoC) EU compliance requirement by March 2013. Philippines has only four FSC CoC certified companies while there are 177 in Vietnam and 500 in China. FSC CoC certified products are already present in Thailand, Vietnam, Malaysia, China, Japan, Australia, New Zealand, and most of the Western countries like France and UK, etc. Lack of globally accredited/certified testing laboratory Market Abrupt Strengthening of Peso against the dollar Lack of capability to develop new markets through properly organizing and conducting, through foreign posts business missions to target countries Lack of sufficient and sustained market intelligence to improve industry strategies against the competitors (pricing, trade policies, standards, new technologies, etc) Insufficient funding support for strategic marketing and promotion of the industry Institutional Lack of an intensified global marketing strategy/ approach for the industry Lack of sustainable supply of raw materials wood (EO 23) and other non-timber products Influx of foreign furniture products due to the low tariff imposed to China, Malaysia and Indonesia products. Local condominiums, residential, hotels and resorts tend to import furniture rather than purchase locally. Lack of management education/manufacturing program for middle managers and skilled workers institutionalize in selected schools in the Philippines High cost of inter-island shipping due to the Cabotage Strengths and Opportunities of the Industry Strengths Skilled workforce (designers, carvers, weavers) Design creativity Material variety and development Productive flexibility Ability to produce smaller quantities Quality of production

Ability to communicate Understanding customer requirements Opportunities Develop new markets, i.e., BRICS Develop new distribution strategies Strengthen show Domestic real estate development (hotels, resorts, etc.) Develop/ innovate waste materials C. Support to Industry Development General Support Training programs are offered by both government and non-government institutions while regular courses on furniture-making are taught in various technical education institutes and schools of arts and trade. Design Center of the Philippines offers assistance on design consultation, trends briefing and technology updating workshops; Export of Furniture may be supported with incentives under E.O. 226 Specific Industry Programs Design competition for professionals and students Creation of Product Development and Sourcebook Raw Material Highway/ Supply Chain project D. Contact Details Board of Investments 385 Sen. Gil Puyat Ave., Makati City 1200 Tel. No.: 890-3929 Fax no.: 897-3080 Ana Maria V. Bernardo BOI Champion Email: amvbernardo@boi.gov.ph Dir. Rudy B. Caa Manufacturing Industries Department Email: rbcaa@boi.gov.ph Chamber of Furniture Industries of the Philippines Suite H 9/F, Strata 100 Building, Don F. Ortigas, Jr. Road Ortigas Center, Pasig City 1605 Tel. No.: 631-2834, 632-9007 Fax no.: 631-2977 Email: cfip.info@gmail.com Nicolaas K. De Lange Industry Champion Salvio L. Valenzuela Executive Director

Das könnte Ihnen auch gefallen

- Profit Making Strategy of Furniture IndustryDokument26 SeitenProfit Making Strategy of Furniture IndustryMadhu Gadre100% (1)

- Furniture Industry ReasearchDokument14 SeitenFurniture Industry ReasearchZyrabelle Perolino SumatraNoch keine Bewertungen

- MBA Project Dealer Satisfaction RootsDokument15 SeitenMBA Project Dealer Satisfaction RootsSelvaKumarMba100% (1)

- Ensuring Tax Compliance for Government ContractsDokument4 SeitenEnsuring Tax Compliance for Government ContractsCarla GrepoNoch keine Bewertungen

- Wooden PackagingDokument51 SeitenWooden PackagingAnujNoch keine Bewertungen

- Bamboo Processing Factory ProposalDokument46 SeitenBamboo Processing Factory ProposalNana Kofi Bimpong IINoch keine Bewertungen

- Century Properties Group Annual Report Highlights Completed ProjectsDokument84 SeitenCentury Properties Group Annual Report Highlights Completed ProjectsMarkCruzNoch keine Bewertungen

- Sector Analysis Architecture Building and Construction 2014Dokument9 SeitenSector Analysis Architecture Building and Construction 2014PritNoch keine Bewertungen

- Post-Pandemic Tenant Rental Revisal RequestDokument2 SeitenPost-Pandemic Tenant Rental Revisal RequestTalia MooreNoch keine Bewertungen

- Educational Wooden Toys 2018Dokument118 SeitenEducational Wooden Toys 2018jagadish NNoch keine Bewertungen

- Products, Services and Brands: Building Customer ValueDokument39 SeitenProducts, Services and Brands: Building Customer ValueAbid Khan Shadhon 1912601030Noch keine Bewertungen

- Effectiveness of ERDB Charcoal Briquette in Sequestrating CarbonDokument2 SeitenEffectiveness of ERDB Charcoal Briquette in Sequestrating CarbonAnonymous VNSytXNoch keine Bewertungen

- Grain Production Business ProposalDokument10 SeitenGrain Production Business Proposalpenna belewNoch keine Bewertungen

- Department of AgricultureDokument26 SeitenDepartment of AgricultureTabanginSnsNoch keine Bewertungen

- JCB Profile 5-22-19Dokument9 SeitenJCB Profile 5-22-19lj_inosaNoch keine Bewertungen

- Sample Business Plans - UK Fulham FurnitureDokument41 SeitenSample Business Plans - UK Fulham FurniturePalo Alto Software89% (9)

- Marketing Study For A Memorial ParkDokument3 SeitenMarketing Study For A Memorial ParkAtnapaz Jod100% (2)

- Feasibility Study For Memorial ParkDokument3 SeitenFeasibility Study For Memorial ParkAtnapaz Jod100% (1)

- JAMIGA GLOBAL LTD - Furniture Business PlanDokument36 SeitenJAMIGA GLOBAL LTD - Furniture Business PlanfrankNoch keine Bewertungen

- Transformational Business - Philippine Business Contributions To The Un SdgsDokument166 SeitenTransformational Business - Philippine Business Contributions To The Un SdgsblackcholoNoch keine Bewertungen

- FETA CORPORATE PROFILE - ScribdDokument10 SeitenFETA CORPORATE PROFILE - ScribdRafael De LarrazabalNoch keine Bewertungen

- Ch.1-7 Cosy Coffin CompanyDokument73 SeitenCh.1-7 Cosy Coffin CompanyMullika Siriwet100% (3)

- Feasibility Study (Group 3)Dokument32 SeitenFeasibility Study (Group 3)Rigel RiveraNoch keine Bewertungen

- RIMS II Input-Output Models: Proper Use of MultipliersDokument28 SeitenRIMS II Input-Output Models: Proper Use of MultipliersSusan ClarkNoch keine Bewertungen

- New Eilc Company ProfileDokument5 SeitenNew Eilc Company ProfileCliffe D. GonzalesNoch keine Bewertungen

- DOST Bamboo S and T ProgramDokument12 SeitenDOST Bamboo S and T ProgramJayson Ramirez SorianoNoch keine Bewertungen

- 7 P's of MarketingDokument42 Seiten7 P's of MarketingSagar Kumar0% (1)

- ICE sCREAMs Business PlanDokument14 SeitenICE sCREAMs Business PlanNicah AcojonNoch keine Bewertungen

- Feasibility StudyDokument107 SeitenFeasibility StudyBlitz KriegNoch keine Bewertungen

- IKEA SWOT and Brand Elements in EgyptDokument3 SeitenIKEA SWOT and Brand Elements in EgyptSerah SalemNoch keine Bewertungen

- Philippine Furniture Is One of The Priority Export Products Given Assistance and Support by The GovernmentDokument5 SeitenPhilippine Furniture Is One of The Priority Export Products Given Assistance and Support by The GovernmentHanna CruzNoch keine Bewertungen

- Approved Specialization 1 - Pamayanang MaliksiDokument26 SeitenApproved Specialization 1 - Pamayanang MaliksiNowitzkiTramonto100% (5)

- Pre-Feasibility Study on UPVC Pipe Manufacturing UnitDokument21 SeitenPre-Feasibility Study on UPVC Pipe Manufacturing UnitShishan AhmadNoch keine Bewertungen

- China Market of FurnitureDokument12 SeitenChina Market of FurnitureradenkholidNoch keine Bewertungen

- Philippine Housing: NUDHF NSP Line Agencies LGUDokument45 SeitenPhilippine Housing: NUDHF NSP Line Agencies LGUliyasedai100% (1)

- PDF Feasibility Study On A Hotel Project CompressDokument3 SeitenPDF Feasibility Study On A Hotel Project CompressJohn Marlo CeleciosNoch keine Bewertungen

- Phase 1 Cbre Team54 1Dokument6 SeitenPhase 1 Cbre Team54 1api-401088780Noch keine Bewertungen

- Feasibility Study On Warehousing in India - Indian School of Business PDFDokument28 SeitenFeasibility Study On Warehousing in India - Indian School of Business PDFgautamNoch keine Bewertungen

- Philippines Telecommunications Industry Report, 2019-2025: Published: November 2019Dokument10 SeitenPhilippines Telecommunications Industry Report, 2019-2025: Published: November 2019nguyenhaiidcNoch keine Bewertungen

- Comprehensive Logistics CompanyDokument25 SeitenComprehensive Logistics CompanyvikaNoch keine Bewertungen

- Fesibility Report of A Construction CompanyDokument13 SeitenFesibility Report of A Construction CompanySyed Rehan RizviNoch keine Bewertungen

- ECO TOURISM (Feasibility Study)Dokument45 SeitenECO TOURISM (Feasibility Study)Silene VenessaNoch keine Bewertungen

- Study Now Pay Later Pilot ProgramDokument6 SeitenStudy Now Pay Later Pilot Programrommel5Noch keine Bewertungen

- Topps Tiles Marketing ReportDokument49 SeitenTopps Tiles Marketing ReportDömmïë Taylor100% (1)

- Project Feasibility Study in Real Estate ManagementDokument24 SeitenProject Feasibility Study in Real Estate ManagementrizaNoch keine Bewertungen

- Output 183 83 230 3 Setting Up A Mini Digital Theatre 2016 04 26 15 21 25 239Dokument5 SeitenOutput 183 83 230 3 Setting Up A Mini Digital Theatre 2016 04 26 15 21 25 239api-316558829Noch keine Bewertungen

- A Brief History of Packaging. BergerDokument5 SeitenA Brief History of Packaging. BergerElizabeth OlivaresNoch keine Bewertungen

- Recommendation On Inventory Control System - TermpaperDokument4 SeitenRecommendation On Inventory Control System - TermpaperiftezarNoch keine Bewertungen

- Macro Analysis PhilippinesDokument9 SeitenMacro Analysis PhilippinesAnthony AlferesNoch keine Bewertungen

- Digital Dividends in Plastic RecyclingDokument60 SeitenDigital Dividends in Plastic RecyclingAkshay HartalkarNoch keine Bewertungen

- Samp Business Plan Pine FurnitureDokument15 SeitenSamp Business Plan Pine FurnitureMichael33% (3)

- Neighborhood Construction SuppliesDokument29 SeitenNeighborhood Construction SuppliesEjay EmpleoNoch keine Bewertungen

- IV. Market Analysis A.Swot Strengths-: Papier Mache Created by The People of Paete, The Turumba of Pakil, The HotDokument1 SeiteIV. Market Analysis A.Swot Strengths-: Papier Mache Created by The People of Paete, The Turumba of Pakil, The Hotapi-3732681100% (2)

- STUDY OF HOTEL INDUSTRY IN KHANDESH REGION by P A ANAWADE PDFDokument11 SeitenSTUDY OF HOTEL INDUSTRY IN KHANDESH REGION by P A ANAWADE PDFanawade100% (1)

- DPWH Order Amends Disability Access RulesDokument4 SeitenDPWH Order Amends Disability Access RulesMatic, Jimuel MatthewNoch keine Bewertungen

- Waluse Thesis PDFDokument114 SeitenWaluse Thesis PDFchristine gay evangelioNoch keine Bewertungen

- Philippines Food Processing DecDokument15 SeitenPhilippines Food Processing Dectopandy100% (1)

- National Sector Export Strategy: Wooden Furniture Industry in VietnamDokument70 SeitenNational Sector Export Strategy: Wooden Furniture Industry in VietnamJannie NguyenNoch keine Bewertungen

- Term PaperDokument14 SeitenTerm Paperjeshel caturanNoch keine Bewertungen

- Imam Hassan Furnitures and Fixtures: Pre-Feasibility Study (Furniture Manufacturing Unit)Dokument7 SeitenImam Hassan Furnitures and Fixtures: Pre-Feasibility Study (Furniture Manufacturing Unit)jibranNoch keine Bewertungen

- Economic Development in The Philippines: High Potential, Big Challenges, Wide ImpactDokument31 SeitenEconomic Development in The Philippines: High Potential, Big Challenges, Wide ImpactArangkada PhilippinesNoch keine Bewertungen

- Tracker - May 2014Dokument21 SeitenTracker - May 2014Arangkada PhilippinesNoch keine Bewertungen

- Legislative Priorities - June 2014 - 16th CongressDokument5 SeitenLegislative Priorities - June 2014 - 16th CongressArangkada PhilippinesNoch keine Bewertungen

- AmCham Statement - Investment OmbudsmanDokument1 SeiteAmCham Statement - Investment OmbudsmanArangkada PhilippinesNoch keine Bewertungen

- TPP Updates-JuneDokument4 SeitenTPP Updates-JuneArangkada PhilippinesNoch keine Bewertungen

- May Trans-Pacific Partnership UpdatesDokument4 SeitenMay Trans-Pacific Partnership UpdatesArangkada PhilippinesNoch keine Bewertungen

- UNDESA E-Gouvernement, Étude Complète 2014Dokument284 SeitenUNDESA E-Gouvernement, Étude Complète 2014usinemarocNoch keine Bewertungen

- Ernst & Young Trade SecretsDokument50 SeitenErnst & Young Trade SecretsArangkada PhilippinesNoch keine Bewertungen

- UNDESA E-Gouvernement, Étude Complète 2014Dokument284 SeitenUNDESA E-Gouvernement, Étude Complète 2014usinemarocNoch keine Bewertungen

- Legislative Priorities - May 2014 - 16th CongressDokument5 SeitenLegislative Priorities - May 2014 - 16th CongressArangkada PhilippinesNoch keine Bewertungen

- Palafox Masterplan Ilocos NorteDokument33 SeitenPalafox Masterplan Ilocos NorteArangkada Philippines100% (3)

- WCY Technical Note 5 18 2014 FinalDokument9 SeitenWCY Technical Note 5 18 2014 FinalArangkada PhilippinesNoch keine Bewertungen

- Tracker - Jun 2014Dokument21 SeitenTracker - Jun 2014Arangkada PhilippinesNoch keine Bewertungen

- 2013 August NewsletterDokument2 Seiten2013 August NewsletterArangkada PhilippinesNoch keine Bewertungen

- Joint Position Paper To Improve The Implementation of The EPIRADokument2 SeitenJoint Position Paper To Improve The Implementation of The EPIRAArangkada PhilippinesNoch keine Bewertungen

- WCY 2014 Press Release 5 18 2014 FinalDokument2 SeitenWCY 2014 Press Release 5 18 2014 FinalArangkada PhilippinesNoch keine Bewertungen

- 2013 July NewsletterDokument2 Seiten2013 July NewsletterArangkada PhilippinesNoch keine Bewertungen

- REFMAD-V Enterprise Ilocos NorteDokument11 SeitenREFMAD-V Enterprise Ilocos NorteArangkada PhilippinesNoch keine Bewertungen

- Overseas Filipino Remittance Ilocos NorteDokument7 SeitenOverseas Filipino Remittance Ilocos NorteArangkada PhilippinesNoch keine Bewertungen

- Deloitte Philippines Competitiveness ReportDokument15 SeitenDeloitte Philippines Competitiveness ReportArangkada PhilippinesNoch keine Bewertungen

- Medical Tourism Ilocos NorteDokument34 SeitenMedical Tourism Ilocos NorteArangkada PhilippinesNoch keine Bewertungen

- 2013 September NewsletterDokument2 Seiten2013 September NewsletterArangkada PhilippinesNoch keine Bewertungen

- FCC Presentation FinalDokument27 SeitenFCC Presentation FinalArangkada PhilippinesNoch keine Bewertungen

- 2013 November NewsletterDokument2 Seiten2013 November NewsletterArangkada PhilippinesNoch keine Bewertungen

- BPO-ICT Potentials Ilocos NorteDokument20 SeitenBPO-ICT Potentials Ilocos NorteArangkada PhilippinesNoch keine Bewertungen

- 2013 December NewsletterDokument2 Seiten2013 December NewsletterArangkada PhilippinesNoch keine Bewertungen

- 2013 October NewsletterDokument2 Seiten2013 October NewsletterArangkada PhilippinesNoch keine Bewertungen

- 2014 January NewsletterDokument2 Seiten2014 January NewsletterArangkada PhilippinesNoch keine Bewertungen

- 2022 ICT Mentorship 5Dokument50 Seiten2022 ICT Mentorship 5dcratns dcratns100% (21)

- The Wisdom of Solomon by George Gainer Retyped 1nov16Dokument47 SeitenThe Wisdom of Solomon by George Gainer Retyped 1nov16kbsd3903Noch keine Bewertungen

- Philippine LiteratureDokument75 SeitenPhilippine LiteratureJoarlin BianesNoch keine Bewertungen

- Corporate Surety BondsDokument9 SeitenCorporate Surety BondsmissyaliNoch keine Bewertungen

- 30 Chichester PL Apt 62Dokument4 Seiten30 Chichester PL Apt 62Hi TheNoch keine Bewertungen

- Boardingpass VijaysinghDokument2 SeitenBoardingpass VijaysinghAshish ChauhanNoch keine Bewertungen

- English JAMB Questions and Answers 2023Dokument5 SeitenEnglish JAMB Questions and Answers 2023Samuel BlessNoch keine Bewertungen

- Economical Writing McCloskey Summaries 11-20Dokument4 SeitenEconomical Writing McCloskey Summaries 11-20Elias Garcia100% (1)

- The Paombong Public MarketDokument2 SeitenThe Paombong Public MarketJeonAsistin100% (1)

- The Wizards' Cabal: Metagaming Organization ReferenceDokument3 SeitenThe Wizards' Cabal: Metagaming Organization ReferenceDawn Herring ReedNoch keine Bewertungen

- 021810the History of Lent and EasterDokument28 Seiten021810the History of Lent and EasterTrinity of Orange100% (2)

- Selected Candidates For The Post of Stenotypist (BS-14), Open Merit QuotaDokument6 SeitenSelected Candidates For The Post of Stenotypist (BS-14), Open Merit Quotaامین ثانیNoch keine Bewertungen

- Regional Diagnostic Assessment Report SY 2022-2023Dokument3 SeitenRegional Diagnostic Assessment Report SY 2022-2023Dina BacaniNoch keine Bewertungen

- 50Dokument3 Seiten50sv03Noch keine Bewertungen

- Cpar Q1 Las 1Dokument10 SeitenCpar Q1 Las 1Jaslor LavinaNoch keine Bewertungen

- English File: Grammar, Vocabulary, and PronunciationDokument4 SeitenEnglish File: Grammar, Vocabulary, and PronunciationEvelyn BoccioNoch keine Bewertungen

- Mulla Nasiruddin and The TruthDokument3 SeitenMulla Nasiruddin and The TruthewfsdNoch keine Bewertungen

- Essential Rabbi Nachman meditation and personal prayerDokument9 SeitenEssential Rabbi Nachman meditation and personal prayerrm_pi5282Noch keine Bewertungen

- Final PaperDokument5 SeitenFinal PaperJordan Spoon100% (1)

- The Books of The Bible-ModuleDokument38 SeitenThe Books of The Bible-Modulejillene catapang67% (3)

- Illustrative Bank Branch Audit FormatDokument4 SeitenIllustrative Bank Branch Audit Formatnil sheNoch keine Bewertungen

- Ecommerce Product: Why People Should Buy Your Product?Dokument3 SeitenEcommerce Product: Why People Should Buy Your Product?khanh nguyenNoch keine Bewertungen

- The Current State of The U.S EconomyDokument7 SeitenThe Current State of The U.S EconomysoarrorNoch keine Bewertungen

- Administrative Assistant II Job DescriptionDokument2 SeitenAdministrative Assistant II Job DescriptionArya Stark100% (1)

- FCP Business Plan Draft Dated April 16Dokument19 SeitenFCP Business Plan Draft Dated April 16api-252010520Noch keine Bewertungen

- Elementary Present Continuous and Present Simple AnswersDokument5 SeitenElementary Present Continuous and Present Simple AnswersFabio SoaresNoch keine Bewertungen

- Impact of corporate governance on firm performanceDokument4 SeitenImpact of corporate governance on firm performancesamiaNoch keine Bewertungen

- People v. Campomanes PDFDokument10 SeitenPeople v. Campomanes PDFJaneNoch keine Bewertungen

- Introduction To Asset Pricing ModelDokument8 SeitenIntroduction To Asset Pricing ModelHannah NazirNoch keine Bewertungen