Beruflich Dokumente

Kultur Dokumente

Martin Insertable Dust Collectors: Technical Data Sheet

Hochgeladen von

Nath BoyapatiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Martin Insertable Dust Collectors: Technical Data Sheet

Hochgeladen von

Nath BoyapatiCopyright:

Verfügbare Formate

Technical Data Sheet

Form No. L3420-5/98

Pg. 1 of 2

MARTIN Insertable Dust Collectors

MARTIN Insertable Dust Collectors filter dust inside transfer points. Insertable dust collectors can effectively handle the heavy concentrations of dust and high volumes of air arising at belt conveyor transfer points. There is no large fan, no ductwork, and no central bag house. Insertable filters are integrated into the transfer point enclosure, where they can return collected material to the conveying system.

MARTIN Insertable Dust Collector Specifications

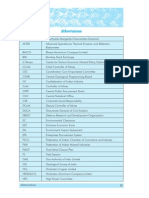

Model DLM V4/7 DLM V6/10 DLM V7/7 DLM V8/7 DLM V9/15 DLM V10/10 DLM V12/10 DLM V14/7 DLM V15/15 DLM V18/15 DLM V20/10 DLM V21/7 DLM V30/10 DLM V30/15 DLM V45/15 DLM V60/15 Filtration Area 2 2 43 ft (4 m ) 2 2 64 ft (6 m ) 2 2 75 ft (7 m ) 2 2 86 ft (8 m ) 2 2 97 ft (9 m ) 2 2 108 ft (10 m ) 2 2 129 ft (12 m ) 2 2 150 ft (14 m ) 2 2 161 ft (15 m ) 2 2 194 ft (18 m ) 2 2 215 ft (20 m ) 2 2 226 ft (21 m ) 2 2 323 ft (30 m ) 2 2 323 ft (30 m ) 2 2 484 ft (45 m ) 2 2 646 ft (60 m ) Number of Elements 6 6 10 12 6 10 12 20 10 12 20 30 30 20 30 40 Pad Length (feet) 2 3-9/16 3 3-3/8 2 3-9/16 2 3-9/16 4 11-1/16 3 3-3/8 3 3-3/8 2 3-9/16 4 11-1/16 4 11-1/16 3 3-3/8 2 3-9/16 3 3-3/8 4 11-1/16 4 11-1/16 4 11-1/16 Pad Length (meters) (0.7 m) (1.0 m) (0.7 m) (0.7 m) (1.5 m) (1.0 m) (1.0 m) (0.7 m) (1.5 m) (1.5 m) (1.0 m) (0.7 m) (1.0 m) (1.5 m) (1.5 m) (1.5 m)

Compressed Air Requirements

Pulse Pulse Model Air Pressure Air Volume Duration Interval 3 200 ms 25 sec. DLM V4/7, V6/10, V9/15 65 psig (4.5 bar) 2.3 cfm (3.9m /h) 3 DLM V7/7, V10/10, V15/15 65 psig (4.5 bar) 2.8 cfm (4.7m /h) 200 ms 25 sec. 3 DLM V8/7, V12/10, V18/15 90 psig (6.2 bar) 4.2 cfm (7.1m /h) 200 ms 25 sec. 3 DLM V14/7, V20/10 (5 valve) 90 psig (6.2 bar) 5.0 cfm (8.5m /h) 200 ms 25 sec. 3 DLM V20/10 (10 valve) 65 psig (4.5 bar) 3.6 cfm (6.1m /h) 60 ms 12 sec. 3 DLM V21/7, V30/10 75 psig (5.2 bar) 4.6 cfm (7.8m /h) 60 ms 12 sec. 3 DLM V30/15 65 psig (4.5 bar) 5.1 cfm (8.7m /h) 110 ms 12 sec. 3 DLM V45/15 75 psig (5.2 bar) 6.6 cfm (11.2m /h) 110 ms 12 sec. 3 DLM V60/15 90 psig (6.2 bar) 9.5 cfm (16.1m /h) 110 ms 12 sec. Note: Minimum pipe diameter is _. Suitable for runs of pipe up to 100 ft (30m) in length. Consult Martin Engineering for longer runs.

MARTIN ENGINEERING ONE MARTIN PLACE NEPONSET, IL 61345-9766 USA PHONE 1-800-544-2947 or 309-594-2384 FAX 309-594-2432 www.martin-eng.com COPYRIGHT 1998

Technical Data Sheet

xxxx

Form No. L3420-5/98

Pg. 2 of 2

MARTIN Insertable Dust Collectors

Electrical Specifications

Controller requires 115VAC, 50/60 Hz, single phase power. A transformer is available for voltages above 115VAC. Fan motor requires 230/460VAC, 60 Hz, 3 phase power. 575VAC motors also available. Fan Motor Horsepower Ratings: F1 1.0 HP, K3 2.0 HP, K5 3.0 HP, F6 7.5 HP, F10 7.5 HP, K11 10.0 HP.

Order Information

For applications involving coal dust or any other potentially explosive material, specify explosion-proof packages.

P/N Standard 35238 35239 35240 35241 35242 35243 35244 35245 35246 35247 35248 35249 35250 35251 35252 35253 35254 35255 35256 35257 P/N Explosion Proof 35238-EP 35239-EP 35240-EP 35241-EP 35242-EP 35243-EP 35244-EP 35245-EP 35246-EP 35247-EP 35248-EP 35249-EP 35250-EP 35251-EP 35252-EP 35253-EP 35254-EP 35255-EP 35256-EP 35257-EP

DCE Model w/ Fan DLMV 4/7 - F1 DLMV 6/10 - F1 DLMV 7/7 - F1 DLMV 7/7 - K3 DLMV 8/7 - F1 DLMV 8/7 - K3 DLMV 9/15 - F1 DLMV 9/15 - K3 DLMV 10/10 - F1 DLMV 10/10 - K3 DLMV 12/10 - F1 DLMV 12/10 - K3 DLMV 12/10 - K5 DLMV 14/7 - K3 DLMV 14/7 - K5 DLMV 15/15 - K3 DLMV 15/15 - K5 DLMV 18/15 - K3 DLMV 18/15 - K5 DLMV 18/15 - K7

P/N Standard 35258 35259 35260 35261 35262 35263 35264 35265 35266 35267 35268 35269 35270 35271 35272 35273 35274 35275

P/N Explosion Proof 35258-EP 35259-EP 35260-EP 35261-EP 35262-EP 35263-EP 35264-EP 35265-EP 35266-EP 35267-EP 35268-EP 35269-EP 35270-EP 35271-EP 35272-EP 35273-EP 35274-EP 35275-EP

DCE Model w/ Fan DLMV 20/10 - K3 DLMV 20/10 - K5 DLMV 20/10 - K7 DLMV 21/7 - K3 DLMV 21/7 - K5 DLMV 21/7 - K7 DLMV 30/10 - K5 DLMV 30/10 - K7 DLMV 30/10 - F10 DLMV 30/15 - K5 DLMV 30/15 - K7 DLMV 30/15 - F10 DLMV 45/15 - K7 DLMV 45/15 - F10 DLMV 45/15 - K11 DLMV 60/15 - K7 DLMV 60/15 - F10 DLMV 60/15 - K11

Standard package includes: Collector with 16 oz. felt filter media, mild steel inserts, solid state electronic control panel and solenoid valves in a weather-proof enclosure, moisture separator/pressure regulator, oleophobic bag treatment (moisture and oil resistant), acoustic diffuser. Explosion-Proof package includes: Collector with 16 oz. anti-static felt filter media, stainless steel seal frames, solid state electronic control panel and solenoid valves in a NEMA 9 enclosure, explosion-proof motor, spark resistant fan, moisture separator/pressure regulator, oleophobic bag treatment, acoustic diffuser.

MARTIN ENGINEERING ONE MARTIN PLACE NEPONSET, IL 61345-9766 USA PHONE 1-800-544-2947 or 309-594-2384 FAX 309-594-2432 www.martin-eng.com COPYRIGHT 1998

Form No. L3418-6/98

Insertable Dust Collector

Filters Inside Transfer Point Collect Dust Without Ductwork

To overcome the maintenance problems and operating costs of centralized dust control systems, Martin Engineering recommends the use of insertable dust collectors on conveyor transfer points.

Rather than carry dust-laden air to a central collector, insertable systems filter the air inside the transfer point. There is no large fan, no ductwork, and no central bag house. Insertable filters are integrated into the transfer point enclosure, where they can easily return material to the conveying system. Insertable collectors can effectively handle the heavy concentrations of dust and high volumes of air arising at belt conveyor transfer points.

MARTIN Insertable Dust Collector

Effective Dust Capture

High efficiency filters remove 99.9 percent of all particles larger than one micron.

Economical Installation

No ductwork to install, balance, or clean.

Low Energy Costs

Small, efficient integral fan operates only when conveyor runs.

Continuous Operation

Automatic reverse jet cleaning sequence keeps filters working effectively with minimum compressed air.

Compact Design

Small footprint reduces space requirements and installation cost.

Returns Product To The Process

Dust stays within the transfer point. Valuable material returns to the material handling system.

Insertable Filter Efficiency

DCE Dalmatic (MARTIN ) Insertable Dust Collectors are designed to remove 99.9 percent by weight of all dry particulate particles one micron and larger in size.

(This efficiency is based on a timeweighted average and assurances the collector will be installed, operated, and maintained in accordance with instructions.)

Minimum Maintenance

Clean side access for inspection and filter changeout.

No Dust Disposal

No haulage costs for waste disposal. Valuable material returns to the process. No equipment needed to handle, package, or dispose of dust.

Flexible Design

Stand alone system or use to supplement existing central dust collector systems.

MARTIN Insertable Dust Collectors

How Insertable Dust Collectors Work

An integral fan pulls dust-laden air through the filter elements. The air passes through the filter, leaving the particles on the fabric. Each filter element is regularly cleaned by a reverse jet of compressed air, which is injected into the filter element through the jet tube. This causes a momentary reversal of the air flow, resulting in a brief inflation of the filter element, dislodging the dust cake back into the main material body.

Cleaned Air Outlet header Sealing flange and ring Jet tube - injecting burst of compressed air into filter element via the header

CLEAN SIDE

Seal frame

Additional air induced by force of jet

Recessed slots for filter elements Wire frame insert Airflow briefly reversed, inflating pad and dislodging dust

Dust accumulating on outer surface of pad as the air penetrates the fabric

Felt pad

Dislodged dust layer falling into container

A. Filtering operation (continuous) Dust laden air

DIRTY SIDE

B. Cleaning operation (intermittent)

Systems To Fit Your Application

Martin Engineering offers a full range of system sizes and filter materials to match application requirements. Filters can be installed horizontally or vertically to meet application requirements. Explosion-proof packages are available.

Typical Sizing

Belt Width in. (mm) 24 (500-650) 30 (650-800) 36 (800-1000) 42 (1000-1200) 48 (1200-1400) 54 (1400-1600) 60 (1600-1800) 72 (1800-2000) Filter Material Required (Filtration Velocity of 7) 143 (13.3) 179 (16.6) 214 (19.9) 250 (23.2) 286 (26.6) 321 (29.8) 357 (33.2) 429 (39.9) Filter Mode Number DLM-V14/7F K3 DLM-V18/15F K5 DLM-V20/10F K5 DLM-V21/7F K7 DLM-V30/15F K7 DLM-V30/15F K7 DLM-V30/15F F10 DLM-V45/15F F10 MARTIN P/N P/N ExplosionProof 35251-EP 35256-EP 35259-EP 35263-EP 35268-EP 35268-EP 35269-EP 35271-EP

35251 35256 35259 35263 35268 35268 35269 35271

The Insertable Dust Collector sizing shown in the above table is based on generic air flow assumptions. Accurate sizing would require air flow measurements. Actual size of dust collector may vary, depending on measured air flow, type of material being collected, and material drop height.

Explosion-proof units are supplied with explosion-proof fan motor, spark-resistant fan, NEMA 9 control panel, anti-static filter media, and stainless steel inserts.

LLLL LLL LL LL L L L L L L L L

LLLLL LL L L L L L L

SOLUTE AB

OSITIVELY, N ,P LY

LLLLL LL L L L L L L

RANTEE GUA

LLLLLLLL L LL L L L L L L L

Form No. L3418-6/98

CUSES EX

COPYRIGHT 1998 MARTIN ENGINEERING

One Martin Place Neponset, Illinois 61345-9766 USA 800-544-2947 or 309-594-2384 FAX: 309-594-2432 http://www.martin-eng.com

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Belt ConveyorDokument12 SeitenBelt ConveyorNath Boyapati100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Measurement of Bearing Clearance - Turbomachinery MagazineDokument3 SeitenMeasurement of Bearing Clearance - Turbomachinery MagazineNath BoyapatiNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Dunlop Technical ManualDokument41 SeitenDunlop Technical ManualGonzalo AriasNoch keine Bewertungen

- Ideal Gas-Turbine Cycle T-S Diagram With The Same Processes As in Fig. 6 Complete-Cycle Gas Turbine Shown Below The T-S DiagramDokument1 SeiteIdeal Gas-Turbine Cycle T-S Diagram With The Same Processes As in Fig. 6 Complete-Cycle Gas Turbine Shown Below The T-S DiagramNath BoyapatiNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Minor Loss 1Dokument1 SeiteMinor Loss 1Nath BoyapatiNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Cole Brook-White Equation Representation of Moody's Friction Factor Is Plotted in Fig. 1Dokument1 SeiteThe Cole Brook-White Equation Representation of Moody's Friction Factor Is Plotted in Fig. 1Nath BoyapatiNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- 155-MW Natural-Gas-Fired Gas Turbine Featuring A Dry Low NO Combustor (Power)Dokument1 Seite155-MW Natural-Gas-Fired Gas Turbine Featuring A Dry Low NO Combustor (Power)Nath BoyapatiNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Ì Iêv Êãõ Ià I Ìiàê Vviàãê Ià Ì Êv Iý L Ìþê 'Ê V Ê I Ê Àiûi Ìê' ) Iêì Êãõ Ià I ÌiàêìõliãDokument1 SeiteÌ Iêv Êãõ Ià I Ìiàê Vviàãê Ià Ì Êv Iý L Ìþê 'Ê V Ê I Ê Àiûi Ìê' ) Iêì Êãõ Ià I ÌiàêìõliãNath BoyapatiNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- NOTIS - Basic Theory: Basic Types of ScalesDokument1 SeiteNOTIS - Basic Theory: Basic Types of ScalesNath BoyapatiNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- >ÀiêÌêàiµõÀi'ÊìÊ««Ìêì IêDokument1 Seite >ÀiêÌêàiµõÀi'ÊìÊ««Ìêì IêNath BoyapatiNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Abbreviations Abbreviations Abbreviations Abbreviations AbbreviationsDokument3 SeitenAbbreviations Abbreviations Abbreviations Abbreviations AbbreviationsNath BoyapatiNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Sources of Textile Fibers: Solar Energy Is The Basis of LifeDokument1 SeiteSources of Textile Fibers: Solar Energy Is The Basis of LifeNath BoyapatiNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Recommended Fluid Velocities in Piping: Determine The Pipe Schedule NumberDokument1 SeiteRecommended Fluid Velocities in Piping: Determine The Pipe Schedule NumberNath BoyapatiNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Book CatalogueDokument16 SeitenBook CatalogueAnusha GayathriNoch keine Bewertungen

- The General Balance EquationDokument18 SeitenThe General Balance EquationNath BoyapatiNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Th857 Programmable Timer Module Instruction ManualDokument2 SeitenTh857 Programmable Timer Module Instruction ManualNath BoyapatiNoch keine Bewertungen

- Mass & Energy Balances: Environmental Transport and FateDokument11 SeitenMass & Energy Balances: Environmental Transport and FateNath Boyapati100% (1)

- Step-By-Step Guide - Sensors Alarms1Dokument14 SeitenStep-By-Step Guide - Sensors Alarms1Andy_kokoNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Catalogo de Oleohidraulica AGVDokument73 SeitenCatalogo de Oleohidraulica AGVadjime3Noch keine Bewertungen

- Sensibo Sky User ManualDokument34 SeitenSensibo Sky User ManualMauMadie FuntanarNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Patrick C Hall@yahoo - com-TruthfinderReportDokument13 SeitenPatrick C Hall@yahoo - com-TruthfinderReportsmithsmithsmithsmithsmithNoch keine Bewertungen

- Braemar ApplicationDokument2 SeitenBraemar Applicationjoemedia0% (1)

- Indonesia's First Maritime Service Solution Provider: Company ProfileDokument10 SeitenIndonesia's First Maritime Service Solution Provider: Company Profilemuh_akbar2451Noch keine Bewertungen

- PQ070XF02SZH: Features Outline DimensionsDokument4 SeitenPQ070XF02SZH: Features Outline DimensionsJulio Cesar CastilloNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Pressure Flow and Temperature SwitchesDokument16 SeitenPressure Flow and Temperature SwitchesMD SAMANNoch keine Bewertungen

- Tutorial Joint Push Pull - English - V1.1 - 20 Feb 08Dokument31 SeitenTutorial Joint Push Pull - English - V1.1 - 20 Feb 08shadownrunNoch keine Bewertungen

- 1743 LKWActrosXXXXXX 954frDokument4 Seiten1743 LKWActrosXXXXXX 954frgeothermal3102100% (1)

- Make A Project of Calculator in Visual BasicDokument9 SeitenMake A Project of Calculator in Visual BasicCHITRA MINI96% (23)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- QA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #Dokument3 SeitenQA/QC Filling INDEX: North Gas Compression Plants (NGCP) Pipelines Index File Name File #deva017Noch keine Bewertungen

- BK Report and ProjectDokument55 SeitenBK Report and ProjecttesfuNoch keine Bewertungen

- 5 Blasting Limit GuidelinesDokument7 Seiten5 Blasting Limit GuidelinesTry Oka Afandy SinagaNoch keine Bewertungen

- LennoxDokument32 SeitenLennoxCharly ColumbNoch keine Bewertungen

- Patrol For Unix and Linux Unix Get StartedDokument112 SeitenPatrol For Unix and Linux Unix Get StartedRamesh SharmaNoch keine Bewertungen

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Dokument4 Seiten7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallNoch keine Bewertungen

- Mobil Pyrotec™ HFD 46Dokument2 SeitenMobil Pyrotec™ HFD 46ABDUL REHMAN PIPRANINoch keine Bewertungen

- Cakewalk CA-2A T-Type Leveling Amp For FreeDokument2 SeitenCakewalk CA-2A T-Type Leveling Amp For FreeM. NngwenyaNoch keine Bewertungen

- Scope of Work Diesel Fuel Tank For The Rifle-Garfield County Regional Airport Fuel Farm IFB-GC-AP-01-14 - Diesel Fuel TankDokument4 SeitenScope of Work Diesel Fuel Tank For The Rifle-Garfield County Regional Airport Fuel Farm IFB-GC-AP-01-14 - Diesel Fuel TankMSNoch keine Bewertungen

- LPIC-2 Exam PrepDokument882 SeitenLPIC-2 Exam PrepcuthieuNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Principles of Accounting, Volume 2: Managerial AccountingDokument59 SeitenPrinciples of Accounting, Volume 2: Managerial AccountingVo VeraNoch keine Bewertungen

- Pds Luxathane 5000 VocDokument2 SeitenPds Luxathane 5000 Vocmuthukumar100% (1)

- Illumination: "The Established Leader Ee Review"Dokument6 SeitenIllumination: "The Established Leader Ee Review"IVex Brykz Jay Ro60% (5)

- BC Ii 800Dokument38 SeitenBC Ii 800Pop Ciprian100% (2)

- Commodity Sourcing Strategy ProjectDokument5 SeitenCommodity Sourcing Strategy ProjectMohit TalwarNoch keine Bewertungen

- 27U RackDokument6 Seiten27U Racknitin lagejuNoch keine Bewertungen

- Data Structures and Algorithms: (CS210/ESO207/ESO211)Dokument24 SeitenData Structures and Algorithms: (CS210/ESO207/ESO211)Moazzam HussainNoch keine Bewertungen

- Resume For FaisalDokument3 SeitenResume For FaisalFaisal Zeineddine100% (1)

- Government College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusDokument111 SeitenGovernment College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusSalma Mehajabeen ShajahanNoch keine Bewertungen

- University of Chicago Press Fall 2009 CatalogueVon EverandUniversity of Chicago Press Fall 2009 CatalogueBewertung: 5 von 5 Sternen5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesVon EverandUniversity of Chicago Press Fall 2009 Distributed TitlesBewertung: 1 von 5 Sternen1/5 (1)