Beruflich Dokumente

Kultur Dokumente

03

Hochgeladen von

Faycel OuerdienOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

03

Hochgeladen von

Faycel OuerdienCopyright:

Verfügbare Formate

Components and Antioxidant Activity in Teas after Autoclave Treatment Research Article

109

Components and Antioxidant Activity in Teas after Autoclave Treatment

Bo-Long Chen and Horng-Liang Lay*

Department of Plant Industry, National Pingtung University of Science & Technology, Neipu, Pingtung Hsien 91201, Taiwan ROC

In this study, Puerh and Oolong teas were used as materials to investigate the changes in catechins content and to compare their antioxidant activities, with different time periods of autoclave treatment. Tea samples were extracted with methanol and the quantitative variation of each catechin marker component was analyzed by high performance liquid chromatography. Moreover, antioxidant assays were determined according to total phenolic content and scavenging ability of 1,1-diphenyl-2-picrylhydrazyl (DPPH) free-radicals. Two kinds of tea showed similar results after autoclave treatment. Catechins were transformed from epicatechins into non-epicatechins. Gallate acid content was increased; however, caffeine was not affected. In antioxidant assays, the antioxidant ability of Puerh tea with time in descent order was 10 min > 20 min > control > 30 min > 40 min and of Oolong tea was control > 10 min > 20 min > 30 min > 40 min. In total phenolic content, Oolong tea was rapidly decreased to 36.95% after 10 minutes of autoclave treatment and Puerh tea was gradually decreased from 10 min to 40 min. Finally, this study showed that autoclave treatment directly affected catechins and indirectly affected total phenolic content. Antioxidant ability of teas decreased with the increase of duration of autoclave treatment. Key words: Tea, Catechins, Antioxidant, Total phenolic content.

(HPLC) 1,1-diphenyl-2-picrylhydrazyl (DPPH) 10 min > 20 min > control > 30 min > 40 min control > 10 min > 20 min > 30 min > 40 min 10 min 36.95% 10 min 40 min

* , layhl@mail.npust.edu.tw 2011 3 10 2011 6 10 8:109-118 (2011) Crop, Environment & Bioinformatics 8:109-118 (2011) 189 Chung-Cheng Rd., Wufeng, Taichung 41362, Taiwan ROC

INTRODUCTION

Tea tree [Camellia sinensis (L.) O. Kuntze], which belongs to Theaceae family and Camellia genus, is the most important economic crop of Theaceae. It had been used as medicine in ancient times and became a daily beverage in the early

110

Crop, Environment & Bioinformatics, Vol. 8, June 2011

West Han Dynasty (200 BC) in China. In fact, tea drinking has thousands years of history in China, and forms a specific culture (Juan and Chen 1998, Chen1999, Wu et al. 2007). Recently, tea is one of the most popular non-alcohol drinks world-wide, after coffee and cocoa. According to recent studies, many functionally healthful contents were found in tea, and made it known as a health care beverage (Juan and Chen 1998, Baletine 1997, Jain et al. 2006). There are many chemical compounds in tea, including polyphenolic compounds, volatile fragrances, pigments, alkaloids, proteins and free amino acids, carbohydrates, fat, organic acids, and minerals (Yu 1992). Among the components listed above, polyphenolics were the most special and important ones. The content of polyphenolics in tea has been proven its natural antioxidant activity (Tanizawa et al. 1984) and its good prevention efficacy on cardiovascular diseases, tumors forming, anticancer, and anti-antherosclerosis (Che et al. 2005, Farhoosh et al. 2007, Mamati et al. 2006). The content of catechins is the highest and makes up almost 80% of polyphenolic compounds. The major components of catechins include (+)-catechin (C), gallic acid (GA), (-)-epicatechin (EC), (+)gallocatechin (GC), (-)-catechin gallate (CG), (-)gallocatechin gallate (GCG), (-)-epicatechin gallate (ECG), (-)-epigallocatechin (EGC), and (-)epigallocatechin gallate (EGCG) (Sanderson 1972). Previous studies found that EC, ECG, EGC, and EGCG were transformed into C, CG, GC, and GCG by heat treatment which caused a change of the second position of the structure inducing isomerization (Haginaka et al. 2007, Ito et al. 2003). Therefore, the objective of this study was to quantitatively analyze the antioxidant ability of teas using high performance liquid chromatography (HPLC) and to assess the effect of different time periods of autoclave treatment on quality variation.

Standard samples of caffeine, C, GA, EC, GC, CG, GCG, ECG, EGC, EGCG, quercetin, 1,1-diphenyl-2-picrylhydrazyl (DPPH), butylated hydroxyltoluene (BHT), and Folin-Ciocalteus phenol reagent were obtained from Sigama Chemical Company (St. Louis, Mo, USA). Scopoletin was purchased from Fluka Chemie AG (Switzerland) and was used as an internal standard. Acetonitrile, methanol, and DMSO (HPLC grade) were obtained from Mallinckrodt, Incorporation (USA), and sodium carbonate and phosphoric acid (analytical-reagent grade) were from Kanto Chemical (Japan). Ultra-pure distilled water with a resistance greater than 18.2 M cm-2 was prepared with a mini-Q system (Millipore, Bedford, MA, USA). All other reagents were of analytical grade.

Autoclaving Treatment of Tea Leaves

One hundred grams of Puerh and Oolong tea leaves were put into an autoclave for 0 (control), 10, 20, 30, and 40 min treatments under high pressure (1.5 kg cm-2) and high temperature (121oC). All treatments were triplicated and the average values were used.

Preparation of Sample Solutions

All samples were dried at 60oC for 24 h. One gram of each sample was reflux and extracted with 100 mL methanol at 80oC for 2 h. The solutions were filtered, evaporated, and adjusted up to 25 mL using methanol. Meanwhile internal standard scopoletin was added to each solution to a concentration of 50 g mL-1 and used for subsequent HPLC analysis after filtration through a 0.45 m membrane filter.

Preparation of Standards and Internal Standard Solution

All standard components were weighed and dissolved in 70% methanol to yield sequential concentrations as follows: GA 100.0 g mL-1, caffeine 1140.0 g mL-1, GC 120.0 g mL-1, EGC 200.0 g mL-1, C 110.0 g mL-1, EC 10.0 g mL-1, EGCG 1590.0 g mL-1, GCG 270.0 g mL-1, ECG 290.0 g mL-1, and CG 60.0 g mL-1. They were then prepared as the standard stock solutions. Scopoletin of 50.0 g mL-1 was prepared as the internal standard stock solution.

MATERIALS AND METHODS

Materials

Puerh tea produced in Yun-Nan Province of China was purchased from a local market in Kaohsiung City. Locally made Oolong tea was purchased from Min-Gein Township, Nan-Tou Hsien.

Chemicals and Reagents

Components and Antioxidant Activity in Teas after Autoclave Treatment

111

HPLC Measuring System nd Conditions

Analysis was conducted by a Hitachi HPLC system equipped with a degasser (DG-2410), pump (L-7100), UV/VIS detector (L-7420), photodiode array detector (L-4500) and autosampler (L-7200). Peak areas were calculated with the software D-7000 HSM (Hitachi). The reversed phase of an Inertsil 5 ODS-2 column (4.6 mm I.D. 250 mm) was used. The oven temperature set for column was 40oC. The mobile phase consisted of water, 20% acetonitrile aqueous solution, and 100% acetonitrile aqueous solution (each adjusted to pH 3.0 with phosphoric acid), and a linear gradient elution was performed as shown in Table 1. The injection volume was 20 L, with the flow rate of 1.0 mL min-1. The detection wavelength was 220 nm in UV. The samples were quantified by interpolating the linear regression plot obtained from standard solutions. Table 1. Gradient elution program for mobile phase of HPLC anaysis. Time (min) 0 5 15 25 35 45 55 60 70 80 85 90 95 100 H2O 98 85 70 58 58 40 35 35 30 30 0 0 98 98 20% acetonitrile 2 15 30 42 42 60 65 65 70 70 70 10 2 2 100% acetonitrile 0 0 0 0 0 0 0 0 0 0 30 90 0 0

200.0g mL-1; C: 1.56, 3.12, 6.25, 12.5, 25.0, 50.0, and 110.0 g mL-1; EC: 1.71, 3.43, 6.87, 13.75, 27.5, 55.0, and 110.0 g mL-1; EGCG: 24.84, 49.68, 99.37, 198.75, 398.5, 795.0, and 1590.0 g mL-1; GCG: 4.21, 8.43, 16.87, 33.75, 67.5, 135.0, and 270.0 g mL-1; ECG: 4.53, 9.06, 18.12, 36.25, 72.5, 145.0, and 290.0 g mL-1; and CG: 0.93, 1.87, 3.75, 7.5, 15.0, 30.0, and 60.0 g mL-1. Each dilution contained 50 g mL-1 of scopoletin, the internal standard solution. After filtering through a 0.45 m membrane filter, an aliquot of 20 L of each concentration solution was injected into the HPLC column for analysis. The calibration line was plotted by using the ratio of the peak areas that corresponded to each standard solution and the internal standard solution on the Y-axis versus each concentration on the X-axis. Linear regression method was used to evaluate the parameters of y = ax + b and the correlation coefficient (r).

Validation test 1. Precision

Standard stock solutions were diluted with 70% methanol to three different concentrations (Table 1). Intra-day tests (injecting each concentration three times within 24 h) and inter-day tests (injecting each concentration four times over 7 d with each injection separated at least 24 h) were carried out to check reproducibility. The standard deviation (S.D.) and relative standard deviation (R.S.D., %) were calculated.

2. Accuracy

Each standard stock solution of various concentrations was spiked into methanol solution of tea leaves, and then refluxed at 80oC for 2 h. Internal standard solution was added to each solution to afford a concentration of 50 g mL-1. Then the solution was filtered and subjected to HPLC analysis in triplicates. The recovery (%) was calculated by the equation of [(C3-C2)/C1] 100%, where C1 is the amount of each standard spiked, C2 is the amount of each marker in methanol solution of tea leaves, and C3 is the total amount of each marker in the solution.

Each adjusted to pH 3.0 with phosphoric acid.

Calibration Method

The standard solutions of each marker substance were diluted by 70% methanol to give sequential concentrations of GA: 1.56, 3.12, 6.25, 12.5, 25.0, 50.0, and 100.0 g mL-1; caffeine: 17.81, 35.62, 71.25, 142.5, 285.0, 570.0, and 1140.0 g mL-1; GC: 1.87, 3.75, 7.50, 15.0, 30.0, 60.0, and 120.0 g mL-1; EGC: 3.12, 6.25, 12.50, 25.0, 50.0, 100.0, and

Analysis of Antioxidant Activity 1. Sample Extraction

112

Crop, Environment & Bioinformatics, Vol. 8, June 2011

One gram of each grounded samples was extracted by reflux with 100 mL methanol at 80oC for 2 h. Each solution was filtered and evaporated, and each extract was freeze-dried and stored at -4C for the analysis of antioxidant activity.

2. Total Phenolic Content

Total phenolic content was determined by the Folin-Ciocalteu assay of Li et al. (2006). Briefly, fifty micro-liter sample solution (1 mg mL-1) was mixed with 250.0 L of 10% Folin-Ciocalteu solution, added with 750.0 L of 7.5% (w/v) Na2CO3, and then reacted at room temperature for 2 h in dark. The absorbance was measured at 765 nm using a UV-visible spectrophotometer (ChromTech Co., Taiwan). Total phenolic content was calculated using various concentrations of gallic acid solution (8.13-130.0 g mL-1) from the calibration curve.

11.36 min for GA, 18.80 min for caffeine, 28.99 min for GC, 31.25 min for EGC, 33.32 min for C, 45.47 min for EC, 47.57 min for EGCG, 53.25 min for GCG, 56.37 min for ECG, 68.33 min for CG, and 73.36 min for the internal standard, scopoletin. The peaks of marker substances in the tea sample solutions were qualified by HPLC with photodiode array detector. High purity (more than 0.99) of each peak stood for each marker substance. The results showed that GA, caffeine, GC, EGC, C, EC, EGCG, GCG, ECG, and CG were separated completely and were not interrupted by other compounds under the performed analytical conditions in this study. The result also showed high purification and separation efficacy. Therefore, the conditions described above can be used for quantification of the marker substances.

3. Free-Radical Scavenging Ability

The scavenging ability of methanol extracts on 1,1-diphenyl-2-picrylhydrazyl (DPPH) freeradicals was estimated according to the method of Shimada et al. (1992). Briefly, 2 mL of each test sample was mixed with 0.5 mL of 1 mM DPPH in methanol. The mixture was shaken vigorously and then steadily stayed for 30 min at room temperature in dark. The absorbance of the resulting solution was detected at 517 nm against an aliquot blank. The scavenging ability was calculated as follows: scavenging ability (%) = [(A517 of control A517 of sample) / A517 of control] 100. The higher the scavenging ability value, the higher the antioxidant activity is detected in the methanol extract (Shimada et al. 1992).

Calibration Curve

The regression equations and correlation coefficients of calibration lines for those marker substances are listed in Table 2. All calibration curves were in good linear correlation with correlation coefficient of 0.9980~0.9999.

Precision and Accuracy

According to the standard solutions with various concentrations shown in Table 3, the relative standard deviations of the intra-day and inter-day were between 0.16 to 3.08 % and 0.52 to 3.92%, respectively. It suggested that the HPLC analysis in this study is stable and reproducible. Recovery rates of the analysis were shown in Table 3, and were all greater than 98.01%, indicating the analysis using HPLC in this study was accurate.

Statistical analysis

All the experiments were triplicate. One-way ANOVA with Duncans multiple range test was used to analyze and compare the data, with P < 0.05 as the limit of significance by SAS (Statistical Analysis System).

Component Contents in Tea Leaves after Autoclave Treatment

In general, products were sterilized for a period of time at 120C when tea beverages were canned and packaged. It was found that GCG was increased from the isomerization of EGCG while tea beverages were autoclaved (Okumura et al. 2008). In this study, Puerh tea and Oolong tea were autoclaved for 10, 20, 30, and 40 min and were then compared with the control. The results w e r e s ho w n i n T a b l e 4 , i nd i c a t i n g t h a t epicatechins in Puerh tea decreased significantly after autoclaving. Among epicatechins, contents of EGCG, EGC, ECG and EC decreased rapidly in

RESULTS AND DISCUSSION

Separation of Marker Substances by HPLC

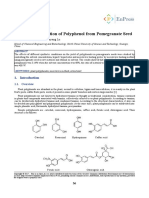

HPLC chromatograms of the methanol extracts of Puerh tea and Oolong tea are shown in Fig. 1. The chromatograms indicated the respective retention time for each of components:

Components and Antioxidant Activity in Teas after Autoclave Treatment

113

Fig. 1. HPLC chromatograms of marker component (A), Pu-erh tea (B), autoclaved Puerh tea (C), Oolong tea (D), and autoclaved Oolong tea (E). 1: gallic acid; 2: (+)-gallocatechin; 3: (-)-epigallocatechin; 4: (+)-catechin; 5: caffeine; 6: (-)-epicatechin; 7: (-)-epigallocatechin gallate; 8: (-)-gallocatechin gallate; 9: (-)-epicatechin gallate; 10: (-)-catechin gallate; and IS: scopoletin. Table 2. The regression equations of calibration curves of each compounds. Compound GA CA GC EGC C EC EGCG GCG ECG CG Concentration range (g mL-1) 1.56 ~ 100.0 17.81~1,140.0 1.87 ~ 120.0 3.12 ~ 200.0 1.71 ~ 110.0 1.71 ~ 110.0 24.84 ~ 1590.0 4.21 ~ 270.0 4.53 ~ 290.0 0.93 ~ 60.0 Regression equation y = 0.9802x + 0.0013 y = 1.0963x - 0.0703 y = 1.0553x - 0.0082 y = 1.0376x - 0.011 y = 1.0536x - 0.0135 y = 1.1067x - 0.0087 y = 1.0552x-0.1497 y = 1.0973x - 0.0143 y = 1.2638x - 0.0136 y = 1.0063x - 0.0011 r 0.9999 0.9980 0.9996 0.9994 0.9995 0.9996 0.9982 0.9997 0.9998 0.9999 N 3 3 3 3 3 3 3 3 3 3

GA:gallic acid, CA: caffeine, GC: (+)-gallocatechin, EGC: (-)-epigallocatechin, C:(+)-catechin, EC: (-)-epicatechin, EGCG: (-)-epigallocatechin gallate, GCG: (-)-gallocatechin gallate, ECG: (-)-epicatechin gallate, and CG: (-)-catechin gallate.

114

Crop, Environment & Bioinformatics, Vol. 8, June 2011

Table 3. Relative standard deviations of intra-day, inter-day, and recovery analysis of each compounds. Compound Concentration (g mL-1) 100.00 12.50 1.56 1140.00 142.50 17.81 120.00 15.00 1.88 200.00 25.00 3.13 110.00 13.75 1.72 110.00 13.75 1.72 1590.00 198.75 24.84 270.00 33.75 4.22 290.00 36.25 4.53 60.00 7.50 0.94 R.S.D. % intra-day inter-day (n=3) (n=4) 1.20 1.98 3.08 3.32 0.13 1.16 0.40 1.80 0.26 1.34 0.41 2.04 0.61 1.13 0.23 1.10 0.53 2.25 0.35 1.17 0.41 1.48 0.71 2.99 1.14 3.20 0.92 1.02 0.32 3.92 0.87 2.19 1.88 3.28 0.50 0.90 0.54 1.27 0.16 2.35 0.24 2.06 0.98 1.32 0.37 2.62 0.26 1.98 0.41 1.10 0.18 1.54 0.38 3.33 0.95 3.22 1.19 0.52 1.21 2.31 Recovery Mean S.D. (R.S.D. %) 108.821.65 (1.51) 116.590.06 (0.05) 101.840.77 (0.75) 101.120.89 (0.88) 108.581.19 (1.09) 97.560.18 (0.18) 110.190.29 (0.26) 114.460.62 (0.54) 98.450.04 (0.04) 106.190.82 (0.77) 110.840.33 (0.29) 109.371.14 (1.04) 112.540.95 (0.84) 117.450.25 (0.21) 115.710.09 (0.07) 104.100.57 (0.54) 115.120.73 (0.63) 109.890.69 (0.62) 105.481.32 (1.25) 107.161.03 (0.96) 114.610.99 (0.86) 103.950.83 (0.79) 112.710.61 (0.54) 114.480.83 (0.72) 104.860.52 (0.49) 98.011.21 (1.23) 112.780.75 (0.66) 101.510.69 (0.67) 107.730.32 (0.29) 100.410.44 (0.43)

Gallic acid

(+)-Gallocatechin

(-)-Epigallocatechin

(+)-Catechin

Caffeine

(-)-Epicatechin

(-)-Epigallocatechin gallate

(-)-Gallocatechin gallate

(-)-Epicatechin gallate

(-)-Catechin gallate

S.D.: Standard deviation; R. S. D.: Relative standard deviation. 40 min after autoclaving and the decreasing rates were 61.59, 48.84, 48.91 and 30.96%, respectively. However, contents of GA, GC, C, GCG and CG increased 2.4, 1.9, 1.1, 9.5 and 6 times, respectively. Total catechins reduced 31.36%. Oolong tea had the similar results as that of Puerh tea. The contents of EGCG, EGC, ECG and EC in Oolong tea decreased rapidly in 40 min after autoclaving and the decreasing rates were 40.17, 63.45, 37.49 and 48.99%, respectively; whereas, GA, GC, GCG and CG increased 2.1, 1.8, 15.3 and 1.4 times, respectively. Total catechins reduced 30.6%, whereas, caffeine was not decomposed by autoclaving with time. When autoclaving time reduced, contents of EGCG, EGC, ECG, and EC decreased, while contents of GC, C, GCG, and CG increased, in both Puerh tea and Oolong tea. Previous reports had similar results in the experiments of autoclaving water extract of green tea (Kim et al. 2007, Sun et al. 2004). The major reason behind the increase of GA might be the decomposition of lipid catechins under oxidization or autoclaving (Juan, et al. 1989). However, caffeine was not

Components and Antioxidant Activity in Teas after Autoclave Treatment 115

Table 4. Contents of compounds of Pu-erh tea and Oolong tea under different time periods of autoclave treatment.

CA GC EGC C EC EGCG GCG ECG CG TC

Time

GA

(min) 30.210.32b 2.430.03b 3.540.03c 3.500.02c 3.090.03d 19.890.16a 0.620.02e 0.690.01b 0.650.01d 0.670.02c 1.770.08e 1.950.01d 36.270.20d 33.560.11e 2.130.02c 40.640.34c 2.670.02b 48.740.64b 0.710.01a 3.470.04a 56.090.93a 0.640.01e 3.910.10d 6.300.06c 7.300.06b 9.800.06a 1.200.06c 1.940.03e 13.820.19e 10.380.17a 1.210.02c 2.170.02c 16.100.17d 8.800.10b 1.250.01b 2.080.04d 17.200.18c 7.240.03c 8.680.04c 8.350.09d 7.250.11e 10.990.24 10.220.85b 7.780.06c 7.270.03cd 6.870.07d 6.450.04a 1.330.01a 3.370.02a 26.470.48b 4.530.01d 10.660.05b 1.410.02c 6.040.07b 1.110.02d 2.810.03b 35.980.53a 1.090.01e 14.190.21a 0.480.01e 1.890.01d 2.150.14c 2.750.03b 2.900.02a nd 0.330.03d 0.840.01c 1.100.02b 1.410.01a 63.11 57.13 44.68 45.65 43.32 93.92 83.53 72.28 66.12 65.18

1.630.03e

10 30.490.28ab 2.540.03b 2.770.03a 2.740.01a 2.130.02e

2.640.02d 30.800.12a

Puerh

20

3.020.03c

tea 30.220.19b 23.250.13b

30

3.450.05b 30.710.27a

40

3.840.30a

0.310.01e

10 24.000.20ab 3.490.03c 3.680.03b 3.830.02a 7.270.03d 7.900.04d 10.220.08c

0.390.05d 23.940.27ab 3.190.03d 13.850.18b

Oolong

20

0.460.01c

tea 24.340.14a

30

0.640.04b 24.110.13a

40

0.660.03a

Each sample was triplicated in the test and results were mean (mg mL-1) SD. nd: not detectable.

116

Crop, Environment & Bioinformatics, Vol. 8, June 2011

decomposed by the longer autoclaving time. When tea leaves were roasted, increase of roasting time at high temperature would decrease catechins content, as in the process of autoclaving, and induced isomerization, oxidized polymerization, and degradation (Wang and Helliwell 2000, Chen et al. 2001). It was ensured that the longer the autoclaving time, the higher was the degree of epicatechins transformed into non-epicatechins. The degree of transformation of epicatechins into non-epicatechins depended on the time period of autoclaving.

100oC, but increased at temperatures higher than 120oC. When roasting temperature higher than 160oC, total phenolic content decreased (Juan et al. 1989). Results indicated that the total phenolic content decreased at 121oC under high pressure.

The DPPH Radical-scavenging Capacity of Tea Leaves after Autoclave Treatment

The DPPH free-radical scavenging ability of methanol extracts of Puerh tea and Oolong tea under different autoclaving time periods was shown in Fig. 3. At the concentration of 20 g mL-1, the scavenging ability was higher than 71.64%, no matter how long was the autoclaving time. DPPH scavenging ability depended on the extract concentration. When concentration was 5 g mL-1, DPPH scavenging ability of both extracts decreased to 7.86 to 43.63%. Scavenging ability was lower when Puerh tea and Oolong tea were autoclaved for 30 to 40 min. When comparing Puerh tea and Oolong tea with standard solutions of vitamin C and BHA, all had DPPH scavenging ability of 79.63% at the concentration of 15 to 50 g mL-1. At concentration of 5 g mL-1, the scavenging ability decreased to 22.34%. Control group of Puerh tea had the same free-radical scavenging ability as the methanol

Total Phenolic Content of Tea Leaves after Autoclave Treatment

The total phenolic content of the methanol extract of Puerh tea and Oolong tea under different autoclaving time periods was shown in Fig. 2. Results showed that total phenolic content in Oolong tea was drastically decreased to 36.95% when autoclaved for 10 min. However, total phenols in Puerh tea decreased gradually from 10 to 40 minutes, similar to previous reports (Sun et al. 2004, Wang and Helliwell 2000). Total phenolics content in green tea were decreased when autoclaved. Total phenolic content of Puerh tea and Oolong tea changed little when roasted at

Fig. 2. Effect of different time periods of autoclave treatments on content of total phenols in Puerh tea and Oolong tea. Each sample was triplicated in the test and data were average (mg g-1 ) SD.

Components and Antioxidant Activity in Teas after Autoclave Treatment

117

Fig. 3. DPPH scavenging ability of methanol extracts from Puerh tea and Oolong tea with different time periods of autoclave treatment. extract of Oolang tea control group at 5 g mL-1, when Puerh tea was autoclaved for 10 to 20 min. provide a taste of astringent, while, nonepicatechins provide bitter taste first and sweet flavor later and its astriction was weaker than epicatechins (Sun et al. 2004). Autoclaving and roasting may change color, aroma, and tastes of tea, relating to the change of chemical compounds in tea leaves.

CONCLUSIONS

As a result, autoclave treatment directly affects the transformation from epicatechins to non-epicatechins and indirectly affects the total phenolic content. Longer processing time is disadvantageous to antioxidant ability. Catechins were the source of bitter and astringent taste (Kuo 1999), especially epicatechins, EGCG and ECG. They are the components that formed the quality of tea flavor and affect the taste. Epicatechins

REFERENCES

Baletine D (1997) Tea and health. Crit. Rev. Food Sci. Nutr. 37:691-692. Chen CC (1999) Anti-carcinogenesis and antitumorigenesis of tea catechins. Food Ind.

118

Crop, Environment & Bioinformatics, Vol. 8, June 2011

31:1-15. Chen H, M Zhang, B Xie (2005) Components and antioxidant activity of polysaccharide conjugate from green tea. Food Chem. 90: 17-21. Chen ZY, QY Zhu, D Tsang, Y Huang (2001) Degradation of Green Tea Catechins in Tea Drinks. J. Agric. Food Chem. 49:477-482. Farhoosh R, GA Golmovahhed, MHH. Khodaparast (2007) Antioxidant activity of various extracts of old tea leaves and black tea wastes (Camellia sinensis L.). Food Chem. 100: 231-236. Haginaka J, H Tabo, M Ichitani, T Takihara, A Sugimoto, H Sambea (2007) Uniformly-sized, molecularly imprinted polymers for ()epigallocatechin gallate, -epicatechin gallate and -gallocatechin gallate by multi-step swelling and polymerization method. J. Chromatogr. A 1156:45-50. Ito R, A Yamamoto, S Kodama, K Kato, Y Yoshimura, A Matsunaga, H Nakazawa (2003) A study on the change of enantiomeric purity of catechins in green tea infusion. Food Chem. 83:563-568. Jain NK, MA Siddiqi, JH Weisburger (2006) Protective effects of tea on human health. CAB International, Oxfordshire, U.K. Juan IM, RH Chang, LF Chang (1989) Effects of different roasting temperature and time on chemical components and quality of pouchong tea. (in Chinese with English abstract) Taiwan Tea Res. Bull. 8:71-82. Juan IM, YL Chen (1998) Studies on the extraction and purification of catechins in tea. (in Chinese with English abstract) Taiwan Tea Res. Bull. 17:1-8. Kim ES, YR Liang, J Jin, QF Sun, JL Lu, YY Du, C Lin (2007) Impact of heating on chemical compositions of green tea liquor. Food Chem. 103:1263-1267. Kuo CH (1999) A Natural antioxidatanttea catechins. Food Ind. 31:27-33.

Li BB, B Smith, MM Hossain (2006) Extraction of phenolics from citrus peels II. Enzyme-assisted extraction method. Sep. Puri. Technol. 48:189196. Mamati GE, Y Liang, J Lu (2006) Expression of basic genes involved in tea polyphenol synthesis in relation to accumulation of catechins and total tea polyphenols. J. Sci. Food Agric. 86:459-464. Okumura HM, T Ichitani, K Takihara, K Kunimoto (2008) Effect of cyclodextrins on the thermal epimerization of tea catechins. Food Sci. Technol. Res. 14:83-88. Sanderson GW (1972) The chemistry of tea and tea manufacturing. p. 247-316. In: Recent Advances in Phytochemistry. Vol. 5. VC Runeckles, TC Tso (eds.) Academic press, New York, USA. Shimada K, K Fujikawa, K Yahara, T Nakamura (1992) Antioxidative properties of xanthan on the antioxidation of soybean oil in cycodextrin emulsion. J. Agric. Food Chem. 40:945-948. Sun QF, YR Liang, JL Lu (2004) Effect of different sterilization treatments on biochemical components in green teat liquor. J. Tea 30:146148. Tanizawa HT, S Sazuka, T Taniyama, T Hayashi, T Arich (1984) Natural Antioxidants. I. Antioxidative components of tea leaf (Thea sinensis L.). Chem. Pharm. Bull. 32:20112014. Wu GH, KL Ku, CF Chiou, CP Liu (2007) Effects of different plucking crops on shoot characters and individual catechins, and the correlations among shoot characters and individual catechins in large-leaf-type teas (in Chinese with English abstract). Crop Environ. Bioinform. 4:161-171. Wang H, K Helliwell (2000) Epimerisation of catechins in green tea infusions. Food Chem. 70:337-344. Yu SH (1992) Quality evaluation of tea drinks from tea leaves. Food Ind. 24:16-27.

Das könnte Ihnen auch gefallen

- Microwave Extraction of Polyphenol From Pomegranate Seed: Original Research ArticleDokument11 SeitenMicrowave Extraction of Polyphenol From Pomegranate Seed: Original Research ArticleFaycel OuerdienNoch keine Bewertungen

- Alice Doyle 17 19Dokument3 SeitenAlice Doyle 17 19Faycel OuerdienNoch keine Bewertungen

- Tunisia Who Aims ReportDokument31 SeitenTunisia Who Aims ReportFaycel OuerdienNoch keine Bewertungen

- Pome 2Dokument8 SeitenPome 2Faycel OuerdienNoch keine Bewertungen

- Verification Letter 2018Dokument1 SeiteVerification Letter 2018Faycel OuerdienNoch keine Bewertungen

- 2011 Boes Dauber Springnagel Organizational Culture AustriaDokument19 Seiten2011 Boes Dauber Springnagel Organizational Culture AustriaVanessa DuarteNoch keine Bewertungen

- Microwave Extraction of Polyphenol From Pomegranate Seed: Original Research ArticleDokument11 SeitenMicrowave Extraction of Polyphenol From Pomegranate Seed: Original Research ArticleFaycel OuerdienNoch keine Bewertungen

- Chocolate Covered Pretzel ShotDokument1 SeiteChocolate Covered Pretzel ShotFaycel OuerdienNoch keine Bewertungen

- PomeDokument5 SeitenPomeFaycel OuerdienNoch keine Bewertungen

- Food Hygiene PracticeDokument65 SeitenFood Hygiene PracticeFaycel OuerdienNoch keine Bewertungen

- FishDokument15 SeitenFishFaycel OuerdienNoch keine Bewertungen

- DessertDokument1 SeiteDessertFaycel OuerdienNoch keine Bewertungen

- Stainless Steel Finishing PDFDokument2 SeitenStainless Steel Finishing PDFFaycel OuerdienNoch keine Bewertungen

- Psychometric Test Training CoursesDokument1 SeitePsychometric Test Training CoursesFaycel OuerdienNoch keine Bewertungen

- Not Ready YetDokument1 SeiteNot Ready YetFaycel OuerdienNoch keine Bewertungen

- Dry Running Mechanical Seal PDFDokument4 SeitenDry Running Mechanical Seal PDFFaycel OuerdienNoch keine Bewertungen

- Organizational Culture as a Tool for Management Control and Employee PerformanceDokument11 SeitenOrganizational Culture as a Tool for Management Control and Employee PerformanceFaycel OuerdienNoch keine Bewertungen

- Mech Seals Selection Guide 2Dokument6 SeitenMech Seals Selection Guide 2taghdirimNoch keine Bewertungen

- Smarty 220 XLDokument132 SeitenSmarty 220 XLFaycel OuerdienNoch keine Bewertungen

- Stability of Essential Oils A Review PDFDokument14 SeitenStability of Essential Oils A Review PDFFaycel Ouerdien100% (1)

- Nazi EconomyDokument6 SeitenNazi EconomyFaycel OuerdienNoch keine Bewertungen

- Air Heat KW m3 HDokument3 SeitenAir Heat KW m3 HFaycel OuerdienNoch keine Bewertungen

- 145334Dokument115 Seiten145334Faycel OuerdienNoch keine Bewertungen

- Fin 1819Dokument4 SeitenFin 1819Faycel OuerdienNoch keine Bewertungen

- A Sound Idea - Phonetic Effects of Brand Names On Consumer JudgmentsDokument9 SeitenA Sound Idea - Phonetic Effects of Brand Names On Consumer JudgmentsAndré Pereira AzedoNoch keine Bewertungen

- Spirax Sarco Design of Fluid Systems 2Dokument66 SeitenSpirax Sarco Design of Fluid Systems 2mahonde100% (2)

- Vacuum Distillation Plants: Thin Film Evaporators and Short Path DistillatorsDokument12 SeitenVacuum Distillation Plants: Thin Film Evaporators and Short Path DistillatorsFaycel OuerdienNoch keine Bewertungen

- Applications of The Coanda Effect OcrDokument9 SeitenApplications of The Coanda Effect OcrFaycel OuerdienNoch keine Bewertungen

- Fin 1819Dokument4 SeitenFin 1819Faycel OuerdienNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Alberty (2002) Thermodynamics of Systems of Biochemical ReactionsDokument11 SeitenAlberty (2002) Thermodynamics of Systems of Biochemical ReactionsSultan ShaikhNoch keine Bewertungen

- Size ReductionDokument11 SeitenSize ReductionsakshiNoch keine Bewertungen

- Bioprocessing Films: Films For All Your Bioproduction NeedsDokument2 SeitenBioprocessing Films: Films For All Your Bioproduction NeedsCampaign MediaNoch keine Bewertungen

- Kiln Audit H&M Balance Calculation 2012Dokument24 SeitenKiln Audit H&M Balance Calculation 2012Anonymous 3ESYcrKP100% (7)

- Thermal Stability of Biodegradable Plastic Films Produced Using Clay From Pyata, Niger StateDokument3 SeitenThermal Stability of Biodegradable Plastic Films Produced Using Clay From Pyata, Niger StateInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Bathroom Care - Cognis' Holistic Solutions For Bathroom Care PDFDokument43 SeitenBathroom Care - Cognis' Holistic Solutions For Bathroom Care PDFtml100% (2)

- Clinker Reactivity Presentation - Sept 2012 - LafargeDokument33 SeitenClinker Reactivity Presentation - Sept 2012 - LafargeTin Nguyen100% (5)

- Prelog-Djerassi LactoneDokument4 SeitenPrelog-Djerassi Lactonealchemist90Noch keine Bewertungen

- Biresin U1404: Elastomeric Casting Resin For Mould MakingDokument2 SeitenBiresin U1404: Elastomeric Casting Resin For Mould MakingDraganNoch keine Bewertungen

- Nutrients of Bitter GourdDokument2 SeitenNutrients of Bitter GourdEva Arian JoyNoch keine Bewertungen

- CHE 4613 Radfrac ModelingDokument6 SeitenCHE 4613 Radfrac ModelingHuda AlkhouriNoch keine Bewertungen

- MicroPara LAB - M2Dokument2 SeitenMicroPara LAB - M2Gianna LingadNoch keine Bewertungen

- Advance Computational Tools For Cement PlantsDokument16 SeitenAdvance Computational Tools For Cement PlantsJomarie GañalongoNoch keine Bewertungen

- Glass Production: From Wikipedia, The Free EncyclopediaDokument10 SeitenGlass Production: From Wikipedia, The Free EncyclopediaMahfuzur Rahman SiddikyNoch keine Bewertungen

- 2020 - Kemira FennoPol Composite Polymer ABTCP Tres Lagoas Brazil - Final - 2Dokument14 Seiten2020 - Kemira FennoPol Composite Polymer ABTCP Tres Lagoas Brazil - Final - 2Carlos UngarettiNoch keine Bewertungen

- IFE Level 4 Certificate in Fire Investigation UnitDokument7 SeitenIFE Level 4 Certificate in Fire Investigation UnitFuzail AyazNoch keine Bewertungen

- Compact Heat Exchangers Selection Application Design and Evaluation PDFDokument128 SeitenCompact Heat Exchangers Selection Application Design and Evaluation PDFFabio GuedesNoch keine Bewertungen

- GTU BE Semester V Mass Transfer Operations I exam questionsDokument3 SeitenGTU BE Semester V Mass Transfer Operations I exam questionsShivam PanchalNoch keine Bewertungen

- Elems 06Dokument101 SeitenElems 06Reynald de VeraNoch keine Bewertungen

- IFA Atex WoodDokument7 SeitenIFA Atex Woodrafabustamante7651Noch keine Bewertungen

- Modelling The Seismic Response of An Unreinforced Masonry StructureDokument152 SeitenModelling The Seismic Response of An Unreinforced Masonry Structurecandsbanda100% (1)

- Böhler 70t4 enDokument1 SeiteBöhler 70t4 enValentin Hernández TrianoNoch keine Bewertungen

- Soils and Granular Materials Mechanical PropertiesDokument41 SeitenSoils and Granular Materials Mechanical Propertiesmadhav choudharyNoch keine Bewertungen

- A Timeline of Atomic Spectroscopy: Volker ThomsenDokument11 SeitenA Timeline of Atomic Spectroscopy: Volker ThomsencamiloNoch keine Bewertungen

- BCS theory explains superconductivityDokument3 SeitenBCS theory explains superconductivitySobuj RajNoch keine Bewertungen

- June 2015 (IAL) QP - Unit 1 Edexcel Chemistry A-LevelDokument21 SeitenJune 2015 (IAL) QP - Unit 1 Edexcel Chemistry A-LevelNabindra RuwaliNoch keine Bewertungen

- Organic Chemistry - Unit 5Dokument4 SeitenOrganic Chemistry - Unit 5RUGRLNNoch keine Bewertungen

- Compressed Gases ChecklistDokument3 SeitenCompressed Gases ChecklistImam FirdausNoch keine Bewertungen

- G 75 - 95 Rzc1lvjfra - PDFDokument22 SeitenG 75 - 95 Rzc1lvjfra - PDFWaldomiroCanoNoch keine Bewertungen

- Process Safety-24.04.17 1Dokument232 SeitenProcess Safety-24.04.17 1Rupal PandyaNoch keine Bewertungen