Beruflich Dokumente

Kultur Dokumente

Refrigerator

Hochgeladen von

Rasel IslamOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Refrigerator

Hochgeladen von

Rasel IslamCopyright:

Verfügbare Formate

Introduction Refrigeration is a process in which work is done to move heat from a low temperature to a high temperature and typically

also from one location to another. The work of heat transport is traditionally driven by mechanical work, but can also be driven by

heat, magnetism, electricity, laser, or other means. Refrigeration has many applications, including, but not limited to: household refrigerators, industrial freezers, cryogenics, and air conditioning. Heat pumps may use the heat output of the refrigeration process, and also may be designed to be reversible, but are otherwise similar to refrigeration units. Unit of Refrigeration: Capacity of refrigeration unit is generally defined in ton of refrigeration. A ton of refrigeration is defined as the quantity of heat to be removed in order to form one ton (1000 kg) of ice at 00C in 24 hrs, from liquid water at 00C. This is equivalent to 3.5 kJ/s (3.5 kW) or 210 kJ/min. Methods of refrigeration can be classified as Non-cyclic, cyclic, thermoelectric and magnetic. Non-cyclic refrigeration In non-cyclic refrigeration, cooling is accomplished by melting ice or by subliming dry ice (frozen carbon dioxide). These methods are used for small-scale refrigeration such as in laboratories and workshops, or in portable coolers. Cyclic refrigeration This consists of a refrigeration cycle, where heat is removed from a low-temperature space or source and rejected to a high-temperature sink with the help of external work, and its inverse, the thermodynamic power cycle. In the power cycle, heat is supplied from a high-temperature source to the engine, part of the heat being used to produce work and the rest being rejected to a low-temperature sink. This satisfies the second law of thermodynamics. The most common types of refrigeration systems use the reverse-Rankine vapor-compression refrigeration cycle, although absorption heat pumps are used in a minority of applications.

Cyclic refrigeration can be classified as: 1. Vapor cycle, and 2. Gas cycle Vapor cycle refrigeration can further be classified as: 1. Vapor-compression refrigeration 2. Vapor-absorption refrigeration Vapor compression refrigeration: The vapor-compression cycle is used in most household refrigerators as well as in many large commercial and industrial refrigeration systems. Figure 1 provides a schematic diagram of the components of a typical vapor-compression refrigeration system.

Figure 1: Vapor compression refrigeration

Vapor compression refrigerator System There are six main components in a refrigeration system The Compressor The Condenser The Metering Device or expansion valve The Evaporator

Compressor It is heart of the refrigeration system as it circulates the refrigerant in the system like the heart of a human being circulating the blood in the body. The inlet to the compressor is called the Suction Line. It brings the low pressure vapor into the compressor. After the compressor compresses the refrigerant into a high pressure Vapor, and the outlet of the compressor is called the Discharge Line. Condenser The Discharge Line leaves the compressor and runs to the inlet of the condenser. Because the refrigerant was compressed, it is a hot high pressure vapor.

The hot vapor enters the condenser and starts to flow through the tubes. Cool air is blown across the outside of the finned tubes of the condenser (usually air by a fan or water with a pump). Since the air is cooler than the refrigerant, heat jumps from the tubing to the cooler air (energy goes from hot to cold latent heat).

As the heat is removed from the refrigerant, it reaches its saturated temperature and starts to change state, into a high pressure liquid. The high pressure liquid leaves the condenser through the liquid line and travels to the metering device through a filter dryer to remove any dirt or foreign particles.

Expansion Valve Expansion Valve regulate how much liquid refrigerant enters the evaporator as per heat load on evaporator. Now we have a low pressure, cooler liquid refrigerant entering the evaporative coil.

Evaporator The evaporator is where the heat is removed from your house, business or be cooled. Low pressure liquid leaves the metering device and enters the evaporator. Usually, a fan will move warm air from the conditioned space across the evaporator finned coils. The cooler refrigerant in the evaporator tubes, absorb the warm room air. The change of temperature causes the refrigerant to flash or boil, and changes from a low pressure liquid to a low pressure cold vapor. The low pressure vapor is pulled into the compressor and the cycle starts over. products to

Application of Refrigerator: In chemical industries, for separating and liquefying the gases. In manufacturing and storing ice. For the preservation of perishable food items in cold storages. For cooling water. For controlling humidity of air manufacture and heat treatment of steels. For chilling the oil to remove wax in oil refineries. For the preservation of tablets and medicines in pharmaceutical industries. For the preservation of blood tissues etc., For comfort air conditioning the hospitals, theatres, etc.,

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elements of ArtDokument1 SeiteElements of Artsamson8cindy8louNoch keine Bewertungen

- Chronic Kidney DiseaseDokument15 SeitenChronic Kidney Diseaseapi-270623039Noch keine Bewertungen

- Log Building News - Issue No. 76Dokument32 SeitenLog Building News - Issue No. 76ursindNoch keine Bewertungen

- Carriage RequirementsDokument63 SeitenCarriage RequirementsFred GrosfilerNoch keine Bewertungen

- GPS Spoofing (2002-2003)Dokument8 SeitenGPS Spoofing (2002-2003)Roger JohnstonNoch keine Bewertungen

- TIMO Final 2020-2021 P3Dokument5 SeitenTIMO Final 2020-2021 P3An Nguyen100% (2)

- Hima OPC Server ManualDokument36 SeitenHima OPC Server ManualAshkan Khajouie100% (3)

- Organization and Management Module 3: Quarter 1 - Week 3Dokument15 SeitenOrganization and Management Module 3: Quarter 1 - Week 3juvelyn luegoNoch keine Bewertungen

- EWU PHRM 410 Lecture Slide 1 PDFDokument20 SeitenEWU PHRM 410 Lecture Slide 1 PDFRasel IslamNoch keine Bewertungen

- Adrenal Gland1Dokument27 SeitenAdrenal Gland1Rasel IslamNoch keine Bewertungen

- Major Intra and Extracellular IonsDokument29 SeitenMajor Intra and Extracellular IonsRasel IslamNoch keine Bewertungen

- Biochemistry - PPT 01Dokument28 SeitenBiochemistry - PPT 01Rasel IslamNoch keine Bewertungen

- Rule 113 114Dokument7 SeitenRule 113 114Shaila GonzalesNoch keine Bewertungen

- Assessment of Students' Oral Communication in English ClassDokument10 SeitenAssessment of Students' Oral Communication in English ClassKeebeek S ArbasNoch keine Bewertungen

- IKEA SHANGHAI Case StudyDokument5 SeitenIKEA SHANGHAI Case StudyXimo NetteNoch keine Bewertungen

- Laboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)Dokument76 SeitenLaboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)gyanendraNoch keine Bewertungen

- Post Appraisal InterviewDokument3 SeitenPost Appraisal InterviewNidhi D100% (1)

- Opc PPT FinalDokument22 SeitenOpc PPT FinalnischalaNoch keine Bewertungen

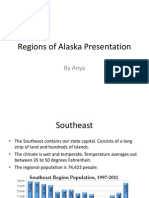

- Regions of Alaska PresentationDokument15 SeitenRegions of Alaska Presentationapi-260890532Noch keine Bewertungen

- RSA - Brand - Guidelines - 2019 2Dokument79 SeitenRSA - Brand - Guidelines - 2019 2Gigi's DelightNoch keine Bewertungen

- Lithuania DalinaDokument16 SeitenLithuania DalinaStunt BackNoch keine Bewertungen

- Chemistry: Crash Course For JEE Main 2020Dokument18 SeitenChemistry: Crash Course For JEE Main 2020Sanjeeb KumarNoch keine Bewertungen

- Farmer Producer Companies in OdishaDokument34 SeitenFarmer Producer Companies in OdishaSuraj GantayatNoch keine Bewertungen

- Vendor Information Sheet - LFPR-F-002b Rev. 04Dokument6 SeitenVendor Information Sheet - LFPR-F-002b Rev. 04Chelsea EsparagozaNoch keine Bewertungen

- Dtu Placement BrouchureDokument25 SeitenDtu Placement BrouchureAbhishek KumarNoch keine Bewertungen

- Solved Simplex Problems PDFDokument5 SeitenSolved Simplex Problems PDFTejasa MishraNoch keine Bewertungen

- Revenue and Expenditure AuditDokument38 SeitenRevenue and Expenditure AuditPavitra MohanNoch keine Bewertungen

- Chapter 13 Exercises With AnswerDokument5 SeitenChapter 13 Exercises With AnswerTabitha HowardNoch keine Bewertungen

- BMOM5203 Full Version Study GuideDokument57 SeitenBMOM5203 Full Version Study GuideZaid ChelseaNoch keine Bewertungen

- Lec 33 - Householder MethodDokument11 SeitenLec 33 - Householder MethodMudit SinhaNoch keine Bewertungen

- ME Eng 8 Q1 0101 - SG - African History and LiteratureDokument13 SeitenME Eng 8 Q1 0101 - SG - African History and Literaturerosary bersanoNoch keine Bewertungen

- Hdfs Default XML ParametersDokument14 SeitenHdfs Default XML ParametersVinod BihalNoch keine Bewertungen

- Networker Performance Tuning PDFDokument49 SeitenNetworker Performance Tuning PDFHarry SharmaNoch keine Bewertungen

- Application Activity Based Costing (Abc) System As An Alternative For Improving Accuracy of Production CostDokument19 SeitenApplication Activity Based Costing (Abc) System As An Alternative For Improving Accuracy of Production CostM Agus SudrajatNoch keine Bewertungen