Beruflich Dokumente

Kultur Dokumente

Variable Body Bias Thesis-Libre

Hochgeladen von

riyazpashaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Variable Body Bias Thesis-Libre

Hochgeladen von

riyazpashaCopyright:

Verfügbare Formate

An Efficient Approach to Low-leakage

Power VLSI Design using Variable Body

Biasing

A thesis Presented

By

Md. Asif Jahangir Chowdhury

Student Id. 0606047

&

Md. Shahriar Rizwan

Student Id. 0606072

In partial fulfillment of the

Requirements for the B.Sc in

Electrical and Electronics Engineering

Department of Electrical and Electronics Engineering,

BUET, Bangladesh

March 2012

iii

Bangladesh University of Engineering

and Technology

CERTIFICATE

This is to certify that the thesis report entitled An Efficient Approach to Low-

leakage Power VLSI Design using Variable Body Biasing submitted by Md. Asif

Jahangir Chowdhury, (student id. 0606047), and Md. Shahriar Rizwan, (student id.

0606072) in partial fulfillment of the requirements for the award of B.Sc degree in

Department of Electrical and Electronics Engineering in Bangladesh University of

Engineering and Technology is an authentic work under my supervision and guidance.

To the best of my knowledge, the matter embodied in the thesis has not been submitted

to any other University / Institute for the award of any Degree or Diploma.

Approved by:

Dr. Md. Shafiqul Islam

Professor

Department of Electrical And Electronics Engineering

BUET.

iv

Dedicated

To Our Parents

v

ACKNOWLEDGEMENTS

We would like to express our sincere gratitude and appreciation to everyone who made

this thesis possible. Most of all, we would like to thank our advisor, Professor Dr. Md.

Shafiqul Islam for giving us the opportunity to work under him and lending every

support at every stage of this thesis. We are deeply indebted to his esteemed guidance,

constant encouragement and fruitful suggestions from the beginning to the end of this

thesis. His trust and support inspired us in the most important moments of making right

decisions and we are delighted to work under his supervision.

We would also like to express our gratitude to our beloved parents who inspired us in

each and every step of our lives.

THE AUTHORS

vi

TABLE OF CONTENTS

DEDICATION ......................................................................................................... IV

ACKNOWLEDGEMENTS ...................................................................................... V

LIST OF TABLES ................................................................................................ VIII

LIST OF FIGURES ................................................................................................. IX

LIST OF SYMBOLS OR ABBREVIATIONS ....................................................... XI

ABSTRACT ........................................................................................................... XII

CHAPTER 1: INTRODUCTION........................................................................... 14

1.1 PROBLEM STATEMENT .................................................................................. 16

1.2 CONTRIBUTIONS ...................................................................................... 16

1.3 THESIS ORGANIZATION ........................................................................... 17

CHAPTER 2: MOTIVATION ............................................................................... 18

CHAPTER 3: NOTATION AND BACKGOUND .................................................. 22

3.1 LEAKAGE POWER ............................................................................................... 22

3.2 SRAM CELL LEAKAGE PATHS ............................................................................ 26

3.3 SWITCHING POWER AND DELAY TRADEOFFS........................................................ 27

3.4 CIRCUIT PERFORMANCE ESTIMATION ................................................................. 28

CHAPTER 4: PREVIOUS WORKS ...................................................................... 31

4.1 STATIC POWER REDUCTION VLSI RESEARCH ..................................................... 31

4.1.1 Static power reduction research for generic logic circuits .......................... 31

4.1.1.1 Sleep transistor .................................................................................... 32

4.1.1.2 Forced Stack ........................................................................................ 33

4.1.1.3 Sleepy Stack ........................................................................................ 34

4.1.1.4 Sleepy keeper ...................................................................................... 35

4.1.1.5 Dual Sleep ........................................................................................... 36

4.1.1.6 Dual Stack ........................................................................................... 37

vii

4.1.2 Static power reduction research for SRAM ................................................. 38

4.1.2.1 Sleep transistor .................................................................................... 38

4.1.2.2 Dual Sleep ........................................................................................... 39

4.1.2.3 Dual Stack ........................................................................................... 40

4.1.2.4 Sleepy Keeper in SRAM ...................................................................... 41

CHAPTER 5: VARIABLE BODY BIASING TECHNIQUE ................................ 42

5.1 VARIABLE BODY BIASING APPROACH .................................................................. 42

5.2 VARIABLE BODY BIASING STRUCTURE ................................................................ 43

5.3 VARIABLE BODY BIASING OPERATION ................................................................. 44

5.4 ANALYSIS OF SUBTHRESHOLD LEAKAGE REDUCTION .......................................... 45

5.5 ESTIMATION OF DELAY FOR VARIABLE BODY BIASING TECHNIQUE ....................... 46

CHAPTER 6: EXPERIMENTAL RESULTS ....................................................... 48

6.1 EXPERIMENTAL RESULTS FOR GENERAL LOGIC CIRCUITS ..................................... 48

6.1.1 Experimental results for CO4 ..................................................................... 48

6.1.2 Experimental results for FA ....................................................................... 54

6.2 EXPERIMENTAL RESULTS FOR SRAM ................................................................. 59

6.3 COMPARISON WITH PREVIOUS METHODS ............................................................. 63

CHAPTER 7: CONCLUSION ............................................................................... 65

7.1 CONCLUSION ........................................................................................... 65

7.2 SUGGESTIONS FOR FUTURE WORK ............................................. 66

APPENDIX .............................................................................................................. 67

A. AREA ESTIMATION .................................................................................... 67

B. CIRCUIT DIAGRAMS .................................................................................. 67

BIBLIOGRAPHY .............................................................................................. 73

viii

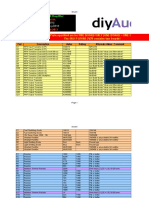

LIST OF TABLES

Table 1 Power and area results from [15] ................................................................... 19

Table 2 Energy consumption scenario of a cell phone (0.07) from [15] .................... 20

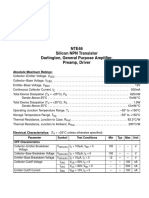

Table 3 Leakage model parameters (0.5 tech) ........................................................... 25

Table 4 Chosen technology and V

dd

value .................................................................. 48

Table 5 Static power data for chain of 4 inverters (nano watt) .................................... 49

Table 6 Dynamic power data for chain of 4 inverters (micro watt) ............................. 50

Table 7 propagation delay data for chain of 4 inverters (Pico seconds) ....................... 51

Table 8 Power delay Product data for chain of 4 inverters (femto joule) ..................... 52

Table 9 Area delay data for chain of 4 inverters (m

2

) ............................................... 53

Table 10 Static power data for 1 bit full adder (nano watt) ......................................... 54

Table 11 Dynamic power data for 1 bit full adder (micro watt) .................................. 55

Table 12 Data of propagation delay for 1 bit full adder (nano second) ........................ 56

Table 13 Power delay product data for 1 bit full adder (femto joule) .......................... 57

Table 14 Area data for 1 bit full adder (m

2

) .............................................................. 58

Table 15 Static power data for SRAM (nano watt) ..................................................... 59

Table 16 Dynamic power data for SRAM (micro watt) .............................................. 60

Table 17 Data of propagation delay for SRAM (nano second) .................................... 61

Table 18 Power delay product data for SRAM (femto joule) ...................................... 62

Table 19 Area data for SRAM (m

2

) ......................................................................... 62

Table 20 Comparison of VBB Approach for a Chain of Four Inverters (for 90 nm

process) ..................................................................................................................... 64

Table 21 Comparison of VBB Approach for a 1 bit full adder (for 90 nm process) ..... 64

Table 22 Comparison of VBB Approach for a SRAM (for 90 nm process) ................. 64

ix

LIST OF FIGURES

Figure 1 Sub-threshold leakage of an nFET ................................................................ 22

Figure 2 (a) A single transistor (left) and (b) stacked transistors (right) ...................... 23

Figure 3 SRAM cell leakage paths ............................................................................. 26

Figure 4 logical efforts of basic logic gates ................................................................ 29

Figure 5 Sleep transistor............................................................................................. 32

Figure 6 Forced Stack ............................................................................................. 33

Figure 7 sleepy stack .................................................................................................. 34

Figure 8 Sleepy keeper ............................................................................................... 35

Figure 9 Dual Sleep ................................................................................................... 36

Figure 10 Dual Stack ................................................................................................. 37

Figure 11 SLEEP TRANSISTOR IN SRAM.............................................................. 38

Figure 12 DUAL SLEEP IN SRAM ....................................................................... 39

Figure 13 DUAL STACK IN SRAM ...................................................................... 40

Figure 14 SLEEPY KEEPER IN SRAM................................................................. 41

Figure 15 An Inverter with (a) Sleepy Keeper (left) (b) Variable body biasing structure (right) .... 43

Figure 16 (a) Sleep transistor without body biasing transistor ..................................... 45

Figure 17 (a) Inverter with VBB Technique (left) (b) Inverter of equal strength (right) ........ 46

Figure 18 Static Power Consumption (CO4) .............................................................. 49

Figure 19 Dynamic power consumption (CO4) .......................................................... 50

Figure 20 Propagation delay (CO4) ............................................................................ 51

Figure 21 power delay product ................................................................................... 52

Figure 22 Area comparison (CO4) ............................................................................. 53

Figure 23 Static power consumption for FA ............................................................... 54

Figure 24 Dynamic power consumption for FA .......................................................... 55

Figure 25 Propagation delay comparison in FA .......................................................... 56

Figure 26 Power Delay Product for FA ...................................................................... 57

Figure 27 Area Comparison for FA ............................................................................ 58

Figure 28 Static power consumption for SRAM cell .................................................. 59

Figure 29 Dynamic power consumption for SRAM .................................................... 60

Figure 30 Propagation delay comparison for SRAM .................................................. 61

x

Figure 31 Power Delay Product of SRAM.................................................................. 62

Figure 32 Area comparison for SRAM ....................................................................... 63

Figure 33 SLEEP TRANSISTOR .............................................................................. 67

Figure 34 FORCED STACK METHOD ................................................................. 68

Figure 35 SLEEPY KEEPER METHOD ................................................................ 68

Figure 36 DUAL SLEEP METHOD ....................................................................... 69

Figure 37 DUAL STACK METHOD ..................................................................... 69

Figure 38 VARIABLE BODY BIASING TECHNIQUE ........................................ 70

Figure 39 SLEEPY KEEPER (FA) ......................................................................... 71

Figure 40 DUAL SLEEP (FA) ................................................................................ 71

Figure 41 DUAL STACK (FA) .............................................................................. 72

Figure 42 VBB (FA) ............................................................................................... 72

xi

LIST OF SYMBOLS OR ABBREVIATIONS

6-T 6 Transistors.

CMOS Complementary Metal Oxide Semiconductor.

CO4 Chain of 4 Inverter

DIBL Drain Induced Barrier Lowering.

FBB Forward-Body Bias.

FA Full Adder

ITRS International Technology Roadmap for Semiconductors.

MTCMOS Multi-Threshold-voltage CMOS.

RBB Reverse-Body Bias.

SRAM Static Random Access Memory.

VLSI Very Large Scale Integration

ZBB Zero Body Bias

VBB Variable Body Bias

xii

ABSTRACT

The ubiquitous era of emerging portable devices demands long battery life time as a

primary design goal. Subthreshold circuit design can reduce energy per cycle in an

order of magnitude of nominal operating circuits by scaling power supply voltage (V

dd

)

below the device threshold voltage. But, it lowers signicantly circuit performance as a

penalty. Stringent energy budget and moderate speed requirements of ultra low power

systems in the market may not be best satised just by scaling a single supply voltage.

Optimized circuits with dual supply voltages provide an opportunity to resolve these

demands.

The primary focus of this thesis is to provide more efficient low-power solutions for

Very Large Scale Integration (VLSI) designers. Especially, we concentrate on leakage

power reduction. Although leakage power was negligible at 0.18 technology and

above, in nano scale technology, such as 0.07, leakage power is almost equal to

dynamic power consumption.

In this thesis we present a new CMOS circuit design technique called VARIABLE

BODY BIASING. This structure dramatically reduces leakage. It tries to combine the

good features from the sleep transistor technique, sleepy keeper technique, dual sleep

technique and dual stack technique. The sleepy transistor technique can achieve ultra-

low leakage power consumption, but loses logic state during sleep mode. Sleepy

keeper, dual sleep and dual stack technique can retain state but the static power

consumption is not satisfactory in these methods. To get satisfactory leakage power

dual - V

th

is a must for these techniques. We know using body biasing we can control

the threshold voltage. If a voltage difference is created between body and source of a

MOSFET the threshold voltage increases. With the increase of the threshold voltage

leakage current decreases resulting in a decrease in Static Power or Leakage power. If

high- V

th

MOS is used in the circuit (i.e. sleepy keeper, dual sleep, dual stack) delay

increases. So if we can make such arrangements so that the V

th

of the sleep transistors

remains low during active mode and becomes high in sleep mode both leakage power

and delay can be checked within desired limits. In our design we have designed this

arrangement.

xiii

In sleep transistor there are two sleep transistors, one PMOS and one NMOS. In our

design we have added another two transistors; one PMOS and one NMOS in such way

that the drain of the added MOS is connected to the body of the sleep transistors

respectively, the gates and source are in parallel. With this arrangement we also added

two MOS like sleepy keeper technique to save state. So when the circuit is in active

mode, there is now voltage difference between the body and source in the sleep

transistors as the added transistors are on and offer no resistance between the body and

source (means body and source are short). When the circuit is in sleep mode there is a

high resistance between body and source resulting in a higher - V

th

. Consequently, the

leakage power consumed reduces. Moreover, due to low - V

th

during active mode delay

remains in a reasonable range.

One of the advantages of the Variable Body Biasing technique is saving state.

Therefore, the Variable Body Biasing technique can be applicable memory design,

i.e., Static Random Access Memory (SRAM). When we apply the sleepy stack to

SRAM cell design, we can observe new Pareto points which have not been presented

prior to the research in this thesis. Although the Variable Body Biasing incurs some

area overheads, the Variable Body Biasing SRAM cell can achieve ultra-low leakage

power consumption while suppressing two main leakage paths in an SRAM cell. When

compared to a high-V

th

SRAM cell, which is the best prior state-saving SRAM cell.

14

CHAPTER 1

INTRODUCTION

Ultra-low power applications such as micro-sensor networks, pacemakers, and many

Portable devices require extreme energy constraint for long battery life time.

Subthreshold operation presents an opportunity for such energy-constrained

applications with its very low energy consumption [1-6]. Subthreshold circuits oer a

promising solution for implementing highly energy-constrained systems in clock ranges

of low to medium frequencies for remote or mobile applications.

As the power supply voltage (V

dd

) is scaled below the device threshold voltage (V

th

),

the subthreshold current ever so slowly charges and discharges nodes for the circuits

logic function [4]. This weak driving current inherently limits the performance but

minimum energy operation of the circuit is achieved with reduced dynamic and leakage

power, resulting in long battery life [7-9].

In the past decades, subthreshold circuit design was not well recognized in the area of

digital circuits as high performance demand was a major concern. Lately, however,

portability has become a trend in the electronics market place. Low energy per

operation is a primary design parameter in such applications. Without the performance

requirement, a subthreshold circuit can operate at its minimum energy operating point

that is only slightly above the absolute minimum voltage [10] that would guarantee the

correct logic function. Even for applications requiring high peak performance, ultra-

dynamic voltage scaling (UDVS) [11] can provide an opportunity for subthreshold

circuit design that would switch between a nominal voltage high performance mode

and an energy ecient subthreshold mode according to the system work load.

Before the mobile era, power consumption has been a fundamental problem. To solve

the power dissipation problem, many researchers have proposed different ideas from

the device level to the architectural level and above. However, there is no universal way

15

to avoid tradeoffs between power, delay and area, and thus designers are required to

choose appropriate techniques that satisfy application and product needs. Power

consumption of CMOS consists of dynamic and static components. Dynamic power is

consumed when transistors are switching, and static power is consumed regardless of

transistor switching. Dynamic power consumption was previously (at 0.18

technology and above) the single largest concern for low-power chip designers since

dynamic power accounted for 90% for more of the total chip power. Therefore, many

previously proposed techniques, such as voltage and frequency scaling, focused on

dynamic power reduction. However, as the feature size shrinks, e.g., to 0.09 and

0.065, static power has become a great challenge for current and future technologies.

Based on the International Technology Roadmap for Semiconductors (ITRS) [12] Kim

et al. report that sub threshold leakage power dissipation of a chip may exceed dynamic

power dissipation at the 65nm feature size [13] .One of the main reasons causing the

leakage power increase is increase of sub threshold leakage power. When technology

feature size scales down, supply voltage and threshold voltage also scale down. Sub

threshold leakage power increases exponentially as threshold voltage decreases.

Furthermore, the structure of the short channel device lowers the threshold voltage even

lower. In addition to sub threshold leakage, another contributor to leakage power is

gate-oxide leakage power due to the tunneling current through the gate-oxide insulator.

Since gate-oxide thickness will be reduced as the technology decreases, in nano-scale

technology, gate-oxide leakage power may be comparable to sub threshold leakage

power if not handled properly. However, we assume other techniques will address gate-

oxide leakage; for example, high-k dielectric gate insulators may provide a solution to

reduce gate-leakage [13]. Therefore, this thesis focuses on reducing sub threshold

leakage power consumption.

There are quite a few static power reduction methods present currently. Most of these

try to establish a balance between power and delay trade-off by implementing different

techniques. One of the most effective dynamic power reduction techniques is lowering

the supply voltage of CMOS transistors because the power consumption of CMOS

transistors increases quadratically proportional to the supply voltage. However,

lowering the supply voltage incurs an increase in transistor switching delays. Therefore,

designing CMOS circuits typically necessitates tradeoffs between performance (in

terms of delay) and power consumption. In this dissertation, we provide a circuit

16

structure named variable body biasing as a new remedy for designers in terms of static

power. With almost 95% reduction of static power, the variable body biasing method

does not degrade the delay or dynamic power consumption of the circuit, which makes

this approach a very attractive one for the circuit designers.

1.1 Problem Statement

This research work addresses new low power approaches for Very Large Scale

Integration (VLSI) logic and memory. Power dissipation is one of the major concerns

when designing a VLSI system. Until recently, dynamic power was the only concern.

However, as the technology feature size shrinks, static power, which was negligible

before, becomes an issue as important as dynamic power. Since static power increases

dramatically (indeed, even exponentially) in nano-scale silicon VLSI technology, the

importance of reducing leakage power consumption cannot be overstressed. A well-

known previous technique called the sleep transistor technique cuts off V

dd

and/or Gnd

connections of transistors to save leakage power consumption. However, when

transistors are allowed to float, a system may have to wait a long time to reliably

restore lost state and thus may experience seriously degraded performance. Therefore,

retaining state is crucial for a system that requires fast response even while in an

inactive state. Our research provides new VLSI techniques that achieve ultra-low

leakage power consumption while maintaining logic state, and thus can be used for a

system with long inactive times but a fast response time requirement.

1.2 Contributions

The following items are the main contributions of this research:

Design of Variable body biasing technique for logic circuits

The VARIABLE BODY BIASING technique is applied to generic logic circuits, and

we achieve orders of magnitude leakage power reduction compared to the best prior

state saving technique we could find (namely, sleepy stack [14,15], sleepy keeper [16],

dual sleep [17], dual stack [18]).

Design of a Variable body biasing SRAM cell

17

Static Random Access Memory (SRAM) is a power hungry component in a VLSI chip.

Therefore, we apply the VARIABLE BODY BIASING technique to SRAM design.

We provide new Pareto points that can be used by designers who want extremely low

leakage power consumption.

1.3 Thesis organization

The thesis is organized into eight chapters:

CHAPTER 1: INTRODUCTION. This chapter introduces power consumption issues in

VLSI. This chapter also summarizes the contributions of this thesis. Finally, this

chapter explains organization of the thesis.

CHAPTER 2: MOTIVATION. This chapter addresses our motivation for this research.

CHAPTER 3: NOTATION AND BACKGROUND. This chapter explains important

notation and background used throughout this dissertation.

CHAPTER 4: PREVIOUS WORK. This chapter describes previous work in power

reduction research and explains key differences between our solutions and previous

work.

CHAPTER 5: VARIABLE BODY BIASING TECHNIQUE APPLICATION. This

chapter introduces the VARIABLE BODY BIASING technique. First the structure of

the circuit is explained followed by a detailed explanation of the circuit operation. An

analytical model of the circuit is derived and compared to the previous techniques.

CHAPTER 6: EXPERIMENTAL RESULTS. This chapter discusses the experimental

results from various applications of the technique. The variable body biasing

technique is empirically compared to well-known previous approaches. The

comparisons are assessed in terms of static power, dynamic power, delay, power delay

product and area occupied while changing numerous VLSI and CMOS circuit

parameters.

CHAPTER 7: CONCLUSION. This chapter summarizes the major accomplishments of

this thesis.

18

CHAPTER 2

MOTIVATION

Subthreshold circuit design is suitably applicable for emerging portable applications

that need tremendously low energy operation. The limitation of this technique is very

slow speed of operation due to the extremely scaled down supply voltage. Despite a

very high energy eciency, the subthreshold design has been applied only in niche

markets due to its low performance. Depending upon the application, size, weight and

cost can be equally important as performance. Especially for remote, portable and

mobile applications, low-power has signicance. Reduced power consumption makes

the circuits lighter, reduces or eliminates cooling subsystems, and reduces the weight

and extends the life of the energy source.

The multi-V

dd

technique has been widely implemented for two supply voltages [19].

The dual-V

dd

design is best suited for exploiting the time slack in a subthreshold circuit

as well. Although the gate delay exponentially depends on V

dd

in the subthreshold

region it may be possible to nd an optimal lower supply voltage for the available time

slack in the circuit. A DC to DC voltage converter [20] will then allow the voltage

management.

Historically, in the 1980s CMOS technology took over the mainstream of VLSI

design because CMOS consumes far less power than its predecessors (NMOS, bipolar,

etc.). Although this advantage still holds, power dissipation of CMOS has nonetheless

become a problem. For a long time, dynamic power accounted for more than 90%

(typically, over 99%) of total chip power, and thus was frequently used as the metric

for total power consumption for technologies 0.18 and above. However, as technology

scales down to tens of nanometers, leakage power becomes as important as dynamic

power. Therefore, many ideas have been proposed to tackle the leakage power problem.

Although cutting off transistors from power rails, e.g., using the sleep transistor

19

technique, is one of the possible solutions, losing state during inactive mode incurs long

wake-up time and thus may not be appropriate for a system that requires fast response

times.

To provide a motivational scenario to illustrate the possible impact of this thesis, let us

compare the impact of static (leakage) power consumption in the context of a cell

phone example. We assume that in general, the cell phone we consider is always on

(i.e., 24 hours a day). However, the actual usage time of the cell phone is very limited.

If we assume a 500 minute calling plan with 500 minutes total used per month, the cell

phone is active only 1.15% (500min/(30Joys 24 bours 60mins)) of the total

on-time. This means that during rest 98.85% of the time the cell phone is non-

active; however, due to static power consumption, during rest (standby) the cell phone

still consumes energy and reduces battery life. In technology such as 0.07, the impact

of leakage power is huge. Let us consider an energy consumption scenario of a cell

phone predicted based on experimental results from [15]. Specifically, Table 1 shows

some specific results from [15] for 0.07 technology at 25oC. Table 2 shows a

hypothetical energy consumption scenario.

Table 1 Power and area results from [15]

Forced Stack Sleepy Stack

Active

Power(W)

Leakage Power

(W)

Area (

2

) Active

Power(W)

Leakage Power

(W)

Area (

2

)

4

inverters

1.25E-06 9.81E-10 5.97E+00 1.09E-06 4.56E-12 9.03E+00

512B

SRAM

5.22E-04 5.39E-06 2.00E+01 5.80E-04 3.24E-07 3.66E+01

20

Table 2 Energy consumption scenario of a cell phone (0.07) from [15]

Forced stack Sleepy stack

Active

power

(W)

Leakage

power (W)

Area (

2

) Energy (J)

(Month)

Active

power

(W)

Leakage

power

(W)

Area (

2

) Energy (J)

(Month)

Processor

logic

circuits

1.38E-01 1.02E-01 6.61E+05 2.65E+05 1.47E-01 5.74E-04 1.21E+06 5.87E+03

32KB

SRAM

5.54E-03 4.15E-02 6.61E+05 1.06E+05 6.09E-03 2.44E-03 1.21E+06 6.44E+03

TOTAL 1.43E-01 1.43E-01 1.32E+06 3.72E+05 1.53E-01 3.01E-03 2.42E+06 1.23E+04

First, we assume a single chip containing an embedded processor core in 0.07

technology. The chip largely consists of logic circuits and a 32KB SRAM; note that

we exclude I/Os and the pad frame. Furthermore, we only consider here the digital

chip; i.e., the liquid crystal display, Radio Frequency (RF) circuitry, etc., are all

ignored. Second, we assume that SRAM and logic circuits each occupy half of the

digital chip area, respectively. We estimate 32KB SRAM area based on SRAM cell

area which we will present in Chapter 5 note that in all cases we exclude test, e.g., our

SRAM does not include Built-In Self Test (BIST). The forced stack 32KB SRAM area

is 6.61 10

5

2

, and the sleepy stack SRAM area is 1.21 10

6

2

. Then we estimate

that the processor logic gates occupy the same amount of area as the 32KB SRAM as

shown in the area columns of Table 2.

Third, we also assume that at 0.07 technology leakage power consumption is as much

as active power consumption when we use the forced stack technique. We multiply

forced stack leakage values from Table 1 by a factor (specifically, 939), so that forced

stack leakage power becomes the same as forced stack active power, i.e., 143mW. Then

we apply the same factor (939) to the sleepy stack leakage power from Table 1,

resulting in sleepy stack leakage power of 3.01mW. In other words, while Table 1 is

based on Berkeley Predicted Technology Model (BPTM) [21], we instead assume a

scenario where leakage power equals active power (which is, we believe, a hypothetical

situation we may possibly see in the future.) Now, recalling that our cell phone is active

500 minutes per month and thus inactive 42700 minutes per month, we calculate forced

stack digital chip energy per month as follows:

21

Encrgy1 = 143mw (500 60scc) + 143mw 42700 60scc

= 37.2K[

Similarly, we calculate sleepy stack digital chip energy per month as follows:

Encrgy2 = 153mw (500 60scc) +3.01mw 42700 60scc

= 1.23K[

The result predicts that the ultra-low leakage power technology, i.e., sleepy stack,

serves 30X total energy consumption compared to the best prior work, i.e., forced

stack. Therefore, potentially, the ultra-low leakage power technique can extend by 30X

the cell phone battery life in this motivational example. There is a cost for this 30X

savings, however, note that the overall area increase 83% (from 1.32 mm

2

to 2.42 mm

2

-

Table 2).

Although there already exist many low-leakage techniques, the best prior low-leakage

technique in terms of leakage power reduction, the sleep transistor technique, loses

logic state during sleep mode. Therefore, the sleep transistor technique requires non-

negligible time to wake-up the device from the sleep mode. If we consider an

emergency calling situation to use cell phone, this wake-up time may not be acceptable.

Therefore, an ultra- low-leakage technique that can save state even in non-active mode

can be quite important in nano-scale technology VLSI.

In this dissertation, we use circuit based techniques to reduce leakage power

consumption. Especially, our technique can retain logic state and thus fast response

time can be achieved even during non-active mode. The technique can be applicable to

generic logic circuits as well memory, i.e., SRAM, since our technique can retain state.

In this chapter, some motivation for the importance of this research is provided. In the

next chapter, we explain expressions, notation and background important for this thesis.

22

CHAPTER 3

NOTATION AND BACKGOUND

In this chapter, we explain important notation and VLSI background used in this

dissertation. First, we introduce subthreshold leakage power consumption on which our

research focuses. Next, we explain the background underlying a particular leakage

power model able to explain the stack effect. We then explain the body-bias effect,

which is an important leakage reduction factor in our research. Furthermore, we explain

subthreshold leakage power consumption of a conventional 6 Transistor (6-T) SRAM

cell. Finally, we explain switching power and delay tradeoffs of CMOS circuits and

some key terms of circuit performance estimations.

3.1 Leakage power

In this section, we explain notation and background relevant to leakage power

consumption.

Although dynamic power is dominant for technologies at 180nm and above, leakage

(static) power consumption becomes another dominant factor for 130nm and below.

One of the main contributors to static power consumption in CMOS is subthreshold

leakage current shown in Figure 1, i.e., the drain to source current when the gate

Figure 1 Sub-threshold leakage of an nFET

23

voltage is smaller than the transistor threshold voltage. Since subthreshold current

increases exponentially as the threshold voltage decreases, nano scale technologies wit h

scaled down threshold voltages will severely suffer from subthreshold leakage power

consumption.

Assuming the leakage current is constant the static power dissipation is the

product of total leakage current and supply voltage,

stotic

= I

stotic

I

JJ

(3.1)

Static power reduction involves minimizing I

stotic

, which is almost equal to the

subthreshold leakage current I

sub

for V

gs

< I

tb

.

Subthreshold leakage can be reduced by stacking transistors, i.e., taking advantage of

the so-called stack effect [22] or alternatively applying variable body biasing (I

sb0

),

which we will use in section 5. The stack effect occurs when two or more stacked

transistors are turned off together; the result is reduced leakage power consumption. Let

us explain an important stack effect leakage reduction model. The model we explain

here is based on the leakage models in [22] and [23]. For a turned off single transistor

shown in Figure 2(a), leakage current (I

sub0

) can be expressed as follows:

I

sub 0

= A c

1

n I

0

(I

gs0

I

tb0

I

sb0

+pI

Js0

)

(1 c

I

Js0

/I

0

)

= A c

1

n I

0

(I

tb0

+pI

JJ

)

Figure 2 (a) A single transistor (left) and (b) stacked transistors (right)

24

Where,

A =

0

C

ox

_

w

I

c

]I

0

2

c

1.8

,

n is the subthreshold swing coefficient

I

0

is the thermal voltage.

I

gs0

, I

tb0

, I

sb0

and I

Js0

are the gate-to-source voltage, the zero-bias threshold

voltage, the source-to-base voltage and the drain-to-source voltage,

respectively.

is the body-bias effect coefficient

p is the Drain Induced Barrier Lowering (DIBL) coefficient.

0

is zero-bias mobility,

C

ox

is the gate-oxide capacitance,

w is the width of the transistor, and

I

c

is the effective channel length [24].

(Note that throughout this thesis we assume

n

= 2

p

, i.e., nMOS carrier mobility is

twice PMOS carrier mobility. Also note that we use a W/L ratio based on a actual

transistor size, in which way a W/L ratio properly characterizes circuit models used in

this thesis.) We assume 1 >> c

I

Js0

/I

0

.

Let us assume that the two stacked transistors (M1 and M2) in Figure 2(b) are turned

off. We also assume that the transistor width of each of M1 and M2 is the same as the

transistor width of M0 ( w

H0

= w

H1

= w

H2

). Two leakage currents I

sub 1

of the

transistor M1 and I

sub 2

of the transistor M2 can be expressed as follows:

I

sub 1

= A c

1

n I

0

(I

gs1

I

tb1

I

sb1

+pI

Js1

)

(1 c

I

Js1

/I

0

)

= A c

1

n I

0

(I

x

I

tb0

I

x

+p(I

JJ

I

x

))

I

sub 2

= A c

1

n I

0

(I

gs2

I

tb2

I

sb2

+pI

Js2

)

(1 c

I

Js2

/I

0

)

= A c

1

n I

0

(I

tb0

+pI

x

)

(1 c

I

x

/I

0

)

Where I

x

is the voltage at the node between M1 and M2, and we assume 1 >>

c

I

Js1

/I

0

.

Now consider leakage current reduction between I

sub 0

and I

sub 1

(= I

sub 2

). The

reduction factor X can be expressed as follows:

25

X =

I

sub 0

I

sub 1

=

A c

1

n I

0

(I

tb0

+pI

JJ

)

A c

1

n I

0

(I

x

I

tb0

I

x

+p(I

JJ

I

x

))

= c

I

x

n I

0

(1++p)

(3.2)

I

x

in Equation (3.2) can be derived by letting I

sub 1

= I

sub 2

and by solving the

following equation:

c

1

n I

0

(pI

JJ

I

x

(1++2p))

+ c

I

x

I

0

= 1 (3.3)

If all the parameters are known, we can calculate stack effect leakage power reduction

using Equations (3.2) and (3.3). As an example, we consider leakage model parameter

values targeting 0.5 technology in Table 3 obtained from [22]. From Equation (3.3),

we calculate I

x

=0.0443V, and from Equation (3.2), we obtain leakage reduction

factor X = 4.188.

Table 3 Leakage model parameters (0.5 tech)

Although the reduction is 4.188X at 0.5 technology, the reduction increases at nano-

scale technology because p increases as technology feature size shrinks.

Threshold voltage of a CMOS transistor can be controlled using body bias. In

general, we apply V

dd

to the body (e.g., an n-well or n-tub) of PMOS and apply gnd to a

body (e.g., p-well or p-substrate) of NMOS. This condition, in which source voltage

and body voltage of a transistor are the same, is called Zero-Body Bias (ZBB).

Threshold voltage at ZBB is called ZBB threshold voltage. When body voltage is lower

than source voltage by biasing negative voltage to body, this condition is called

Reverse-Body Bias (RBB). Alternatively, when body voltage is higher than source

voltage by biasing positive voltage to body, this condition is called Forward-Body Bias

Parameter Value

I

JJ

1V

I

tb

0.2V

n (subthreshold slope coefficient) 1.5

p (DIBL coefficient) 0.05 V/V

(body-bias effect coefficient) 0.24 V/V

26

(FBB). When RBB is applied to a transistor, threshold voltage increases, and when

FBB applied to a transistor, threshold voltage decreases. This phenomenon is called

body-bias effect, and this is frequently used to control threshold voltage dynamically

[25].

In this section, Section 3.1, we explained subthreshold leakage power

consumption, the stack effect, and body-bias effects which can alter subthreshold

leakage power consumption. In the next section, we explain leakage current of an

SRAM cell.

3.2 SRAM cell leakage paths

In this section, we explain the major subthreshold leakage components in a 6-T

SRAM cell. The subthreshold leakage current in an SRAM cell is typically categorized

into two kinds [26] as shown in Figure 3: (i) cell leakage current that flows from V

dd

to

Gnd internal to the cell and (ii) bitlinc leakage current that flows from bitlinc (or

bitlinc) to Gnd.

Although an SRAM cell has two bitlinc leakage paths, the bitlinc leakage

current and bitlinc leakage current differs according to the value stored in the SRAM

bit. If an SRAM cell holds 1 as shown in Figure 3, the bitlinc leakage current passing

through N3 and N2 is effectively suppressed due to two reasons. First, after precharging

bitlinc and bitlinc both to 1, the source voltage and the drain voltage of N3 are the

same and thus potentially no current flows through N3. Second, two stacked and turned

Figure 3 SRAM cell leakage paths

27

off transistors (N2 and N3) induce the stack effect. Meanwhile, for this case where the

SRAM bit holds value 1, a large bitlinc leakage current flows passing through N4

and N1. If, on the other hand, the SRAM cell holds 0, a large bitlinc leakage current

flows while bitlinc leakage current is suppressed.

In this section, Section 3.2, we explain the two major types of leakage paths in

an SRAM cell (cell leakage and bitlinc leakage). In next section, we explain tradeoffs

between switching power and delay.

3.3 Switching power and delay tradeoffs

In this section, we explain tradeoffs between switching power and delay. In

CMOS, power consumption consists of leakage power and dynamic power note that

dynamic power includes both switching power and short-circuit power. Switching

power is consumed when a gate charges its output load capacitance, and short-circuit

power is consumed when a pull-up network and a pull-down network are on together

for an instant while transistors are turning on and off. For 0.18 channel lengths and

above, leakage power is very small compared to dynamic power. Furthermore, short-

circuit power is also less than 10% of the dynamic power for a typical CMOS design,

and the ratio between dynamic power and short-circuit power does not change as long

as the ratio between supply voltage and threshold voltage remains the same [27]. Since,

for 0.18 and above, short circuit power and leakage power are relatively small

compared to switching power, CMOS power consumption of a particular CMOS gate

under consideration can be represented by the following switching power (P

switching

)

equation for 0.18 and above:

switc bing

= p

t

C

I

I

JJ

2

(3.4)

Where, C

L

, V

dd

, and f denote the load capacitance of a CMOS gate, the supply voltage

and the clock frequency, respectively [28]. Notation p

t

denotes the switching ratio of a

gate output; this switching ratio represents the number of times the particular gates

output changes from Gnd to V

dd

per second please note that when output capacitance

discharges from V

dd

to Gnd, switching power is not consumed because power from V

dd

is not used (e.g., discharging to Gnd does not consume battery power). The switching

ratio varies according to the input vectors and benchmark programs, and thus an

average value of each benchmark may be used as a switching ratio.

28

Equation (3.4) shows that lowering V

dd

decreases CMOS switching power

consumption quadratically. However, this power reduction unfortunately entails an

increase in the gate delay in a CMOS circuit as shown in following approximated

equation:

I

J

I

JJ

(I

JJ

I

tb

)

(3.5)

Where, T

d

, V

th

, and denote the gate delay in a CMOS circuit, the threshold voltage

and velocity saturation index of a transistor, respectively. It is well-known that while

has values close to 2 for above 2.0, for 0.25 is between 1.3 and 1.5, and for below

0.1 is close to 1 [28-29]. However, instead of scaling down a value along with

the technology feature size, CMOS technology may take a constant value to avoid

the hotcarrier related problem [30]. A constant value could be accomplished by

changing V

th

because is a function of gate-source voltage [31]. If we scale down V

dd

,

switching power in Equation (3.4) decreases, while the gate delay in Equation (3.5)

increases. Therefore, CMOS circuit speed can be traded with switching power

consumption as shown in Equations (3.4) and (3.5).

When there exist tradeoffs between multiple criteria, e.g., power and delay, we

may say one design is better than another design in specific criteria. The point of design

space is called a Pareto point if there is no point with one or more inferior objective

[32]. In this thesis we estimate leakage power consumption by measuring static power

when transistors are not switching. Furthermore, we estimate active power

consumption by measuring power when transistors are switching. This active power

includes dynamic power consumption and leakage power consumption. In this chapter

we explained important notation and VLSI background used in this thesis. In the next

section, we explain previous low-power research related to our research.

3.4 Circuit Performance Estimation

In this section we introduce a vastly used technique to estimate the propagation

delay of VLSI circuits, Linear Delay Model. Using this model one can quickly and

crudely calculate the propagation delay in unit of = 3RC (parasitic delay of a unit

an inverter). For 180nm process =15ps.

29

In general the propagation delay of a gate can be written as

J = + p (3.6)

Where, p is the parasitic delay inherent to the gate when no load is attached; f is the

effort delay that depends on the complexity and fan-out of the gate: [33]

= gb

The complexity is represented by the logical effort, g. An inverter is defined to have a

logical effort of 1. Logical effort of a gate is defined by ratio of the input capacitance

to the input capacitance of an inverter that can deliver the same output current. For 2-

input NAND gate and 2-input NOR gate g is 4/3 and 5/3 respectively. (Figure 4)

For general case it can be shown that that logical effort of n-input NAND gate, g =

(n+2)/3 and n-input NOR gate, g = (2n+1)/3. A gate driving h identical copies of itself

is said to have fan-out or electrical effort of h. If the load is not identical h is defined by

b =

C

out

C

in

The parasitic delay p of a gate is the delay of the gate when drives zero load. A crude

method is count the diffusion capacitance on the output node. It can be shown that the p

of n-input NAND gate and n-input NOR is equals to n. For calculating delay in

multistage logic networks we define following terms:

Figure 4 logical efforts of basic logic gates

30

Path logical effort, 0 = [g

i

Path electrical effort, E =

C

out(potb)

C

in

(potb)

Branching effort, b =

C

onpotb

+C

opotb

C

onpotb

Path branching effort, B = [b

i

Path effort, F = 0BE

Path effort delay,

F

= _

i

Path parasitic delay, = _p

i

Finally, the path delay, D is the sum of the delays each stage:

= J

i

=

F

+

In this section, we discussed a simple model to estimate propagation delay of a

circuit by hand calculation. This model gives the designers an insight of the circuit

using which he can design faster circuits.

31

CHAPTER 4

PREVIOUS WORKS

In this chapter, we review important prior work that is closely related to our research.

Furthermore, the previous works are compared to our research. We explore the prior

work targeting leakage power reduction mainly. But we also shed light to other

performance criteria such as dynamic power, propagation delay, power delay product

and area etc.

4.1 Static Power Reduction VLSI research

In this section, we discuss previous low-power techniques that primarily target

reducing leakage power consumption of CMOS circuits. Techniques for leakage power

reduction can be grouped into two categories: (I) state-saving techniques where circuit

state (present value) is retained and (II) state-destructive techniques where the current

Boolean output value of the circuit might be lost [13]. A state-saving technique has an

advantage over a state-destructive technique in that with a state-saving technique the

circuitry can immediately resume operation at a point much later in time without

having to somehow regenerate state. We characterize each low-leakage technique

according to this criterion. We study low-leakage techniques for generic logic circuits

followed by low-leakage SRAM designs separately.

4.1.1 Static power reduction research for generic logic circuits

This section explains previously proposed low-leakage techniques for generic logic

circuits. As introduced, previously proposed work can be divided into techniques that

either (i) save state or (ii) destroy state. Although our research focuses on techniques

which save state, we also review the state-destructive techniques for the purposes of

comparison. In state-destructive category there is sleep transistor technique and forced

stack. The state saving category includes sleepy stack, sleepy keeper, dual sleep and

dual stack method.

32

4.1.1.1 Sleep transistor

State-destructive techniques cut off transistor (pull-up or pull-down or both) networks

from supply voltage or ground using sleep transistors [34]. These types of techniques

are also called gated-V

dd

and gated-Gnd (note that a gate dc lock is generally used for

dynamic power reduction). Motoh et al. propose a technique they call Multi-Threshold

Voltage CMOS (MTCMOS) [34], which adds high-V

th

sleep transistors between pull-

up networks and V

dd

and between pull-down networks and ground as shown in Figure 1

while logic circuits use low-V

th

transistors in order to maintain fast logic switching

speeds. The sleep transistors are turned off when the logic circuits are not in use. By

isolating the logic networks using sleep transistors, the sleep transistor technique

dramatically reduces leakage power during sleep mode. However, the additional sleep

transistors increase area and delay. Furthermore, the pull-up and pull-down networks

will have oating values and thus will lose state during sleep mode. These oating

values signicantly impact the wake-up time and energy of the sleep technique due to

the requirement to recharge transistors which lost state during sleep (this issue is

nontrivial, especially for registers and ip-ops).

Comparison with prior works using sleep transistors

The sleep transistor technique and the Variable Body Biasing technique both achieve

roughly the same static power savings over conventional CMOS. However, unlike the

sleep transistor technique, the Variable Body Biasing technique saves logic state

during low leakage mode (sleep mode), and this is a signicant advantage over the

state-destructive sleep transistor technique. The sleep transistor technique requires non-

Figure 5 Sleep transistor

33

negligible power consumption to restore lost state. Further, the wake-up time of the

sleep transistor technique is signicant, while the Variable Body Biasing technique

needs only a very small extra wake-up time (a few clock cycles).

4.1.1.2 Forced Stack

Another technique to reduce leakage power is transistor stacking. Transistor

stacking exploits the stack effect explained in Chapter3; the stack effect results in

substantial subthreshold leakage current reduction when two or more stacked transistors

are turned off together.

Example1: The stack effect can be understood from the forced stack inverter

example shown in Figure 6. Unlike a generic CMOS inverter, this forced stack inverter

consists of two pull-up transistors and two pull-down transistors. All inputs share the

same input A. If A =0, then both transistors M1 and M2 are turned off. Due to the

internal resistance of M2, the intermediate node voltage V

x

is higher than Gnd. The

positive potential of V

x

results in a negative gate-source voltage (V

gs

) for M1 and

negative source-base voltage (V

sb

) for M1. Furthermore, M1 has a reduced drain-source

voltage (V

ds

), which degrades the Drain Induced Barrier Lowering (DIBL) effect [35].

All three effects together change the leakage reduction factor X in Equation 3.2

(see Chapter 3), reducing leakage current by an order of magnitude for todays channel

lengths (0.18, 0.13, 0.10 and 0.07) [36].

Narendra et al. study the effectiveness of the stack effect including effects from

increasing the channel length [37]. Since forced stacking of what previously was a

Figure 6 Forced Stack

34

single transistor increases delay, Johnson et al. propose an algorithm that nds circuit

input vectors that maximize stacked transistors of existing complex logic [38].

Comparison with prior work using the forced stack approach

Compared to the forced stack technique, the Variable Body Biasing technique

potentially achieves more power savings because the Variable Body Biasing can

control the change in body bias during circuit operation. The forced stack technique

cannot use high-V

th

transistors without dramatic delay increase (larger than 5X delay

increase compared to conventional CMOS).

4.1.1.3 Sleepy Stack

The sleepy stack approach has a structure combining the stack and sleep approaches by

dividing every transistor into two transistors of half width and placing a sleep transistor

in parallel with one of the divided transistor [14, 15]. As shown in Figure 7, sleep

transistors are placed in parallel to the divided transistor closest to V

dd

for pull-up and

in parallel to the divided transistor closest to GND for pull-down. The sleepy stack

approach can have advantages of both the stack approach and the sleep approach.

During active mode, the sleepy stack approach results in lower delay than the stack

approach because sleep transistors placed in parallel (i) reduce resistance and (ii) are

already on. When sleep transistors are turned off; the existence of a path from either

V

dd

or GND prevents floating output. Also, leakage current can further be reduced by

applying high-V

th

on sleep transistors and the transistors in parallel to the sleep

transistors. However, area penalty is significant matter since every transistor is replaced

by three transistors and since additional wires are added for S and S, which are sleep

signals.

Figure 7 SLEEPY STACK

35

Comparison with prior work using the sleepy stack approach

Compared to the sleepy stack technique, the Variable Body Biasing technique

achieves 86% more power savings because the Variable Body Biasing can control the

change in body bias during circuit operation. The sleepy stack requires 32.3% more

area than Variable Body Biasing technique. This area overhead is a major

improvement over sleepy stack technique.

4.1.1.4 Sleepy keeper

Another approach called sleepy keeper utilizes leakage feedback technique [16] and is

shown in Figure 8. In this approach, a PMOS transistor is placed in parallel to the sleep

transistor (S) and a NMOS transistor is placed in parallel to the sleep transistor (S').

The two transistors are driven by the output of the inverter. During sleep mode, sleep

transistors are turned off and one of the transistors in parallel to the sleep transistors

keep the connection with the appropriate power rail.

Comparison with prior work using the sleepy keeper approach

Compared to the sleepy keeper technique, the Variable Body Biasing technique

achieves 50% more power savings because the Variable Body Biasing can control the

change in body bias during circuit operation. The sleepy keeper requires less area than

Variable Body Biasing technique. But the reduction in leakage power is more useful.

Figure 8 Sleepy keeper

36

4.1.1.5 Dual Sleep

Dual sleep approach uses the advantage of using the two extra pull-up and two extra

pull-down transistors in sleep mode either in OFF state or in ON state. Since the dual

sleep portion can be made common to all logic circuitry, less number of transistors is

needed to apply a certain logic circuit. In OFF state each of the pull-up and pull-down

networks consists of both PMOS and NMOS transistors in order to reduce the leakage

power. There are three obvious advantages. Firstly, it maintains state in sleep mode.

Secondly, like the sleep, sleepy stack and sleepy keeper approaches, dual-V

th

technology can be applied in dual sleep approach to obtain greater leakage power

reduction [17].

Comparison with prior work using the dual sleep approach

Dual sleep method requires 94.7%, 95.3% and 80.49% more leakage power compared

to Variable Body Biasing technique respectively for chain of 4 inverters, 1 bit Full

adder and SRAM cell. There is around 7% improvement in propagation delay for logic

circuits for Variable Body Biasing technique compared to dual sleep method.

Figure 9 Dual Sleep

37

4.1.1.6 Dual Stack

The dual stack approach (Figure 10) uses 2 extra PMOS in the pull down network and

2 extra NMOS in the pull up network. As a result the NMOS degrades high logic level

and the PMOS degrades the low logic level. Due to the body effect they further

decrease the voltage level. So, the pass transistor decreases the voltage applied across

the main circuit. The stacked transistors are held in reverse body bias. As a result their

threshold is high. High threshold voltage causes low leakage current and hence low

leakage power. Again minimum transistor size of aspect ratio 1 is used to reduce the

static power more [18].

Comparison with prior work using the dual stack approach

Dual sleep method requires 92.93%, 94.58% and 77.14% more leakage power

compared to Variable Body Biasing technique respectively for chain of 4 inverters, 1

bit Full adder and SRAM cell. There is improvement also in propagation delay for both

logic circuits and memory circuits (i.e. SRAM) for Variable Body Biasing technique

compared to dual sleep method.

Figure 10 Dual Stack

38

4.1.2 Static power reduction research for SRAM

In this section, we discuss state-of-the-art low-power memory techniques, especially

SRAM on which our research focuses and hence make comparisons.

4.1.2.1 Sleep transistor

This is same as applying sleep transistor in generic logic circuits i.e. chain of four

inverters. The V

dd

and Gnd rails are separated from the circuit through a PMOS and an

NMOS transistor respectively.

Comparison with our work

Sleep transistor method requires 35.4% more static power and 35.7% more

dynamic power than our approach. It has 0.89% less delay and 31.9% area compared to

our approach. Our proposed approach has overall power delay product 35.05% more

than sleep transistor approach.

Figure 11 SLEEP TRANSISTOR IN SRAM

39

4.1.2.2 Dual Sleep

Sleep transistors are crucial part in any low leakage power design. Generally, the sleep

transistor is used to reduce leakage power in off mode and other techniques are adopted

to save the state. In this method, each of the rails is separated by a header and footer

sleep transistor. It is similar to the case of logic circuits. We apply S=1 when the circuit

is in active mode and S=0 when it is in sleep mode.

Comparison with our work

Dual sleep method requires 84.12% more static power and 35.49% more

dynamic power than our approach. It has 0.10% more delay compared to our approach.

Our proposed approach has overall power delay product 35.35% more than dual sleep

approach.

Figure 12 DUAL SLEEP IN SRAM

40

4.1.2.3 Dual Stack

Figure 13 shows the configuration of dual stack method in case of a SRAM. In this

method, there are two extra MOSFETS parallel to the sleep transistors. These extra

MOSFET helps to retain state which is crucial for the operation of SRAM. As the

retention transistors are stacked they help to reduce leakage power. Its operation is

similar to the case of logic circuits. We apply S=1 when the circuit is in active mode

and S=0 when it is in sleep mode.

Comparison with our work

Dual stack method requires 80.73% more static power and 0.48% less dynamic

power than our approach. It has 0.05% less delay compared to our approach. Our

proposed approach has overall power delay product 0.46% less than dual stack

approach.

Figure 13 DUAL STACK IN SRAM

41

4.1.2.4 Sleepy Keeper in SRAM

Figure 14 shows the configuration of sleepy keeper method in case of a SRAM. In this

method, there is extra MOSFET parallel to the sleep transistors. These extra MOSFET

helps to retain state which is required for the operation of SRAM. In this case the

retention transistors are not stacked so they offer small amount of reduction in leakage

power. Its operation is similar to the case of logic circuits. We apply S=1 when the

circuit is in active mode and S=0 when it is in sleep mode.

Comparison with our work

Sleep transistor method requires 37.1795% more static power and 39.5954%

more dynamic power than our approach. It has 0.43471% more delay compared to our

approach. Our proposed approach has overall power delay product 39.86% more than

sleepy keeper approach.

Figure 14 SLEEPY KEEPER IN SRAM

42

CHAPTER 5

VARIABLE BODY BIASING TECHNIQUE

In this chapter, we introduce our new leakage power reduction technique we name

Variable Body Biasing. We derived this technique by controlling the V

th

of the sleep

transistor of sleepy keeper technique mode wise so that the subthreshold leakage can be

minimized in sleep mode. However, unlike the sleep transistor technique, the variable

body biasing technique retains the exact logic state; and, unlike the sleepy keeper

technique, our technique can utilize variable V

th

using body effect without suffering

delay penalties. Therefore, far better than any prior approach known to this thesis

author, the variable body biasing technique can achieve ultra-low leakage power

consumption while saving state.

We first explain the structure of the variable body biasing technique using an

inverter. Then we describe the details of variable body biasing operation in active mode

and sleep mode. The advantages of the variable body biasing technique over the sleep

transistor technique and the sleepy keeper technique are explored. Finally, we apply

linear delay model to our variable body biasing technique to estimate the propagation

delay.

5.1 Variable body biasing approach

In this section, we explain our variable body biasing structure comparing to the sleepy

keeper technique for an inverter. The details of the variable body biasing inverter are

described as an example. Two operation modes, active mode and sleep mode, of the

variable body biasing technique are explored.

43

5.2 Variable body biasing structure

We have already described the sleepy keeper structure in section 4.1.1.4. In sleepy

keeper structure the sleep transistors still have some subthreshold leakage in sleep

mode which can be reduced by increasing their V

th

using body effect. To implement

this we use a PMOS (M2) and a NMOS (M5) (Figure15 (b)). The drain of the PMOS

(M2) is connected with the body of the sleep PMOS (M1) and the source the PMOS

(M2) is connected to the V

dd

. Similarly the drain of the NMOS (M5) is connected with

the body of the sleep NMOS (M4) and the source the NMOS (M5) is connected to the

Gnd. The other PMOS (M3) and NMOS (M6) are used as keeper to retain the state of

the output in sleep mode. The W/L ratio of the inverter PMOS is 6 and NMOS is 3. All

other transistor have W/L ratio of unity.

Figure 15 An Inverter with (a) Sleepy Keeper (left) (b) Variable body biasing structure

(right)

44

5.3 Variable body biasing operation

During active mode (S=1, S=0) transistor M1, M2, M4 and M5 act as short circuit so

the inverter works normally. The V

sb

of the PMOS (M1) and NMOS (M4) is almost

zero. As a result the V

th

of sleep transistors decreases by body effect. (Equation (5.1))

I

tb

= I

tb0

+ (

s

+ I

sb

s

) (5.1)

Where I

tb0

is the threshold voltage source is at the body potential,

s

= 2I

0

ln(N

A

/n

i

)

is the surface potential at threshold, is the body-bias effect coefficient, typically in the

range 0.4 to 1 V

1/2

, N

A

is the doping level and I

0

is the thermal voltage.

On the other hand, during sleep mode (S=0, S=1) transistor M1, M2, M4 and M5 are

cutoff which make V

sb

of the sleep transistor non zero. As a result the V

th

of sleep

transistors increases hence the subthreshold leakage is reduced by the following

equation:

I

sub

= A c

1

n I

0

(I

gs

I

tb0

I

sb

+pI

Js

)

(1 c

I

Js

/I

0

) (5.2)

Where A =

0

C

ox

_

w

I

c

]I

0

2

c

1.8

, n is the subthreshold swing coefficient and I

0

is the

thermal voltage. I

gs

, I

tb0

, I

sb

and I

Js

are the gate-to-source voltage, the zero-bias

threshold voltage, the source-to-base voltage and the drain-to-source voltage,

respectively. is the body-bias effect coefficient, and p is the Drain Induced Barrier

Lowering (DIBL) coefficient.

0

is zero-bias mobility, C

ox

is the gate-oxide

capacitance, w is the width of the transistor, and I

c

is the effective channel length.

Reducing the subthreshold leakage makes the static dissipation lower. Thus the V

th

of

the sleep transistors (M1, M4) are varied mode wise. In active mode it is necessary to

decrease the V

th

for reducing the propagation delay:

I

J

I

JJ

(I

JJ

I

tb

)

(5.3)

Where T

d

, V

th

, and denote the gate delay in a CMOS circuit, the threshold voltage

and velocity saturation index of a transistor, respectively.

45

The state retention is accomplished by keeper pair NMOS (M3) and PMOS (M6).

During sleep mode, if output is high the NMOS (M3) keeps the state high and if the

output is low PMOS (M6) keeps the state low independent of any margin of noise.

5.4 Analysis of Subthreshold leakage reduction

Using analytical approach we can show that the subthreshold current can be reduced by

variable body biasing technique. In Figure 16(a) we have a sleep transistor without

body biasing transistor and in Figure 16(b) a sleep transistor (M1) with body biasing

transistor (M2).

For sleep transistor without body biasing subthreshold leakage is given by

I

sub

= A c

1

n I

0

(I

gs

I

tb0

I

sb

+pI

Js

)

(1 c

I

Js

/I

0

) (5.4)

During sleep mode S is high, so I

gs

is zero. As source is at body potential, the

subthreshold leakage becomes

I

sub

= A c

1

n I

0

(I

tb0

+pI

Js

)

(1 c

I

Js

/I

0

) (5.5)

Now for sleep transistor with body biasing transistor subthreshold leakage through M2

is

I

sub 2

= A c

1

n I

0

(I

gs2

I

tb0

I

sb2

+pI

Js2

)

(1 c

I

Js2

/I

0

) (5.6)

Here during sleep mode I

gs2

is zero. Unlike the sleep transistor (M1), the body biasing

transistor (M2)s source is connected with body. So I

sb2

is also zero. Hence

Figure 16 (a) Sleep transistor without body biasing transistor

(b) With body biasing transistor

46

I

sub 2

= A c

1

n I

0

(I

tb0

+pI

Js2

)

(1 c

I

Js2

/I

0

) (5.7)

I

sub 2

= A c

1

n I

0

(I

tb0

+pI

Js2

)

A c

1

n I

0

(I

tb0

+ (pn) I

Js2

)

(5.8)

Now the subthreshold leakage through M1 is given by

I

sub 1

= A c

1

n I

0

(I

gs1

I

tb0

I

sb1

+pI

Js1

)

(1 c

I

Js1

/I

0

) (5.9)

Here I

gs1

is zero and I

sb1

is equal to I

Js2

. Hence I

sub 1

becomes

I

sub 1

= A c

1

n I

0

(I

tb0

I

sJ2

+pI

Js1

)

(1 c

I

Js1

/I

0

) (5.10)

From Figure 16(b) we see that only I

sub 1

contributes to the static current. Comparing

subthreshold leakage of sleep transistor without body biasing from equation (5.5) with

subthreshold leakage of sleep transistor with body biasing from equation (5.10) we find

that,

I

sub 1

< I

sub

So by body biasing the static current during sleep mode is reduced thus resulting in a

reduced static power (according to Equation 3.1).

5.5 Estimation of delay for variable body biasing technique

In this section we estimate the propagation delay of an inverter by applying the linear

delay model which is discussed in section (3.4).

Figure 17 (a) Inverter with VBB Technique (left) (b) Inverter of equal strength (right)

47

To find the logical effort of the inverter with variable body biasing technique Figure

17(a) we have to determine its the input capacitance and also input capacitance of a

simple inverter of equal strength Figure 17(b).

Input capacitance of the inverter with variable body biasing technique is

C

in

=6+3=9,

Input capacitance of a simple inverter of equal strength is

C

in

=3/2+3/4=9/4.

Logical effort, g =

9

9/4

= 4

Transistor M3 and M6 contributes to parasitic capacitance. So p = 6 +3 +1 + 1 = 11

Assuming fan-out of one identical gate, Electrical effort, b = 1

Now according to linear delay model, propagation delay, J = gb + p = 4 1 +11 =

15 in unit of = 3RC, parasitic delay of unit inverter. For 180nm process, = 15ps.

So, propagation delay of the inverter with variable body biasing technique is estimated

to be 15 11 ps = 165ps for 180 nm process.[33]

In this chapter, we introduced the variable body biasing technique for leakage power

reduction. In this technique, the V

th