Beruflich Dokumente

Kultur Dokumente

Preventive Maintenance & Routine Inspection of Contactors

Hochgeladen von

Nor Hassan AmbaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Preventive Maintenance & Routine Inspection of Contactors

Hochgeladen von

Nor Hassan AmbaCopyright:

Verfügbare Formate

PREVENTIVE MAINTENANCE & ROUTINE INSPECTION OF CONTACTORS:

Preventive attention is better than cure.

Page # 1/5

PREVENTIVE MAINTENANCE & ROUTINE INSPECTION OF CONTACTORS

A. B. GENERAL INSPECTION:

A.1. Check for loose, missing, broken or corroded hardware, pivot pins, cotter pins, springs and other mechanical parts.

ARC BOXES:

B.1. B.2. B.3. Check arc boxes for broken or eroded parts and Grid plates and also for excessive collection of contact material or other foreign conducting material on the surface of insulating parts. Replace broken or badly eroded parts. Clean or replace parts having excessive build of conducting material.

C.

CONTACTS:

C.1. C.2. C.3. C.4. C.5. Remove oxide or large beads of contact materials from the faces of contacts, using a fine file or sandpaper.(Emery cloth should not be used for cleaning contacts.) Do not file or sand silver or alloy contact faces unless considerable foreign matter has collected on the surface of the contacts. When replacing contacts or other current-carrying parts, clean surfaces, which are to be bolted together. Realign contacts and set over travel if necessary. Do not substitute contact material without factory approval.

D.

SHUNTS:

D.1. D.2. Replace shunts having broken of frayed strands. Clean connection points if current-carrying parts are discolored.

E. F.

BLOWOUT COILS:

E.1. Inspect blowout coils for discolored connections, shorted turns, and loose hardware.

TERMINALS, CNTACT SUPPORTS, BUS BARS, AND CONNECTORS.

F.1. F.2. Discolored connections usually indicate that overheating has occurred, probably because of loose connections. Clean connection points which are discolored and tighten all hardware.

PERFECT ELEKTRO MEK PAKISTAN Perfection with convenience

Suit # 5, 2nd floor Business Arcade, Defense More Walton Road, Lahore-Cantt. Ph. 042-668-0902/03. Fax: 042-668-6685. E mail: pempak@hotmaul.com

PREVENTIVE MAINTENANCE & ROUTINE INSPECTION OF CONTACTORS:

Preventive attention is better than cure.

Page # 2/5

G.

INSULATORS.

G.1. G.2. G.3. G.4. Remove dust and dirt from insulating parts. If carbonized tracks or cracked or broken insulators are found, replace the defective parts. As a last resort, carbonized tracks may be scraped clean and painted with insulating varnish. Before a repaired part is put into service give it an over voltage test.

H.

MAGNET ASSEMBLY.

H.1. H.2. H.3. H.4 Check magnet for dirty or corroded pole faces, pivot points, and other moving parts. Check for loose, broken, or missing shading coils, residual shims, and hardware. Inspect operating coil for evidence of electrical or mechanical damage. Operate armature by hand and check for mechanical interference and friction.

I.

ELECTRICAL OPERATION.

I.1. I.2. I.3. I.4. Operate the contactor electrically without load and observe magnet operation to be sure it opens and closes cleanly and that armature is fully sealed in the closed position. If an a-c magnet is used, check for abnormal Magnet noise. Test a sample of oil used with oil-immersed contactors and fill oil tank to the proper level with good oil. Megger insulation between phases, to ground, and to the control circuit. Operate the contactor under load and check for abnormal report and arcing both on opening and closing. A Loud report and arcing on closing is usually due to contact bounce. The magnitude of the report and arcing found on opening and closing will depend upon the type of contactor, operating load, and phase angle at which the contacts separate or touch. Since no absolute standard can be set for covering this detail, it will be necessary to judge performance on the basis of past experience with equipment when it was new or with other applications having similar equipment and operating conditions.

J.

Sl A.

01

ELECTRICAL OPERATION.

The following table will be of great help in trouble shooting of contactors: Trouble/Defect Cause MAGNET.

Coil Burned out. Mechanical damage. Protective resistance or high resistance winding is not Inserted in series with d-c coil when armature seals in. Coil voltage is too high.

What to do/Remedy

Replace. Adjust, repair, or replace interlock and series resistance so that continuous rating of coil is not exceeded when armature is sealed. Correct coil voltage. Use higher-voltage coil.

PERFECT ELEKTRO MEK PAKISTAN Perfection with convenience

Suit # 5, 2nd floor Business Arcade, Defense More Walton Road, Lahore-Cantt. Ph. 042-668-0902/03. Fax: 042-668-6685. E mail: pempak@hotmaul.com

PREVENTIVE MAINTENANCE & ROUTINE INSPECTION OF CONTACTORS:

Preventive attention is better than cure. Ambient temperature is too high. Intermittent coil is energized too long. Jogging duty is too severe. Abnormal atmosphere. Defective coil. Low voltage. Mechanical interference or friction Magnetic lockout. Provide better ventilation. Relocate starter. Re-adjust operating cycle. Check factory for special coil. Readjust operating cycle. Check factory for special coil. Relocate starter. Check factory for special coil. Replace. Correct coil voltage or system Voltage. Check mechanical operation by hand and make necessary Adjustments and/or repairs. Use nonmagnetic-armature-stop details. Add nonmagnetic Shim between armature and armature stop. Check mechanical operation by hand and make necessary adjustments and/or repairs. Replace springs. Remove friction from moving contact assembly. Adjust spring length if adjustment is provided. Correct coil Voltage or System Voltage. Use lower-voltage coil. Adjust, repair, or replace interlock and/or series resistance.

02

Does not pick up.

03.

Does not seal; hesitates at Contact touch; drops open to contact touch. (This condition may exist only when operating coil is hot or line voltage is low.)

Mechanical interference or friction. Contact force too high. Coil voltage too low. Series protective resistance or high-resistance coil winding is inserted too early, or series resistance is too high (For DC Magnets). Coils of two-coil d-c magnet have bucking polarity.

04.

Does not dropout, dropout is sluggish.

or

Dirt or grease on pole faces. Mechanical interference or friction. Residual shim is pounded down or is missing. Residual air gap is pounded down. Kick out spring is defective or missing. Control relay does not open d-c side of rectifier. Control relay has long arcing time.

Reverse polarity of one coil and check operation with load disconnected. Clean. Check mechanical operation by hand and make necessary adjustments and/or repairs. Replace residual shim or magnet assembly. Replace (Kick out spring is not used on all contractors). Add contact in control circuit. Repair or replace relay. Repair or replace relay. Replace coil. Adjust or Replace.

05.

Magnet chatter or

Shorted coil turns. (DC Magnet) Shading coil broken or out of place.

PERFECT ELEKTRO MEK PAKISTAN Perfection with convenience

Suit # 5, 2nd floor Business Arcade, Defense More Walton Road, Lahore-Cantt. Ph. 042-668-0902/03. Fax: 042-668-6685. E mail: pempak@hotmaul.com

PREVENTIVE MAINTENANCE & ROUTINE INSPECTION OF CONTACTORS:

Preventive attention is better than cure. pumping. Series protective resistance or high-resistance coil Winding is inserted too early, or series resistance is too high or is open. (Applies to DC magnets having over voltage during Pickup.) Chattering contacts on control relay, control switch, Pressure switch, temperature switch, etc. Adjust, Repair or replace interlock and/or series resistance.

06.

Noisy a-c magnet.

Loose connections. Armature does not seal in tight. Pole faces rough. Magnet misaligned. Shading coil broken or out of place. Coil voltage is low.

Check over travel and contact force on control device. Replace control device. Move control device to a location having less vibration, or insulate control device from shock And vibration. Tighten connections. Clean pole faces. Remove mechanical interference and/or friction. Replace magnet assembly. File pole faces as a last resort If new parts are not available. Realign. Replace. Correct coil voltage or system voltage. Reduce load. Use larger contactor. Clean discolored or dirty Connections and retighten. Adjust over travel, replace contacts, and replace contact Springs as required to correct defect. Clean with fine file or sandpaper. Use dust -tight enclosure for dusty atmosphere. Change operating procedure. Check factory for more Suitable contacts Reduce load. Provide better ventilation. Relocate starter. Use larger contactor. Apply cable in line with existing load. Adjust over travel, replace contacts, and replace contact spring See Magnet, this table. See Magnet, this table. See Magnet this table. Correct coil over voltage condition. Correct mechanical defects.

B. 01.

Overheating.

Contacts. Load current too high. Loose connections. Over travel and/or contact force too low. Collection of copper oxide or foreign matter on contact Faces. Load is on in excess 8hr. Ambient temperature is too high. Line and/or load cables are too small. Over travel and/or contact force is too low. Magnet stalls or hesitates at contact touch point. Magnet drops open at contact touch due to voltage dip. Magnet chatter. Contact bounce on closing.

02.

Welding of contacts.

PERFECT ELEKTRO MEK PAKISTAN Perfection with convenience

Suit # 5, 2nd floor Business Arcade, Defense More Walton Road, Lahore-Cantt. Ph. 042-668-0902/03. Fax: 042-668-6685. E mail: pempak@hotmaul.com

PREVENTIVE MAINTENANCE & ROUTINE INSPECTION OF CONTACTORS:

Preventive attention is better than cure. Contacts rebound to contact touch when opening. Poor contact alignment. Jogging duty is too severe. Excessive inrush current. Correct mechanical defects in stop assembly. Correct Mechanical defects in latch if one is used. Adjust contacts to touch simultaneously within 1/32 in. Reduce jogging cycle. Check factory for more weld-resistant contact material. Use larger contactor. Readjust accelerating time or operating sequence. Use larger contactor. Check factory for more weld-resistant contact material. Move starter to location having less shock and vibration. Insulate starter from shock and vibration. Provide more rigid Support for starter. Reduce jogging cycle. Check factory for more durable contact material. Use larger contactor. Air break contactors may have 10 to 20 times longer contact life than oil-immersed contactors of equal ratings

Vibration in starter mounting.

Jogging cycle is too severe.

C. Poor arc interruption.

Oil-immersed contactor is used where an air break Contactor could be used. ARC INTERRUPTION Arc box not in place. Install arc box in line with instruction-leaflet data. Arc box damaged. Replace broken or eroded insulating parts, arc horns, and grid plates. Clean or replace insulating parts having a heavy Coating of foreign conducting material. Dirt or paint on arc horns or steel grid plates. Remove insulating materials, which may have accumulated on arc horns and steel grid plates. Magnetic hardware substituted for nonmagnetic Replace with correct hardware. hardware in arc box and blowout assemblies. Blowout coil reversed or short-circuited. Replace coil. Correct defect. Magnet opening is sluggish. See Magnet, this Table.

PERFECT ELEKTRO MEK PAKISTAN Perfection with convenience

Suit # 5, 2nd floor Business Arcade, Defense More Walton Road, Lahore-Cantt. Ph. 042-668-0902/03. Fax: 042-668-6685. E mail: pempak@hotmaul.com

Das könnte Ihnen auch gefallen

- Summary Ac Contactor Failure Cause and EffectDokument9 SeitenSummary Ac Contactor Failure Cause and EffectVinci Valcu ParneNoch keine Bewertungen

- Ijert Ijert: Dynamic Contact Resistance Measurements On HV Circuit BreakerDokument5 SeitenIjert Ijert: Dynamic Contact Resistance Measurements On HV Circuit Breakerkokonut1128Noch keine Bewertungen

- Cranes and Derricks in Construction Shift and Monthly Inspection ChecklistDokument3 SeitenCranes and Derricks in Construction Shift and Monthly Inspection ChecklistRabar TahaNoch keine Bewertungen

- Ac Contactor Common Faults and Maintenance Case AnalysisDokument3 SeitenAc Contactor Common Faults and Maintenance Case AnalysisZelalem LeyikunNoch keine Bewertungen

- R8035 FDokument16 SeitenR8035 FVishwanath TodurkarNoch keine Bewertungen

- S-T MaintenanceManualDokument34 SeitenS-T MaintenanceManualgeraleao208Noch keine Bewertungen

- Procedure of Maintenance For Electrical EquipmentDokument16 SeitenProcedure of Maintenance For Electrical EquipmentThức Võ100% (2)

- Installation Manual: Suspended Overhead ElectromagnetDokument6 SeitenInstallation Manual: Suspended Overhead ElectromagnetudhayNoch keine Bewertungen

- Modern Trends and Accident Prevention On Distribution and Power TransformersDokument10 SeitenModern Trends and Accident Prevention On Distribution and Power Transformersashutosh2009Noch keine Bewertungen

- RelaysReliability PDFDokument8 SeitenRelaysReliability PDFcazzocazzocazzoNoch keine Bewertungen

- Trouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsDokument7 SeitenTrouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsBilly MecanizadoNoch keine Bewertungen

- Damage Due To Esd Allpl Note Avago TechDokument4 SeitenDamage Due To Esd Allpl Note Avago TechhimsnileshNoch keine Bewertungen

- Del Core My ElectricalDokument56 SeitenDel Core My Electricaljohanbl88Noch keine Bewertungen

- Practical Work No 6Dokument5 SeitenPractical Work No 6Potter A. VijayNoch keine Bewertungen

- Body Electrical SystemDokument59 SeitenBody Electrical SystemLeonardo Gómez Berniga100% (1)

- USCO CatalogDokument56 SeitenUSCO CatalogDavid LeviNoch keine Bewertungen

- Electrical safety devices and precautionsDokument7 SeitenElectrical safety devices and precautionsUFC Fight ClubNoch keine Bewertungen

- SUBSTATIONDokument22 SeitenSUBSTATIONAmrit Aggarwal100% (1)

- Areva MVTT Relay ManualDokument42 SeitenAreva MVTT Relay ManualjbatoyNoch keine Bewertungen

- Large HV Machine Repair: Repair Options & Rewind Good Practice With Examples of More Unusual RepairsDokument9 SeitenLarge HV Machine Repair: Repair Options & Rewind Good Practice With Examples of More Unusual RepairsmersiumNoch keine Bewertungen

- Circuit BreakersDokument3 SeitenCircuit BreakersJitendra KumarNoch keine Bewertungen

- Instruction Manual of EDM MachineDokument18 SeitenInstruction Manual of EDM MachineJanak ValakiNoch keine Bewertungen

- Technical ReferencesDokument16 SeitenTechnical Referencessudhi_786Noch keine Bewertungen

- Tm170tig PVCDokument9 SeitenTm170tig PVCAndrea MorsianiNoch keine Bewertungen

- Abb ContactorabbDokument16 SeitenAbb ContactorabbRoga29Noch keine Bewertungen

- Unit-Iii Risks During Installation of Electric Plant and EquipmentDokument9 SeitenUnit-Iii Risks During Installation of Electric Plant and EquipmentsaraswatthiNoch keine Bewertungen

- If Trouble Occurs. (2) To Repair Trouble Cause TroubleshootingDokument1 SeiteIf Trouble Occurs. (2) To Repair Trouble Cause TroubleshootingbayuNoch keine Bewertungen

- CL-21Z50MQ K16CDokument73 SeitenCL-21Z50MQ K16CRonald CastellarNoch keine Bewertungen

- BTC30 40insDokument4 SeitenBTC30 40inspatgarettNoch keine Bewertungen

- R8501G K1RangeDokument208 SeitenR8501G K1RangeRinda_RaynaNoch keine Bewertungen

- Revision Harness y ConectoresDokument9 SeitenRevision Harness y ConectoresVladimir Illich Pinzon BallenNoch keine Bewertungen

- Molded Case Circuit Breakers - Application and SelectionDokument108 SeitenMolded Case Circuit Breakers - Application and SelectionManuel L LombarderoNoch keine Bewertungen

- Switchyard Components GuideDokument22 SeitenSwitchyard Components GuideAnand SwamiNoch keine Bewertungen

- Acb Fault ReasonsDokument14 SeitenAcb Fault ReasonsDakshinaMoorthyNoch keine Bewertungen

- MC-300 CD - Service ManualDokument28 SeitenMC-300 CD - Service ManualMilorad Pajovic100% (1)

- 2014 Led LG 32lb55-A-T - Chassis Lb45bDokument58 Seiten2014 Led LG 32lb55-A-T - Chassis Lb45bdanielradu2760% (5)

- 3electrical & Information System - ENGLISG-G9165Dokument48 Seiten3electrical & Information System - ENGLISG-G9165George Jhonson100% (4)

- Manual 2Dokument0 SeitenManual 2Rafat ThongNoch keine Bewertungen

- TV Samsung CL29A551GQ9XZD Chassis KSDA-N-CB5G Manual de ServicioDokument73 SeitenTV Samsung CL29A551GQ9XZD Chassis KSDA-N-CB5G Manual de ServicioGabriel Grieco100% (3)

- Led LCD TV: Service ManualDokument60 SeitenLed LCD TV: Service ManualFrank VillaNoch keine Bewertungen

- Samsung m1712n Silver SMDokument23 SeitenSamsung m1712n Silver SMdieselroarmt875bNoch keine Bewertungen

- Led Monitor: Service ManualDokument16 SeitenLed Monitor: Service ManualabdelkaderNoch keine Bewertungen

- Contactor: Electrical Equipment Operation and MaintenanceDokument23 SeitenContactor: Electrical Equipment Operation and MaintenanceKenneth LewisNoch keine Bewertungen

- Electrical Panel Inspection & MaintenanceDokument4 SeitenElectrical Panel Inspection & MaintenanceFawaaz KhurwolahNoch keine Bewertungen

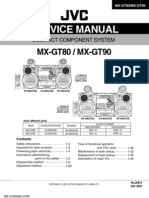

- JVC mx-gt80 gt90 SM No-Sch (ET)Dokument48 SeitenJVC mx-gt80 gt90 SM No-Sch (ET)Cliffton FilipinoPrd ShraderNoch keine Bewertungen

- Led LCD TV: Service ManualDokument42 SeitenLed LCD TV: Service ManualJm QuemadoNoch keine Bewertungen

- Circuit Protection DevicesDokument8.924 SeitenCircuit Protection DevicesKristen Phillips100% (1)

- Electrical Testing Dry Type TransformersDokument5 SeitenElectrical Testing Dry Type Transformersread4freeNoch keine Bewertungen

- Packet Switches General PDFDokument12 SeitenPacket Switches General PDFHeri SetyantoNoch keine Bewertungen

- SRP-350 v2 SVC EngDokument125 SeitenSRP-350 v2 SVC EngMichael HanniganNoch keine Bewertungen

- Panasonic Tc-l24x5 Tc-l24x5x Tc-l24x5l Mtnc120570ceDokument30 SeitenPanasonic Tc-l24x5 Tc-l24x5x Tc-l24x5l Mtnc120570ceAlberto CamarenaNoch keine Bewertungen

- DLP Projector: Service ManualDokument34 SeitenDLP Projector: Service ManualcrosspoyNoch keine Bewertungen

- MVGC Voltage Regulating Relay ManualDokument46 SeitenMVGC Voltage Regulating Relay ManualLê Văn PhúNoch keine Bewertungen

- Service Manual Type MHOA 04, MHOB 04, MHOC 04 Translay Feeder Protection SchemesDokument36 SeitenService Manual Type MHOA 04, MHOB 04, MHOC 04 Translay Feeder Protection SchemesRinda_RaynaNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

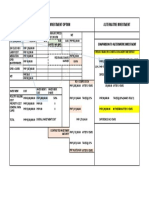

- Investment CalculationDokument1 SeiteInvestment CalculationNor Hassan AmbaNoch keine Bewertungen

- Estimating Electrical Construction Book PreviewDokument18 SeitenEstimating Electrical Construction Book PreviewCordero FitzGerald100% (1)

- Eres2013 Edu 102.contentDokument9 SeitenEres2013 Edu 102.contentEllaNoch keine Bewertungen

- South Africa Works Public Works: Because ofDokument104 SeitenSouth Africa Works Public Works: Because ofNor Hassan AmbaNoch keine Bewertungen

- What Is Medical Equipment and Types of Medical EquipmentDokument5 SeitenWhat Is Medical Equipment and Types of Medical EquipmentNor Hassan AmbaNoch keine Bewertungen

- OrgChartAdminFinance WebDokument4 SeitenOrgChartAdminFinance WebNor Hassan AmbaNoch keine Bewertungen

- Medical Device Technical Specifications ArmeniaDokument27 SeitenMedical Device Technical Specifications ArmeniaKartik PrabhakarNoch keine Bewertungen

- Chapter 15 Lighting Fundamentals - 2 PDFDokument13 SeitenChapter 15 Lighting Fundamentals - 2 PDFaymen145771552Noch keine Bewertungen

- Instructions and Advices To Use The Electronic Controller Logik 26-SDokument28 SeitenInstructions and Advices To Use The Electronic Controller Logik 26-SsebastianNoch keine Bewertungen

- Rules for Ships / High Speed, Light Craft and Naval Surface Craft, January 2005 Pt.4 Ch.8 Sec.4 – Page 43Dokument2 SeitenRules for Ships / High Speed, Light Craft and Naval Surface Craft, January 2005 Pt.4 Ch.8 Sec.4 – Page 43Stefanita0% (1)

- Ipss HandbookDokument45 SeitenIpss HandbookSarbendu PaulNoch keine Bewertungen

- Manual de Control Universal ArtticoDokument139 SeitenManual de Control Universal ArtticoJohn VicentNoch keine Bewertungen

- Acti 9Dokument55 SeitenActi 9Anonymous BwLfvuNoch keine Bewertungen

- Emergency Stop SIL2 and SIL3Dokument3 SeitenEmergency Stop SIL2 and SIL3SARFRAZ ALINoch keine Bewertungen

- Aib Ga11-30c PDFDokument40 SeitenAib Ga11-30c PDFtheloniussherekNoch keine Bewertungen

- Instruction Manual: General-Purpose InverterDokument74 SeitenInstruction Manual: General-Purpose Inverteranhthong3k100% (2)

- Short Circuit Protection Considerations for Motor StartersDokument4 SeitenShort Circuit Protection Considerations for Motor StarterssanthoshNoch keine Bewertungen

- Schneider Electric Contactors and Reversing Contactors Product GuideDokument12 SeitenSchneider Electric Contactors and Reversing Contactors Product GuidebernardoNoch keine Bewertungen

- Tech Article - Effect of Under-Voltage On Capacitor Duty ContactorDokument4 SeitenTech Article - Effect of Under-Voltage On Capacitor Duty ContactorSandeep NairNoch keine Bewertungen

- Contactors CB-line Leaflet English Ed04!10!680876Dokument6 SeitenContactors CB-line Leaflet English Ed04!10!680876Osun Deji LanaNoch keine Bewertungen

- Eba 1597 0562 Afp Aflx Vupx Me GBDokument44 SeitenEba 1597 0562 Afp Aflx Vupx Me GBrhusseinpos4765Noch keine Bewertungen

- Mgv34Range: Installation, Use and Maintenance GearlessDokument36 SeitenMgv34Range: Installation, Use and Maintenance Gearlessعادل شريفNoch keine Bewertungen

- AEG ContactorsDokument5 SeitenAEG ContactorsYonhelis ParejoNoch keine Bewertungen

- M101-P M102-P Parameter Description 1TNC911106M0201Dokument61 SeitenM101-P M102-P Parameter Description 1TNC911106M0201Sameer SyedNoch keine Bewertungen

- Galaxy Traction Elevator ControllerDokument436 SeitenGalaxy Traction Elevator Controllerdidik sukocoNoch keine Bewertungen

- 3.22 Digital Output Module SM 322 DO 16 X AC 120/230 V/1 A (6ES7322-1FH00-0AA0)Dokument106 Seiten3.22 Digital Output Module SM 322 DO 16 X AC 120/230 V/1 A (6ES7322-1FH00-0AA0)miltonNoch keine Bewertungen

- Presentation On: Presented byDokument36 SeitenPresentation On: Presented byShamimSarkar100% (1)

- DC2100e - DC Drive Fact Sheet - ENDokument4 SeitenDC2100e - DC Drive Fact Sheet - ENJames BlackNoch keine Bewertungen

- Wiring For MotorsDokument4 SeitenWiring For MotorspomodoroNoch keine Bewertungen

- Eaton 12kV Power Xpert UX Catalog EN US PDFDokument20 SeitenEaton 12kV Power Xpert UX Catalog EN US PDFGanesh SantoshNoch keine Bewertungen

- Magnetic Contactors and Starters SpecificationsDokument8 SeitenMagnetic Contactors and Starters SpecificationsSyed Abrar HussainNoch keine Bewertungen

- MS-N - Technical CatalogueDokument44 SeitenMS-N - Technical CatalogueOle BudiNoch keine Bewertungen

- Basic Calculation of DOLDokument4 SeitenBasic Calculation of DOLumerNoch keine Bewertungen

- CC848894724 - Product Manual I2 PMSDokument93 SeitenCC848894724 - Product Manual I2 PMSNarendra Kumar Soni100% (2)

- Ex2100 SesDokument118 SeitenEx2100 SesAmeer Basha100% (1)

- 03 Mammoth WSHP E Series 50HZ R410A Catalogue 2020Dokument22 Seiten03 Mammoth WSHP E Series 50HZ R410A Catalogue 2020Anonymous oKTCFZNTmNoch keine Bewertungen

- Mitsubishi S500 ManualDokument85 SeitenMitsubishi S500 Manualnyamai20008234100% (1)

- GE-Controls and Power Electronics Catalogue-English-Ed 07-17-680804-PN123036Dokument492 SeitenGE-Controls and Power Electronics Catalogue-English-Ed 07-17-680804-PN123036Nomada Gr100% (1)