Beruflich Dokumente

Kultur Dokumente

Candu Poster

Hochgeladen von

John BaynerCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Candu Poster

Hochgeladen von

John BaynerCopyright:

Verfügbare Formate

Overview of CANDU Pressurized Heavy Water Reactor (PHWR) and the Canadian Nuclear Industry

Mikko I. Jyrkama and Mahesh D. Pandey

Department of Civil Engineering, University of Waterloo, Waterloo, Ontario, N2L 3G1, Canada

The hot heavy water coolant from the reactor is transferred to the steam generators to produce steam.

Steam (light water)

CANDU

- CANada Deuterium Uranium

Point Lepreau Turbine-Generator

Steam Generator Pressurizer Pump/Motor Assembly

To Fuel Channels

Uses natural uranium as fuel and deuterium oxide (D2O) or "heavy water" as coolant and moderator Started as the Canadian contribution to the War effort Designed by AECL (Atomic Energy of Canada Limited) All nuclear power reactors in Canada are CANDUs Can be refuelled at full power Multiple shutdown systems for added safety

The steam turns tthe turbines and the turbines turn the generator to produce electricity.

Low Pressure Turbines

CANDU Evolution

Darlington

Regulation

CANDU 9 Bruce B Advanced CANDU Reactor

900 800

(image courtesy of AECL)

900 MW Class Reactors

Bruce A

ACR

Qinshan 1,2 Wolsong 2,3,4

The Canadian Nuclear Safety Commission (CNSC), an independent agency of the Government of Canada operates and enforces regulations under the Nuclear Safety and Control Act (NSC Act) As the federal regulator, the CNSC

executes licensing decisions made by the Commission or its designates continually monitors licensees to ensure they comply with safety requirements that protect workers, the public, and the environment uphold Canadas international commitments on the peaceful use of nuclear energy

700

Pt. Lepreau Embalse

Power (MWe)

600 500 400 300 200

From Fuel Channels Feeders Feedwater (light water)

600 MW Class Reactors

Pickering A

Gentilly 2 Wolsong 1

Cernavoda 1

(CANDU 6s)

Pickering B

Calandria

Heavy water coolant circulates in the Primary Heat Transport System through the reactor core.

Fueling Machine

RAPP 1,2 Douglas Point NRU ZEEP KANUPP

Generator

Power to Grid

Fueling Machine Fuel Fuel Channels

High Presure Turbine Feedwater Pump Assembly Condenser Cooling Water

Research & Prototype Reactors

Switchyard

100

NRX

The CNSC functions as a tribunal, taking into account the views, concerns and opinions of interested parties and intervenors when establishing regulatory policy, making licensing decisions and implementing programs In addition to the NSC Act, the CNSC also administers other nuclear related regulations and bylaws in the form of policies, standards, guides and notices

NPD

Moderator (heavy water)

1950

1960

1970

Moderator Pump

Moderator Heat Exchanger

Uranium atoms are split in the core under controlled conditions to produce a chain reaction, providing large amounts of energy in the form of heat.

(Source: Atomic Energy of Canada Limited)

Years

1980

1990

2000

2010

The condenser turns the steam back into water which is then returned to the steam generators through the feedwater system.

CANDU Nuclear Power Plant Schematic

Operator

Nuclaire Nuclear

(image courtesy of AECL)

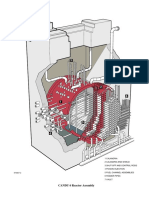

Reactor Assembly

Calandria - a horizontal, cylindrical, single-walled, 6 m long stepped shell enclosed at each end by tubesheets and spanned by calandria tubes and 1. Calandria 2. Calandria end shield filled with the heavy water moderator 3. Shut-off and control rods 4. Poison injection Moderator - consists of heavy water at near atmospheric pressure and at a 5. Fuel channel assemblies 6. Feeder pipes temperature of 70C, used for moderating (slowing down) the high energy 7. Vault fission neutrons Calandria Tubes - provide access through the calandria for the fuel channel assemblies and also support the pressure tubes by means of four garter 7 spring spacers per channel Fuel Channels - the fuel channels contain the pressure tubes that hold the (image courtesy of AECL) 6 fuel bundles in the neutron flux of the reactor core Gas Annulus - the gap between the fuel channel pressure tubes and the calandria tubes insulates the hot pressure tubes from the relatively cool moderator Feeders - inlet and outlet feeders connect each fuel channel individually to connectors (headers) above the core and then to the steam generators

CANDU Reactor Assembly (during construction)

Reactor Unit

Gross Capacity (per unit) Net Capacity (per unit)

Bruce A 1-4 791 MW 740 MW Dec 1970 Jul 1976 37/13 6240 480 a. Zircaloy-2 129/1.37 cw. Zr-2.5%Nb 103.4/4.06

Bruce B 5-8 807 MW 750 MW Jan 1978 May 1984 37/13 6240 480 a. Zircaloy-2 129/1.37 cw. Zr-2.5%Nb 103.4/4.11

Pickering A 1-4 542 MW 508 MW Jun 1966 Feb 1971 28/12 4680 390 a. Zircaloy-2 130.8/1.55 cw. Zr-2.5%Nb 103.4/4.06

Pickering B 5-8 540 MW 508 MW Nov 1974 Oct 1982 28/12 4560 380 a. Zircaloy-2 129/1.37 cw. Zr-2.5%Nb 103.4/4.01

Darlington 1-4 935 MW 881 MW Sep 1981 Nov 1989 37/13 6240 480 a. Zircaloy-2 129/1.37 cw. Zr-2.5%Nb 103.4/4.19

Point Lepreau N/A 680 MW 635 MW May 1975 Jul 1982 37/12 4560 380 a. Zircaloy-2 129/1.37 cw. Zr-2.5%Nb 103.4/4.19

Gentilly 2 675 MW 640 MW Apr 1974 Sep 1982 37/12 4560 380 a. Zircaloy-2 129/1.37 cw. Zr-2.5%Nb 103.4/4.19

Construction Start Start-up Fuel:

Elements in bundle/bundles per channel Total number of fuel bundles in core

Fuel Channels:

Number Calandria tube material Calandria tube ID/wall thickness (mm) Pressure tube material Pressure tube ID/wall thickness (mm)

Heat Transport System

Number of loops Reactor inlet/outlet temperature (C) Number of heat transport pumps Number of steam generators Number of SG tubes/material 4 250-265/304 4 8* 4200/Inconel 600 4 250-265/304 4 8* 4200/Inconel 600 2 249/293 12 plus 4 spare 12 2600/Monel 2 249/293 12 plus 4 spare 12 2573/Monel 4 267/310 4 4 4663/Incoloy 800 2 266/310 4 4 3542/Incoloy 800 2 266/310 4 4 3542/Inconel 600

5 4

Heat Transport System

(image courtesy of CANTEACH)

* Bruce A and B steam generators have separate preheaters

(Sources: International Atomic Energy Agency IAEA and Canadian Nuclear Safety Commission CNSC)

Calandria Heavy Water Moderator Lattice Tube Fuel Channel

Cross-Section

(image courtesy of AECL)

End Shield Tubesheet End Fitting

Feeder Pipe

Fuel Bundles

Shield Plug

Channel Liner Tube Closure

The heavy water coolant in the primary heat transport system removes heat from the reactor core by circulating in the pressure tubes and cooling the fuel bundles The HTS operating pressure is ~10 MPa and the typical Steam Outlet Nozzle Manway variation of coolant temperature is from 266C at the channel inlet to 312C at the channel outlet The HT water has a pH above 10 and a very low oxidation Secondary Cyclone Separators potential in order to protect the HT piping such as pressure Primary Cyclone Separators tubes, steam generator tubes, feeders, and fuel Steam Generators - transfer the heat from the hot Shroud Cone heavy water (D2O) circulating in the primary heat transport U Bend system to ordinary "light" water in the steam generator

Tube Bundle

Demand for Electricity

UNENE University Network of Excellence in Nuclear Engineering

Current energy infrastructure in Ontario will be unable to meet future supply requirements

coal phase-out will place additional strains on supply imports can only meet fluctuations in demand

Future demand can be met with a mix of sources, including Nuclear

MW Dispatchable (after avg. Capacity Factors applied)

Wind/Renewable ~10% of Installed MW IMO Median Demand Growth ~0.9% p.a. Pickering 2,3 Restart Total Gas ~12,000 MW (~30% of Installed MW) New Gas Builds ~7,000 MW Installed New Hydro (incl. ~1,400 MW from Manitoba)

36,000 34,000 32,000 30,000 28,000

Resources (MW)

UNENE is an alliance of universities, nuclear power utilities, research and regulatory agencies for the support and development of nuclear education and R&D capability in Canadian universities The main purpose of UNENE is to assure a sustainable supply of qualified nuclear engineers and scientists to meet the current and future needs of the Canadian nuclear industry Nuclear Research and Development

Positioning Assembly

Fuel

Pressure Tube

Shroud Grid Tube Support Plate

UNENE has established Industrial Research Chairs (professorships) in six Ontario universities through a partnership with NSERC and generous support from the Canadian nuclear industry UNENE has created a fully accredited course-based Master's of Engineering (MEng) program in Nuclear Engineering which is offered jointly by the member universities

New Nuclear (6,100 MW net) Six ACR-1000 units

Nuclear Engineering Education Program

Calandria Tube

Fuel Bundle Annulus Spacer Annulus Gas (CO2) Heavy Water Coolant

Close-up

End Plate Spacer Pad

Fuel Bundle

End Cap UO2 Fuel Pellet

Zircaloy Fuel Rod (fuel sheath)

The CANDU fuel consists of natural uranium, which contains a fraction of 0.72 % (isotopic abundance) of isotope 235U, with the remaining fraction in the form of 238U The fuel is fabricated into small UO2 pellets which are then placed inside 0.5 m long fuel rods (small Zircaloy tubes) The tubes are then arranged into fuel bundles consisting of an assembly of 37 elements Spacer pads on the surface of the tubes prevent direct contact of the fuel rods with the pressure tube walls and allow space for coolant flow through the bundles

26,000 24,000

Coal (as shutdown)

Tube Bundle Cold Leg

Tube Bundle Hot Leg

22,000 20,000 18,000

Nuclear Refurbishment Bruce & Darlington (Pickering A&B run to end of current life) Existing Resources (2005) 11,000 MW Nuclear 7,700 MW Hydro 7,600 MW Coal 5,100 MW Gas

Preheater Section

Acknowledgements

This work is part of the NSERC-UNENE Industrial Research Chair (IRC) program at the University of Waterloo. The Chair is one of the six university professorships established by UNENE in Ontario. The program is funded by UNENE in partnership with NSERC. Industrial sponsorship is provided by Ontario Power Generation, Bruce Power, and Atomic Energy of Canada Limited.

U N E N E University Network of Excellence in Nuclear Engineering

Feedwater Inlet Nozzle Tubesheet

16,000 14,000 12,000

D2 O Outlet

D2O Inlet

10,000

Steam Generator

(image courtesy of CANTEACH)

13

14

16

11

15

17

05

07

18

21

22 20

06

08

12

09

10

20

20

20

20

20

20

20

20

20

19

20

20

20

20

20

20

20

(Sources: Atomic Energy of Canada Limited AECL and Canadian Nuclear Association CNA)

20

20

20

23

Das könnte Ihnen auch gefallen

- 34.vver 1000 (V 466B)Dokument40 Seiten34.vver 1000 (V 466B)Dang LuNoch keine Bewertungen

- Introduction To CANDU Systems and OperationDokument258 SeitenIntroduction To CANDU Systems and OperationIsma-MANoch keine Bewertungen

- Codes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety ConceptsDokument14 SeitenCodes and Standards For Candu Plants: Presented By: A. Stretch Principal Engineer - Safety Conceptsjose_sebastian_2Noch keine Bewertungen

- CANDU & Differences With PWRDokument19 SeitenCANDU & Differences With PWRTenali AmareswarNoch keine Bewertungen

- B2 Stress IndexDokument12 SeitenB2 Stress IndexParilla13Noch keine Bewertungen

- Nuclear Power Reactors in The WorldDokument86 SeitenNuclear Power Reactors in The Worlddamp1rNoch keine Bewertungen

- Seismic Analysis of Steel Fuel Storage Tanks PDFDokument7 SeitenSeismic Analysis of Steel Fuel Storage Tanks PDFBala SutharshanNoch keine Bewertungen

- Assessment Protocol For Nozzle Loads On Pressure VesselsDokument5 SeitenAssessment Protocol For Nozzle Loads On Pressure VesselsBramJanssen76Noch keine Bewertungen

- Ver TubagemDokument7 SeitenVer TubagemHernâni CruzNoch keine Bewertungen

- A Model For Vortex Induced Oscillation of Structures (Iwan1974Dokument6 SeitenA Model For Vortex Induced Oscillation of Structures (Iwan1974taosyeNoch keine Bewertungen

- Stress AnalysisDokument30 SeitenStress AnalysisDinesh SunderNoch keine Bewertungen

- Modeling and Nonlinear Analysis of A Low-Power Gas Turbine - PsDokument25 SeitenModeling and Nonlinear Analysis of A Low-Power Gas Turbine - PszanjebooreNoch keine Bewertungen

- Netting Analysis of Composite Pressure VesselsDokument3 SeitenNetting Analysis of Composite Pressure VesselsPratyu Ch100% (1)

- CANDU6 Reactor Assembly PDFDokument1 SeiteCANDU6 Reactor Assembly PDFShrishma PaikNoch keine Bewertungen

- Barutzki PDFDokument9 SeitenBarutzki PDFesutjiadiNoch keine Bewertungen

- Arc Discharge Method: Sudama Chaurasiya Dr. A. Vadivel MuruganDokument14 SeitenArc Discharge Method: Sudama Chaurasiya Dr. A. Vadivel MuruganNithin ChandraNoch keine Bewertungen

- 10.1.1.144.9002 SW FatigueDokument13 Seiten10.1.1.144.9002 SW Fatigueb_wooNoch keine Bewertungen

- Dynamic AnalysisDokument16 SeitenDynamic AnalysismshNoch keine Bewertungen

- Barry Dooley Introducton-to-ACC-FAC-and-Cycle-ChemistryDokument37 SeitenBarry Dooley Introducton-to-ACC-FAC-and-Cycle-Chemistrychemicalchouhan9303Noch keine Bewertungen

- In Elastic Buckling of Geometrically Imperfect TubesDokument16 SeitenIn Elastic Buckling of Geometrically Imperfect TubesSiva RajNoch keine Bewertungen

- NUREG-1061 Vol.1 PDFDokument404 SeitenNUREG-1061 Vol.1 PDFAnonymous VzcJHaNoch keine Bewertungen

- Ch6 Thermal Stress Analysis Sp16Dokument34 SeitenCh6 Thermal Stress Analysis Sp16Haidar YafieNoch keine Bewertungen

- Elbow Center of GravityDokument2 SeitenElbow Center of GravityMallela Sampath KumarNoch keine Bewertungen

- Candu Material SelectionDokument12 SeitenCandu Material Selectionutpal singhaNoch keine Bewertungen

- High Voltage Pspice Manual PDFDokument35 SeitenHigh Voltage Pspice Manual PDFMuhammad Ahtisham AsifNoch keine Bewertungen

- 07MnMoVR Steel chn786s1 - T PDFDokument11 Seiten07MnMoVR Steel chn786s1 - T PDFAnonymous AkzeMHNTUyNoch keine Bewertungen

- Piping - Nozzle LoadingDokument2 SeitenPiping - Nozzle Loadingaap1100% (1)

- Tank Loading Data ExplanationDokument20 SeitenTank Loading Data ExplanationAnonymous xcFcOgMi100% (1)

- Fatigue Life Testing of Metal Expansion JointsDokument1 SeiteFatigue Life Testing of Metal Expansion JointsVirjil AycochoNoch keine Bewertungen

- Design Procedures For Profiled Metal Sheeting and DeckingDokument11 SeitenDesign Procedures For Profiled Metal Sheeting and DeckingPrapa KaranNoch keine Bewertungen

- Introduction To WRC 107 Concepts Limitations and FormulaDokument5 SeitenIntroduction To WRC 107 Concepts Limitations and FormulamoryNoch keine Bewertungen

- A New Method For Calculating The Busemann Head Coefficients For Radial ImpellersDokument7 SeitenA New Method For Calculating The Busemann Head Coefficients For Radial ImpellersIvan RaulNoch keine Bewertungen

- Vietnam Design CodeDokument5 SeitenVietnam Design Codesanh137Noch keine Bewertungen

- Thermal Fatigue Due To Statification in PipingDokument16 SeitenThermal Fatigue Due To Statification in PipinghamadaniNoch keine Bewertungen

- SR EN 13480 - 5 2002 EnglezaDokument4 SeitenSR EN 13480 - 5 2002 EnglezaTudorNoch keine Bewertungen

- Pipe Expansion & FlexibilityDokument92 SeitenPipe Expansion & Flexibilityfileseeker100% (1)

- Pipe StandardDokument30 SeitenPipe StandardOtto Wai Nursela100% (1)

- Adigrat University: College of Engineering and Technology Department of Chemical EnginneringDokument39 SeitenAdigrat University: College of Engineering and Technology Department of Chemical EnginneringSeid Aragaw100% (1)

- CuprionDokument93 SeitenCuprionSswahyudiNoch keine Bewertungen

- Nuclear Piping System Under Seismic LoadingDokument12 SeitenNuclear Piping System Under Seismic LoadingKing1971Noch keine Bewertungen

- Project Standards and Specifications Cooling Tower Systems Rev01Dokument11 SeitenProject Standards and Specifications Cooling Tower Systems Rev01ravirawat15Noch keine Bewertungen

- Done By: 1. Giyon Bezabh 0572/10 2. Mikiyas Adefa 0837/10Dokument50 SeitenDone By: 1. Giyon Bezabh 0572/10 2. Mikiyas Adefa 0837/10Mikey CouthinhoNoch keine Bewertungen

- Vacuum Basics: Kinetic Theory of GasDokument19 SeitenVacuum Basics: Kinetic Theory of GasFederico LeonNoch keine Bewertungen

- BS 4504 Slip On Flanges PDFDokument7 SeitenBS 4504 Slip On Flanges PDFMaclean ArthurNoch keine Bewertungen

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDokument12 SeitenStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAnonymous qhVGVpNoch keine Bewertungen

- Improved Analysis of External Loads On Flanged JointsDokument1 SeiteImproved Analysis of External Loads On Flanged JointsTiHoRNoch keine Bewertungen

- Effect of Gap Between Pad and Vessel For Moment Loading On NozzleDokument7 SeitenEffect of Gap Between Pad and Vessel For Moment Loading On NozzleRiccardo CozzaNoch keine Bewertungen

- Mechanics - Case Study Solution: Stress Transformation Equations Principal StressesDokument31 SeitenMechanics - Case Study Solution: Stress Transformation Equations Principal StressesPaldexNoch keine Bewertungen

- 07 Thermal StressDokument13 Seiten07 Thermal StressSundaravathanan ChellappanNoch keine Bewertungen

- A Comparison Between ASME B31.1 and ASME B31.3 On Some TopicsDokument4 SeitenA Comparison Between ASME B31.1 and ASME B31.3 On Some TopicsPranpath Narupantawart100% (1)

- Dimensional Analysis and Development of Similitude Rules For Dynamic Structural ModelsDokument5 SeitenDimensional Analysis and Development of Similitude Rules For Dynamic Structural ModelsgauravNoch keine Bewertungen

- Plasma Lighting System of LowDokument10 SeitenPlasma Lighting System of LowStanislavNoch keine Bewertungen

- Atomic and Nuclear PhysicsDokument42 SeitenAtomic and Nuclear PhysicsAvinash BoodhooNoch keine Bewertungen

- BatmanDokument11 SeitenBatmanDark KnitNoch keine Bewertungen

- Sudan University of Science and Technology College of Engineering School of Electrical and Nuclear Engineering Department of Nuclear Engineering Assignment On: Pressurized Water Reactor (PWR)Dokument19 SeitenSudan University of Science and Technology College of Engineering School of Electrical and Nuclear Engineering Department of Nuclear Engineering Assignment On: Pressurized Water Reactor (PWR)امجداحمدNoch keine Bewertungen

- Nuclear Reactors TypesDokument10 SeitenNuclear Reactors TypesDhita Rurin AdistyaningsihNoch keine Bewertungen

- Unesco - Eolss Sample Chapters: Pressurized Heavy Water ReactorsDokument8 SeitenUnesco - Eolss Sample Chapters: Pressurized Heavy Water ReactorsAnonymous qDCftTW5MNoch keine Bewertungen

- Energy Resources IDokument60 SeitenEnergy Resources IAkmal XusanovNoch keine Bewertungen

- Super Critical Water-Cooled Nuclear Reactors (SCWRS) Thermodynamic Cycle Options and Thermal Aspects of Pressure-Channel DesignDokument22 SeitenSuper Critical Water-Cooled Nuclear Reactors (SCWRS) Thermodynamic Cycle Options and Thermal Aspects of Pressure-Channel Designspnx13Noch keine Bewertungen

- AWB120 Dynamics 02 Modal AnalysisDokument40 SeitenAWB120 Dynamics 02 Modal AnalysisJohn BaynerNoch keine Bewertungen

- Getting Started, PepS TutorialDokument14 SeitenGetting Started, PepS TutorialJohn BaynerNoch keine Bewertungen

- Candu PosterDokument1 SeiteCandu PosterJohn BaynerNoch keine Bewertungen

- PowerShot G16 Camera User GuideDokument214 SeitenPowerShot G16 Camera User GuideJohn BaynerNoch keine Bewertungen

- 20040501Dokument54 Seiten20040501ioi999Noch keine Bewertungen

- ANSYS 14 Capabilities ManualDokument8 SeitenANSYS 14 Capabilities ManualAniruddha KulkarniNoch keine Bewertungen

- 2012 Publ Voice WinDokument40 Seiten2012 Publ Voice WinJohn BaynerNoch keine Bewertungen

- The COSMOS Companion, Understanding COSMOS Accuracy - Meshing and ConvergenceDokument36 SeitenThe COSMOS Companion, Understanding COSMOS Accuracy - Meshing and ConvergenceJohn BaynerNoch keine Bewertungen

- KZPOWER Full Genset RangeDokument2 SeitenKZPOWER Full Genset RangeNos GoteNoch keine Bewertungen

- Damper SelectionDokument11 SeitenDamper SelectionJKKNoch keine Bewertungen

- Assessment of The Need To Chemical Clean Effects of Waterside Deposits On Heat Recovery Steam Generator Performance TR-1008089Dokument50 SeitenAssessment of The Need To Chemical Clean Effects of Waterside Deposits On Heat Recovery Steam Generator Performance TR-1008089jycortes100% (2)

- Turbine Bypass Systems-Small Size PDFDokument12 SeitenTurbine Bypass Systems-Small Size PDFनिखिल बायवारNoch keine Bewertungen

- Boiler Feed Pump - Presentation Handbook PDFDokument51 SeitenBoiler Feed Pump - Presentation Handbook PDFAnonymous wIPMQ5rh91% (11)

- Internal Combustion EnginesDokument32 SeitenInternal Combustion Enginespramodkb_cusatNoch keine Bewertungen

- The Engineer's Guide To Plant Layout and Piping Design For The Oil and Gas Industries, Geoff Barker, 2018 PDFDokument28 SeitenThe Engineer's Guide To Plant Layout and Piping Design For The Oil and Gas Industries, Geoff Barker, 2018 PDFLawrensiaNoch keine Bewertungen

- GE Gasturbine CC ProductsDokument21 SeitenGE Gasturbine CC Productssameng82Noch keine Bewertungen

- Worksheet Wind TurbinesDokument3 SeitenWorksheet Wind TurbinesSarah SarahNoch keine Bewertungen

- Auxiliary Steam SystemDokument8 SeitenAuxiliary Steam SystemSherwin SabandoNoch keine Bewertungen

- Kubota Diesel Engine Super 03 Series - Model V1903Dokument3 SeitenKubota Diesel Engine Super 03 Series - Model V1903FalconNoch keine Bewertungen

- Boiler Normal Shut DownDokument13 SeitenBoiler Normal Shut DownRajat SharmaNoch keine Bewertungen

- Counter: AWS 50 G1 Single Line Diagram Pakai CompressorDokument1 SeiteCounter: AWS 50 G1 Single Line Diagram Pakai CompressorroozeipiNoch keine Bewertungen

- Boilers BasicsDokument19 SeitenBoilers BasicsShayan Hasan KhanNoch keine Bewertungen

- Despiece Volvo Penta TAMD162C-C, - TAMD163A-A, - TAMD163P-ADokument476 SeitenDespiece Volvo Penta TAMD162C-C, - TAMD163A-A, - TAMD163P-AHoracio SaltenoNoch keine Bewertungen

- How Car Engines Work PDFDokument3 SeitenHow Car Engines Work PDFMiguel Campusano RodriguezNoch keine Bewertungen

- MCQ Unit 3, 4 & 5 EC339Dokument20 SeitenMCQ Unit 3, 4 & 5 EC339zohaib100% (3)

- Design of Solar PV For K.K. Wagh Boy's HostelDokument14 SeitenDesign of Solar PV For K.K. Wagh Boy's HostelIJRASETPublicationsNoch keine Bewertungen

- Piston Maintenance: So - Ge.Vi. SRL Safety Management System C-7-22Dokument2 SeitenPiston Maintenance: So - Ge.Vi. SRL Safety Management System C-7-22Filip NikolevskiNoch keine Bewertungen

- 2022 Winter Model Answer PaperDokument18 Seiten2022 Winter Model Answer PaperShantanu WaghmareNoch keine Bewertungen

- GovernorStability, Pressure Rise& Speed RiseDokument5 SeitenGovernorStability, Pressure Rise& Speed Risejhaamit4Noch keine Bewertungen

- Egee 101h Reflective Essay OneDokument4 SeitenEgee 101h Reflective Essay Oneapi-218300213Noch keine Bewertungen

- Madhya Pradesh Power Transmission Company Limited: S, Nayagaon, Rampur, JabalpurDokument18 SeitenMadhya Pradesh Power Transmission Company Limited: S, Nayagaon, Rampur, JabalpurbhargavNoch keine Bewertungen

- SymbolsDokument34 SeitenSymbolsjoejex123Noch keine Bewertungen

- Boiler Tank in Tank ACV Smart Line Multi Energy - 400 Litri - Fisa - Tehnica PDFDokument2 SeitenBoiler Tank in Tank ACV Smart Line Multi Energy - 400 Litri - Fisa - Tehnica PDFambientinstal instalNoch keine Bewertungen

- Panou Solar Hibrid Termic Si FotovoltaicDokument2 SeitenPanou Solar Hibrid Termic Si FotovoltaicMarius BanuNoch keine Bewertungen

- Science: Quarter 4 - Module 6: Heat Energy Transfer in Heat EnginesDokument24 SeitenScience: Quarter 4 - Module 6: Heat Energy Transfer in Heat EnginesEden Cabarrubias75% (8)

- Maintenance Boiler Maintenance - Thermal Power Plant A-ZDokument4 SeitenMaintenance Boiler Maintenance - Thermal Power Plant A-ZkriziameiahnNoch keine Bewertungen

- Module 4 Diesel CycleDokument11 SeitenModule 4 Diesel CycleRalph Bernard Dela RosaNoch keine Bewertungen

- VGB PowerTech Magazine ArticleDokument7 SeitenVGB PowerTech Magazine ArticlemacrespoNoch keine Bewertungen