Beruflich Dokumente

Kultur Dokumente

Cross-Docking: Scheduling of Incoming and Outgoing Semi Trailers

Hochgeladen von

Rohan ViswanathOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cross-Docking: Scheduling of Incoming and Outgoing Semi Trailers

Hochgeladen von

Rohan ViswanathCopyright:

Verfügbare Formate

19 International Conference on Production Research

th

CROSS-DOCKING: SCHEDULING OF INCOMING AND OUTGOING SEMI TRAILERS

P.Baptiste, M.Y.Maknoon Dpartement de mathmatiques et gnie industriel, Ecole polytechnique Montral Montral, Qubec, Canada. Abstract This paper presents the scheduling of incoming and outgoing semi trailers in a transshipment platform. A set of incoming semi trailers, containing products for different destinations, arrives to the cross-docking. The incoming and outgoing doors are limited; consequently, the semi trailers have to be sequenced. This paper studies the simultaneous scheduling of incoming and outgoing semi trailers for a single inbound and outbound door. The objective is to maximize the direct flow from incoming semi trailers to outgoing semi trailers. The problem is decomposed into three parts. Tabu search is integrated with dynamic programming and a heuristic method is proposed to solve the three cases of the problem. In addition, few examples are performed and the results are shown. Keywords: Cross-docking, Scheduling incoming and outgoing semi trailers, scheduling, Tabu search, heuristic methods, dynamic programming

1 INTRODUCTION Transshipment is a logistic activity between producer and consumer in supply chain process that aims to reduce the costs by reducing inventory level. It breaks down incoming items, process and consolidates them for reshipment. Transshipment aims to reduce the cost and the lead time. In this paper, the authors focus on transshipment platforms. There are two sets of semi trailers beside transshipment platform: the incoming and the outgoing. The two sets have to be sequenced in a manner so that the platform respects just-in-time requirements. There are two ways to transfer products through the platform: moving directly from inbound to outbound door or using a temporary inventory area in the platform. Transshipment efficiency can be measured by the amount of products that passes directly through the platform. The second approach could not be acceptable. In addition to the inventory cost, there are additional movements of the products from inbound door to the storage area and from storage area to the outbound door. Therefore, there are several extra movements which occupy the transshipment facilities but do not enhance transshipment efficiency. This paper studies the problem of simultaneous sequencing inbound and outbound semi-trailers in transshipment in three parts. The three cases differ by the knowledge of incoming or outgoing sequence. In general three approaches are used to solve the problems: dynamic programming, Tabu search and Heuristic. The approach is being tested for some examples and the results are analyzed. 1.1 Literature review Generally in research papers, two aspects of transshipment are studied: strategically and operational. The research at the strategically level concerns mainly the platform location or the assignment of transportation jobs. Operational aspects deal with the efficiency of operational activities. One of the operational activities of transshipment is semi trailers transportation. Ping Chen et al. consider delivery and pickup time windows, warehouse capacities and inventory-handling to minimize the total transportation and

inventory cost in a transshipment network [1]. Young Hae Lee et.al. [2] proposed an integration model of transshipment and semi trailers scheduling to obtain more robust program. Lim et.al develop polynomial algorithm for transshipment problem considering just in time objective in the transshipment model [3]. Amano et al. [4] presents modal-shift transportation planning in cross docking network. It contains sets of facilities, orders and carriers with the objective to find a feasible schedule for carriers with minimum total cost which respect to deadlines. Steepest decent algorithm is used to solve the problem. Changing the physical layout can enhance transshipment performance. According to Bartholdi et al. [5] cross docking is a labor intensive area and workers performance depends on how well semi trailers are assigned to doors; moreover, a good layout reduces travel distances without creating congestion. They conclude that changing layout reduce reduces shipping and handling cost within transshipment platform. Time span in scheduling increases the transshipment efficiency. Li et al. [6] propose a problem in which each container should be filled in exact time. Machine scheduling problem is used as a model. In this model the transshipment platform is divided into loading and unloading areas. The arriving dates for incoming semi trailer are variable. The received Items are then either shipped away directly or sent to the exportation area in order to be loaded for reshipment. In this problem the time to start unloading semi trailer is scheduled in order that each loading semi trailer is completed at its due date. Douglas L. Mc Williamsa et al. [7] have studied the problem of parcel industry. The research focuses on the transfer operation platforms. Parcels are unloaded and shipped to outbound semitrailers. The objective is to minimize time interval from the first unloaded parcel till the last loaded parcel. An integrated simulation model that integrates a genetic algorithm is proposed to find the solution. Wooyen Yu et al. consider the scheduling of inbound and outbound semi-trailers in order to minimize completion time while the storage is located at shipping dock. Two approaches are proposed to obtain the results: mathematical model and heuristic algorithms. Mathematical models are used to solve small size

problems while they are not practical for the large problems. In contrast, the heuristic methods are used to solve the large problems [8]. Scheduling the sequence of loading and unloading semi trailers also increases the efficiency of the transshipment platform. In fact, synchronize loading and unloading sequences decreases inventory level and increases direct product flow from inbound to outbound door. As a result it increases transshipment efficiency. In this paper scheduling of loading and unloading semi trailers in cross docking are studied. 2 PROBLEDESCRIPTION: In practice, transshipment has various layouts. In this research the layout is being restricted to one inbound and one outbound door. This restriction is not realistic (in a real transshipment platform) but can be used as a baseline for other layouts. In this model an incoming semi trailer arrives at inbound door and unloads products for various destinations. If the outgoing semi trailer is going to the fine destination, the products are moved directly to outbound semi trailer (direct transit of products), in the other hand, the products are moved to a temporary storage (products in temporary storage). In studied model, the following assumptions are considered: Each trailer leaves the inbound door when it is fully unloaded. On the other side, each trailer leaves the outbound door when it is fully loaded. The internal operations of cross docking such as sorting and merging are not considered. The storage capacity is assumed unlimited. Each outbound semi trailers leaves only for one destination. All incoming and outgoing semi trailers are available at time zero. The total numbers of arriving and departing products are equal. The products differ by their destination. Loading, unloading and transfer time are constant and are not considered. Inside incoming semi trailers there are products for different destinations while for outgoing semi trailers there are products for just one destination.

the output door, and items are already waiting on the ground for the same destination. The manager can choose to ship those items or wait till an incoming semi trailer arrives with items that can be shipped directly to this destination. Obviously, the loading and unloading sequences (variables 1 and 2) and products movement policies (variables 3 and 4) are two important factors which affect transshipment performance. For the fourth variable, there are two different policies. At the first policy, products already on the ground are systematically used to complete a semi trailer (fewer inventories). At the second policy, items already on the ground remain for the last semi trailer for their destination. The optimal policy is a combination of the two extreme policies. In general some times, it is better to use inventory, compare to waiting for direct transshipment. Three cases are proposed. The definition of each case is as follows: Case 1: the sequences of incoming and outgoing semi trailers are known a priori and only variables 3 and 4 are examined. Case 2: The sequences of incoming semi trailers are known a priori and variables 2, 3 and 4 are examined. Case 3: no sequences are known a priori and variables 1, 2, 3 and 4 are examined. With the above assumptions the resolution approaches are discussed in the next section. 3 RESOLUTIONS

In addition, the information about type of products and the quantity of arriving products for each destination are known. For this problem, the following decision variables are considered: 1. Incoming sequence 2. Outgoing sequence 3. Unloading sequence of semi trailers 4. Unloading policy The first two variables are obvious, but the third variable corresponds to the fact that unloading order of an incoming semi trailer contains items to be shipped in different destinations, which can influence the efficiency. Obviously, items that can be shipped in the active destination (current outgoing semi trailer) have to be unloaded first. This variable can be free or fixed (due to technical constraints for the unloading operations). For the last case, the optimal decision is usually evident. The fourth variable (unloading policy) corresponds to the following situation: an outgoing semi trailer is positioned at

3.1 First case resolution approach Objective in the first case is to obtain the optimal policy (maximizing direct transiting products) when the sequence of loading and unloading semi trailers are known. Complete enumeration technique is used to obtain optimal policy. A graph is used to present all the possibilities of assignments. The graph nodes are used to present assignment state and the arcs are used to present forthcoming possibilities. The following variables are saved in each node: Vector of variables indicates possible direct transiting product for each destination. (PDT) Vector of variables indicates the number of products which are now in temporary storage, for each destination. (PTS) cost (the total number of direct transiting product from beginning to the current node) (C) Order number of loaded semi trailer. (ON) For each arc, unloading semi trailer order number and cost (the number of direct transferred product for forthcoming assignment) are saved. For the Initial node, the PDT variables are equal to the first semi trailer products content for each destination and the rest of the variables default numbers are zero. This algorithm starts with the initial node, afterwards, in each iteration, it increments the order number of loading semi trailer and reads all the generated nodes for current loading semi trailer. For each node, it generates all the possible arcs for remaining loading semi trailers order;

19 International Conference on Production Research

th

therefore, all the future possible nodes are obtained. This process repeats as long as all the loading semi trailers are chosen. At the last iteration the node which has the highest cost is chosen as the final node. The path from the initial node up to the final node is loading and unloading optimal policy In practice, two domination rules are used to decrease computational time. The first rule proposes that if for all destinations the summation of direct transiting and storage products for two or more nodes are the same, the node with the highest cost dominates the others. However, the second rule is applied when two or more nodes have the same cost. The node with higher summation of direct transiting products for all destinations dominates the others. Dynamic programming is used to solve this algorithm. The steps are as follows: Optimal policy algorithm Step 1: create an initial node (discussed before) Step 2: do as long as all outbound semi trailers are assigned. Step 3: obtain all forthcoming assignments. Step 4: check domination rule. Step 5: go to step 2. Step 6: find the node with highest cost in the last iteration Step 7: find the path for optimal policy. Example: In this example there are 6 incoming semi trailers containing the products for 3 destinations. The first semi trailer contains 3 products for destination A, 2 and 0 for destinations B and C, respectively. Table 1 presents the incoming semi trailer orders. The sequence of outgoing semi trailers is C-B-A-A-B-A and the trailer capacity is 5 units.

10 10 8 0 1 5 2 3 5 4 0 i Node(i) with cost 0 Optimal Path i Dominated Node 5 9 6 7 7 8 9 9 9 10 7 11 10 12 12 13 10 14 12 15 12 16

Figure 1 : Optimal policy algorithm for the example The optimal path is 1-2-4-7-11-14-16 with the cost of 12 units. The nodes 9, 12 and 16 are dominated nodes. 3.2 Second case resolution approach In this case, two methods are proposed. Using Tabu search integrated with optimal policy algorithm and a heuristic method. The first method proposes the following algorithm: Loading semi trailer sequence algorithm: Step 1: Run optimal policy algorithm for the initial value Step2: Select two loading semi trailers order number Step3: Swap the order number and save it in Tabu list (if they are not for same destination and are not in Tabu list). Step 4: Run optimal policy algorithm. Step 5: Save the cost and optimal path if it is improved. Step 6: Go to step 2 or stop if the cost is not modified after 20 iterations.

Table 1 : Example

Order 1 2 3 4 5 6

The algorithm flow chart is presented in figure 2. C 0 1 1 0 3 0

LIMIT=0

START

Destination

A 3 0 4 4 2 2 B 2 4 0 1 0 3

RUN OPTIMAL POLICY ALGORITHM RANDOMLY SWAP 2 LOADING SEMI TRAILER DESTINATION ORDER RUN OPTIMAL POLICY ALGORITHM LIMIT=LIMIT+1

The graph is presented in figure 1:

YES COST IMPROVE NO LIMIT=20 NO

STOP

Figure 2: loading semi trailer sequence algorithm

In loading semi trailer algorithm, the optimal policy is not the combination of sub optimal policies. In other words, sometimes selecting the arc with lower cost would lead us to the node with highest cost. On the other hand in proposed heuristic method it is supposed that sub optimal assignments lead the process to the optimal result. In heuristic algorithm, the preceding graph is used to illustrate all the assigned possibilities. Furthermore, deep first search method is used searching for the best assignment. The algorithm is described as follows and the flow chart is presented in figure 3: Loading semi trailer sequence heuristic algorithm Step 1: Create an initial state (the value of direct transiting products for each destination equals to the first unloaded semi trailer products, the rest is zero) Step 2: For all loading semi trailers Step 3: For all destinations Step 4: Do as long as direct transiting product is more than semi trailer capacity Step 5: For current state, calculate the cost if the summation of direct transiting products and in storage products for selected destination equals to or greater than semi trailer capacity. Persevere the results, if the cost is improved. Step 6: Unload the next semi trailer and update values. Step 6: Go to step 4 Step 7: Save the best assignment Step 8: Set best assignment as current state and go to step 2 Step 8: The final list is the optimal assignment

Example:

In the previous example, for the given incoming sequence, the solution obtained with the first algorithm is 23 with B-AA-C-B-A sequence. For the second algorithm the obtained sequence is B-A-A-C-A-B with the value of 23. 3.3 Third case resolution approach The previous two methods are developed to obtain the good sequence of loading and unloading semi trailers. Tabu search integrates with loading semi trailer algorithm or loading semi trailer heuristic algorithm to obtain good unloading sequence. The algorithm is presented in the following steps:

Loading and unloading sequence algorithm Step 1: Run loading semi trailer sequence algorithm/ loading semi trailer sequence heuristic algorithm for initial value Step2: Select two unloading semi trailers order numbers Step3: If they are not in Tabu list, Swap the order number and save it in Tabu list. Step 4: Run loading semi trailer algorithm/ loading semi trailer heuristic algorithm Step 5: Save the cost and optimal path if it increase. Step 6: Go to step 2 or Stop if the cost is not improved after 20 iterations. The figure 4 presents the algorithm:

START

START

FOR ALL LOADING ORDER FOR ALL DESTINATIONS

RUN LOADING SEMI TRAILER SEQUENCE ALGORITHM OR RUN LOADING SEMI TRAILER SEQUENCE HEURISTIC ALGORITHM FOR INITIAL ANSWER RANDOMLY SWAP 2 UN LOADING SEMI TRAILER ORDER RUN LOADING SEMI TRAILER SEQUENCE ALGORITHM OR RUN LOADING SEMI TRAILER SEQUENCE HEURISTIC ALGORITHM

CALCULATE COST KEEP IT IF IT IS IMPROVED

UNLOAD NEXT SEMI TRAILER AND UPDATE VALUES

LIMIT=0

LIMIT=LIMIT+1

DIRECT TRANSITING PRODUCT > SEMI TRAILER CAPACITY

NO

YES

COST IMPROVE NO LIMIT=20 NO

SET BEST CHOSEN NODE AS CURRENT STATE

OBTAIN LIST IS OPTIMAL POLICY

STOP

END

Figure 4: loading and unloading sequence algorithm Figure 3: Loading semi trailer sequence heuristic algorithm

19 International Conference on Production Research

th

Example:

In the previous example, for the given data, the solution obtained with the first algorithm is 27 with A-B-C-A-B-A and 3-6-4-5-1-2 sequences. For the second algorithm the obtained sequence is A-B-A-A-C-B and 4-1-6-2-5-3 with the cost value of 26. 4 EXPERIMENT

100 90 80 70 60 50 40 30 20 10 0 3-3-3-3 6-3-2-1 4-4-2-2 4-4-3-1

CASE 1 CASE 2-1 CASE 2-2 CASE 3-1 CASE 3-2

Medium size problems (contains 12 loaded and 12 unloaded semi trailers) are considered as the test problems. Four different destination combinations (3-3-3-3, 6-3-2-1, 4-2-2-2 and 4-4-3-1) are selected to cover the problem diversity. For each combination 4 sets of data are generated. The loading and unloading trailers capacities are considered as 10 units. Each algorithm is run for all generated data and combinations. The results are shown in table 2 and are summarized in figure 5 and table 3. The results depend on the combination of destinations (Figure 5). The improvement for case 3-3-3-3 is 13.75% and for the case 4-4-3-1 is 34.75% (Table 3). The results indicate that the combinations of destinations are important to implement cross docking semi trailer scheduling.

Figure 5 : Experimental results for different sequence combination

Figure 6 and 7 present the Tabu search results for selected problem (4-4-3-1, data test 1) for case 3-1 and 3-2. It seems that integrated Tabu search with heuristic method reach to good value with less iteration.

Table 3 : Summary of improvements approach implementation

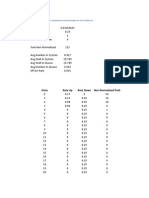

Combination CASE 1 CASE 2-1 Improve percentage CASE 2-2 Improve percentage CASE 3-1 Improve percentage CASE 3-2 Improve percentage 3-3-3-3 62.25 68.5 6.25% 67 4.75% 76 13.75% 74.75 12.50% 6-3-2-1 64 81 17.00% 81 17.00% 86 22.00% 86.5 22.50% 4-4-2-2 48 74.25 26.25% 73.25 25.25% 78.75 30.75% 80.75 32.75% 4-4-3-1 47.25 76.5 29.25% 75.75 28.50% 80.75 33.50% 82 34.75% average 55.375 75.0625 19.69% 74.25 18.88% 80.375 25.00% 81 25.63%

Table 2 : Experimental results for different sequence

combination

Results

Destination Data CASE CASE CASE CASE CASE Set 1 2-1 2-2 3-1 3-2

3-3-3-3

6-3-2-1

4-4-2-2

Claculated Value

4-4-3-1

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

61 59 67 62 66 65 63 62 47 49 47 49 47 47 46 49

68 66 69 71 80 82 83 79 75 73 74 75 76 74 78 78

62 61 71 74 78 78 86 82 74 73 74 72 78 75 77 73

78 73 79 74 86 85 85 88 74 80 80 81 79 79 79 86

76 69 79 75 87 84 86 89 80 80 80 83 81 79 82 86

Tabu search iteration results 90 80 70 60 50 40 1 3 5 7 9 11 13 15 17 19

For case 2 of the problem, integrated Tabu search with dynamic programming show better performance compare to the heuristic method with improvement between 6.25% to 29.25% and 4.75% to 28.5% respectively. In contrast, for case 3 heuristic method show better performance. In addition, for test data, on average there is almost 20 percent improvement when the sequence of outgoing semi trailers is planned compare to 25 percent improvement ,in average when both sequences are planned.

Iteration

Figure 6 : Tabu search results for selected problem (4-4-3-1, data test 1) Case 3-1

Tabu search iteration results (Heuristic Method) 90 80

[3]

[4]

70 60 1 2 3 4 5 6 7 8 9 10 11 12 13 14

Iteration

[5]

Figure 7 : Tabu search results for selected problem (4-4-3-1, data set 1) Case 3-2

[6]

CONCLUSION

[7]

Transshipment platform is a place where the products from incoming semi trailers are unloaded and then loaded for reshipment. Efficiency of such platform is related to the ratio of direct moves (only one manipulation). Scheduling the incoming and outgoing semi trailers can increases transshipment efficiency. This research explores the particular case of a platform with a single incoming door and a single outgoing door. Three cases of this problem are studied and dynamic programming and heuristic methods are proposed as a two major function to solve the problems. A medium size problem is defined as test data for numerical results. When both schedules are known, an optimal algorithm based on dynamic programming finds the optimal use of the temporary inventory. When one or both sequence is unknown, two different approaches have been proposed. The first uses a stochastic algorithm for the schedule and an optimal evaluation function. The second is a heuristic. The heuristic is much faster and as efficient that the stochastic algorithm. The heuristic algorithm reaches the good results in a very few iterations, moreover, because of the assumptions for heuristic algorithm, it run in shorter time rather than other algorithm. For generated case it is shown that by scheduling both incoming and outgoing semi-trailers, there is 25% improvement in transshipment performance. Most of this improvement can be obtained with scheduling only outgoing semi trailers (20%). To conclude, it is shown that scheduling loading and unloading semi trailers increases transshipment efficiency. Those results have to be extended to general platform, with more than one incoming door and more than one outgoing door.

[8]

Engineering, 2006, article in press. Lim A., Miao Z., Rodrigues B., Xu A., Transshipment through Cross docks with Inventory and Time Windows, Wiley Inter science, 2005. 724-733. Amano M., Yoshizumi T., Okano H., 2003, The modal-shift transportation planning problem and its fast steepest descent algorithm, Proc. of the Winter Simulation Conference. 1720-1728. Bartholdi J.J., Gue K.R., Reducing labor costs in an LTL cross docking terminal. Operation Research, 2002, 48,823-832. Li Y., Rodrigues B., Cross docking JIT scheduling with time windows , Journal of the Operational Research Society,2004 55, 13421351 Mc Williams D.L., Stanfield P.M., Geiger C.D., The parcel hub scheduling problem: A simulation-based solution approach ,Computers and Industrial Engineering 2005,49, 393412 Yu W., Egbelu P.J., Scheduling of inbound and outbound trucks in cross docking system with temporary storage, European journal of operation research,2006, Article in press.

6

[1]

REFERENCES

Chen P., Guo Y., Lim A., Rodrigues B. ,Multiple cross docks with inventory and time windows, Computers and Operations Research 2006, 33, 4363. Lee Y.H., Jung J.W., Lee K.M., Vehicle routing scheduling for cross-docking in the supply chain, Computers and Industrial

[2]

Claculated Value

Das könnte Ihnen auch gefallen

- Session4 Automotive Front End DesignDokument76 SeitenSession4 Automotive Front End DesignShivprasad SavadattiNoch keine Bewertungen

- Mixing and Agitation 93851 - 10 ADokument19 SeitenMixing and Agitation 93851 - 10 Aakarcz6731Noch keine Bewertungen

- Activity Evaluation Form: "Where Children Come First"Dokument1 SeiteActivity Evaluation Form: "Where Children Come First"TuTitNoch keine Bewertungen

- Case Study - 440Dokument4 SeitenCase Study - 440Rohan ViswanathNoch keine Bewertungen

- Stewart, Mary - The Little BroomstickDokument159 SeitenStewart, Mary - The Little BroomstickYunon100% (1)

- 1 A Simulation Based Model For The BerthDokument9 Seiten1 A Simulation Based Model For The BerthMonu KumarNoch keine Bewertungen

- Liu 2003Dokument15 SeitenLiu 2003UlyviatrisnaNoch keine Bewertungen

- Scheduling Trucks in A Multi-Door Cross-Docking SyDokument14 SeitenScheduling Trucks in A Multi-Door Cross-Docking SyAhmad BuchoriNoch keine Bewertungen

- A Hybrid Approach For Cross-Docking Scheduling: 1. IntroductionDokument10 SeitenA Hybrid Approach For Cross-Docking Scheduling: 1. IntroductionSHUBHAM JAINNoch keine Bewertungen

- 1 s2.0 S1877042813023458 MainDokument10 Seiten1 s2.0 S1877042813023458 MainMary Anne SiegaNoch keine Bewertungen

- Linehaul-Backhaul: Solutions With Spacefilling CurvesDokument2 SeitenLinehaul-Backhaul: Solutions With Spacefilling CurvesAlFayedArnobNoch keine Bewertungen

- Truck Scheduling at Zero Inventory Cross Docking TerminalsDokument10 SeitenTruck Scheduling at Zero Inventory Cross Docking TerminalssanjapetNoch keine Bewertungen

- Synchronization in Vehicle Routing - A Survey of Vrps With Multiple Synchronization ConstraintsDokument58 SeitenSynchronization in Vehicle Routing - A Survey of Vrps With Multiple Synchronization ConstraintskazaparuNoch keine Bewertungen

- A Robust Optimization Approach For The Milk Run Problem With Time Windows Under Inventory Uncertainty - An Auto Industry Supply Chain Case StudyDokument7 SeitenA Robust Optimization Approach For The Milk Run Problem With Time Windows Under Inventory Uncertainty - An Auto Industry Supply Chain Case Studyvarun_gupta_68Noch keine Bewertungen

- Expert Systems With Applications: Christopher Expósito-Izquierdo, Belén Melián-Batista, Marcos Moreno-VegaDokument13 SeitenExpert Systems With Applications: Christopher Expósito-Izquierdo, Belén Melián-Batista, Marcos Moreno-VegaBouchra GhailanNoch keine Bewertungen

- Vehicle Routing ProblemDokument9 SeitenVehicle Routing ProblemJohan OscarNoch keine Bewertungen

- A Simulation Study On A Workload-Based Operation Planning Method in Container TerminalsDokument11 SeitenA Simulation Study On A Workload-Based Operation Planning Method in Container TerminalssajjadNoch keine Bewertungen

- Sciarrone 1988Dokument18 SeitenSciarrone 1988Juan Sebastián Poveda GulfoNoch keine Bewertungen

- Online Rules For Container Stacking: Bram Borgman Rommert DekkerDokument30 SeitenOnline Rules For Container Stacking: Bram Borgman Rommert DekkerJesus ZuñigaNoch keine Bewertungen

- Simulación de SistemasDokument10 SeitenSimulación de SistemasEfrain Parra QuispeNoch keine Bewertungen

- Cross-Docking Operation Scheduling: Truck Arrivals, Shop-Floor Activities and Truck DeparturesDokument7 SeitenCross-Docking Operation Scheduling: Truck Arrivals, Shop-Floor Activities and Truck DeparturesVadimNoch keine Bewertungen

- Implementation of Milk Run Material Supply System in Vehicle Routingproblem With Simultaneous Pickup and DeliveryDokument3 SeitenImplementation of Milk Run Material Supply System in Vehicle Routingproblem With Simultaneous Pickup and DeliveryInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Highly Efficient AGV Transportation System Management Using Agent Cooperation and Container Storage PlanningDokument6 SeitenHighly Efficient AGV Transportation System Management Using Agent Cooperation and Container Storage Planningyokito85Noch keine Bewertungen

- Braekers 2012Dokument22 SeitenBraekers 2012rajNoch keine Bewertungen

- İbrahim İşit - The Soluti̇on of The Problem of Locating The Distrubition of Goods by A Shipping AgentDokument8 Seitenİbrahim İşit - The Soluti̇on of The Problem of Locating The Distrubition of Goods by A Shipping Agentİbrahim İşitNoch keine Bewertungen

- Research Article: Algorithms For Pallet Building and Truck Loading in An Interdepot Transportation ProblemDokument12 SeitenResearch Article: Algorithms For Pallet Building and Truck Loading in An Interdepot Transportation ProblemHữu BìnhNoch keine Bewertungen

- A Model For The Stowage Planning of 40 Feet Containers at Container TerminalsDokument9 SeitenA Model For The Stowage Planning of 40 Feet Containers at Container Terminalsliao_marcoNoch keine Bewertungen

- Alternative Mixed-Integer Linear Programming Models of A MaritimeDokument26 SeitenAlternative Mixed-Integer Linear Programming Models of A Maritimemajid yazdaniNoch keine Bewertungen

- Flexsim CTDokument6 SeitenFlexsim CTAhmed SamyNoch keine Bewertungen

- Poms 2023 10 19Dokument20 SeitenPoms 2023 10 19g1305626957Noch keine Bewertungen

- 2013 IjbmDokument7 Seiten2013 IjbmSafwan AltaraziNoch keine Bewertungen

- Research Article: Simulation-Based Planning and Control of Transport Flows in Port Logistic SystemsDokument13 SeitenResearch Article: Simulation-Based Planning and Control of Transport Flows in Port Logistic SystemsBee ThymeNoch keine Bewertungen

- 24 IJTPE Issue54 Vol15 No1 Mar2023 pp164 170Dokument7 Seiten24 IJTPE Issue54 Vol15 No1 Mar2023 pp164 170ahmedNoch keine Bewertungen

- Int. J. Production Economics: Hsiao-Fan Wang, Ying-Yen ChenDokument10 SeitenInt. J. Production Economics: Hsiao-Fan Wang, Ying-Yen ChenFelipe Rodríguez RojasNoch keine Bewertungen

- Yard Crane Management by Simulation and OptimisationDokument22 SeitenYard Crane Management by Simulation and OptimisationRatna YanuarNoch keine Bewertungen

- Transportation Cost in Multi-Item Economic Order Quantity: Full Length Research PaperDokument9 SeitenTransportation Cost in Multi-Item Economic Order Quantity: Full Length Research PaperAkshay ThoratNoch keine Bewertungen

- Paper 1Dokument16 SeitenPaper 1sivaNoch keine Bewertungen

- A Novel Mathematical Model For Cross Dock Open-Close Vehicle Routing Problem With SplittingDokument12 SeitenA Novel Mathematical Model For Cross Dock Open-Close Vehicle Routing Problem With Splittingaravind kumarNoch keine Bewertungen

- Om Group 8Dokument15 SeitenOm Group 8SowmyaNoch keine Bewertungen

- A Comparative Analysis of Bus Transitvehicle Scheduling ModelsDokument22 SeitenA Comparative Analysis of Bus Transitvehicle Scheduling ModelsRichie Jeet SinhaNoch keine Bewertungen

- Application of DEA To The Analysis of AGV Fleet Operations in A Port Container Terminal - ScienceDirectDokument10 SeitenApplication of DEA To The Analysis of AGV Fleet Operations in A Port Container Terminal - ScienceDirectHo Van RoiNoch keine Bewertungen

- 1 A Simulation Based Model For The BerthDokument9 Seiten1 A Simulation Based Model For The Berthmonu_vitsNoch keine Bewertungen

- A Distributed Metaheuristic For The Transportation Problem: Lcruz@itcm - Edu.mx, Ia32, Juanarturo Jgvaldez50, cggs71Dokument10 SeitenA Distributed Metaheuristic For The Transportation Problem: Lcruz@itcm - Edu.mx, Ia32, Juanarturo Jgvaldez50, cggs71cruzreyeslauraNoch keine Bewertungen

- Crane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeDokument7 SeitenCrane and Shuttle Optimization in Warehousing Systems: Amatol, Bade2, PasqualeGilmar Vieira de SouzaNoch keine Bewertungen

- A Hybrid Genetic Algorithm For The Traveling Salesman Problem With DroneDokument29 SeitenA Hybrid Genetic Algorithm For The Traveling Salesman Problem With DroneRayanNoch keine Bewertungen

- Open VRPDokument13 SeitenOpen VRPdeffanda vista putriNoch keine Bewertungen

- Transportation Research Part B: Dong-Ping Song, Jing-Xin DongDokument20 SeitenTransportation Research Part B: Dong-Ping Song, Jing-Xin Donglegislatif FTKNoch keine Bewertungen

- Efh Ausimm PaperDokument7 SeitenEfh Ausimm PaperSunny SouravNoch keine Bewertungen

- Analyzing A Unified Ant System For The VRP and Some of Its VariantsDokument11 SeitenAnalyzing A Unified Ant System For The VRP and Some of Its VariantsFelipe Rodríguez RojasNoch keine Bewertungen

- Determining The Best Fleet Sizing of A Container Terminal For A Given LayoutDokument9 SeitenDetermining The Best Fleet Sizing of A Container Terminal For A Given LayoutMoiz Ahmed KapadiaNoch keine Bewertungen

- Population Metaheuristics To Solve The Professional Staff Transportation ProblemDokument15 SeitenPopulation Metaheuristics To Solve The Professional Staff Transportation ProblemkofiomariNoch keine Bewertungen

- J Tre 2006 01 003Dokument17 SeitenJ Tre 2006 01 003Bella ArishaNoch keine Bewertungen

- Six Sigma Very GoodDokument14 SeitenSix Sigma Very Goodsornapudi472Noch keine Bewertungen

- Simulating Dispatching Strategies For Automated Container TerminalsDokument6 SeitenSimulating Dispatching Strategies For Automated Container TerminalsAdn AdinaNoch keine Bewertungen

- QTDM PRJDokument5 SeitenQTDM PRJakilanNoch keine Bewertungen

- A Monolithic Approach To Vehicle Routing and Operations Scheduling of A Cross-Dock SystemDokument22 SeitenA Monolithic Approach To Vehicle Routing and Operations Scheduling of A Cross-Dock SystemAhmad BuchoriNoch keine Bewertungen

- 2000 Holguin-Veras e ThorsoDokument12 Seiten2000 Holguin-Veras e ThorsothiagocanhosNoch keine Bewertungen

- The Petrol Station Replenishment Problem With Time WindowsDokument17 SeitenThe Petrol Station Replenishment Problem With Time WindowsJuan FelipeNoch keine Bewertungen

- Li 2005Dokument13 SeitenLi 2005Yoya LoyaNoch keine Bewertungen

- Automacao e ControleDokument11 SeitenAutomacao e ControleErnestina CarvalhoNoch keine Bewertungen

- Operations by Forklifts in Warehouses: Aurelija BurinskieneDokument7 SeitenOperations by Forklifts in Warehouses: Aurelija BurinskieneasdNoch keine Bewertungen

- In Search of The Ideal Truck-Excavator CombinationDokument9 SeitenIn Search of The Ideal Truck-Excavator CombinationJairo Toledo SxeNoch keine Bewertungen

- MIP For VRP With Simultaneous Delivery and Pick-Up With Maximum Route-LengthDokument22 SeitenMIP For VRP With Simultaneous Delivery and Pick-Up With Maximum Route-LengthMinh Châu Nguyễn TrầnNoch keine Bewertungen

- 4 448608543793217861 PDFDokument10 Seiten4 448608543793217861 PDFMaryam ShirbanNoch keine Bewertungen

- SK II Japan Marketing Plan - Group 1-LibreDokument23 SeitenSK II Japan Marketing Plan - Group 1-LibreRohan ViswanathNoch keine Bewertungen

- Sai Sameer Tammana, Rohan ViswanathDokument1 SeiteSai Sameer Tammana, Rohan ViswanathRohan ViswanathNoch keine Bewertungen

- Ioe 419 ExamDokument6 SeitenIoe 419 ExamRohan ViswanathNoch keine Bewertungen

- PDCA CyclesDokument9 SeitenPDCA CyclesRohan ViswanathNoch keine Bewertungen

- Alpha Delay Overtime Objective 0.999 20 240 20.22 0.001 140 60 60.08 0.5 100 100 100Dokument1 SeiteAlpha Delay Overtime Objective 0.999 20 240 20.22 0.001 140 60 60.08 0.5 100 100 100Rohan ViswanathNoch keine Bewertungen

- Case SCMDokument9 SeitenCase SCMbarkha_agarwal_4Noch keine Bewertungen

- 591 DiagramDokument1 Seite591 DiagramRohan ViswanathNoch keine Bewertungen

- Answers Are Due Before Start of Class On Thursday, March 27, 2014Dokument2 SeitenAnswers Are Due Before Start of Class On Thursday, March 27, 2014Rohan ViswanathNoch keine Bewertungen

- IOE 510 FinalsDokument1 SeiteIOE 510 FinalsRohan ViswanathNoch keine Bewertungen

- Assignment 6Dokument1 SeiteAssignment 6Rohan ViswanathNoch keine Bewertungen

- Whats AppDokument4 SeitenWhats AppPetruNoch keine Bewertungen

- Notice ConcerningDokument87 SeitenNotice ConcerningRohan ViswanathNoch keine Bewertungen

- Sai Sameer Tammana, Rohan ViswanathDokument1 SeiteSai Sameer Tammana, Rohan ViswanathRohan ViswanathNoch keine Bewertungen

- An Example of Dantzig-Wolfe DecompositionDokument7 SeitenAn Example of Dantzig-Wolfe DecompositionRohan ViswanathNoch keine Bewertungen

- 第六單元:Inventory Management: Safety Inventory (I)Dokument54 Seiten第六單元:Inventory Management: Safety Inventory (I)Rohan ViswanathNoch keine Bewertungen

- The International Poker RulesDokument2 SeitenThe International Poker RulesOutontheBubbleNoch keine Bewertungen

- Electric Motor Cycle and ScooterDokument9 SeitenElectric Motor Cycle and ScooterA A.DevanandhNoch keine Bewertungen

- Optimal Dispatch of Generation: Prepared To Dr. Emaad SedeekDokument7 SeitenOptimal Dispatch of Generation: Prepared To Dr. Emaad SedeekAhmedRaafatNoch keine Bewertungen

- ArcGIS Shapefile Files Types & ExtensionsDokument4 SeitenArcGIS Shapefile Files Types & ExtensionsdanangNoch keine Bewertungen

- Advent Wreath Lesson PlanDokument2 SeitenAdvent Wreath Lesson Planapi-359764398100% (1)

- BRAND AWARENESS Proposal DocumentDokument11 SeitenBRAND AWARENESS Proposal DocumentBuchi MadukaNoch keine Bewertungen

- Bigbazaar PDFDokument14 SeitenBigbazaar PDFazhagu sundaramNoch keine Bewertungen

- Engine Controls (Powertrain Management) - ALLDATA RepairDokument3 SeitenEngine Controls (Powertrain Management) - ALLDATA RepairRonald FerminNoch keine Bewertungen

- Countable 3Dokument2 SeitenCountable 3Pio Sulca Tapahuasco100% (1)

- AcousticsDokument122 SeitenAcousticsEclipse YuNoch keine Bewertungen

- Hindi ShivpuranDokument40 SeitenHindi ShivpuranAbrar MojeebNoch keine Bewertungen

- Business Statistic Handout Bba - Sem 2Dokument7 SeitenBusiness Statistic Handout Bba - Sem 2hanirveshNoch keine Bewertungen

- The Piano Lesson Companion Book: Level 1Dokument17 SeitenThe Piano Lesson Companion Book: Level 1TsogtsaikhanEnerelNoch keine Bewertungen

- Standard nfx15-211Dokument2 SeitenStandard nfx15-211Luis Enrique Cóndor PorrasNoch keine Bewertungen

- A Review of Mechanism Used in Laparoscopic Surgical InstrumentsDokument15 SeitenA Review of Mechanism Used in Laparoscopic Surgical InstrumentswafasahilahNoch keine Bewertungen

- Uneb U.C.E Mathematics Paper 1 2018Dokument4 SeitenUneb U.C.E Mathematics Paper 1 2018shafickimera281Noch keine Bewertungen

- Meriam Mfc4150 ManDokument40 SeitenMeriam Mfc4150 Manwajahatrafiq6607Noch keine Bewertungen

- Liquid Chlorine SdsDokument7 SeitenLiquid Chlorine SdsIPKL RS BHAYANGKARA KEDIRINoch keine Bewertungen

- Principles of Business Grade 10 June 2021 Time: 1 1/2 Hrs. Paper 2 Answer ONLY 1 Question in Section I. Section IDokument3 SeitenPrinciples of Business Grade 10 June 2021 Time: 1 1/2 Hrs. Paper 2 Answer ONLY 1 Question in Section I. Section Iapi-556426590Noch keine Bewertungen

- Practical Cs Xii Mysql 2022-23 FinalDokument9 SeitenPractical Cs Xii Mysql 2022-23 FinalHimanshu GuptaNoch keine Bewertungen

- Mode of Action of Vancomycin: L D D D D DDokument8 SeitenMode of Action of Vancomycin: L D D D D DNolanNoch keine Bewertungen

- LRAD Datasheet 2000XDokument2 SeitenLRAD Datasheet 2000XOkkar MaungNoch keine Bewertungen

- ThaneDokument2 SeitenThaneAkansha KhaitanNoch keine Bewertungen

- Tachycardia Algorithm 2021Dokument1 SeiteTachycardia Algorithm 2021Ravin DebieNoch keine Bewertungen

- Vernacular ArchitectureDokument4 SeitenVernacular ArchitectureSakthiPriya NacchinarkiniyanNoch keine Bewertungen

- 0 BA Design ENDokument12 Seiten0 BA Design ENFilho AiltonNoch keine Bewertungen