Beruflich Dokumente

Kultur Dokumente

Casing Tubing Brochure

Hochgeladen von

Amer RehanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Casing Tubing Brochure

Hochgeladen von

Amer RehanCopyright:

Verfügbare Formate

TUBING & CASING PERFORMANCE

Tubing & Casing Thread Inspection System

Get Fast, Accurate, Repeatable Readings Every Time Ensure Stronger Connections and Optimize Performance... Take the Guesswork out of Inspecting Tubing or Casing!

www.gagemaker.com

TUBING & CASING PERFORMANCE

TUBING & CASING PERFORMANCE

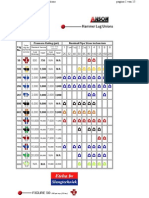

Inspect with the Acclaimed Gagemaker Tubing & Casing System to Optimize Performance Inspect both Standard and Non-Standard connections Scrutinize ALL thread elements with precision all using the same gages and accuracy Ensure proper thread interference when pipe Protect against mechanical forces such as tension and coupling make-up and leakage that tend to destroy tubing & casing Pinpoint thread errors that cause expansion of Inspect any type of tubing or casing connector the coupling and compression of the pipe end including API round thread, long thread, short thread, line pipe, and buttress

Gagemakers Tubing & Casing Inspection System

Gagemakers Tubing & Casing Thread Inspection System takes the guesswork out of inspecting tubing and casing.

The Gagemakers Tubing and Casing Thread Inspection Gages inspect all required thread elements - Thread Form, Ovality, Crest Diameter, Thread Lead, Thread Height, and Thread Taper all with the precise accuracy required in todays demanding industry.

Correct Thread Form is important for a pipe end and coupling to make up properly. Doing a quick check using a Gagemaker Thread Profile Gage verifies the thread form is correct.

Thread Form

Pitch Diameter governs the strength of the actual thread assembly and ensures API dimensional measurement specs are met. The Gagemaker MRP gages measure the internal and external pitch diameters of tapered threaded connectors. Any slight variations in diameter are immediately detected with these precision gages granting you total control over your quality.

Pitch Diameter/ Crest Cone Diameter

Verifying Thread Lead is within tolerance is a required inspection according to API. The Gagemaker Lead Gage inspects both internal and external thread lead. Lead variation has a direct impact on diameter and make up.

Thread Lead

Proper Thread Height maximizes the performance of the connection. Thread height is also an API requirement. Gagemaker thread height gages inspect external or internal thread height for a variety of thread forms. A shallow thread height may allow the connection to pull apart under stress.

Thread Height

Thread Taper is also a required API Spec 5B inspection. For more accurate taper inspections, the Gagemaker Thread Taper Gages confirm that the coupling and an end will have matching tapers. As connections are made up, taper errors induce high stresses that can eventually lead to connection failure.

Thread Taper

www.gagemaker.com

www.gagemaker.com

TUBING & CASING PERFORMANCE

System Essentials

TDWIN TAPER is the perfect accessory to Gagemakers Tubing and Casing API Inspection Gages . It is the only software program dedicated to the manufacturing and inspection of downhole tubular connections. It has everything you need to machine, inspect, and document tubular connection threads. TDWIN TAPER displays connection drawings, inspection gage information, and setup and inspection reports. Simply, it is a must have for any machine shop.

Maintain the highest quality. Save time and money by calibrating gages in-house. Our MIC TRAC calibration packages are perfect for any and all in-house calibration needs. The MT-3000 is excellent for the shop floor, while the MT-4000 can meet higher precision requirements.

Gagemaker LP, P.O. Box 87709, Houston, Texas 77287-7709 712 East Southmore Ave., Pasadena, Texas 77502 Phone: 713-472-7360 Fax: 713-472-7241 Email: gagemaker@gagemaker.com

2011 Gagemaker, LP

www.gagemaker.com

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- 3Rd Party Inspection Companies - Inspection Criteria - : (Updated December 16Th 2018)Dokument72 Seiten3Rd Party Inspection Companies - Inspection Criteria - : (Updated December 16Th 2018)Amer RehanNoch keine Bewertungen

- Barton Chart Recorder 202 242 j8 Tech Data SpanishDokument4 SeitenBarton Chart Recorder 202 242 j8 Tech Data SpanishratneshtNoch keine Bewertungen

- Air Compressor Tanks CKLSTDokument2 SeitenAir Compressor Tanks CKLSTAmer RehanNoch keine Bewertungen

- 01 Samss 035Dokument28 Seiten01 Samss 035Cherukunnon Jubu100% (2)

- 압력배관 적용 codeDokument12 Seiten압력배관 적용 codeKumar SateshNoch keine Bewertungen

- Positive and Adjustable Choke CatalogueDokument7 SeitenPositive and Adjustable Choke CatalogueAmer RehanNoch keine Bewertungen

- Adjustable Ckoke (Not Cortec) SOPDokument10 SeitenAdjustable Ckoke (Not Cortec) SOPAmer RehanNoch keine Bewertungen

- Ip 15Dokument42 SeitenIp 15owenh796100% (4)

- 109-2014 SAWCOD Grounding GuidelineDokument7 Seiten109-2014 SAWCOD Grounding GuidelineAmer Rehan0% (1)

- 3009 Product Spec SheetDokument2 Seiten3009 Product Spec SheetAmer RehanNoch keine Bewertungen

- 2FRM 6 PDFDokument12 Seiten2FRM 6 PDFAmer RehanNoch keine Bewertungen

- Canalta DBB Product ManualDokument13 SeitenCanalta DBB Product ManualAmer RehanNoch keine Bewertungen

- Manual For Level Controller Type 2500Dokument40 SeitenManual For Level Controller Type 2500Amer RehanNoch keine Bewertungen

- TB Woods Sure-FlexDokument18 SeitenTB Woods Sure-FlexAlfred Hernandez MendozaNoch keine Bewertungen

- FNW Fig.B7Dokument2 SeitenFNW Fig.B7kinjalpatel12345Noch keine Bewertungen

- Workbench Tutorial Boundary LayerDokument10 SeitenWorkbench Tutorial Boundary LayersferrandNoch keine Bewertungen

- CmeronDokument9 SeitenCmeronAmer RehanNoch keine Bewertungen

- Acme Thread DesignstdDokument7 SeitenAcme Thread DesignstdFilipe Martinho100% (2)

- Hamerlug Unions (Anson)Dokument15 SeitenHamerlug Unions (Anson)Leonardo ViannaNoch keine Bewertungen

- Six Sigma Green BeltDokument44 SeitenSix Sigma Green BeltAntonio2009183% (6)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Machine Design Elements11 - : God BlessDokument101 SeitenMachine Design Elements11 - : God BlessReynald de VeraNoch keine Bewertungen

- CNC Turning Programming Exellent ExplainationDokument29 SeitenCNC Turning Programming Exellent ExplainationschrienerNoch keine Bewertungen

- Design of Bolt and NutDokument41 SeitenDesign of Bolt and NutRa Balamurugan67% (3)

- Wheatland RMC Spec Sheet 2008Dokument2 SeitenWheatland RMC Spec Sheet 2008abd mohamedNoch keine Bewertungen

- Hblt-Wire - Level Sensor: Instruction ManualDokument11 SeitenHblt-Wire - Level Sensor: Instruction ManualMaxiwendelNoch keine Bewertungen

- Aircraft Fastener NotesDokument76 SeitenAircraft Fastener NotesHarimau Merah100% (2)

- HALCO 2020catalogue Hammer+BitDokument33 SeitenHALCO 2020catalogue Hammer+BitHodumi JosefNoch keine Bewertungen

- ETA - 110030 - Rotho Blaas HBS ScrewsDokument25 SeitenETA - 110030 - Rotho Blaas HBS ScrewsGuillaumeHNONoch keine Bewertungen

- 002 Bolt Tightening Structural PDFDokument22 Seiten002 Bolt Tightening Structural PDFarunNoch keine Bewertungen

- Frontierfastener Inch MetricDokument1 SeiteFrontierfastener Inch MetricjayendrapatilNoch keine Bewertungen

- Overtorque in BoltsDokument6 SeitenOvertorque in BoltsHolmer MorenoNoch keine Bewertungen

- PP67 PE GEN 00 DOR SP Q 004 - Rev06 Piping Material ClassesDokument45 SeitenPP67 PE GEN 00 DOR SP Q 004 - Rev06 Piping Material ClassesHEINER_P100% (1)

- IS: 4218 (Part 4) - 2001Dokument6 SeitenIS: 4218 (Part 4) - 2001sangita ghaisasNoch keine Bewertungen

- Boom and Bucket HidraulicsDokument44 SeitenBoom and Bucket HidraulicsSERGIO CARDENAS CASTILLONoch keine Bewertungen

- Catalogue Eng 2022Dokument91 SeitenCatalogue Eng 2022luis fernandezNoch keine Bewertungen

- List of ISO StandardsDokument18 SeitenList of ISO Standardspremchandar100% (1)

- Boom / Bucket HydraulicsDokument20 SeitenBoom / Bucket HydraulicsSales AydinkayaNoch keine Bewertungen

- Dry Seal Pressure PlugsDokument2 SeitenDry Seal Pressure PlugsS DasNoch keine Bewertungen

- WeldingDokument64 SeitenWeldingLiyana100% (1)

- RexrothDokument75 SeitenRexrothiosbogdannNoch keine Bewertungen

- 0743 MA0711 WDokument1 Seite0743 MA0711 WJose Luis RattiaNoch keine Bewertungen

- Standart Torque BoltDokument4 SeitenStandart Torque BoltHeribudi23Noch keine Bewertungen

- JUki DNU-1541S Eng ManualDokument56 SeitenJUki DNU-1541S Eng ManualAnonymous MIhQRlxrmfNoch keine Bewertungen

- Murali - Metrology & Measurements Lab ManualDokument30 SeitenMurali - Metrology & Measurements Lab ManualsubhashNoch keine Bewertungen

- GF Elbow ZDokument2 SeitenGF Elbow ZLuis CarlosNoch keine Bewertungen

- Valves & Controls: Crosby Safety Valves Style HSLDokument12 SeitenValves & Controls: Crosby Safety Valves Style HSLeborresonNoch keine Bewertungen

- Shineking Cone Crusher Manual BookDokument32 SeitenShineking Cone Crusher Manual BookRiki D. PrastyoNoch keine Bewertungen

- Senr3130 14 00 AllDokument20 SeitenSenr3130 14 00 AllAhmed MoustafaNoch keine Bewertungen

- BS 31 Steel Conduit and Fittings For Electrical Wiring PDFDokument36 SeitenBS 31 Steel Conduit and Fittings For Electrical Wiring PDFEddy Volao100% (3)

- FixinDokument44 SeitenFixinJaime EscobarNoch keine Bewertungen