Beruflich Dokumente

Kultur Dokumente

Variable Frequency Drive

Hochgeladen von

nksuthar5399Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Variable Frequency Drive

Hochgeladen von

nksuthar5399Copyright:

Verfügbare Formate

COMPLEX FUNCTION REALISATION

Adopting the advanced modular design, TG600 series inverters are custom design products that could lower the customer's

purchasing cost efficiently. n the mean time, we offer an open platform to make the clients realize their customized function

easily. All the belowlisted Extension cards are OPTONAL

Tension ControI Card

Water SuppIy ControI Card

I/O Extension Card

FUNCTION EXTENSION CARD

Receive high-speed pulse from encoder to realize high-accuracy close-loop vector control.

1. Both push-and pull input and open-circuit collector input.

2. Offer frequency division output, the frequency-division factor can be selected by dial switch.

3. Connect to the encoder by softwire. (Simulation)

Offers RS 232 and RS 485 dual physical communication interface.

1. RS 232 adopts standard D9 master seat.

2. 3-hole RS 485 interface.

3. n-line MODBus RTU standard communication protocol.

Wind and Unwind control, compensation of moment of inertia, multiple tension setting mode, automatic winding diameter

calculation and display, linear speed collect and display, prevent wire breakage, prevent overdrive, RS 485 port

Offer more input / output terminal to enhance the external function of inverter, RS 485 port.

Injection MouIding Card

Achieve energy saving function for injection moulding machine by collecting and processing pressure and

flow signal.

Realize functions such as close-loop constant of water supply pressure, multi pumps variable frequency switch,

time and multi-segment water supply, dormant protect, prevent water hammer, water level control and synthetic

process of supply-discharge etc, RS 232 port.

SeriaI Communication

Card

PG Card

True Genius AC Drive is suitable for various types of constant and variable torque loads in industries such as:-

APPLICATIONS

Pharmaceutical

Tyre and Rubber

Material Handling

Sugar

Steel

Food Processing

Textile

Paper

Cement

Plastic

Chemical

Machine Tool

EOT Cranes

Mining

G

e

m

in

i P

rin

te

rs

. P

h

: 0

8

0

-4

1

2

4

1

9

3

2

The design and manufacture of our products are subject to constant improvement. Hence the above specification / model may slightly vary from the product illustrated / supplied.

KIPLCSKAP

E

L

E

C

T

P

I

C

T+:e e++:;

TG - 600

Certified ISO 9001:2000 by

AC DklVE5

0.75 lo 900 kW @ 415V

Lifts

22 lo 1500 kW @ 90V

No.INV / TG-600 / 2008 - 09

Issue: May 2008

Contact Details:

Industrial Supply Syndicate

54, Ezra Street, Kolkata - 700 001, INDIA

Phone: 32916080, 22356676 Fax: +91 33 30222923

Email: info@industrialindia.com Website: www.industrialindia.com

Phone: 033 32916080

Fax: 033 30222923

info@industrialindia.com

Variable Frequency Drive VFD AC Drive AC Motor Drives Kirloskar VFD Indian Manufacturer of AC Drives Variable Frequency Drive Kolkata Haldia Pune Mumbai Delhi Hyderabad Bangalore Chennai Kolkata jamshedpur Calcutta West Bengal Indian Product Indian Manufacturer Trader Distributer Kirloskar Electric AC Variable Frequency Drives AC Motor Speed Controller

Inverters for AC motor Speed Control Variable Frequency Drive Kirloskar VFD Drive vary speed change frequency of AC Motors Low Price Best Features AC Drive Dealer Best Price in India Ready Stock Fast Delivery Delta Yaskava Siemens Kirloskar Kolkata Fuji BCh LZ Kolkata AC Drive

INTRODUCTION

True Genius TG-600 series AC Drives are high performance Vector controlled inverters, adopting modular design based

on dual CPU control. Three types of control methodology are built into the drive software, which are selectable

through parameters, based on the application requirement, viz., V/f control, Sensor less Vector control and the closed loop

vector control.

Closed loop Torque control is easily achieved through using the PG card option to detect the motor speed and adjust the

output torque in time according to the changing load demand.

AVRFUNCTION

ENERGYSAVING

PARAMETERCOPY

SERIALCOMMUNICATION

Whenever this function is enabled, the drive output

voltage does not change in accordance with the input

voltage or DC Bus voltage and is maintained

constant within the output capacity range.

Whenever this function is enabled, the drive will adjust the

output vol tage i n accordance wi th the l oad

by detecting the output load current thereby saving

Energy automatically ( fan and pump loads ).

This enables uploading / downloading of parameters

to external LCD display unit thereby reducing the

commissioning time taken for identical machines.

Standard RS-485 communication with MODBus RTU

protocol as option.

SIMPLEPLCPROGRAMMING

PIDCONTROL

MOTORAUTO TUNING

S-CURVE

MULTIPLEV/F CURVESETTING

Ensures 16 step speed control, without the usage of

multi-step speed programming.

Precise control of the application in accordance with the

changing load / output pattern.

Ensures precise control and fast response to cater the

output requirement.

Ensures smooth acceleration and deceleration for

applications like lifts, elevators etc.

Enables to suit the drive for various applications

constant torque & variable torque, employing

V/f control.

both

only

Special feature of Automatic adjustment of Carrier frequency, if enabled, ensures quiet operation by adjusting the carrier

frequency automatically in accordance with the changing load and temperature.

TECHNICAL SPECIFICATION

Frequency - Setting Mode : Digital Setting, Analog Setting, Pulse Frequency Setting, Serial

Communication Setting, Multi-Speed, Simple PLC Setting and PD Setting etc. The switch

between the defining combination and the defining mode can be realized.

Torque-Control Function offers multimode torque setting.

PDControl Function offers precise process control.

Simple PLC&Multi-segments Speed Control Function offers 16 segments speed Control.

Traverse Control Function

Length and Time Control Function.

Non-Stop Function while instantaneous power failure

Speed trace Function (Catch-on fly) offers smooth start of the running motor.

QUCK/ JOG Function offers Multi-function shortcut key defined by user.

Automatic Voltage Adjust Function offers to maintain the output voltage constant automatically

when mains voltage is fluctuating.

Up to 29 functions for failure protection offers protection against over current, over voltage, under

voltage, over temperature, input / output phase failure, drive / motor load, GBTfailure, etc.

Input

Output

ExternaI

Interface

TechnoIogy

Features

nput Voltage Range

nput Frequency Range

Output Voltage Range

Output Frequency Range

Programmable Digital nput

Programmable Analog nput

Programmable Open Circuit

Collector Output

Relay Output

Analog Output

Control Mode

Overload Capacity

Starting Torque

Speed-Adjust Ratio

Speed Accuracy

Carrier Frequency

3 phase, 415V / 690V AC 15%

47 ~ 63Hz

3 phase, 415V AC / 690V AC (Same as input voltage)

0 ~ 600 Hz

Six Channel inputs. One is the high-speed pulse input (HD1).

Another four channel inputs can be extended by optional /O card

A1; 0~10V, A2; 0~10V or 0~20mA, optional /O extension card

can offer another two inputs; A 10V~10V, A4; 0~10V or 0~20mA.

One channel output, optional /O extension card can offer another one

(Open circuit collector output or high-speed pulse output)

Two channel outputs, optional /O extension card can offer another one

One channel output, optional /O extension card can offer

another one, 0/4~20mA or 0/2~10V selectable.

Sensorless Vector control, Vector Control with PG, V/f Control.

150% rated current for 60 sec. 200% rated current for 2 sec, (Vector control)

Sensorless Vector Control: 0.5 Hz / 150%, Vector Control: 0 Hz / 180%

Sensorless Vector Control: 1:100, Vector Control with PG: 1:1000.

Sensorless Vector Control : 0.5% of maximum speed,

Vector Control: 0.02% of maximum speed.

1.0KHz~16.0 KHz. t can be adjusted automatically according to the

features of temperature and load.

Function

Features

SELECTION CHART

Motor Output (kW)

Drive Model TG 600

3.8

250*160*180

6.5

320*220*180

21 45

467*290*215 577*375*270

Rated Current at

415V (Amps)

Nett Weight (kg)

Dimension(H*W*D) in mm

075 P75 1P5 2P2 3P7 5P5 7P5 011 015 018 022 030 037 045 055

NA

86

75 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55

2.5 3.7 5.0 9.0 13 17 25 32 37 45 60 75 90 110

NA NA NA NA NA NA NA NA NA 28 35 45 52 63

Rated Current at

690V (Amps)

Motor Output (kW)

Drive Model TG 600

755*460*330

150

1180*490*390

220

1264*750*400

Rated Current at

415V (Amps)

Nett Weight (kg)

Dimension(H*W*D) in mm

Rated Current at

690V (Amps)

90

176

98

75

090

110

210

121

110

132 132 160 185 200 200 220 250 280 315 350 400

NA 250 300 340 NA 380 415 470 520 600 NA NA

150 NA 175 198 218 NA 240 270 320 350 380 430

132 132 160 185 200 200 220 250 280 315 350 400

75

150

NA

075

FEATURES

Motor Output (kW)

Drive Model TG 600

Rated Current at

415V (Amps)

Nett Weight (kg)

Dimension(H*W*D) in mm

Rated Current at

690V (Amps)

400

690

NA

400

500

860

540

500

560

950

600

560

350

640

NA

350

350

640

NA

350

630

1100

680

630

710

1210

710

800

1360

800

900

1520

900

1000

NA

1000

1100

NA

1100

1200

NA

1200

1500

NA

1500 1300

1300

NA

760 860 970 1070 1180 1290 1610 1400

1821*1505*400

650

1821*2260*400

975

N A - Not Applicable

Variable Frequency Drive VFD AC Drive AC Motor Drives Kirloskar VFD Indian Manufacturer of AC Drives Variable Frequency Drive Kolkata Haldia Pune Mumbai Delhi Hyderabad Bangalore Chennai Kolkata jamshedpur Calcutta West Bengal Indian Product Indian Manufacturer Trader Distributer Kirloskar Electric AC Variable Frequency Drives AC Motor Speed Controller

Inverters for AC motor Speed Control Variable Frequency Drive Kirloskar VFD Drive vary speed change frequency of AC Motors Low Price Best Features AC Drive Dealer Best Price in India Ready Stock Fast Delivery

Das könnte Ihnen auch gefallen

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Tech Characteristic VEGADokument16 SeitenTech Characteristic VEGADark _Noch keine Bewertungen

- Advanced Drives for AutomationDokument4 SeitenAdvanced Drives for AutomationFranklin DannyNoch keine Bewertungen

- Fuji Frenic-Vg7sDokument50 SeitenFuji Frenic-Vg7sMathawee ChotchaiNoch keine Bewertungen

- Compact & Powerful Inverter iG5ADokument32 SeitenCompact & Powerful Inverter iG5Amy27100% (1)

- LG VFD Drive ManualDokument16 SeitenLG VFD Drive ManualrnkmipNoch keine Bewertungen

- LG Surucu Ig5Dokument16 SeitenLG Surucu Ig5uyung_mustofaNoch keine Bewertungen

- I G5Dokument16 SeitenI G5MoustaffaNoch keine Bewertungen

- iG5A E (2012.01)Dokument44 SeiteniG5A E (2012.01)ao0511Noch keine Bewertungen

- Compact & Powerful Inverter iG5ADokument44 SeitenCompact & Powerful Inverter iG5AdanarcanaNoch keine Bewertungen

- Bholanath Step Servo Motors User's ManualDokument20 SeitenBholanath Step Servo Motors User's ManualDeepak RainaNoch keine Bewertungen

- P26-33 wBAL501A-2007Dokument8 SeitenP26-33 wBAL501A-2007circlelineNoch keine Bewertungen

- C100 CatalogDokument20 SeitenC100 CatalogMarcela RoneNoch keine Bewertungen

- 124 Catalog Convertizoare de Frecventa IV5Dokument32 Seiten124 Catalog Convertizoare de Frecventa IV5bmonaandaNoch keine Bewertungen

- Invertek 2011 85-Idlbr-01 Stock Drives Catalogue v4.05 1aDokument28 SeitenInvertek 2011 85-Idlbr-01 Stock Drives Catalogue v4.05 1at_meierNoch keine Bewertungen

- Mitsubishi v500 VFD Brochure UpdatedDokument12 SeitenMitsubishi v500 VFD Brochure UpdatedMROstop.comNoch keine Bewertungen

- Compacte Handleiding V7Dokument60 SeitenCompacte Handleiding V7gui9871Noch keine Bewertungen

- Analog Servo Drive: Description Power RangeDokument13 SeitenAnalog Servo Drive: Description Power RangeElectromateNoch keine Bewertungen

- 8200 MotecDokument3 Seiten8200 Motecyera1Noch keine Bewertungen

- 87 Catalog Invertere Ic5Dokument19 Seiten87 Catalog Invertere Ic5vga1234Noch keine Bewertungen

- Inversor IG5A LSDokument36 SeitenInversor IG5A LSBuratti2010100% (1)

- Analog Servo Drive: Description Power RangeDokument9 SeitenAnalog Servo Drive: Description Power RangeElectromateNoch keine Bewertungen

- User Manual: HGM6100K Series Genset ControllerDokument31 SeitenUser Manual: HGM6100K Series Genset ControllerW MoralesNoch keine Bewertungen

- Variador Yaskawa Pl.a1000.01Dokument76 SeitenVariador Yaskawa Pl.a1000.01Tomas Enrique Ramirez GomezNoch keine Bewertungen

- Analog Servo Drive: Description Power RangeDokument9 SeitenAnalog Servo Drive: Description Power RangeElectromateNoch keine Bewertungen

- Tài Liệu Biến Tần LS IC5Dokument20 SeitenTài Liệu Biến Tần LS IC5hieudaivuongNoch keine Bewertungen

- 10 A 8 DDDokument7 Seiten10 A 8 DDElectromateNoch keine Bewertungen

- Frekventni RegulatoriDokument6 SeitenFrekventni RegulatoriGogyNoch keine Bewertungen

- Isel ControlerDokument18 SeitenIsel Controlermihail91smNoch keine Bewertungen

- LG VFDDokument38 SeitenLG VFDDenuj jouNoch keine Bewertungen

- M/V™ Series Servo Drive: Description Power RangeDokument12 SeitenM/V™ Series Servo Drive: Description Power RangeElectromateNoch keine Bewertungen

- Description Power Range: Analog Servo DriveDokument8 SeitenDescription Power Range: Analog Servo DriveElectromateNoch keine Bewertungen

- LS Inverter Series PDFDokument16 SeitenLS Inverter Series PDFQuang Chánh NguyễnNoch keine Bewertungen

- 3G3RV V1Dokument76 Seiten3G3RV V1Omiga HatemNoch keine Bewertungen

- WEG Soft StartersDokument36 SeitenWEG Soft StartersgamasistemNoch keine Bewertungen

- IC5 Catalogue 2013.10 ENGDokument20 SeitenIC5 Catalogue 2013.10 ENGKurnia FajarNoch keine Bewertungen

- Advanced Motion Controls Dpeaniu-C100a400Dokument11 SeitenAdvanced Motion Controls Dpeaniu-C100a400ElectromateNoch keine Bewertungen

- Description Power Range: Analog Servo DriveDokument8 SeitenDescription Power Range: Analog Servo DriveElectromateNoch keine Bewertungen

- LS Inverter iC5 SeriesDokument20 SeitenLS Inverter iC5 SeriesKỹ Sư TđhNoch keine Bewertungen

- Programmable DC power supplies offer high power density and waveform creationDokument8 SeitenProgrammable DC power supplies offer high power density and waveform creationbillallusNoch keine Bewertungen

- Analog Servo Drive: Description Power RangeDokument9 SeitenAnalog Servo Drive: Description Power RangeElectromateNoch keine Bewertungen

- LG Inverter iC5 Series CompactDokument20 SeitenLG Inverter iC5 Series CompactlamonahNoch keine Bewertungen

- Sec-Ac EnusDokument10 SeitenSec-Ac EnusJohan JorezNoch keine Bewertungen

- Amc B15a8 SpecsheetDokument8 SeitenAmc B15a8 SpecsheetElectromateNoch keine Bewertungen

- Analog Servo Drive: Description Power RangeDokument9 SeitenAnalog Servo Drive: Description Power RangeElectromateNoch keine Bewertungen

- Description Power Range: Analog Servo DriveDokument8 SeitenDescription Power Range: Analog Servo DriveElectromateNoch keine Bewertungen

- A1000Dokument8 SeitenA1000monikaNoch keine Bewertungen

- Analog Servo Drive: Description Power RangeDokument9 SeitenAnalog Servo Drive: Description Power RangeElectromateNoch keine Bewertungen

- Amc B25a20ac SpecsheetDokument9 SeitenAmc B25a20ac SpecsheetElectromateNoch keine Bewertungen

- AC Inverter Drive: A1000 SeriesDokument8 SeitenAC Inverter Drive: A1000 Seriesabhi_0302Noch keine Bewertungen

- Programmable Power Supplies up to 1700W in 1UDokument4 SeitenProgrammable Power Supplies up to 1700W in 1UJovaneiNoch keine Bewertungen

- Inv. FUJI, Frenic-MultiDokument39 SeitenInv. FUJI, Frenic-MultiTandin IgorNoch keine Bewertungen

- AC Invertor1000dsDokument20 SeitenAC Invertor1000dsRonak PatelNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Analog Circuit Design Volume Three: Design Note CollectionVon EverandAnalog Circuit Design Volume Three: Design Note CollectionBewertung: 3 von 5 Sternen3/5 (2)

- Digital Power Electronics and ApplicationsVon EverandDigital Power Electronics and ApplicationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Putting Advanced Array Formulas To Work - ExcelDokument3 SeitenPutting Advanced Array Formulas To Work - Excelnksuthar5399Noch keine Bewertungen

- CommentsDokument6 SeitenCommentsJeremy AveryNoch keine Bewertungen

- Excel - Advanced Formulas and Functions - Ischool TutorialsDokument5 SeitenExcel - Advanced Formulas and Functions - Ischool Tutorialsnksuthar5399Noch keine Bewertungen

- Prabha Steel Industries Inspection & Test PlanDokument2 SeitenPrabha Steel Industries Inspection & Test PlansesabcdNoch keine Bewertungen

- BHEL guidelines for submitting supplier bidsDokument14 SeitenBHEL guidelines for submitting supplier bidsnksuthar53990% (1)

- Excel Formulas - 10 Formulas That Helped Me Keep My JobDokument6 SeitenExcel Formulas - 10 Formulas That Helped Me Keep My Jobnksuthar5399Noch keine Bewertungen

- Advanced Excel: Multiple WorksheetsDokument9 SeitenAdvanced Excel: Multiple WorksheetsGajendra TodakarNoch keine Bewertungen

- Examples of Commonly Used Formulas - ExcelDokument2 SeitenExamples of Commonly Used Formulas - Excelnksuthar5399Noch keine Bewertungen

- Prabha Steel Industries Inspection & Test PlanDokument2 SeitenPrabha Steel Industries Inspection & Test PlansesabcdNoch keine Bewertungen

- Design Pumping StationsDokument5 SeitenDesign Pumping Stationsnksuthar5399Noch keine Bewertungen

- L&T Type 2 Co-Ordination Selection ChartsDokument48 SeitenL&T Type 2 Co-Ordination Selection Chartsrdeepak99100% (7)

- Excel FormulasDokument8 SeitenExcel Formulasnksuthar5399Noch keine Bewertungen

- Firepumpshopdrawings4 01Dokument2 SeitenFirepumpshopdrawings4 01nksuthar5399Noch keine Bewertungen

- K For MCP-2 Rev 0 - 05.01.11Dokument1 SeiteK For MCP-2 Rev 0 - 05.01.11sesabcdNoch keine Bewertungen

- Electrical Tender ResidentialDokument10 SeitenElectrical Tender ResidentialsesabcdNoch keine Bewertungen

- Web Soft Starter PB Dkddpb07b102Dokument35 SeitenWeb Soft Starter PB Dkddpb07b102MajdanpekNoch keine Bewertungen

- 380kV CT-VT Calculation - C4 - Rev - D 17.12.09Dokument137 Seiten380kV CT-VT Calculation - C4 - Rev - D 17.12.09siva2001eee80% (5)

- Flameproof MotorsDokument16 SeitenFlameproof MotorsKiran KumarNoch keine Bewertungen

- Excel Formulas ExamplesDokument67 SeitenExcel Formulas ExamplesMohamad Razali Abdul HamidNoch keine Bewertungen

- Prabha Steel Industries Inspection & Test PlanDokument2 SeitenPrabha Steel Industries Inspection & Test PlansesabcdNoch keine Bewertungen

- DSLP Dirct Srole Lightning ProtectionDokument7 SeitenDSLP Dirct Srole Lightning Protectiongsaiswaroopg100% (2)

- Electric MotorsDokument25 SeitenElectric Motorsnikorn123Noch keine Bewertungen

- Setting Calculation for IDMT RelaysDokument2 SeitenSetting Calculation for IDMT Relaysrefaate100% (2)

- Calculate Step & Touch PotentialDokument1 SeiteCalculate Step & Touch PotentialkjfenNoch keine Bewertungen

- Microsoft Excel 2007 Keyboard Shortcuts 1Dokument3 SeitenMicrosoft Excel 2007 Keyboard Shortcuts 1Dhaval LagwankarNoch keine Bewertungen

- Grouping Factors For Cables Laid Direct in The GroundDokument4 SeitenGrouping Factors For Cables Laid Direct in The Groundnksuthar5399Noch keine Bewertungen

- Calculate Step & Touch PotentialDokument1 SeiteCalculate Step & Touch PotentialkjfenNoch keine Bewertungen

- 01 Hgu Feed Index - Rev1Dokument2 Seiten01 Hgu Feed Index - Rev1nksuthar5399Noch keine Bewertungen

- RF Product Selector GuideDokument49 SeitenRF Product Selector GuideZamir HussainNoch keine Bewertungen

- Sony Kdl-70 Xbr3Dokument135 SeitenSony Kdl-70 Xbr3Saeid PourfarzibNoch keine Bewertungen

- ISO Series Analog Signal Isolation TransmitterDokument2 SeitenISO Series Analog Signal Isolation TransmitterArio FitriantoNoch keine Bewertungen

- Fabrication Techniques of A PN Junction DiodeDokument5 SeitenFabrication Techniques of A PN Junction DiodeNida Amber100% (3)

- HV Cable ConstructionDokument44 SeitenHV Cable ConstructionAbdul RahimNoch keine Bewertungen

- Boiler Controls - SPB-1019 PDFDokument16 SeitenBoiler Controls - SPB-1019 PDFAbbas AmirifardNoch keine Bewertungen

- NMR Spectroscopy: by Darshan R. Telange, KNCP, Butibori (Nagpur)Dokument60 SeitenNMR Spectroscopy: by Darshan R. Telange, KNCP, Butibori (Nagpur)team engineerNoch keine Bewertungen

- Chemical Engineering Department Physical Chemistry for Engineers 2 LABORATORY Instruction ManualDokument53 SeitenChemical Engineering Department Physical Chemistry for Engineers 2 LABORATORY Instruction ManualJohn Fritz FestejoNoch keine Bewertungen

- C600 - Inventec Calcutta 10Dokument5 SeitenC600 - Inventec Calcutta 10Vika Fivi AnggrainiNoch keine Bewertungen

- Iq 2000Dokument120 SeitenIq 2000OskarNoch keine Bewertungen

- Ia - Electronics - Assemble and Disassemble Consumer Electronic Product Ans SystemDokument32 SeitenIa - Electronics - Assemble and Disassemble Consumer Electronic Product Ans SystemBenjamin CoNoch keine Bewertungen

- Eacon Inv Ec500Dokument74 SeitenEacon Inv Ec500michalis zisisNoch keine Bewertungen

- Electric QuantitiesDokument34 SeitenElectric Quantitiestear6025Noch keine Bewertungen

- Lecture Nonlinear and Anisotropic MaterialsDokument25 SeitenLecture Nonlinear and Anisotropic MaterialsJabir Khan JadoonNoch keine Bewertungen

- Current Clamp Adaptor For Multimeters: by John ClarkeDokument7 SeitenCurrent Clamp Adaptor For Multimeters: by John Clarkemor3danNoch keine Bewertungen

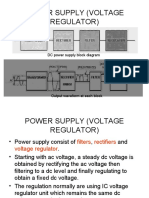

- DC Power Supply Block DiagramDokument15 SeitenDC Power Supply Block DiagramKuAdenan KuSyakranNoch keine Bewertungen

- Technical Specification TRDokument14 SeitenTechnical Specification TR武文凯Noch keine Bewertungen

- Sim Q Mkii Installation Instructions 4189330024 UkDokument17 SeitenSim Q Mkii Installation Instructions 4189330024 UkPrakash VNoch keine Bewertungen

- Eaton Afdd Appl Guide Brochure Br003016en en UsDokument7 SeitenEaton Afdd Appl Guide Brochure Br003016en en UsMardiansyah AtrimaNoch keine Bewertungen

- MRCET UG Model Question Papers on Electric & Hybrid VehiclesDokument8 SeitenMRCET UG Model Question Papers on Electric & Hybrid VehiclesDilip KumarNoch keine Bewertungen

- PhysicsDokument580 SeitenPhysicsSangam VaniNoch keine Bewertungen

- RF Systems Both PartsDokument124 SeitenRF Systems Both PartsJonathan CuroleNoch keine Bewertungen

- Validate Logic Gate Truth TablesDokument8 SeitenValidate Logic Gate Truth Tablesshivansh50% (2)

- TP10 Fundamentals of Power System Modeling v2018-11-12 43rd ANC (FCLeynes)Dokument37 SeitenTP10 Fundamentals of Power System Modeling v2018-11-12 43rd ANC (FCLeynes)Edwin LoquinaNoch keine Bewertungen

- Frenic vg7sDokument50 SeitenFrenic vg7sramon navaNoch keine Bewertungen

- MOS Investigate AVR & CBF RelayDokument25 SeitenMOS Investigate AVR & CBF Relaybuayasa22Noch keine Bewertungen

- 480E09 DatasheetDokument3 Seiten480E09 Datasheetram_unltd1518Noch keine Bewertungen

- CatalogueDokument29 SeitenCatalogueAnonymous CPmZqMNoch keine Bewertungen

- MG17 K802 DanfossDokument98 SeitenMG17 K802 DanfossMr.K chNoch keine Bewertungen

- Manual de Instalación Smart Energy Controller Sec1000 HybridDokument7 SeitenManual de Instalación Smart Energy Controller Sec1000 HybridJavier Barranco LaraNoch keine Bewertungen