Beruflich Dokumente

Kultur Dokumente

Prabha Steel Industries Inspection & Test Plan

Hochgeladen von

nksuthar5399Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Prabha Steel Industries Inspection & Test Plan

Hochgeladen von

nksuthar5399Copyright:

Verfügbare Formate

ITP No.

775

Page 1 of 2

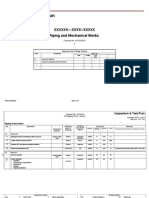

PRABHA STEEL INDUSTRIES INSPECTION & TEST PLAN

CLIENT P. O. NO. EQUIPMENT ITEM NO. DRAWING NO. INSPECTION BY Sr. INSPECTION No. 1.0 1.1 ACTIVITY & COMPONENT MATERIALS INSPECTION Material Plates, Pipes, flats etc. Chemical analysis Mechanical properties, Non Destructive Test, Visual & dimensional including finish, Wherever applicable Chemical analysis Mechanical properties, Non Destructive Test, Visual & dimensional including finish, Wherever applicable Review of test certificates, markings, Visual and Dimensional inspection, Identification, Correlation & transer of identity Review of test certificates ASME Sec.IIA/ Drawings ASME Sec.IIA/ Drawings Inspection Report R R R ASME Sec.IIA/ Spec/Standards/ Drawings ASME Sec. IIA/ Spec/Standards/ Drawings ASME Sec.IIA/ Spec/Standards/ Drawings ASME Sec.IIA/ Spec/Standards/ Drawings Mill / Supp. Test Certificates R To be procured from manufacturers / Supplier with TC. M/S. SHIVA PHARMACHEM PVT. LTD. SES/PO/16/2010-11 DT.08/03/2011 HOT WELL & COLD WELL TANK T-106 PSI-2010-775 M/S. BUREAU VERITAS CHARACTERISTIC

ITP No.

Rev :

775 0

Dtd. 18-03-2011

REFERENCE DOCUMENT

ACCEPTANCE STD

FORMAT OF REPORT

PSI

BV

REMARK

1.2

Forgings, Fasteners, Gaskets etc. (as applicable)

Mill / Supp. Test Certificates

R To be procured from manufacturers / Supplier with TC.

1.3

Materials After Receipt (For pressure parts) Plates, Pipes, Forging, Fastners, gaskets etc.

ASME Sec.IIA/ Drawings

ASME Sec.IIA/ Drawings

Material Clearance Record

1.4

Non Pressure Parts, (Including cleats Leg supports etc.)

3.0 WELDING INSPECTION WPS AND PQR 3.1 3.2 PQR WPQ Welding parameters Qualification Requirement 3.3 Welding consumables To check for chemical & physical properties ASME Sec.IIC/Drag. ASME SEC II-C Supplier TC W R ASME Sec.IX/Spec. ASME Sec.IX/Spec. ASME Sec.IX/Spec. ASME Sec.IX/Spec. WPS/PQR WPQ W W R R

Review of WPS/PQR

Review of WPS/PQR

ITP No. 775

Page 2 of 2

Sr. No.

INSPECTION ACTIVITY & COMPONENT

CHARACTERISTIC

REFERENCE DOCUMENT

ACCEPTANCE STD

FORMAT OF REPORT

PSI

BV

REMARK

4.0 INSPECTION DURING FABRICATION 4.1 Weld Edge preparation & setup of pressure parts Visual & dimensional Inspection, weld edge,

Root gap, Offset, alignment etc.

ASME Sec.VIII-Div1/

Drawings ASME Sec.VIII-1 ASME Sec.V Drawings

Inspection Report Inspection Report Inspection Report Inspection Report NDT Report

RW

4.2

Intermediate Insp. Of welds wherever possible Inspection of Completed welds

4.3

PT of weld edges for cracks, laminations, segregations Visual/PT Insp. After chip back Visual inspection for reinforcement, undercuts, surface defects etc. Non destructive Test if / as applicable Dimensions, completeness of assembly leak check Leak check Visual Insp. For workmanship Verifying stamping details Verification & Compliation of inspection & test records for submission to customer

Spec./Drawings Drawings/Spec.

W W

R R

Drawins/Spec/ ASME Sec.VIII-1 Drawins/Spec/ ASME Sec.VIII-1 Drawings/Standards Drawings/Spec. Drawings/Spec/ Drawins/Spec. Drawings Drawing / Spec

Drawins/Spec/ ASME Sec.VIII-1 Drawins/Spec/ ASME Sec.VIII-1 Drawings/Standards/ Spec. Should be leak proof Should be leak proof Drawins/Spec. Drawings Drawing / Spec.

W W

W R

5.0 FINAL INSPECTION 5.1 Visual and Dimensional Inspection 5.2 Air test of pads at 1.05 Kgs/cm2g 5.3 Hydrostatic Test (Full of Water) 5.4 Pickling & passivation 5.5 5.6 Final Stamping of equipment & Release etc. DOCUMENTATION

Inspection Report Test Report Hydro test Report Inspection Report Rub-off Q.C Dossier

W W W W W W

W R H R H H

Legends:H - Hold (Offer for witness & obtain clearance) W- Witness, R-Review, RW - Random Witness W/R - Witness of Review

FOR PRABHA STEEL INDUSTRIES

FOR SHIVA PHARMACHEM

FOR BV

Das könnte Ihnen auch gefallen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Standard Inspection and Test Plan For API6D Valves PDFDokument4 SeitenStandard Inspection and Test Plan For API6D Valves PDFWaqas JawaidNoch keine Bewertungen

- ITP-001 Steelwork Fabrication Rev ADokument5 SeitenITP-001 Steelwork Fabrication Rev AMarcus Cox100% (2)

- Bay Marshalling BoxesDokument4 SeitenBay Marshalling BoxesSimbu ArasanNoch keine Bewertungen

- Sample QAPDokument3 SeitenSample QAPsniperiNoch keine Bewertungen

- WPS & PQR - 2021Dokument82 SeitenWPS & PQR - 2021Subramanian RNoch keine Bewertungen

- Tank Erection Itp & Org ChartDokument34 SeitenTank Erection Itp & Org Charthasan_676489616100% (2)

- Inspection Test Plan PV Nozzle Modification/AlterationDokument4 SeitenInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNoch keine Bewertungen

- ITP Format For New PVDokument8 SeitenITP Format For New PVDavid LambertNoch keine Bewertungen

- Quality Assurance Plan for Structural FabricationDokument1 SeiteQuality Assurance Plan for Structural FabricationproxywarNoch keine Bewertungen

- Inspection and Test Plan For Process PipingDokument4 SeitenInspection and Test Plan For Process Pipingsatya_chaganti100% (1)

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDokument4 SeitenRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksAjoy Prasad75% (4)

- Resume An Welding InspectorDokument7 SeitenResume An Welding InspectorspearboraNoch keine Bewertungen

- Fabrication Process Inspection PlanDokument48 SeitenFabrication Process Inspection Planmohd as shahiddin jafriNoch keine Bewertungen

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDokument5 SeitenQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Column Condenser ITP inspection planDokument2 SeitenColumn Condenser ITP inspection planAshish DhokNoch keine Bewertungen

- Inspection Test Plan For Fabrication & Erection 2016Dokument14 SeitenInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Dokument28 SeitenField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNoch keine Bewertungen

- Siemens: 1200 MW DGEN Mega Power ProjectDokument4 SeitenSiemens: 1200 MW DGEN Mega Power ProjectJuzer MadarwalaNoch keine Bewertungen

- Inspection and Test Procedure of SwitchgearDokument4 SeitenInspection and Test Procedure of SwitchgearShahadat HossainNoch keine Bewertungen

- ITP-000 Piping Fabrication (Exemple)Dokument5 SeitenITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- Sample ItpDokument4 SeitenSample ItpWijayanto BekasiNoch keine Bewertungen

- ITP Valves PDFDokument4 SeitenITP Valves PDFric leonisoNoch keine Bewertungen

- Itp Pipe SupportsDokument4 SeitenItp Pipe SupportskamlNoch keine Bewertungen

- Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Dokument7 SeitenInspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Akhilesh KumarNoch keine Bewertungen

- Itp For SSDP Project Rev CDokument9 SeitenItp For SSDP Project Rev CRachel FloresNoch keine Bewertungen

- Inspection Testing Plan (ITP)Dokument1 SeiteInspection Testing Plan (ITP)Kdown 99100% (1)

- Quality Assurance PlanDokument3 SeitenQuality Assurance PlanNESTOR YUMULNoch keine Bewertungen

- ITP For Piping WorksDokument3 SeitenITP For Piping WorksOrlando1949100% (3)

- Itp PipingDokument4 SeitenItp Pipingerdemlix100% (2)

- Itp Non AsmeDokument7 SeitenItp Non AsmeAkhilesh Kumar100% (1)

- Inspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselDokument1 SeiteInspection and Test Plan (Itp) For Fabrication Pressure Vessel Inspection and Test Plan (ITP) For Fabrication Pressure VesselNikki RobertsNoch keine Bewertungen

- Water Tank Fabrication QAPDokument2 SeitenWater Tank Fabrication QAPYOGESHNoch keine Bewertungen

- Standard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsedDokument4 SeitenStandard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsednithyaNoch keine Bewertungen

- Pipeline Integrity: Management and Risk EvaluationVon EverandPipeline Integrity: Management and Risk EvaluationBewertung: 4.5 von 5 Sternen4.5/5 (6)

- ITP For PipingDokument5 SeitenITP For PipingAldeline SungahidNoch keine Bewertungen

- Vendor Directory - M&e - FinalDokument2 SeitenVendor Directory - M&e - FinalsesabcdNoch keine Bewertungen

- Inspection & Test Plan PT. Barata Indonesia: Fabrication DocumentDokument22 SeitenInspection & Test Plan PT. Barata Indonesia: Fabrication DocumentmoddysNoch keine Bewertungen

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDokument18 SeitenInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiNoch keine Bewertungen

- Et 0000 97 Toc 001cDokument25 SeitenEt 0000 97 Toc 001cGLEDSONNoch keine Bewertungen

- MDR C40 Pt. DmiDokument14 SeitenMDR C40 Pt. DmiwidiNoch keine Bewertungen

- 102-V-5 QipDokument8 Seiten102-V-5 QipSaleemSahabNoch keine Bewertungen

- Other Requirement: BA-0496 Refap1 Project Disengager / Stripper R-300002, R-300003Dokument7 SeitenOther Requirement: BA-0496 Refap1 Project Disengager / Stripper R-300002, R-300003GLEDSONNoch keine Bewertungen

- Bus Duct-SPBDDokument5 SeitenBus Duct-SPBDSimbu ArasanNoch keine Bewertungen

- API6DValvesInspectionTestPlan PDFDokument4 SeitenAPI6DValvesInspectionTestPlan PDFkeertiraj09Noch keine Bewertungen

- Inspection Test Plan Equipment - AFC Header Plug Seal Weld 1Dokument4 SeitenInspection Test Plan Equipment - AFC Header Plug Seal Weld 1Mohd Shafuaaz KassimNoch keine Bewertungen

- Inspection and Test Program: Fabrication / In-Process InspectionDokument10 SeitenInspection and Test Program: Fabrication / In-Process InspectionGLEDSONNoch keine Bewertungen

- 41.water Cum Foam Monitor-Trailer MountedDokument2 Seiten41.water Cum Foam Monitor-Trailer MountedSimbu ArasanNoch keine Bewertungen

- Docslide - Us - Itp Structural WorkDokument4 SeitenDocslide - Us - Itp Structural Workomda4wadyNoch keine Bewertungen

- Perma - CCC - Insulation IR04Dokument7 SeitenPerma - CCC - Insulation IR04Amro MetwallyNoch keine Bewertungen

- Inspection and Test Plan of Steel StructureDokument2 SeitenInspection and Test Plan of Steel StructureEd Fang100% (1)

- CSCS Rods & BracketsDokument66 SeitenCSCS Rods & BracketsshuklahouseNoch keine Bewertungen

- Attach-2 ITP For Building WaterDokument29 SeitenAttach-2 ITP For Building WaterSukalyan BasuNoch keine Bewertungen

- Neo Structo Construction LTD.: Inspection and Test PlanDokument10 SeitenNeo Structo Construction LTD.: Inspection and Test Planravi00098Noch keine Bewertungen

- Qap Rap PDFDokument1 SeiteQap Rap PDFtrushalpanchalNoch keine Bewertungen

- ReinforcementsDokument1 SeiteReinforcementsAnonymous 3eHGEDbxNoch keine Bewertungen

- SM 001 SRV SpecDokument5 SeitenSM 001 SRV Specvardan_vardanNoch keine Bewertungen

- Inspection and Test Program: Fabrication / In-Process InspectionDokument4 SeitenInspection and Test Program: Fabrication / In-Process InspectionGLEDSONNoch keine Bewertungen

- Inspection and Test Plan: Fabrication / In-Process InspectionDokument17 SeitenInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- Etap 115 in Mumbai 060217Dokument3 SeitenEtap 115 in Mumbai 060217sesabcdNoch keine Bewertungen

- SES 1019 PP STD 058 - Rev0Dokument1 SeiteSES 1019 PP STD 058 - Rev0sesabcdNoch keine Bewertungen

- 1x600 MW Super-Critical Coal Based Thermal PowerDokument2 Seiten1x600 MW Super-Critical Coal Based Thermal PowersesabcdNoch keine Bewertungen

- Consultancy & Design Engineering Servic... Ation Design Consultants From KolkataDokument17 SeitenConsultancy & Design Engineering Servic... Ation Design Consultants From KolkatasesabcdNoch keine Bewertungen

- 0-10 KV MeggerDokument4 Seiten0-10 KV MeggerHasbllah yasirNoch keine Bewertungen

- Finolex House Wires 2016Dokument1 SeiteFinolex House Wires 2016sesabcdNoch keine Bewertungen

- How Do I Configure Bentley Products To ..Dokument4 SeitenHow Do I Configure Bentley Products To ..sesabcdNoch keine Bewertungen

- MicroStation V8i EssentialsDokument2 SeitenMicroStation V8i EssentialssesabcdNoch keine Bewertungen

- Ad Urdi - YouTubeDokument62 SeitenAd Urdi - YouTubesesabcdNoch keine Bewertungen

- SES 1019 PP STD 058 - Rev0Dokument1 SeiteSES 1019 PP STD 058 - Rev0sesabcdNoch keine Bewertungen

- Compare Mutual Funds, Compare Mutual Fu..Dokument3 SeitenCompare Mutual Funds, Compare Mutual Fu..sesabcdNoch keine Bewertungen

- Salicylic AcidDokument1 SeiteSalicylic AcidsesabcdNoch keine Bewertungen

- Ryan Mefiardhi - LinkedInDokument72 SeitenRyan Mefiardhi - LinkedInsesabcdNoch keine Bewertungen

- 7 220KV Control Cable Block Diagram 220KV Suva Rahiyad SS R 1 DT 0Dokument1 Seite7 220KV Control Cable Block Diagram 220KV Suva Rahiyad SS R 1 DT 0sesabcdNoch keine Bewertungen

- 04 - Heat Tracing Isometric DrawingsDokument113 Seiten04 - Heat Tracing Isometric DrawingssesabcdNoch keine Bewertungen

- 0076 Draft FinalDokument26 Seiten0076 Draft FinalsesabcdNoch keine Bewertungen

- Ryan Mefiardhi - LinkedInDokument72 SeitenRyan Mefiardhi - LinkedInsesabcdNoch keine Bewertungen

- EilDokument9 SeitenEildashNoch keine Bewertungen

- Cable DesignDokument26 SeitenCable DesignsesabcdNoch keine Bewertungen

- SES 1019 PP STD 058 - Rev0Dokument1 SeiteSES 1019 PP STD 058 - Rev0sesabcdNoch keine Bewertungen

- Private Sector UtilitiesDokument60 SeitenPrivate Sector UtilitiesRony Abraham0% (1)

- SES 1019 PP STD 058 - Rev0Dokument1 SeiteSES 1019 PP STD 058 - Rev0sesabcdNoch keine Bewertungen

- Condition Monitoring of Transformers SAILDokument17 SeitenCondition Monitoring of Transformers SAILavadiraja100% (1)

- (Instreng - Com) ISO 10976Dokument68 Seiten(Instreng - Com) ISO 10976sesabcd100% (1)

- 1 - Layout Plan TragadDokument1 Seite1 - Layout Plan TragadsesabcdNoch keine Bewertungen

- Private Sector UtilitiesDokument60 SeitenPrivate Sector UtilitiesRony Abraham0% (1)

- A037 2472 2000 MR 0Dokument391 SeitenA037 2472 2000 MR 0sesabcdNoch keine Bewertungen

- Canvas - L&T Electrical& AutomationDokument7 SeitenCanvas - L&T Electrical& AutomationsesabcdNoch keine Bewertungen

- L&T Technology Services Limited-Cost Estimator-VadodaraDokument2 SeitenL&T Technology Services Limited-Cost Estimator-VadodarasesabcdNoch keine Bewertungen