Beruflich Dokumente

Kultur Dokumente

Analysis and Design of Lattice Steel Towers For Electrical Energy Transport According With The EC3 (En) and The EN50341-1

Hochgeladen von

Achmad DamarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Analysis and Design of Lattice Steel Towers For Electrical Energy Transport According With The EC3 (En) and The EN50341-1

Hochgeladen von

Achmad DamarCopyright:

Verfügbare Formate

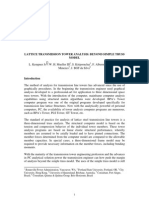

Analysis and Design of Lattice Steel Towers for Electrical Energy Transport according with the EC3(EN) and

the EN50341-1

Joo Rodrigues Dias, nr. 52005 Dissertation in Civil Engineering, Master Degree Setember 2007 Department of Civil Engineering and Architecture Instituto Superior Tcnico Technical University of Lisbon

ABSTRACT The objective of this paper is to perform a comparative study between the application of the new version of Eurocode 3 and the European Standard EN 50341-1 to analyse steel lattice structure for supporting overhead electrical lines. The structure analysed is a tower of the GSLF type (iced zone) with 40m of higher. A code in c# language was developed to calculate the action of the wind on the tower. After the computing the actions (forces) applied to this structure, the internal forces and moments were calculated by means of code SAP2000. Using these results, the member safety checking according to both standards was achieved (this part of the work was completed in an Excel worksheet). This procedure was repeated for two different joint models: one using fixed connection between bars (rigid nodes) and the other using members with pinned connections (pinned nodes). From this work, it was possible to conclude that both standards (EC 3 and EN 50341-1) give similar results, despite being different in nature. Additionally, it was verified that both models (rigid and pinned) also gave similar results, the later being more easy to analyse and perform the design and safety checking. Keywords: Lattice tower; Steel structures; L- section; Finite elements; Eurocode 3, EN 50341-1.

1. Introduction In the last few years several studies have been performed in the area of analysis and design of metallic towers. These studies comprised some full scale tests to different configurations of towers and finite element analyses. These investigations were able to study the ultimate capacity of the structure and other structural proprieties, like the vibration and stability behaviour [1]. Other type of studies are related to the choice of best model to simulate the joints of the tower [2]. Some times the position of one specific bar implies that the joint behaviour is almost fixed, other times it is less stiff (pinned joint). Some years ago, there were studies about the behaviour of similar towers constituted by cold-formed steel profiles. In the present paper, the finite element method is used to evaluate the static and dynamic (vibration) behaviour of lattice towers and the EC3 [3] and EN 50341-1 [4] are used to assess their safety checking. Figure 1: Lattice tower

2. Modelling The structure studied in this work is a tower of 40m high formed of bars with L shaped crosssection (hot-rolled profiles). The geometry is depicted in figure 1, as well as the type of crosssection (dimensions) for each bar. With exception of bars with L45x4 and L50x4 cross-section, which are made of S275JR steel, all the remaining members are made of S355JO steel. The tower was modelled in two different ways: in the first model the lattice tower is formed by members with fully rigid joints while in the second model the lattice tower was modelled by using pinned joints (see figures 2 and 3). These models were made in Autocad 3d [5] and adjusted inside the SAP 2000 code [6].

(a)

(b)

Figure 2 Lattice tower models: (a) rigid joint model (b) pinned joint model 3. Actions The main actions in the tower are (i) the self-weight of the structure, (ii) the self-weight of the cables and the ice loading in the cables and (iii) the wind forces applied on the structure and also on the cables. All this loading possibilities are combined in 10 different load combinations that could be seen with more detail in the complete work [7]. Is important to notice that the combination of wind with ice on the cables could increase in a non-negligible way the loads applied in the cable supports, a fact that is contemplated in the studied combinations. To guarantee that the wind action on the tower was realistic simulated in the programme, this action was modelled applying small forces on the nodes of the tower. The other actions that have origin on the cables were applied as it was already written on the cable supports of the tower. In order to achieve this goal, the calculation of the wind forces applied at the structure nodes, a small programme code was developed, using the rules from the EN 50341-1 [4]. 4. Standards specifications Generally speaking, the EN 50341-1 [4] standard rules are in the majority of cases based on EC3 [3]. However, there are a number of rules in EN 50341-1 [4] that include changes to the EC3 [3] specifications. Due to space limitations, the present paper will not include all the differences existing between the two codes but only the main ones. The cross-section classification in EC3 prescribes four classes (1, 2, 3 and 4) [3] while the EN 50341-1 standard demands that cross-section must be of class 3 and 4 [4]. Therefore, if one section is of class 1, 2 or 3 in EC3 classification [3], it will be of the class 3 in the EN 50341-1 standard. To perform the calculation of the effective properties of a class 4 cross-section it is necessary to determine the parameter (effective width reduction parameter). This parameter has different expressions in the two standards. According to EC3 [8], the parameter is calculated by means of,

sal = =1

2

p 0.188

2 p

if

p > 0.748

(1)

if

p 0.748

The EN 50341-1 [4] standard expressions for this parameter are given by,

= 1 if p = 2 0.91 0.98 if = 2 p

p 0.91

if 0.91 < p 1.213

(2)

p > 1.213

This difference influences directly the result of the safety checking because the EC3 is more restrictive (conservative) as it reduces more significantly the effective proprieties of the class 4 cross-sections than the NNA (National Normative Aspects for Portugal) of EN 50341-1 [9].

Figure 3 Effective width reduction parameter according to EC3 and NNA (EN 50341-1)

The safety checking in the two standards is in accordance with the expressions,

M y ,Ed + N Ed eNy M z ,Ed + N Ed eNz N Ed + k yy + k yz M1 = 1.0 y N Rk LT M y ,Rk M z ,Rk

(3) (4)

M y ,Ed + N Ed eNy M + N Ed eNz N Ed + k zy + k zz z ,Ed M1 = 1 . 0 z N Rk LT M y ,Rk M z ,Rk

However, the two code rules lead to different results every time that the cross section of the bar is not from the class 3. Because the interaction parameters kyy, kyz, kzy and kzz have different values if the cross-section is of (i) class 1 and 2 or (ii) class 3 and 4. Therefore, if some crosssection is of class 1 or 2, it will have one parameter value (kyy, kyz, kzy and kzz) from the EC3 [3] and a different value from the EN 50341-1 standard [4], because EN 50341-1 forces the crosssection to be at least from class 3. In addition, every time that one section is from the class 4, it will display a different parameter according with each standard. Thus, the resistant bending or axial force will be different because of the reduction of the section proprieties.

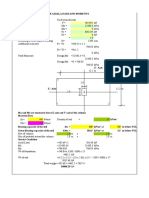

5. Effective proprieties analysis The first analysis performed in this work was done after the calculation of the effective properties of the cross sections. In tables 1 and 2, and considering the section under uniform compression, it is possible to see the EC3 results of (i) the cross-section classification and (ii) the calculation of the effective properties (effective area Aeff).

Table 1 EC3 cross-section classification and effective properties (compression)

Table 2 EN 50341-1 cross-section classification and effective properties (compression)

From the observation of tables 1 and 2, it is possible to conclude that the cross-sections L150x12, L60x4 and L70x5 are of class 4. However, only sections L60x4 and L70x5 suffered a reduction of their gross area. If we compare the results of the effective area according the EN50341-1 standard and the results according EC3 is possible to see that the EN50341-1 standard reduces less the proprieties of the cross section than the EC3. In other hand, these two standards, within the context of axial compressive force, have similar classification for each section. Before showing the results of the cross-section classification and calculation of the effective properties for the bending moment action, it is necessary to indicate that, because of the symmetrical properties of the cross section, is possible to resume the several possibilities of bending axes combination in two cases. Figure 4 shows these cases and the effective width reduction of the cross-section.

Figure 4 Effective width possibilities for the cross-section under bending

Table 3 EC3 cross-section classification and effective properties (bending case 1)

Table 4 EN 50341-1 cross-section classification and effective properties (bending case 1)

From the tables 3 and 4, it is seen that none of the class 1 cross-sections are reduced in their gross properties. However, one can see that all the sections are classified as class 3 in the EN50341-1 standard (table 4), because this is the lower class demanded from this code. This difference on the classification of the cross-section will lead to some differences on the safety checking results: even if it does not reduce the effective section modulus (Weff), it will increase the kyy, kyz, kzy and kzz parameters appearing in expressions (3) and (4). Table 5 EC3 cross-section classification and effective properties (bending case 2)

Table 6 EN 50341-1 cross-section classification and effective properties (bending case 2)

Tables 5 and 6 present the effective proprieties of the cross-sections for the bending case 2. In this case, the two standards exhibit similar classification results. Like in the axial compressive force case, the EN50341-1 standard is less conservative from the section properties point of view. It is clear that the cross-sections are much more penalized in the case 2 than in the case 1. This evidence results from the fact that one leg of the section is in uniform compression in case 2, which increases its susceptibility to local buckling phenomena. Conversely, only a half of the section leg is under compression (linear variation) in the case 1, thus being less prone to local instability. 6. Safety level analyses With the objective of investigating more specifically the results and to do a more insightful comparison between these two standards, a few qualitative parameters were adopted, which can be seen in the next expressions,

1 = number of bars that are unsafety

(5) (6)

2 =

E Ed E Rd

2 = average

E Ed E Rd

(7)

3 =

Ed E

Rd

Lbarra Asec o

Lbarra Asec o

(8)

3 = average

E Ed

Rd

(9)

3 =

Ed E

Lbarra Asec o Rd Lbarra Asec o

(10)

In these expressions, (i) EEd is action internal force or moment value, (ii) ERd is the corresponding resistant value, (iii) Lbar is the length of the member and (iv) Asection is the gross section area. A special attention must be paid to the 1 parameter because it comprises not only the number of bars which are not safe but also considers the number of load combinations that this bar fails and also the stations where the internal forces are higher than the resistant ones (notice that all the members have 3 stations one in the mid-span and the other two in the supports). Table 7 Parameter values used to characterize the safety level of the structure for each model (rigid and pinned) and for EC3 and EN50341-1

From the observation of the table 7 it is possible to mention that, according the EN50341-1 Standard, the number of cases with unsafe bars (1 parameter) is slightly superior to the one according with EC3. Despite this fact, the EN50341-1 Standard has a more safe level than the EC3 because EN50341-1 Standard exhibits lower level of 2 parameter. This means that the bars according this standard are, in general, more far from the collapse than using the EC3. This fact also occurs for the 3 parameter, meaning that the safety level of the bars obtained from the EN50341-1 Standard is superior and that it could be optimised for economical reasons (less steel material). However, the differences between the two codes are not so important if one observes table 8. From that, it is noticed that the combinations leading to failure in bars are similar for the two codes, and precisely in the same bars for each standard. Therefore, the differences visible on table 7 were more a question of the internal force diagram in the bar than a problem of the bar itself. This is due to the fact that the only reason behind the differences found in the value of the 1 parameter could be the distinct internal force values in the different stations of the bar.

Table 8 Unsafe bars and corresponding combinations according to the EC3 and EN503411

In the table 8 it is possible to see that the rigid joint model leads to a less favourable design due to the fact that this model is associated with a greater number of unsafe bars than the pinned joint model. From the pinned model point of view, it is possible to see that the second-order analysis is more favourable than the first-order one. This information could be completed with table 9, where it is presented the average of the axial force on the bars. Table 9 Axial force average values for each model and analysis

Figure 5 Structural model with the representation of the bars with problems according the standards

Figure 5 shows the localization of the bars which do not satisfy the safety checking. As it is seen, all the unsafe bars are those located on the top of the lattice tower. After performing the safety checking of the structure, it was necessary to present some possibilities to replace these unsafe bars. Therefore, two possibilities are proposed. The first one is to increase the cross section of the unsafe bars (see table 10) and the second one is to incorporate a few bars (eight) on the zone of structure with unsafe bars (see figure 6). The additional bars used in this second alternative are of the L45x4 type. Table 10 Possibilities to reach safety in all bars of the lattice tower

Figure 6 Detail of the additional bars incorporated in the structure 7. Buckling analysis According with the EC3 rules, if the cr parameter (critical load parameter) is greater than 10, it is possible to perform a first order analysis of the structure without restrictions [3]. If this parameter is less that 10 but upper than 3, an approximated second order analysis could be performed if the sway internal forces are multiplied by an amplification factor, which is dependent on cr. In any case, second-order analyses are always possible to perform. Therefore, it was necessary to calculate the cr parameter in order to know which type of analyse could be valid. Thus, this was accomplished directly with the programme SAP2000 by performing buckling analyses to find the parameter cr [6].

Table 11 Parameter cr obtained from all the load combinations (rigid and pinned models)

From the observation of table 11, it was possible to conclude that the correct analysis for this structure would be the second-order analysis for the pinned joint model (in 7 out of 10 combinations, the parameter was lower than 10). 8. Vibration analysis To complete the analysis to the different models in this study, a vibration analysis of the structure was done. In table 12, the vibration frequencies are presented for the first 12 vibration modes. As it was expected, the rigid joint model leads to eigen frequencies higher than the ones obtained for the pinned model. This is due to the fact that all the first 12 vibration modes are local vibration modes (each bar vibrates independently of the others, due to the pinned joints). The first global vibration mode of the entire structure was the 142 mode (a bending mode) and its frequency was 2.35. Table 12 Vibration frequencies (in Hz) for the first 12 modes (rigid and pinned models)

9. Conclusions The difference between the two Standards in order of design and safety verify is minimal. Because of this, the results obtained are the same in number of fails and in safety level is almost the same too for this kind of structures. In the analysis of the tower was seen that the tower have structural problems according with the two standards however with a small change in the cross section used in the bars with problems or increasing the number of bars in 8 is possible to solve the problem. In the case of the several analyses produced to compare the two structural models is conclusible that the pinned jointed model is less rigid than the other model. It was observed that the pinned model has an upper axial force level but it conducts to a small number of bars which didnt verify the safety. This proves that, even the axial force is higher the miss presence of the other types of stress compensate that fact. So, and if the level of results are so similar to the two models the pinned jointed model could be better because the verify of safety is easier than the verify of the other model for the reason that the expression are simplified in consequence of the bars in this model have just axial force. After the buckling analysis is possible two conclude that the more counsel analysis for this type of tower is the second order one. Result that is contradictory with the specified in the EC3 Part 3.1, because in this part is advised to do a first order analysis for this specific type of structures 9

The realization of the vibration of analyses permitted to conclude that this structure has a characteristic frequency of 2.5 Hz for the beading mode and 11Hz for the torsion mode. Is to note that this structure has a small mass, so it is not very susceptible to seismic problems, and it could be in the same way not susceptible to the dynamic action of the wind. However this affirmation needs better studies in the relationship between the fluid and the structure, in particular in the relation involving the gust frequency and the wind velocity.

10 References [1] Battista, Ronaldo C.; Rodrigues, Rosngela S. et Pfeil, Michle S. (2003); Dynamic behavior and stability of transmission line towers under wind forces; Journal of Wind Engineering and Industrial Aerodynamics 91 (2003) 10511067 [2] Rao, N. Prasad et Kalyanaraman, V. (2001); Non-linear behaviour of lattice panel of angle towers; Journal of Constructional Steel Research 57 (2001) 13371357 [3] CEN-Comit Europen De Normalisation (2005); Eurocode 3:Design of steel structures Part 1-1:General rules and rules for buildings; Bruxelas [4] CENELEC-Comit Europen De Normalisation Electrotechnique (2001); EN 50341-1 Overhead electrical lines exceeding AC45kV; Part 1: General requirements Common specifications; Bruxelas [5] Santos, Joo (2005); Autocad 2006; FCA Editora de Informatica; Lisboa [6] Computers and Structures, Inc. (2000); SAP2000 Integrated Finite Element Analysis and Design of Structures - STEEL DESIGN MANUAL; Computers and Structures, Inc.; Berkeley, California, USA [7] Dias, Joo R.(2007); Anlise e Dimensionamento de Estruturas Metlicas Treliadas de Transporte de Energia Elctrica de Acordo com o EC3(EN) e a EN50341-1;Departamento de Engenharia Civil; Instituto Superior Tcnico; Lisboa [8] CEN-Comit Europen De Normalisation (2004); Eurocode 3:Design of steel structures Part 1-5: Plated structural elements; Bruxelas [9] CENELEC-Comit Europen De Normalisation Electrotechnique (2001); National Normative Aspects (NNA) for PORTUGAL ; Bruxelas

10

Das könnte Ihnen auch gefallen

- Background To EurocodesDokument106 SeitenBackground To EurocodeshmoncktonNoch keine Bewertungen

- Transmission Tower Limit Analysis and DesignDokument9 SeitenTransmission Tower Limit Analysis and Designjunhe898Noch keine Bewertungen

- Literature Review For Monopole Foundation DesignDokument4 SeitenLiterature Review For Monopole Foundation DesignmrasdanNoch keine Bewertungen

- Is 802 1977 PDFDokument21 SeitenIs 802 1977 PDFBhavin Shah0% (1)

- Circular Tube End Plate Calculation PDFDokument4 SeitenCircular Tube End Plate Calculation PDFALPHYL BALASABASNoch keine Bewertungen

- Composite Section - Tutorials - (CSI Wiki)Dokument4 SeitenComposite Section - Tutorials - (CSI Wiki)Wilson100% (1)

- Dynamic Analysis of An Overhead Transmission Line Subject To Gusty Wind Loading Predicted by Wind-Conductor InteractionDokument10 SeitenDynamic Analysis of An Overhead Transmission Line Subject To Gusty Wind Loading Predicted by Wind-Conductor Interactionsara fernandesNoch keine Bewertungen

- Top Tower Insulator String SwingDokument5 SeitenTop Tower Insulator String SwingvgcasasNoch keine Bewertungen

- Design of Pad & Chimney FoundationDokument26 SeitenDesign of Pad & Chimney FoundationTulsi LakhaniNoch keine Bewertungen

- ECCS Report No 039Dokument34 SeitenECCS Report No 039Cpm102Noch keine Bewertungen

- Tubular Profiles For Telecom Structures PDFDokument8 SeitenTubular Profiles For Telecom Structures PDFJitendraNoch keine Bewertungen

- Angular Towers Offer Lower Costs and Easier ImplementationDokument8 SeitenAngular Towers Offer Lower Costs and Easier ImplementationdsulehNoch keine Bewertungen

- SNiP 2 01 07 85 Loads and Effects PDFDokument40 SeitenSNiP 2 01 07 85 Loads and Effects PDFdjicccNoch keine Bewertungen

- Stub Cleat Design DD-DDEDokument1 SeiteStub Cleat Design DD-DDEHikmat AyerNoch keine Bewertungen

- Collapse Analysis of A Transmission Tower Under Wind ExcitationDokument7 SeitenCollapse Analysis of A Transmission Tower Under Wind ExcitationRm1262100% (1)

- Optimum Body and Leg Extension Selection in PLS CADDDokument5 SeitenOptimum Body and Leg Extension Selection in PLS CADDGiancarlos Fenco BravoNoch keine Bewertungen

- Analysis of Transmission Tower With Different ConfigurationDokument11 SeitenAnalysis of Transmission Tower With Different ConfigurationPankaj_Taneja_9684Noch keine Bewertungen

- CE5710 Assignment IDokument1 SeiteCE5710 Assignment INani RujaNoch keine Bewertungen

- Lecture 5 FoundationsDokument30 SeitenLecture 5 FoundationsCarel De JagerNoch keine Bewertungen

- Chapter 3 Column and Compression MembersDokument60 SeitenChapter 3 Column and Compression Membersbihanba100% (1)

- Comparison Between Manual and Different Software Approach Towards Design of Transmission Line TowerDokument9 SeitenComparison Between Manual and Different Software Approach Towards Design of Transmission Line TowerIJRASETPublicationsNoch keine Bewertungen

- Steel Structures Design Based On Eurocode 3Dokument38 SeitenSteel Structures Design Based On Eurocode 3Oentoeng Kartono100% (1)

- Reference Description of Problem Values Units: Infomile SolutionsDokument3 SeitenReference Description of Problem Values Units: Infomile SolutionsdhawanaxitNoch keine Bewertungen

- Tubular Profiles For Telecom StructuresDokument8 SeitenTubular Profiles For Telecom StructuresbetathokNoch keine Bewertungen

- Design load calculation for 35 degree conductor and earth wireDokument2 SeitenDesign load calculation for 35 degree conductor and earth wireEko Bayu AjiNoch keine Bewertungen

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Dokument1 SeiteEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceNoch keine Bewertungen

- Broken Wire Condition PDFDokument16 SeitenBroken Wire Condition PDFAmritanshu SrivastavaNoch keine Bewertungen

- Calcs for Foundation Analysis (EN1997-1:2004Dokument6 SeitenCalcs for Foundation Analysis (EN1997-1:2004Ruemu Godwin InikoriNoch keine Bewertungen

- Revised Foundation For 315 Mva Transformer 28 10 09 Model PDFDokument1 SeiteRevised Foundation For 315 Mva Transformer 28 10 09 Model PDFepe civilNoch keine Bewertungen

- Transmission Tower (Optimal Design)Dokument3 SeitenTransmission Tower (Optimal Design)Michael Parohinog GregasNoch keine Bewertungen

- 132 KV Tower Analysis PDFDokument11 Seiten132 KV Tower Analysis PDFViswanathan VNoch keine Bewertungen

- CIGRE b2-305Dokument8 SeitenCIGRE b2-305Jorge Pinto RochaNoch keine Bewertungen

- Footing Design - MonopoleDokument5 SeitenFooting Design - Monopolemrprabhu16Noch keine Bewertungen

- Universal Beams... BS 4 Part 1 2005 Dim - PropDokument2 SeitenUniversal Beams... BS 4 Part 1 2005 Dim - PropJagdish ChhuganiNoch keine Bewertungen

- Mechanical Force of Short Circuit On Steel Structure For Terminator Inside EGATDokument9 SeitenMechanical Force of Short Circuit On Steel Structure For Terminator Inside EGATApichartj JusuayNoch keine Bewertungen

- AssignmentDokument2 SeitenAssignmentWudu Mulat AhmedNoch keine Bewertungen

- Shear Check To Eurocode 2Dokument4 SeitenShear Check To Eurocode 2smkumar121Noch keine Bewertungen

- Splice Connection 200Dokument19 SeitenSplice Connection 200Gheorghe IonicaNoch keine Bewertungen

- Lattice Girder Design for Roof StructureDokument12 SeitenLattice Girder Design for Roof StructureMock Khang Hi100% (1)

- Corus - Design of Shs Welded JointsDokument48 SeitenCorus - Design of Shs Welded JointsDylan RamasamyNoch keine Bewertungen

- "Polefdn" - Pole Foundation Analysis ProgramDokument28 Seiten"Polefdn" - Pole Foundation Analysis ProgramBenedict OgbaghaNoch keine Bewertungen

- Axially Loaded Columns - Base Plate DesignDokument2 SeitenAxially Loaded Columns - Base Plate DesignaomareltayebNoch keine Bewertungen

- Eurocode 3 - Design of JointsDokument18 SeitenEurocode 3 - Design of JointsdineshNoch keine Bewertungen

- Lecture 15C.3, Lattice Towers and MastsDokument30 SeitenLecture 15C.3, Lattice Towers and MastsCarlos Alexandre Picoral KindleinNoch keine Bewertungen

- Modeling Tall Guyed TowersDokument9 SeitenModeling Tall Guyed TowersAndreea LucaNoch keine Bewertungen

- Tower Analysis - More Then A Truss PDFDokument12 SeitenTower Analysis - More Then A Truss PDFrichificNoch keine Bewertungen

- Emergency Restoration System: 600H-SeriesDokument16 SeitenEmergency Restoration System: 600H-SeriesNagesh H BNoch keine Bewertungen

- Uniform and Temperature LoadingDokument2 SeitenUniform and Temperature LoadingWessam NourNoch keine Bewertungen

- Technical Specifications Section-Iv 1.0 Transmission Tower 1.1 General Description of The TowerDokument29 SeitenTechnical Specifications Section-Iv 1.0 Transmission Tower 1.1 General Description of The TowerKy TaNoch keine Bewertungen

- 41-Pile FoundationDokument56 Seiten41-Pile Foundationsharif uddinNoch keine Bewertungen

- Geometric Properties of Schifflerized An PDFDokument13 SeitenGeometric Properties of Schifflerized An PDFZaher SharafNoch keine Bewertungen

- Design of Reinforced Concrete Columns PDFDokument9 SeitenDesign of Reinforced Concrete Columns PDFYoshua Yang100% (2)

- Ci 2505 WightDokument8 SeitenCi 2505 WightsshayanmehrNoch keine Bewertungen

- Tubular Truss Design Using Steel Grades S355 and S420Dokument35 SeitenTubular Truss Design Using Steel Grades S355 and S420Muzamil Rather100% (1)

- Shear Buckling Evaluation in Steel Plate Girders With Rigid End Posts Subjected To Elevated TemperaturesDokument6 SeitenShear Buckling Evaluation in Steel Plate Girders With Rigid End Posts Subjected To Elevated Temperaturessonujk23Noch keine Bewertungen

- IJASC5 Post PrintDokument30 SeitenIJASC5 Post PrintHuy NguyenNoch keine Bewertungen

- Composite Columns IDokument15 SeitenComposite Columns IHeng Kimseng100% (1)

- Cold-Formed Steel MembersDokument19 SeitenCold-Formed Steel MembersLiviu IonNoch keine Bewertungen

- 571-Article Text PDF-4626-1-10-20130303Dokument12 Seiten571-Article Text PDF-4626-1-10-20130303CESAR ARMANDO JOSIMAR DEL CID JUAREZNoch keine Bewertungen

- American Fastener TablesDokument7 SeitenAmerican Fastener TablesAhmed BdairNoch keine Bewertungen

- Sheet Pile WallDokument6 SeitenSheet Pile WallAchmad DamarNoch keine Bewertungen

- Substation Structure CatalogDokument17 SeitenSubstation Structure Catalogingmoi0608Noch keine Bewertungen

- Sheet Pile WallDokument6 SeitenSheet Pile WallAchmad DamarNoch keine Bewertungen

- KAMAX - Bolt and Screw CompendiumDokument60 SeitenKAMAX - Bolt and Screw Compendiumjzaw65Noch keine Bewertungen

- KAMAX - Bolt and Screw CompendiumDokument60 SeitenKAMAX - Bolt and Screw Compendiumjzaw65Noch keine Bewertungen

- Tabla de Torque para Pernos de Acero SS304Dokument1 SeiteTabla de Torque para Pernos de Acero SS304Joaquín Indacochea Beltrán88% (8)

- Torque Tension ControlDokument5 SeitenTorque Tension ControlAchmad DamarNoch keine Bewertungen

- Material Properties Dan PembebananDokument1 SeiteMaterial Properties Dan PembebananAchmad DamarNoch keine Bewertungen

- User ID and Key ID LookupDokument1 SeiteUser ID and Key ID LookupNear Gaos33% (3)

- Vibration Testing of Small SatellitesDokument21 SeitenVibration Testing of Small SatellitesYoussef wagdyNoch keine Bewertungen

- Design and Performance of A Low-Frequency Non-Intrusive Acoustic Technique For Monitoring Fouling in Plate Heat ExchangersDokument10 SeitenDesign and Performance of A Low-Frequency Non-Intrusive Acoustic Technique For Monitoring Fouling in Plate Heat ExchangersVishal V BhagwatNoch keine Bewertungen

- Vibratory Bowl Feeders IncompleteDokument21 SeitenVibratory Bowl Feeders IncompleteAJAY SINGHNoch keine Bewertungen

- CM Experience With Boiler Feed PumpsDokument4 SeitenCM Experience With Boiler Feed PumpsLong Nguyen100% (1)

- 1 Page Synopsis ECU CasingDokument2 Seiten1 Page Synopsis ECU CasingIliyas InamdarNoch keine Bewertungen

- Lecture Notes FEMDokument153 SeitenLecture Notes FEMVijendraAgarNoch keine Bewertungen

- Gear Mesh FrequencyDokument8 SeitenGear Mesh FrequencyEndang SubarnaNoch keine Bewertungen

- Tutorial Chapter 3Dokument3 SeitenTutorial Chapter 3Siti ShuhadaNoch keine Bewertungen

- PedestrianBridge Zabia KladkaDokument5 SeitenPedestrianBridge Zabia KladkaValerie BurrisNoch keine Bewertungen

- Modal Analysis of A Cantilever BeamDokument7 SeitenModal Analysis of A Cantilever BeamVictor Perez RiveraNoch keine Bewertungen

- AMLS Users ManualDokument23 SeitenAMLS Users ManualOytun PekselNoch keine Bewertungen

- Vibration Analysis MethodsDokument29 SeitenVibration Analysis MethodsAdrian ArasuNoch keine Bewertungen

- FEA Interview Questions Module 1Dokument22 SeitenFEA Interview Questions Module 1Namit MishraNoch keine Bewertungen

- Viscoelastic Tuned Mass Dampers Optimally DesignedDokument1 SeiteViscoelastic Tuned Mass Dampers Optimally Designedkiran2381Noch keine Bewertungen

- Vibration Analysis of An Oil Production PlatformDokument12 SeitenVibration Analysis of An Oil Production Platformmssm_sNoch keine Bewertungen

- Liebherr P 994 Litronic Operation and Maintenance ManualDokument103 SeitenLiebherr P 994 Litronic Operation and Maintenance ManualAlain DefoeNoch keine Bewertungen

- Finite Element Analysis Unit 1: Fundamental Concepts of FEADokument21 SeitenFinite Element Analysis Unit 1: Fundamental Concepts of FEAExtra UseNoch keine Bewertungen

- Avr 555Dokument5 SeitenAvr 555makroumNoch keine Bewertungen

- Modal AnalysisDokument21 SeitenModal AnalysisemreNoch keine Bewertungen

- BOMAG Roller BMP 8500 Brugervejledning - EnGDokument132 SeitenBOMAG Roller BMP 8500 Brugervejledning - EnGCui100% (3)

- Soil Dynamics and Machine FoundationsDokument5 SeitenSoil Dynamics and Machine FoundationsKarunyamayaNoch keine Bewertungen

- Overview of Tuned Liquid Dampers and Possible Ways of Oscillation Damping Properties ImprovementDokument6 SeitenOverview of Tuned Liquid Dampers and Possible Ways of Oscillation Damping Properties Improvementmostafa shahrabiNoch keine Bewertungen

- 2014 05 Turbine Generator PKG EreDokument8 Seiten2014 05 Turbine Generator PKG EretpplantNoch keine Bewertungen

- Movi PackDokument6 SeitenMovi PackManel MontesinosNoch keine Bewertungen

- AATD ReportDokument14 SeitenAATD ReportKumar RavichandranNoch keine Bewertungen

- Validation Blast JATCDokument18 SeitenValidation Blast JATCPrasannaNoch keine Bewertungen

- Novak ShetaDokument19 SeitenNovak ShetaWendy CohenNoch keine Bewertungen

- Sound Powered Generator Research Proposal Termulo Jessmark and Titular Joe VincentDokument22 SeitenSound Powered Generator Research Proposal Termulo Jessmark and Titular Joe Vincentarondaniel ocampoNoch keine Bewertungen

- S Chand Engineering Books Catalogue 2012-13Dokument80 SeitenS Chand Engineering Books Catalogue 2012-13Suresh GuptaNoch keine Bewertungen

- Huang 2018Dokument5 SeitenHuang 2018Felipe Andres Figueroa VidelaNoch keine Bewertungen