Beruflich Dokumente

Kultur Dokumente

223333

Hochgeladen von

vinchandCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

223333

Hochgeladen von

vinchandCopyright:

Verfügbare Formate

Drilling Rigs

Truck-mounted drilling rigs

- This kind of drilling rigs are designed and manufactured in accordance with API Spec Q1, 4F, 7k, 8C and RP500, GB3826.1, GB3836.2, GB7258, SY6584 Standards as well as "3C" compulsory standard. - The whole rig has a compact structure, which requires a small installation space due to kits high integration. - The heavy-duty and self-propelled chassis: 8x6, l0x8, 12x8, l4x8, 14x12, 16x12 and hydraulic steering system are utilized respectively, which ensures the drilling rig a good passage and cross-country capability. - The reasonable assembly of CATERPILLAR engine and ALLISON transmission box can ensure high driving efficiency and working reliability. - The main brake adopts hydraulic disc brake or band brake and Air brake or hydromatic brake or FDWS brake can be applied as auxiliary brake. - The rotary table transmission box can realize forward-reverse shift, which can be suitable for all kinds of DP rotary operations, and the anti-torque releasing device can be used to make the DP deformation force released safely. - The mast, which is front - open and double-section type with an inclination angle or erective double-section type, can be erected or lowered and telescoped hydraulically. - The drill floor is twin-body telescopic type or with parallelogram structure, which is convenient for easy hoist and transportation. The height of the drill floor can be designed according to the client's requirements. - The perfect configurations of solid control system, well control system, high-pressure manifold system, generator house, engine & mud pump house, doghouse and other auxiliary facilities can meet user's different requirements. - Safety and inspection measures are strengthened under the guidance of the design concept of "Humanism Above All" to meet the requirements of HSE.

1000m Truck-mounted drilling rigs

1500m Truck-mounted drilling rigs

2000m Truck-mounted drilling rigs

3000m Truck-mounted drilling rigs

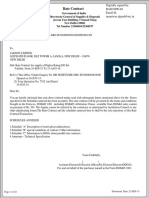

Function 1- Drilling by DP. 2- Meet the requirements on well adjustment and lateral drilling operation. 3- Put and install wellhead equipment and casings. 4- Trip string, examine and repair on the downhole equipment. 5- Grind bridge plug or drill cement plug. 6- Fishing operation. 7- Wash the sand on bottom-hole or perforated well section. Design principle 1. Meet the technical requirement on bidding; 2. The advanced domestic and overseas technology and structure are adopted, key parts are bought in to improve the rig reliability and enhance the standard factor. 3. Insist the design principle of safety first and put double safety device on the key parts to protect person and equipment safety. 4. Strengthen protection against abrasion to prolong using life; 5. Insist the design principle of reliability to prolong the using life of the drilling rig: 6. Strengthen human engineering to improve the working efficiency; 7. Conform to HSE Specs. Technical specification Structure type Nominal drilling depth Max. hook load Engine power Engine model Drive way Transmission model Drawworks gear NO. Mast height Traveling system Wireline dia. Hook block speed Substructure height Opening dia. of rotary table Chassis drive way Main unit weight when moving Overall dimension when moving

double drum, truck -mounted and self-propelled 10000 ft (41/2"DP) 400000lbs 2x475hp (two sets) CAT3408 (two sets) Hydraulic +mechanical Allison 5961 (two sets) 5F+1R lI8/125(ft) 4x5/5x6 F 11/4 in 0.66-4.59(ft/s) 19.685ft 27 .5in l4x8 l70000lbs 73 x l0 x l5 (ft)

4000m Truck-mounted drilling rigs

The trailer -mounted drilling rigs

The trailer -mounted drilling rigs - This kind of drilling rigs are designed and manufactured in accordance with API Spec Q1, 4F, 7k, 8C and RP500, GB3826.1, GB3836.2 GB7258, SY6584 standards as well as "3C" compulsory standard. - These drilling rigs have following advantages: reasonable design structures and high integration, a small working space and a reliable transmission. - The heavy-duty trailer is equipped with some desert tires and large-span axles to improve the moveability and the cross-country performance. - A high transmission efficiency and performance reliability can be maintained by a smart assembly and a utilization of two CAT 3408 diesels and ALLISON hydraulic transmission box. - The drawworks is double-drum type, with which the hydraulic disc brake is equippmed as main brake and air water-cooling disc brake (Model EATON WCB324) is equipped as auxiliary brake. - The derrick which is front-open type and has two-section structure with an inclination angle or erective sections can be lifted up or fallen down and telescoped. - The substructure has a parallelogram integral structure for easy transportation and installation, which can be risen by 6 setbacks spirally. - This kind of drilling rigs with desert adaptability design also have good anti-dust and high/low- temperature proof performances. - Safety and inspection measures are strengthened under the guidance of the design concept of "Humanism Above All" to meet the requirements of HSE.

Water -well drilling rig s

- This kind of drilling rigs are designed and manufactured in accordance with API Spec Q1, 4F, 7k, 8C and RP500, GB3826.1, GB3836.2 GB7258, SY6584 standards as well as "3C" compulsory standard. - This kind of drilling rigs can be used to drill water wells with the Max. depth of 300 meters and Max wellhead diameter of 500mm and to drill the gas wells with the foregoing same specification and to complete workover operations. - The water-well drilling rig is mobile rig. And a heavy-duty and cruise chassis is utilized for loading the hoisting/spinning and circulation system integrally, which has a good motion performance. The operations of these kind of drilling rigs, such as, hoisting operation, spinning operation and the slurry circulations are driven hydraulically,. The parameters for drilling water well can be adjusted automatically. - The water-well drilling rigs also have a function of auto bit feed and high working efficiency, equipped with pressure device for pressurization and depressurization to DP. - A hydraulic brake and a Crown-O-Matic as well as a hydraulic source under the substructure are installed respectively with the purposes of meeting drilling-process requirements and of insuring safety and reliability of the rigs. - Safety and inspection measures are strengthened under the guidance of the design concept of "Humanism Above All" to meet the requirements of HSE.

The main technical specification for the water-well drilling rigs

The skid-mounted drilling rigs

- This kind of drilling rigs are designed and manufactured in accordance with API Spec Q1, 4F, 7k, 8C, 9A and RP500, GB3826.1, GB3836.2, SY5609 standards. - These drilling rigs adopt an advanced AC- VFD-AC or AC-SCR-DC drive system and a non-step speed adjustments can be realized on the drawworks, rotary table and mud pump, which can obtain a good well-drilling performance with the following advantages: calm startup, high transmission efficiency and auto load distribution. - One -to -one control is designed for the VFD system and one-to -two control is designed for the SCR system., The intellectual control of the drillerover the drilling rigs can be realized by PLC system and the integrated design of touch screen parameters of gas, electricity, fluid and drilling instrumentation. - K type mast and the swing-up/sling-shot substructure have a good stability and provide a large working space. The mast and the equipment on the drill floor can be assembled on the ground and raised integrally. - The skid module structure can make the whole unit very compact and quick for movement, which can meet the requirements of the whole-unit-trucked transportation and of cluster-type-well drillings. - The drawworks will be driven by a single-shaft gear with a non-step speed adjustment. The transmission is simple and reliable. - The drawworks is equipped with a hydraulic disc brake and a motor-energy-consumption braking, and the braking torques can be controlled via the computer. - An auto bit feeder is equipped individually to realize real-time monitoring to the dropping process and drilling process of the DP.

The skid-mounted drilling rigs

The main technical performance & specification for the skid-mounted drilling rigs

The skid-mounted drilling rigs

The main technical performance & specification for the skid-mounted drilling rigs

The skid-mounted drilling rigs

- This kind of drilling rigs are designed and manufactured in accordance with API Spec Q1, 4F, 7k, 8C and RP500, GB3826.1, GB3836.2, SY5609 standards. - The drilling rigs can fully meet the well-drilling- process requirements by adoption of flexible driving designs-mechanical drives (high-speed diesels, hydraulic transmission box, angle gear box or middle-speed diesel hydraulic transmission, chain combination box), compound transmission and electrical drives (VFD or SCR) etc. - The whole unit is very compact and a quick whole transportation and installation of the whole drilling rig can be realized due to a utilization of a skid-mounted structure. In addition, the drilling rig requires a small working site due to its high integration and compact configuration. - Masts and substructures have various structures, such as: perpendicular-hoist sectional mast, whole -hoist K-type mast, telescopic substructure, spirally hoisted substructure and folding - frame substructure. - A standard and module design and various ways of combination have been adopted in order to boost up the universal and exchangeable performances of the drilling rigs and to meet the user's different requirements. - Disc brake or band brake can be applied as main brake and air brake or FDWS brake can be used as auxiliary brake and the energy-consumption braking can be available for electrical-drive-rig auxiliary brake. The drawworks can be equipped with bit-feed motor and control system. - The Internet and communication techniques have been used on the drilling rigs, which can realize an integral display for power, air control, hydraulic control, and monitoring and the intellectual and safe control of the driller. - The perfect configurations of the solid control system, well control system, high-pressure pipe manifold system, the generator house, the engine pump house, doghouse and other auxiliary facilities can meet the user's different requirements. Safety and inspection measures are strengthened under the guidance of the design concept of "Humanism Above All" to meet the requirements of HSE.

Das könnte Ihnen auch gefallen

- Workover RigsDokument9 SeitenWorkover RigsShady AbdoNoch keine Bewertungen

- Drilling, Workover & Well Servicing RigsDokument24 SeitenDrilling, Workover & Well Servicing RigsRubén De la Cruz100% (2)

- Model GT200 Track-Mounted Crushing Plant Spec Sheet: 1200Ls Crusher Hydraulic SystemDokument2 SeitenModel GT200 Track-Mounted Crushing Plant Spec Sheet: 1200Ls Crusher Hydraulic SystemVladimir Illich Pinzon BallenNoch keine Bewertungen

- 5Ton Cap SG EOT CraneDokument63 Seiten5Ton Cap SG EOT CraneRaging FayahNoch keine Bewertungen

- Double Girder EOT Crane EnquiryDokument3 SeitenDouble Girder EOT Crane EnquiryvkNoch keine Bewertungen

- Top Drive Level I Course IntroductionDokument31 SeitenTop Drive Level I Course IntroductionGiezy Daniela Velasquez Hernandez100% (2)

- Brochure Pit Viper SeriesDokument16 SeitenBrochure Pit Viper Seriesmanuel eduardo pomahuali liñanNoch keine Bewertungen

- 2000 HP Land Electric Drilling Rig Technical SpecificationDokument44 Seiten2000 HP Land Electric Drilling Rig Technical SpecificationSteveih100% (5)

- ERKE Group, Soilmec SM-8G AnchoringDokument12 SeitenERKE Group, Soilmec SM-8G Anchoringerkegroup100% (1)

- 930G NpiDokument56 Seiten930G NpiAlejandroCristianOjedaOjedaNoch keine Bewertungen

- Rotary Lift Specs SM122Dokument8 SeitenRotary Lift Specs SM122JhoffaXNoch keine Bewertungen

- Mining EquipmentDokument11 SeitenMining EquipmentKaushalendra Kumar Singh100% (1)

- Rig SewaDokument9 SeitenRig Sewayogacruise100% (1)

- 80M1 Drilling RigDokument1 Seite80M1 Drilling Rigapi-3698374Noch keine Bewertungen

- 500e Product GuideDokument8 Seiten500e Product GuideCésar Augusto Quiroga MontenegroNoch keine Bewertungen

- RobbinsDokument4 SeitenRobbinsJuan LopezNoch keine Bewertungen

- Vendor B - Technical ProposalDokument136 SeitenVendor B - Technical ProposalBilal Mehdi100% (1)

- Pipelayer: Engine Engine (Continued)Dokument20 SeitenPipelayer: Engine Engine (Continued)Daniel Marx ChillitupaNoch keine Bewertungen

- 3698 Pit ViperDokument6 Seiten3698 Pit ViperDaniel Quiroz100% (1)

- Land Rig BrochureDokument9 SeitenLand Rig Brochuresatya_dohare100% (1)

- Equipment:: Figure 1: Vertical Turbine PumpDokument8 SeitenEquipment:: Figure 1: Vertical Turbine PumphamizanNoch keine Bewertungen

- International Snubbing Services BrochureDokument10 SeitenInternational Snubbing Services BrochuresanuelNoch keine Bewertungen

- Series E: Product GuideDokument8 SeitenSeries E: Product GuideFrank Felipe Cruz ChavezNoch keine Bewertungen

- Dando Terrier Percussion (Dando Drilling Indonesia)Dokument2 SeitenDando Terrier Percussion (Dando Drilling Indonesia)Dando Drilling IndonesiaNoch keine Bewertungen

- Dando Terrier PercussionDokument2 SeitenDando Terrier Percussionapi-105789617Noch keine Bewertungen

- Cat 914G2Dokument20 SeitenCat 914G2t1me50% (2)

- Series D: Product GuideDokument8 SeitenSeries D: Product GuideFrank Felipe Cruz ChavezNoch keine Bewertungen

- CAT Rotary Blasthole Drill Line - C739015Dokument8 SeitenCAT Rotary Blasthole Drill Line - C739015Dutchie169100% (1)

- SpecificationDokument2 SeitenSpecificationQ8123Noch keine Bewertungen

- Ps 40 9 eDokument8 SeitenPs 40 9 eManuel De LeonNoch keine Bewertungen

- Liebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0Dokument4 SeitenLiebherr STS Ship To Shore Container Gantry Cranes Technical Description 12469-0sheron100% (2)

- Specification of Skid Steer Loader Machine - 1Dokument5 SeitenSpecification of Skid Steer Loader Machine - 1Afshin GhafooriNoch keine Bewertungen

- AlMansoori Directional Drilling Services Technology OverviewDokument60 SeitenAlMansoori Directional Drilling Services Technology OverviewHaider IjazNoch keine Bewertungen

- PHQ Long Tom Manual 2012Dokument42 SeitenPHQ Long Tom Manual 2012Miroslav PenevicNoch keine Bewertungen

- SANY SR250 Rotary Drilling RigDokument8 SeitenSANY SR250 Rotary Drilling RigSandeep Kumar DangdaNoch keine Bewertungen

- Pipelayer: Engine Weights Lift CapacityDokument16 SeitenPipelayer: Engine Weights Lift CapacityEVCYNoch keine Bewertungen

- B&D ManufacuringDokument20 SeitenB&D ManufacuringRodolfoMarínNoch keine Bewertungen

- KL150 Detailed SpecsDokument3 SeitenKL150 Detailed Specsben100% (1)

- A Project Report On Oil Rigs123Dokument17 SeitenA Project Report On Oil Rigs123Somasekhar Koushik Ayalasomayajula100% (1)

- KAT Gouging System - Arcair N7500Dokument2 SeitenKAT Gouging System - Arcair N7500Th NattapongNoch keine Bewertungen

- CPC Pumps Corporate BrochureDokument8 SeitenCPC Pumps Corporate BrochureArdiBarkahNoch keine Bewertungen

- 1581 GB 03Dokument11 Seiten1581 GB 03hasan2525Noch keine Bewertungen

- Steer PropDokument8 SeitenSteer Propfabiorr75Noch keine Bewertungen

- Cargador Frontal Cat 914GDokument28 SeitenCargador Frontal Cat 914GHuayta Apaza Jacinto100% (1)

- SEM C Series Catalogue LOW REZDokument16 SeitenSEM C Series Catalogue LOW REZAnonymous M5F3h2NR3f50% (2)

- XE750G液压挖掘机技术规格书Dokument28 SeitenXE750G液压挖掘机技术规格书abangNoch keine Bewertungen

- Rotary Drills AEXQ0600 01Dokument8 SeitenRotary Drills AEXQ0600 01المصور الدائري100% (1)

- Jica m316d RevDokument7 SeitenJica m316d RevagegnehutamiratNoch keine Bewertungen

- National Boom Trucks Spec Ef6a51Dokument8 SeitenNational Boom Trucks Spec Ef6a51Juan Carlos Torres MartinezNoch keine Bewertungen

- Hydraulic Track Drill AEXQ0599 01Dokument8 SeitenHydraulic Track Drill AEXQ0599 01DrianquisNoch keine Bewertungen

- Dando Geotec 6 (Dando Drilling Indonesia)Dokument2 SeitenDando Geotec 6 (Dando Drilling Indonesia)Dando Drilling IndonesiaNoch keine Bewertungen

- Coal Shearer (Underground Mining Machine)Dokument16 SeitenCoal Shearer (Underground Mining Machine)Donald Berbatov SilitongaNoch keine Bewertungen

- Mantis 20010Dokument16 SeitenMantis 20010thauwui86Noch keine Bewertungen

- Manual Trator IT14G CATDokument20 SeitenManual Trator IT14G CATHermes Sturla Erobregen Thorvalden100% (1)

- P& H 320XPC Blasthole Drill BrochureDokument6 SeitenP& H 320XPC Blasthole Drill Brochurezimscho100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Von EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Bewertung: 5 von 5 Sternen5/5 (2)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Von EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Noch keine Bewertungen

- Bulk Material Handling: Practical Guidance for Mechanical EngineersVon EverandBulk Material Handling: Practical Guidance for Mechanical EngineersBewertung: 5 von 5 Sternen5/5 (1)

- Industrial Piping and Equipment Estimating ManualVon EverandIndustrial Piping and Equipment Estimating ManualBewertung: 5 von 5 Sternen5/5 (7)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheVon EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Hairtypes Measuring PDFDokument1 SeiteHairtypes Measuring PDFvinchandNoch keine Bewertungen

- Countering-Terrorism MunichDokument40 SeitenCountering-Terrorism MunichJimmy LeonardNoch keine Bewertungen

- What to study for NDT examsDokument6 SeitenWhat to study for NDT examsvinchandNoch keine Bewertungen

- 12a - OilFieldSafetyNEO1 (1) ..Dokument34 Seiten12a - OilFieldSafetyNEO1 (1) ..vinchandNoch keine Bewertungen

- %! % PostScript Program For Distilling and Combining An EntireDokument1 Seite%! % PostScript Program For Distilling and Combining An Entirekimlien120382Noch keine Bewertungen

- Use of Internet For Terrorist PurposesDokument158 SeitenUse of Internet For Terrorist PurposesDuarte levyNoch keine Bewertungen

- Notes, Pages and Article on Coming to Aid of CountryDokument3 SeitenNotes, Pages and Article on Coming to Aid of CountryLuis Fernando Peña CastañedaNoch keine Bewertungen

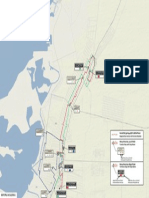

- Local Bus Services in Shahama with Route NumbersDokument1 SeiteLocal Bus Services in Shahama with Route NumbersvinchandNoch keine Bewertungen

- TE ProductionDokument36 SeitenTE ProductionvinchandNoch keine Bewertungen

- Aade 11 Ntce 61Dokument11 SeitenAade 11 Ntce 61AndresoPaezNoch keine Bewertungen

- Workdone Report For FEB & MAR From JCMTDokument2 SeitenWorkdone Report For FEB & MAR From JCMTvinchandNoch keine Bewertungen

- Secularism Revised..Dokument28 SeitenSecularism Revised..vinchandNoch keine Bewertungen

- 12a - OilFieldSafetyNEO1 (1) ..Dokument34 Seiten12a - OilFieldSafetyNEO1 (1) ..vinchandNoch keine Bewertungen

- Abu Dhabi Bus Route MapDokument1 SeiteAbu Dhabi Bus Route MapSiva Kumar Reddy100% (1)

- Adobe Acrobat Xi Edit Text and Images in A PDF File Tutorial UeDokument2 SeitenAdobe Acrobat Xi Edit Text and Images in A PDF File Tutorial UeLockheed NighthawkNoch keine Bewertungen

- Bharathidasan KavithaigalDokument74 SeitenBharathidasan Kavithaigalapi-3835692100% (2)

- Local Bus Services in Shahama with Route NumbersDokument1 SeiteLocal Bus Services in Shahama with Route NumbersvinchandNoch keine Bewertungen

- How To Buy Binoculars - Binoculars Buying Guide - My Binocular Reviews43Dokument4 SeitenHow To Buy Binoculars - Binoculars Buying Guide - My Binocular Reviews43vinchandNoch keine Bewertungen

- Jayakanthan Sirukathaigal - Part3Dokument83 SeitenJayakanthan Sirukathaigal - Part3முரளி கிருஷ்ணன் alias முகி100% (5)

- HVAC UNITSbDokument1 SeiteHVAC UNITSbvinchandNoch keine Bewertungen

- What Every Designer Should Know in AutoCADDokument1 SeiteWhat Every Designer Should Know in AutoCADvinchandNoch keine Bewertungen

- Mech Obj II UpscuDokument24 SeitenMech Obj II UpscuvinchandNoch keine Bewertungen

- Tamil Samayal - Mongo Dish 30 VaritiesDokument14 SeitenTamil Samayal - Mongo Dish 30 VaritiesSakthivel100% (2)

- Tamil Jokes - DinamalarDokument21 SeitenTamil Jokes - DinamalarSakthivel100% (22)

- Bharathidasan - Kudumba VilakkuDokument104 SeitenBharathidasan - Kudumba Vilakkushruthilaya50% (4)

- Chandrikaiyin KathaiDokument54 SeitenChandrikaiyin Kathaia1n2u3s4h5a6Noch keine Bewertungen

- KalithogaiDokument110 SeitenKalithogaivinchandNoch keine Bewertungen

- Practical Details ProgrammeDokument1 SeitePractical Details ProgrammevinchandNoch keine Bewertungen

- Census of India Tamil Nadu 2011 DetailsDokument9 SeitenCensus of India Tamil Nadu 2011 DetailsNagendhiran KumarNoch keine Bewertungen

- 1998 Sea-Doo Service ManualDokument426 Seiten1998 Sea-Doo Service ManualTodd Osberg100% (3)

- Ch5.0 Operation of BoilersDokument80 SeitenCh5.0 Operation of BoilersRey100% (1)

- Otto Cycle and Diesel CycleDokument19 SeitenOtto Cycle and Diesel CycleshubhamNoch keine Bewertungen

- Oil and Gas Technology UpdateDokument66 SeitenOil and Gas Technology Updatemuhammad habib chusnul fikriNoch keine Bewertungen

- Tad 720 GeDokument2 SeitenTad 720 GeRudy Okta LNoch keine Bewertungen

- Jakson LimitedDokument24 SeitenJakson Limitedgs100% (1)

- Oil and Gas Field Delopment PDFDokument97 SeitenOil and Gas Field Delopment PDFManish SoniNoch keine Bewertungen

- L35Dokument317 SeitenL35Mikel FlixNoch keine Bewertungen

- Sotera 825p-850 OriginalDokument64 SeitenSotera 825p-850 OriginalPaul Mcallister BelloNoch keine Bewertungen

- Complete Test Lists for Oils, Coolants, Diesel Fuel & SpecialtyDokument3 SeitenComplete Test Lists for Oils, Coolants, Diesel Fuel & SpecialtyAlfredo GallardoNoch keine Bewertungen

- Manitou MRT 2150 Privilege Plus ST4 - MRT 2540 Privilege Plus ST4 - (EN)Dokument8 SeitenManitou MRT 2150 Privilege Plus ST4 - MRT 2540 Privilege Plus ST4 - (EN)ManitouNoch keine Bewertungen

- Q&A GeneralDokument8 SeitenQ&A GeneralRaunaq AroraNoch keine Bewertungen

- 3-phase motor tutorial problemsDokument3 Seiten3-phase motor tutorial problemsPaul Praneeth MuddamalleNoch keine Bewertungen

- Unit 4Dokument41 SeitenUnit 4DHANASEKAR K IV A 9023Noch keine Bewertungen

- Case 250C Service ManualDokument2.025 SeitenCase 250C Service Manualaksel777100% (6)

- Iso 8217Dokument10 SeitenIso 8217Sumit SamaNoch keine Bewertungen

- AMSOIL Break-In Oil (SAE 30) - BRKDokument2 SeitenAMSOIL Break-In Oil (SAE 30) - BRKamsoildealerNoch keine Bewertungen

- As Pe High Rise Plumbing DesignDokument92 SeitenAs Pe High Rise Plumbing Designalmira lhee cadores100% (1)

- Ecu Chevrolet Aveo 1.5 L (Hv240)Dokument5 SeitenEcu Chevrolet Aveo 1.5 L (Hv240)immanemm90% (10)

- Lombardini 3ld510 Piston KitDokument7 SeitenLombardini 3ld510 Piston KitCornel CristianNoch keine Bewertungen

- 911 1972-1983 Workshop Manual Deel 1 Motor en KoppelingDokument146 Seiten911 1972-1983 Workshop Manual Deel 1 Motor en Koppelingdark_abyss2007255950% (2)

- Continental O-300 Overhaul ManualDokument68 SeitenContinental O-300 Overhaul ManualFaras Alsaid100% (1)

- Toyota Diagnostic Trouble Codes Full List Obdii365Dokument3 SeitenToyota Diagnostic Trouble Codes Full List Obdii365Al-Bohari Kamsani100% (3)

- Cement Recruitment Details With Interview Questions: General 0 CommentsDokument42 SeitenCement Recruitment Details With Interview Questions: General 0 CommentsAsifRazaNoch keine Bewertungen

- 57-62 1m809 - Eng72dpiDokument6 Seiten57-62 1m809 - Eng72dpiAbhinav TewariNoch keine Bewertungen

- List of Auto PartsDokument25 SeitenList of Auto PartsCheng PeitaoNoch keine Bewertungen

- Pin ConnectionDokument5 SeitenPin ConnectionnicamarcosNoch keine Bewertungen

- MECH HovercraftDokument16 SeitenMECH HovercraftNagabhushanaNoch keine Bewertungen

- Ormat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Dokument7 SeitenOrmat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Kiran VeerubhotlaNoch keine Bewertungen

- The Boiler DesignDokument154 SeitenThe Boiler DesignAyman Esa100% (2)