Beruflich Dokumente

Kultur Dokumente

Gregory R Campbell - From A Binder's Point of View (4pp)

Hochgeladen von

galaxy51110 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

40 Ansichten4 Seitenvb bind

Originaltitel

Gregory R Campbell - From a Binder's Point of View [4pp]

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenvb bind

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

40 Ansichten4 SeitenGregory R Campbell - From A Binder's Point of View (4pp)

Hochgeladen von

galaxy5111vb bind

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Anyone can be a book publisher today.

A great many desktop publishers

actually do generate books they will

wish to have bound. A review of our

sales for 1996 showed that some 30% of

sales were made to independent pub-

lishers, not library customers. This did

not happen by accident. We have taken

a strong marketing approach to attract

such new business. When dealing with

a rst time publisher, we have learned

that a good deal of flexibility, patience,

and the development of retail sales

skills are necessary.

Book production is a very technical

business. Most of the general public

has little knowledge of what is

required to produce a book purchased

at the local bookstore. Few have any

knowledge of book design or would

grasp that there may be a vast differ-

ence between the concept of camera

ready copy and copy that is ready to

print. Fewer still have any idea of how

decisions they make about printing

will affect various binding options.

If, by lucky accident, a new, inde-

pendent publisher should nd some-

one with enough time and book design

knowledge to help them achieve their

goals they are very fortunate. If not,

they may make any number of costly

mistakes.

Having been involved in the busi-

ness of bookbinding for some 30 years I

feel just barely condent enough to

offer some rudimentary advice about

book design and book structure to a

beginner. The rst bit of advice I offer is

that I wont have all the answers for

you. The information I am offering is

gleaned from practical experience and

is geared toward desktop publishers

who are seeking hardcover binding

solutions. It is advice that is often given

over the phone or in person to some-

one inquiring about our bookbinding

service by asking the broad question,

How much does it cost to bind a

book? or Can you bind this disk?

The questions most often asked fall

into three main categories.

Paper

Printing formats

Binding

PAPER

The paper chosen for any printing

project may be the most crucial deci-

sion to make. Decisions about paper

will not only affect the printing but will

affect how a book may be bound.

Because of this, there is a heavy con-

centration on the subject.

Handmade Paper

Prior to 1830, all paper was made

by hand from plant ber such as cot-

ton, linen, ax, straw, hemp, or kozo.

Plant bers were torn or, if in the form

of rags, cut up. These shreds are then

beaten into pulp bers and placed into

a vat of water allowing the bers to

oat to the surface. A screen that is

woven tightly enough to catch pulp

bers but open enough to allow water

to escape is dipped into the vat. As the

screen is raised the bers trapped on

top formed the sheet of paper.

In hand papermaking, the size of

the screen is determined by the size of

the sheet needed for any particular

papermaking project and the strength

of the papermaker to lift the screen

from the water. Hand papermaking is

hard, laborious work with very little

mechanical assistance. As such, one of

the beauties of handmade paper is that

there is no discernible, machine-made,

grain direction to its bers.

Machine Made Paper

The demand for paper, even today

remains unsatised. In the early 1800s

paper was in very short supply.

Machinery for making paper was

developed to satisfy growing demand.

The most successful and prolic of

these machines is known as the

Foudrinier papermaking machine. The

Fourdrinier is a great, long, ponderous,

steaming piece of machinery that Dard

Hunter once described as dragon

like. Fourdriniers are capable of pro-

ducing continuous streams of paper,

over 300 inches wide, at more than

2000 feet a minute!

As the still liquid paper is spit from

the Fourdrinier machine in one forceful

direction, the pulp bers line up paral-

lel to each other in the long direction

they are being driven, much like water

droplets streaming from a garden hose.

As paper comes off a Fourdrinier

machine, it travels through a series of

both horizontal and vertical rollers. It is

stretched, dried and rewound. It is then

colored and coated with agents such as

clay, chalk, caesin, and various resins.

Finally, it travels to a calendar or nish-

ing machine that puts articial textures

into the paper.

Common Book Paper

Classications

In general, paper used for books

comes in either text weight or cover

weight. Text weight paper (used for the

printed pages of the text) comes in four

main weights: 50-pound, 60-pound, 70-

pound, and 80-pound.

Cover weight paper (used for print-

ing paperback book covers, magazine

covers, etc.) is approximately three

times thicker or heavier than text

weight paper of the same poundage.

FROM A BINDERS POINT OF VIEW:

SOME ADVICE FOR INDEPENDENT, DESKTOP PUBLISHERS

Gregor R. Campbell : : Campbell-Logan Bindery : : Minneapolis

1 of 4

Standard cover weight paper comes in

65-pound, 70-pound, 80-pound, and

sometimes 100-pound weights. There

would be, however, approximately one

third the number of sheets of 70-pound

cover stock in a carton as there would

be in a carton of 70-pound text weight

paper.

Both text and cover weight papers

come in coated and uncoated versions

for various uses.

Grain direction

Machine made paper, like wood,

has a grain direction which should be

taken into account when choosing

paper for a book. If the paper grain is

not parallel to the spine, the books

pages will not turn easily or lie at.

Folding a sheet of paper across the

grain will break approximately 50% of

the paper bers, weakening the sheet

substantially. Additionally, cross-grain

paper is strangely hydroscopic. It will

absorb moisture from adhesives at a

much faster rate, causing cockling

and warpage.

Grain direction of paper is almost

always with the longest dimensions

The paper merchants catalog desig-

nates grain direction with a small

underline below the number (such as

25 x 38 inches).

Paper Sizes

In the US, paper that is sheeted for

the printing trade, either text weight or

cover weight, comes in standard sizes.

Standard sizes for text weight paper in

inches are 25 x 38, 35 x 40, and 38x 50.

Standard sizes for cover weight paper

are 23 x 35, 25 x 38, 26 x 40 and 35 x 45.

PRINTING FORMAT

Book Sizes

Common book sizes relate to a

printers best yield or (cut) from these

master sheets of paper. Thus 8

1

/2 x 11,

7 x 10, 6 x 9, and 5

1

/2 x 8

1

/2 inches are

traditional sizes of many books. Lately,

due to photocopiers and other emerg-

ing printing technologies, the 5

1

/2 x 8

1

/2

inch size has become much more com-

mon, as you can print two pages at a

time on a standard 8

1

/2 x 11 sheet of

paper.

Book Design

When pages are printed on both

sides there is the possibility of show-

through or bleed-through problems.

This is the dark shadow from type or

an illustration that shows through from

the reverse side of the sheet. This is

caused by the fact that the paper is not

opaque enough to mask out the image.

Ideally, printing that is done on

both sides of the page should back

up or have its shadow hidden by

printing that is done on the reverse or

opposite side of the page. This prevents

show-through and gives a crisp, clean

look to the page.

If show-through problems persist

we advise against the natural inclina-

tion of choosing a heavier weight

paper for the text, especially cover

stock! Heavier paper will only resist

opening and easy reading. Try choos-

ing a text weight paper of another color

such as off-white or light gray.

After decisions about paper have

been made, the next most important

consideration should be what typeface

and what size type to use. Obviously, it

is best to use a size of type that is easy

to read. For text generated by word

processor or computer these sizes

would normally be 10 point, 12 point,

and 14 point.

We would urge you to resist the

temptation to reduce the size of the

typeface by photocopy reduction. This

will only make the text more difcult to

read. It is preferable to add additional

pages if required.

I encourage you to read more about

book design. The best book I have read

on the subject is Adrian Wilsons The

Design of Books (ISBN 0-87905-019-5). In

his book, Wilson lists another dozen or

so references for those who are truly

serious about wanting to learn more.

Typefaces

Thankfully, for the desktop pub-

lisher, computer type has come a long

way from the days when typefaces

were limited to what was easily dis-

played on a computer screen. There are

now thousands of typefaces to choose

from. Each one has its own character.

While hundreds of books have been

written about type and book design,

the choice of which face to use is most

often made by either a typefaces avail-

ability or personal preference.

Typefaces fall into two main cate-

gories: serif or sans serif type. Serif type

has little feet on the letters. This article

is written in a serif typeface. Serif type-

faces are considered easier to read

(as text) than sans serif. Sans serif type

is more often used as a headline or

chapter heading.

Page Margins

Page margins and choosing propor-

tions within a page are very important

design elements. It is a basic principle

of book design that typographic areas

will generally occur within the same

rectangular space, in the same position,

throughout a book. The white space

around the typographic area frames

the text on a page much like a mat

frames a picture. In book design the old

classic standard was one-third black

space to two-thirds white space. This

made for eye appeal and easy reading.

As paper and printing costs have

escalated this rule has been sacriced.

Margins have become narrower and

narrower. As a general rule, and if at

all possible, we recommend a one-inch

all around page margin for desktop

publishing. If this is not possible due

to maximum page count or other con-

siderations leave as much margin as

possible, keeping in mind that most

bookbinders will want to trim three

sides of a book when doing the binding.

BINDING

Ideally, the actual binding on a

book should perform several functions.

2 of 4

These are consolidation or holding the

pages together and providing protec-

tion from moisture and handling. Bind-

ings should provide for identication

of the item. They may also be designed

as a means for attracting attention to

and for promotion of the item.

There are many binding options to

chose from. Factors that determine

choice are usually based upon cost and

availability as well as the expected use

a bound item is to receive. Bindings fall

into three main categories.

Mechanical bindings

Adhesive bindings

Sewn bindings

Mechanical Bindings

Mechanical bindings include ring

binders, loose-leaf or post binders, sta-

ples or saddle stitching, plastic coil,

plastic comb, Velo binding, channel

binding, metal spiral and wire-O bind-

ing. Rivets, grommets, and other fas-

tening devices may also be used. With

the exception of ring or post binders,

mechanical bindings are normally the

least expensive binding option avail-

able for small runs of desktop pub-

lished material.

Adhesive Bindings

Adhesive bindings attach a books

pages together with adhesive (glue or

paste) rather than by mechanical fas-

tening or sewing.

Bookbinding adhesives fall into

two main categories. (1) Hot melt adhe-

sive and (2) cold emulsion, polyvinyl

acetates or PVAs. One form of hot melt

adhesive is the little round stick of glue

that is inserted into a hand-held glue

gun. This glue needs to be heated to

become liquid for application, thus the

term hot-melt.

A familiar form of PVA is Elmers

Glue. This adhesive does not need to be

heated to become liquid, thus the term

cold emulsion.

There are thousands of glue formu-

lations for both types of adhesive, each

formula being for specic usages.

The term perfect binding always

equates to a book that is bound with

adhesive. The adhesive, while usually

a hot melt may occasionally be a cold

emulsion PVA or even a new breed of

adhesive called a polyurethane adhe-

sive (PUR). Perfect bound books are

usually covered in paper, however they

can be made with a hard cover.

Sewn Bindings

Sewn bindings fall into two main

categories. (1) Side sewn or (2) sewn

through the fold. Either category may be

done by machine or by hand.

Some methods of side sewing are

Japanese sewing, block stitching,

Singer side sewing, and Moffett stitch-

ing. Japanese sewing (to my knowl-

edge) is only done by hand, as is block

stitching. Singer sewing and Moffett

sewing both refer to the sewing

machines that are used in the machine

side sewing process.

Sewing through the fold does re-

quire that a book be made up of folded

leaves called signatures. A book may

have a single signature or be made up

of many signatures that will be linked

together during the sewing process.

Books that are sewn through the fold

by hand are referred to, naturally, as

hand sewn books.

Machine sewing through the fold is

most often done on a Smyth sewing

machine. The process, again naturally,

is most often called Smyth sewing,

although there are other through-fold

sewing machines that can accomplish

this task. The National sewing machine

and the Martini sewing machine are

but two examples. Much like

Kleenex is used to designate facial

tissue or Xerox is used to signify a

photocopy, the trade name Smyth

sewing has become so prevalent that

it is the general term for any through-

fold sewing method.

There are other methods and ma-

chines used to attach book pages

together that are, for the most part,

unique to the library binding industry.

The two most common are oversewing

and double-fan adhesive binding.

Oversewing offers the advantage of

being able to sew single leaves into mul-

tiple signatures. Oversewing has the

disadvantage of consuming approxi-

mately 3/16-inch of spine margin.

Additionally, oversewing is so strong

that pages have a tendency to pucker

up along the sewing line, making read-

ing or photo reproduction difcult if

narrow margin material is attached in

this method.

Double-fan adhesive binding may

also be used to attach single leaves

together to form a book block. This

may be done either by hand or by

machine. It is accomplished by clamp-

ing the book into a vise-like contrap-

tion and fanning the pages at a near

90-degree angle, while applying adhe-

sive to the edges of the pages. The

pages are brought back to center and

fanned in the opposite direction. Adhe-

sive is again applied to the pages as

they are fanned. In effect, each page is

tipped to its neighbor, fore and aft.

The strength of double-fan adhe-

sive binding may be augmented by

notching the spine to increase adhesive

penetration or by milling or sanding

the edges of the spine to expose addi-

tional paper ber to adhesive. When

properly done, double-fan adhesive

binding has the advantage of allowing

a book to lie open nearly at for easy

reading or photocopy reproduction.

Book Covers

Hardcover bindings, sometimes

referred to as cases, may be covered

in paper, cloth, leather, or a combina-

tion of two or more of these materials,

which are wrapped around and glued

to a supporting board. The board itself

may be rigid (as in an encyclopedia) or

exible (as in a small Bible).

Paper cover materials are referred

to in the trade as non-woven cover ma-

terial. Non-wovens are often textured

to appear like fabric or leather. They

may also be decorated, as in marbled

3 of 4

paper or laminated with clear polyester

lms for added strength and durability.

Book fabrics (woven materials) are

graded by weight which refers to the

number of threads per square inch in a

particular cloth. Book fabric comes in

A, B, C, D, E, and F weights. A

weight fabric is the lightest weight, F

weight is the heaviest. It is generally

assumed that heavyweight book cloth

is stronger than lightweight cloth.

Book fabric may be left uncoated in

its natural state or coated with mois-

ture resistant substances (vinyl or

acrylics). It may also be textured to

look like leather.

Leather cover materials are har-

vested from any number of animals.

These commonly include cows, sheep,

pigs, and goats. However more exotic

skins have sometimes been used to

cover books, including human skin!

Leather is prepared for use by tan-

ning the hide or skin for durability. It is

also frequently colored with leather

dye and occasionally textured to alter

surface appearance.

Cover Decoration

There are several options available

for cover decoration or titling. Most

people are familiar with foil stamp-

ing, which usually consists of basic

title and author information. This

information is set in metal type and hot

stamped through a colored foil onto

the book fabric or cover. Additional art-

work, in the form of an illustration or

logo, may be added by having a metal

engraving made from lm or line art.

Most library binders will be very famil-

iar and comfortable in providing this

type of cover decoration.

Silkscreening is a second option. It

is a popular method, used primarily on

vinyl covers. However it can work very

successfully on nearly any fabric and

many non-woven cover materials. Silk-

screening has advantages in allowing

larger areas to be decorated. It also

allows for multicolored images and

easy matching of specic ink colors.

Athird option is photo offset print-

ing. As with silkscreening it can be suc-

cessful on both book cloth and non-

woven materials. Photo offset printing

allows for the widest variety of decora-

tion possibilities in design and color.

If a small number of covers are

required and color is desired, it is also

possible to use a color photocopier.

Fabric materials have been developed

which can be manually fed through

some color photocopy machines. How-

ever, if the quantities were large this

would be an expensive method to use

for decoration of book covers. There

may also be possibilities for using inkjet

printers to decorate cover materials.

Printed book jackets are another

alternative for cover decoration. Book

jackets are usually made from paper.

They are easily printed in any number

of ways, and after binding, wrapped

around nished books.

Aword of caution about book jack-

ets! Pay close attention to the direction

of the paper grain. The grain direction

should always run parallel to the spine

of the book. Also, be sure to allow

enough wrap aroundso that the inte-

rior aps of a book jacket are held

rmly in place by the book cover. A

minimum of two-inches for interior

aps is suggested. If this is not done the

jacket will not t well and will not stay

put on the book as the book is handled.

CONCLUSION

Copyright information

Finally, after one has spent count-

less hours producing their rst master

work, we are often asked about obtain-

ing a copyright. This may be done after

production of the book. Copyright

information may be obtained by writ-

ing to the U.S. Copyright Ofce,

Library of Congress, Washington, DC

20559. For books and other printed

works request form TX.

ISBN numbers (used as inventory

control when ordering) may be

obtained by writing to ISBN Agency

(U.S.), R.R. Bowker, 121 Chanson Road,

Providence, NJ 07974. Tel. 908-665-6770.

A new publisher should write a letter

on their letterhead requesting an ISBN

assignment.

Library of Congress Catalog Card

number preassignment may be

obtained by writing to U.S. Library of

Congress, Cataloging in Publication

Division, Washington, DC 20540. The

Library of Congress will send you the

appropriate form and kit describing

Cataloging in Publication procedures.

There are a vast number of re-

sources available in print to those seri-

ous about publishing their books. One

that I recommend is The Prepublishing

Handbook by Patricia A. Bell, Cats-paw

Press 1992, ISBN 0-9618227-2-4. This

book explains in good detail the many

hats worn by a small publisher. It also

has an extensive listing of independent

publishers and regional booksellers

organizations.

I hope this information will be

helpful to the beginning, independent

publisher and to library binders who

wish to offer their services to a growing

constituency. New methods of printing

and binding continue to evolve. It is

estimated that some 5,000 new publish-

ers appear each year! This certainly

gives added testimony to the fact that

nearly everyone has at one time or

another said, I could write a book!

First published in

The New Library Scene, March 1997

4 of 4

Campbell-Logan Bindery

212 North Second Street

Minneapolis MN 55401

Das könnte Ihnen auch gefallen

- SPpiano 5Dokument1 SeiteSPpiano 5galaxy5111Noch keine Bewertungen

- Guitar fingering chart for E major scaleDokument1 SeiteGuitar fingering chart for E major scalegalaxy5111Noch keine Bewertungen

- SPbass 10Dokument1 SeiteSPbass 10galaxy5111Noch keine Bewertungen

- Cpemh 8 110Dokument10 SeitenCpemh 8 110galaxy5111Noch keine Bewertungen

- Cello Extended TechniquesDokument30 SeitenCello Extended TechniquesFábio Videira100% (6)

- 00 IntroductionDokument2 Seiten00 Introductiongalaxy5111Noch keine Bewertungen

- Carl Flesch GMajorDokument5 SeitenCarl Flesch GMajorlilouettesNoch keine Bewertungen

- Tasty MushroomDokument1 SeiteTasty Mushroomgalaxy5111Noch keine Bewertungen

- Cello Positions and Notes On The Bass ClefDokument1 SeiteCello Positions and Notes On The Bass Clefgalaxy5111Noch keine Bewertungen

- Choose Cloth Color Blood Papers: Score/Fold Down Cut Score/Fold Up Optional Glue GlueDokument1 SeiteChoose Cloth Color Blood Papers: Score/Fold Down Cut Score/Fold Up Optional Glue Gluegalaxy5111Noch keine Bewertungen

- TpaperDokument12 SeitenTpapergalaxy5111Noch keine Bewertungen

- Cello TechniqueDokument5 SeitenCello Techniquegalaxy5111100% (8)

- DIY No5 Typography (32pp)Dokument32 SeitenDIY No5 Typography (32pp)galaxy5111Noch keine Bewertungen

- 7 PointsDokument4 Seiten7 Pointsgalaxy5111100% (1)

- HarmonicsDokument23 SeitenHarmonicsgalaxy5111Noch keine Bewertungen

- Robert M Price A Critical Commentary On The Necronomicon (Cut)Dokument80 SeitenRobert M Price A Critical Commentary On The Necronomicon (Cut)galaxy5111Noch keine Bewertungen

- The Physics of Sound ExplainedDokument44 SeitenThe Physics of Sound ExplainedDiego PinheiroNoch keine Bewertungen

- Giant Squid and JollyboatDokument7 SeitenGiant Squid and Jollyboatgalaxy5111Noch keine Bewertungen

- Bookcraft BookRepairGuideDokument35 SeitenBookcraft BookRepairGuidegalaxy5111Noch keine Bewertungen

- PB Hallebeek - Guidelines For The Conservation of Leather and Parchment Book-BindingsDokument73 SeitenPB Hallebeek - Guidelines For The Conservation of Leather and Parchment Book-Bindingsgalaxy5111100% (3)

- Peter D Verheyen - 2001 - Vellum Over BoardsDokument8 SeitenPeter D Verheyen - 2001 - Vellum Over Boardsgalaxy5111Noch keine Bewertungen

- Tony Firman - Making Simple Bookbinding Equipment - A Sewing Frame (10pp)Dokument10 SeitenTony Firman - Making Simple Bookbinding Equipment - A Sewing Frame (10pp)galaxy5111Noch keine Bewertungen

- Vol 1 CH 02Dokument55 SeitenVol 1 CH 02galaxy5111Noch keine Bewertungen

- De Paradoxo Quo Prima Societatum LiterarDokument9 SeitenDe Paradoxo Quo Prima Societatum Literargalaxy5111Noch keine Bewertungen

- Signature 5 DuplexDokument14 SeitenSignature 5 Duplexgalaxy5111Noch keine Bewertungen

- Rly Eh SutraDokument25 SeitenRly Eh Sutragalaxy5111Noch keine Bewertungen

- Signature 0 DuplexDokument16 SeitenSignature 0 Duplexgalaxy5111Noch keine Bewertungen

- IngwersenDokument11 SeitenIngwersengalaxy5111Noch keine Bewertungen

- Phi InfoDokument5 SeitenPhi Infogalaxy5111Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- REVISED Kenya Leather IndustryDokument126 SeitenREVISED Kenya Leather IndustryAwais KhanNoch keine Bewertungen

- Footwear Leather Accessories in India 06.2016 1 KPMGDokument17 SeitenFootwear Leather Accessories in India 06.2016 1 KPMGBibin RajNoch keine Bewertungen

- Exporters of KazakhstanDokument11 SeitenExporters of KazakhstanAgro Export and importNoch keine Bewertungen

- MMT - Book 2016 8 79Dokument72 SeitenMMT - Book 2016 8 79abhishekPuri05Noch keine Bewertungen

- Broschuere Interner RedDokument24 SeitenBroschuere Interner RedCasandra MendezNoch keine Bewertungen

- Minor Project: Cow NubuckDokument12 SeitenMinor Project: Cow NubuckKiruthika KNoch keine Bewertungen

- Final - Tanning and Leather FinishingDokument21 SeitenFinal - Tanning and Leather Finishingjunaid0100% (1)

- Esoterica From Thedas Volume 1 - VaultDokument48 SeitenEsoterica From Thedas Volume 1 - Vaultdr juliao100% (1)

- Rural Tanning Techniques No-68 1974Dokument265 SeitenRural Tanning Techniques No-68 1974Gudruman EdisonNoch keine Bewertungen

- Welting Catalog Rev 6 21aDokument16 SeitenWelting Catalog Rev 6 21ajohnjkjkNoch keine Bewertungen

- Practical Leather Technology. ThorsternsenDokument176 SeitenPractical Leather Technology. ThorsternsenAlfredo AlejosNoch keine Bewertungen

- Nigerian Hides and Skins Industry AssessmentDokument45 SeitenNigerian Hides and Skins Industry Assessmentofoegbu1441Noch keine Bewertungen

- Selic Chemical Company Tanning Auxiliaries - August 2006Dokument10 SeitenSelic Chemical Company Tanning Auxiliaries - August 2006Cancerian AgNoch keine Bewertungen

- SWOT AnalysisDokument5 SeitenSWOT Analysisdr_ashishvermaNoch keine Bewertungen

- Textile & Leather Performance Solutions: Polymer Emulsions & Specialty ChemicalsDokument9 SeitenTextile & Leather Performance Solutions: Polymer Emulsions & Specialty Chemicals950 911Noch keine Bewertungen

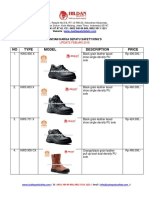

- Safety Shoe Price ListDokument8 SeitenSafety Shoe Price ListurzaNoch keine Bewertungen

- Ethiopia Import Export Sample ReportDokument10 SeitenEthiopia Import Export Sample ReportChuchure TekaNoch keine Bewertungen

- Skiving ProDokument21 SeitenSkiving Proashu tkNoch keine Bewertungen

- Astm D 2208-00Dokument2 SeitenAstm D 2208-00yok patchnakanNoch keine Bewertungen

- Tesla Model S: A Quick Guide For OwnersDokument36 SeitenTesla Model S: A Quick Guide For OwnersgnilretsNoch keine Bewertungen

- LeatherDokument11 SeitenLeatherSumit SonkarNoch keine Bewertungen

- Relatório Food and Agriculture Organization of The United StatesDokument133 SeitenRelatório Food and Agriculture Organization of The United StatesGabriela FortiNoch keine Bewertungen

- The Kasur TanneriesDokument4 SeitenThe Kasur Tanneries11108218Noch keine Bewertungen

- AGP-LMD Value Chain AnalysisDokument160 SeitenAGP-LMD Value Chain AnalysisShimelis BebiNoch keine Bewertungen

- CatalogDokument18 SeitenCataloglangtu2011Noch keine Bewertungen

- Reading Comprehension Test Do They Really Care?Dokument8 SeitenReading Comprehension Test Do They Really Care?jelenabogdanNoch keine Bewertungen

- India's Leather Exports to EuropeDokument103 SeitenIndia's Leather Exports to Europegsrawat123Noch keine Bewertungen

- Skin in The GameDokument48 SeitenSkin in The GameMystery WireNoch keine Bewertungen

- COSMONATE PH: Pure Monomeric MDIDokument3 SeitenCOSMONATE PH: Pure Monomeric MDIOnesany TecnologiasNoch keine Bewertungen

- Exercise - Guangzhou BaiyunDokument9 SeitenExercise - Guangzhou BaiyundannyNoch keine Bewertungen