Beruflich Dokumente

Kultur Dokumente

172 PYROCOMB Tubes ETA120207 EN 2016

Hochgeladen von

Laptuca GabrielOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

172 PYROCOMB Tubes ETA120207 EN 2016

Hochgeladen von

Laptuca GabrielCopyright:

Verfügbare Formate

Authorised and notified according to Article 10 of the Council Directive 89/ 106/EEC of 21 December 1988 on the approximation of laws,

regulations and administrative provisions of Member States relating to construction products

sterreichisches Institut fr Bautechnik Schenkenstrasse 4 | 1010 Vienna | Austria T +43 1 533 65 50 | F +43 1 533 64 23 mail@oib.or.at | www.oib.or.at

ST Member of EOTA INSTITUT F

European technical approval

Handelsbezeichnung: Trade name: PYROCOMB Tubes

ETA-12/0207

(English language translation, the original version is in German language)

Zulassungsinhaber: Holder of approval:

OBO Bettermann GmbH & Co. KG Hingser Ring 52 58710 Menden GERMANY

Zulassungsgegenstand und Verwendungszweck: Generic type and use of construction product: Geltungsdauer Validity vom: from: bis: to:

Abschottung

Penetration seal

21.09.2012 07.11.2016

Herstellwerk: Manufacturing plant:

Werk / plant K GERMANY

Diese Europische technische Zulassung umfasst: This European technical approval contains:

18 Seiten inklusive 4 Anhngen 18 pages including 4 Annexes

European Organisation for Technical Approvals Europische Organisation fr Technische Zulassungen Organisation Europenne pour lAgrment Technique

Page 2 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

I 1

LEGAL BASES AND GENERAL CONDITIONS This European technical approval is issued by sterreichisches Institut fr Bautechnik in accordance with: Council Directive 89/106/EEC of 21 December 1988 on the approximation of laws, regulations and administrative provisions of Member States relating to construction products1 modified by Council Directive 93/68/EEC2 and Regulation (EC) N 1882/2003 of the European Parliament and of the Council3; Bauproduktegesetz. LGBl. V Nr. 33/1994; Common Procedural Rules for Requesting, Preparing and the Granting of European technical approvals set out in the Annex to Commission Decision 94/23/EC4; Guideline for European technical approval of Fire Stopping and Fire Sealing Products: ETAG N 026, Part 2: Penetration Seals.

The sterreichisches Institut fr Bautechnik is authorized to check whether the provisions of this European technical approval are met. Checking may take place in the manufacturing plant(s). Nevertheless, the responsibility for the conformity of the products to the European technical approval and for their fitness for the intended use remains with the holder of the European technical approval. This European technical approval is not to be transferred to manufacturers or agents of manufacturers other than those indicated on page 1, or manufacturing plants other than those indicated on page 1 of this European technical approval. This European technical approval may be withdrawn by sterreichisches Institut fr Bautechnik, in particular pursuant to information by the Commission according to Article 5(1) of Council Directive 89/106/EEC. Reproduction of this European technical approval including transmission by electronic means shall be in full. However, partial reproduction can be made with the written consent of sterreichisches Institut fr Bautechnik. In this case partial reproduction has to be designated as such. Texts and drawings of advertising brochures shall not contradict or misuse the European technical approval. The European technical approval is issued by the approval body in its official language. This version corresponds fully to the version circulated in EOTA. Translations into other languages have to be designated as such.

1 2 3 4

Official Journal of the European Communities N L 40, 11.2.1989, p. 12 Official Journal of the European Communities N L 220, 30.8.1993, p. 1 Official Journal of the European Union N L 284, 31.10.2003, p.1 Official Journal of the European Communities N L 17, 20.1.1994, p. 34

OIB-290-010/11-027

Page 3 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

II 1 1.1 1.1.1

SPECIFIC CONDITIONS OF THE EUROPEAN TECHNICAL APPROVAL Definition of product(s) and intended use Definition of the product PYROCOMB Tubes PYROCOMB Tubes is designed and installed in accordance with the ETA-holders design and installation instructions, deposited at the sterreichisches Institut fr Bautechnik. In accordance to the technical data-sheet PYROCOMB Tubes will be used for occupied or open conduits. Type of penetration seal system: Pipe closure device - collar (see ETAG 026-2, clause 1.1, table 1-1). PYROCOMB Tubes consists of a fire protection collar which comprises of a steel housing and the intumescent inlay "ROKU Strip" in accordance to ETA-10/0117 (reaction to fire class E according to EN 13501-1). All components are factory-produced by the ETA-holder or a supplier. The ETA-holder is ultimately responsible for PYROCOMB Tubes. For installation of PYROCOMB Tubes see Annex C. The fire protection collar type TCX is supplied in several sizes see table below. Collar type TCX-032, 32 mm TCX-040, 40 mm TCX-050, 50 mm TCX-063, 63 mm TCX-075, 75 mm TCX-090, 90 mm TCX-110, 110 mm TCX-125, 125 mm Inlay size (mm) 7,0 x 25,4 7,0 x 25,4 7,0 x 25,4 13,5 x 25,4 13,5 x 25,4 18,3 x 25,4 19,2 x 25,0 19,2 x 38,0 Inlay thickness (mm) 1,5 2,5 1,5 - 2,5 1,5 - 2,5 1,5 - 2,5 1,5 - 2,5 1,5 - 2,5 1,5 - 2,5 1,5 - 2,5

1.1.2

Additional components The collar is installed underneath floors or on both sides of a wall and fixed by rods with nuts or metal anchors. For further details see Annex C and the technical literature of the manufacturer. Gypsum plaster or cementitious mortar may be used to seal the annular gap between conduit and opening edge. For closing joints a non-combustible material (class A1 or A2-s1, d0 according to EN 13501-1) with a dimensionally stable, as e.g. concrete, cementitious mortar or gypsum plaster, shall be used. The ends of occupied or empty conduits may be sealed with the intumescending component Dmmschichtbildner DSX or with plugs. For further details see technical literature of the manufacturer.

OIB-290-010/11-027

Page 4 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

1.2 1.2.1

Intended Use and Use Category Intended Use The intended use of PYROCOMB Tubes is to reinstate the fire resistance performance of flexible wall constructions, rigid wall constructions and rigid floor constructions where they are penetrated by flexible PVC or polyolefine conduits. The specific elements of construction that PYROCOMB Tubes may be used to provide a penetration seal in, are as follows: Flexible walls: The wall must have a minimum thickness of 100 mm and comprise timber or steel studs lined on both faces with minimum 2 layers of 12,5 mm thick boards. For timber stud walls there must be a minimum distance of 100 mm of the seal to any stud and the cavity between stud and seal must be closed with minimum 100 mm insulation of Class A1 or A2 (in accordance with EN 135011). The wall must have a minimum thickness as given in Annex C and comprise concrete, aerated concrete or masonry, with a minimum density of 650 kg/m3. The floor must have a minimum thickness of 150 mm and comprise concrete with a minimum density of 2400 kg/m3 (floor type A) or 550 Kg/m3 (floor type B) respectively.

Rigid walls: Rigid floors:

The supporting construction must be classified in accordance with EN 13501-2 for the required fire resistance period. This ETA does not cover use of this product as a penetration seal in sandwich panel constructions. PYROCOMB Tubes may be used to provide a penetration seal with conduits made of PVC according to EN 61386-1 and EN 61386-22 or Polyolefin according to EN 61386-1 and EN 61386-22. The requirements are according to the technical data sheet of the producer. The conduits may be lead single or in bundles through the fire protection collar type TCX. The maximum inner diameter of a single conduit has to be 50,5 mm (63 mm outer diameter), wall thickness between 0,5 mm and 0,8 mm. The maximum diameter of a single cable has to be 21 mm. The fire protection collar may be filled completely with conduits or conduit bundles. The maximum size oft the fire protection collar is 125 mm. The maximum distance between the intumescent inlay and the conduit or conduit bundle may be 15 mm. Conduits shall be supported at maximum 450 mm away from both faces of wall constructions and maximum 420 mm from the upper face of floor constructions. All cables according to the group small specified in EN 1366-3:2009-07 with an diameter up to 21 mm may be used. The provisions made in this European technical approval are based on an assumed working life of the PYROCOMB Tubes of 10 years, provided that the conditions laid down in sections 4.2/5.1/5.2 for the packaging/transport/storage/installation/use/repair are met. The indications given on the working life cannot be interpreted as a guarantee given by the producer, but are to be regarded only as a means for choosing the right products in relation to the expected economically reasonable working life of the works.

OIB-290-010/11-027

Page 5 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

1.2.2

Use Category The use category of the intumescent inlay according to EOTA TR 024 of PYROCOMB Tubes is Type X.

Characteristics of the product and methods of verification The identification tests and the assessment of the fitness for use according to the Essential Requirements were carried out in compliance with the ETA Guidance no. 026-Part 2 concerning Penetration Seals edition January 2008 (called ETAG 026-2 in this ETA). ETAG clause No. ETA clause No. Assessment of characteristic Not relevant See clause 2.1 See clause 2.2

Characteristic Mechanical resistance and stability Safety in case of fire Reaction to fire Resistance to fire Hygiene, Health and the Environment Air permeability Water permeability Dangerous substances Characteristic Safety in use Mechanical resistance and stability Resistance to impact/movement Adhesion Protection against noise Airborne sound insulation Energy, Economy and Heat Retention Thermal resistance Water vapour permeability General aspects relating to fitness for use Durability and serviceability

2.4.1 2.4.2

2.1 2.2

2.4.3 2.4.4 2.4.5 ETAG clause No. 2.4.6 2.4.7 2.4.8 2.4.9

2.3 2.4 2.5 ETA clause No. 2.6 2.7 2.8 2.9

No performance determined No performance determined See clause 2.5 Assessment of characteristic No performance determined No performance determined No performance determined No performance determined

2.4.10 2.4.11

2.10 2.11

No performance determined No performance determined

2.4.12 2.1

2.12

See clause 2.12

Reaction to fire The material for the metal casing is classified Class A1 according to Commission Decision 96/603/EC. The inlay made from "ROKU Strip" in accordance to ETA-10/0117 fulfils the requirements for reaction to fire class E according to EN 13501-1. For closing joints a non-combustible material (class A1 or A2-s1, d0 according to EN 13501-1) with a dimensionally stable, as e.g. concrete, cementitious mortar or gypsum plaster, shall be used.

OIB-290-010/11-027

Page 6 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

2.2

Resistance to fire PYROCOMB Tubes has been tested according to EN 1366-3:2004 and EN 1366-3:2009, installed within apertures in flexible walls (drywalls), rigid walls (aerated concrete blocks) and high density and low density concrete floors. For details of classification and plastic conduits covered see Annex C. The seals may only be penetrated by the services listed in Annex C. Other parts or support constructions must not penetrate the seal. For details of suitable wall and floor constructions see 1.2.1 and Annex C. The supporting construction must be classified in accordance with EN 13501-2 for the required fire resistance period. The following conditions apply to seals within any of the above constructions: The service support construction must be fixed to the building element containing the penetration seal or a suitable adjacent building element, on both sides of the penetration in such a manner that in the case of fire, no additional load is imposed on the seal. Furthermore it is assumed that this support is maintained on the unexposed side, for the required period of fire resistance. Specific considerations:

Conduits must be perpendicular to the seal surface. The classifications relate to U/C (capped outside the furnace/uncapped inside). For further information refer to national regulations. Other parts or service support constructions must not penetrate the seal.

2.3

Air permeability For annular gaps sealed with cementitious mortar or gypsum plaster no performance has been determined.

2.4

Water permeability For annular gaps sealed with cementitious mortar or gypsum plaster no performance has been determined.

2.5

Dangerous substances According to the manufacturers declaration, the product specification has been compared with the list of dangerous substances of the European Commission to verify that it does not contain such substances above the acceptable limits. A written declaration in this respect was submitted by the ETA-holder. In addition to the specific clauses relating to dangerous substances contained in this ETA, there may be other requirements applicable to the products falling within its scope (e.g. transposed European legislation and national laws, regulations and administrative provisions). In order to meet the provisions of the Construction Product Directive, these requirements need also to be complied with, when and where they apply.

OIB-290-010/11-027

Page 7 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

2.6

Mechanical resistance and stability Due to the nature and size of penetration seals, made from PYROCOMB Tubes, impact tests and a classification according to EOTA TR 001 are not possible.

2.7

Resistance to impact/movement Due to the nature and size of penetration seals, made from PYROCOMB Tubes, impact tests and a classification according to EOTA TR 001 are not possible.

2.8

Adhesion The collars have to be fixed with metal anchors or threaded rods and must be done according to the technical data sheet for PYROCOMB Tubes.

2.9

Airborne sound insulation No performance determined.

2.10

Thermal properties No performance determined.

2.11

Water vapour permeability No performance determined.

2.12

Durability The intumescent product "ROKU Strip" according to ETA-10/0117 fulfils the requirements of use category X in accordance with EOTA TR 024. As conclusion the materials can be exposed to the conditions in interiors with/without moisture loads and external weathering, without expecting significant changes in their fire protection characteristics. No significant changes in expansion ratio and expansion pressure of the material were observed after exposure to a constant temperature of 80C and exposure to permanent water immersion.

OIB-290-010/11-027

Page 8 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

3 3.1

Evaluation of Conformity and CE marking Attestation of Conformity system According to the decision 1999/454/EC of the European Commission5 the system 1 of attestation of conformity applies. This system of attestation of conformity is defined as follows: System 1: Certification of the conformity of the product by a notified certification body on the basis of: (a) Tasks for the manufacturer: (1) (2) (b) factory production control further testing of samples taken at the factory by the manufacturer in accordance with a prescribed test plan

Tasks for the notified body (3) (4) (5) initial type-testing of the product initial inspection of factory and of factory production control continuous surveillance, assessment and approval of factory production control

3.2 3.2.1 3.2.1.1

Responsibilities Tasks of the Manufacturer Factory production control The manufacturer shall exercise permanent internal control of production. All the elements, requirements and provisions adopted by the manufacturer shall be documented in a systematic manner in the form of written policies and procedures, including records of results performed. This production control system shall insure that the product is in conformity with this European technical approval. The manufacturer shall draw up and keep up-to-date documents defining the factory production control that applies. The documentation to be carried out by the manufacturer and the applicable procedures shall be appropriate to the product and manufacturing process. The factory production control shall ensure the conformity of the product to an appropriate level. This involves: a) the preparation of documented procedures and instructions relating to factory production control operations. b) the effective implementation of these procedures and instructions. c) the recording of these procedures and their results. d) the use of these results to correct any deviations, repair the effects of such deviations, treat any resulting instances of non-conformity and, if necessary, revise the factory production control to rectify the cause of non-conformity. e) a procedure to ensure that both the approval Body and the Notified (Certification) Bodies are advised before any significant change to the product, its components or manufacturing process, is made. f) a procedure to ensure that personnel involved in the production processes and the quality control procedures are qualified and adequately trained to carry out their required tasks.

Official Journal of the European Communities N L 178, 14.7.1999, p. 52

OIB-290-010/11-027

Page 9 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

g) that all testing and measuring equipment is maintained and up to date calibration records are documented. h) maintenance of records to ensure every batch produced is clearly labelled with the batch number, which allows traceability to its production to be identified. The manufacturer may only use components stated in the technical documentation of this European technical approval. For the components which the ETA-holder does not manufacture by himself, he shall make sure that factory production control carried out by the other manufacturers gives the guaranty of the components compliance with the European technical approval. The factory production control and the provisions taken by the ETA-holder for components not produced by himself shall be in accordance with the control plan6 relating to this European technical approval which is part of the technical documentation of this European technical approval. The "Control Plan" is laid down in the context of the factory production control system operated by the manufacturer and deposited at the sterreichisches Institut fr Bautechnik. The results of factory production control shall be recorded and evaluated in accordance with the provisions of the control plan. 3.2.1.2 Other tasks of the manufacturer The manufacturer shall, on the basis of a contract, involve a body (bodies) which is (are) approved for the tasks referred to in section 3.1 in the field of penetration seals in order to undertake the actions laid down in section 3.3. For this purpose, the "control plan" referred to in sections 3.2.1.1 and 3.2.2 shall be handed over by the manufacturer to the approved body or bodies involved. The manufacturer shall make a declaration of conformity, stating that the construction product is in conformity with the provisions of this European technical approval. 3.2.2 Tasks of Notified Bodies The Notified Body (Bodies) shall perform the initial type-testing of the product (for system1), The results of the tests performed as part of the assessment for the European technical approval may be used unless there are changes in the production line or plant. In such cases, the necessary initial type testing has to be agreed between the sterreichisches Institut fr Bautechnik and the Notified Bodies involved. initial inspection of factory and of factory production control, The Notified Body (Bodies) shall ascertain that, in accordance with the control plan, the factory (in particular the employees and the equipment) and the factory production control are suitable to ensure continuous and orderly manufacturing of the components according to the specifications mentioned in clause 2 of this ETA. continuous surveillance, assessment and approval of factory production control, The Notified Body (Bodies) shall visit the factory at least twice a year or once a year for surveillance of this manufacturer having a FPC system complying with a quality management system covering the manufacturing of the approval product components. It has to be verified that the system of factory production control and the specified automated manufacturing process are maintained taking into account the control plan.

The control plan is a confidential part of the European technical approval and only handed over to the Notified Body or Bodies involved in the procedure of conformity.

OIB-290-010/11-027

Page 10 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

These tasks shall be performed in accordance with the provisions laid down in the control plan of this European technical approval. The Notified Body (Bodies) shall retain the essential points of its (their) actions referred to above and state the results obtained and conclusions drawn in a written report. The Notified Body involved by the manufacturer shall issue an EC certificate of conformity of the product stating the conformity with the provisions of this European technical approval. In cases where the provisions of the European technical approval and its control plan are no longer fulfilled the certification body shall withdraw the certificate of conformity and inform the sterreichisches Institut fr Bautechnik without delay. 3.3 CE marking The CE marking shall be affixed on the product itself, on a label attached to it, on its packaging or on the commercial documents accompanying the components of the product. The letters CE shall be followed by the identification number of the Notified Body involved and be accompanied by the following additional information: the name or identifying mark and address of the ETA holder the last two digits of the year in which the CE marking was affixed the number of the EC certificate of conformity for the product the number of the European technical approval the number of the ETAG (ETAG N 026 part 2) the designation of the product (trade name) the use category in accordance with the ETA section 1 and 2 see ETA-12/0207 for other relevant characteristics

Assumptions under which the fitness of the product(s) for the intended use was favourably assessed Manufacturing The European technical approval is issued for the product on the basis of agreed data/information, deposited with sterreichisches Institut fr Bautechnik, which identifies the product that has been assessed and judged. Changes to the product or production process, which could result in this deposited data/information being incorrect, should be notified to sterreichisches Institut fr Bautechnik before the changes are introduced. sterreichisches Institut fr Bautechnik will decide whether or not such changes affect the ETA and consequently the validity of the CE marking on the basis of the ETA and if so whether further assessment or alterations to the ETA, shall be necessary.

4.1

4.2

Installation The ETA is issued under the assumption that the installation of the approval product shall be in accordance with the manufacturers technical literature. Additional marking of the seal shall be done in case of national requirements.

1. Seal the opening:

The aperture around the pipe is filled with gypsum plaster or cementitious mortar over the full thickness of the wall/floor on both sides. 2. Clean the plastic pipe. Remove all plaster/mortar or dust from the pipe in the area where the Firestop collar is to be installed. 3. Place the Firestop Collar around the plastic pipe(s) and close the collar. No tools, pins or screws are necessary.

OIB-290-010/11-027

Page 11 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

4. Fasten the Firestop Collar:

After marking the fastening points on the bottomside of the floor/wall, the fire collar has to be fastened with metal anchors/fasteners according to the technical data sheet. If required by national prescriptions mark the penetration seal with an identification plate containing the required information. In such a case fasten the identification plate in a visible position next to the seal. 5. Seal the endings of empty conduits with e. g. Dmmschichtbildner DSX 6. Repeat installation on the other side of the wall Additional marking of the seal shall be done in case of national requirements.

5 5.1

Indications to the manufacturer Packaging, transport and storage In the accompanying document and/or on the packaging the manufacturer shall give information as to transport and storage. At least the following shall be indicated: storing temperature, type of storage, maximum duration of storage and required data related to minimum temperature for transport and storage.

5.2

Use, maintenance, repair The PYROCOMB Tubes should be installed and used as described earlier in this document. The assessment of the fitness for use is based on the assumption that damage, for example caused by accidental impact, is repaired. The relevant manufacturer instructions shall be followed.

On behalf of sterreichisches Institut fr Bautechnik

Rainer Mikulits Managing Director

OIB-290-010/11-027

Page 12 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

ANNEX A REFERENCE DOCUMENTS A.1 References to standards mentioned in the ETA: Fire resistance tests for service installations - Part 3: Penetration seals Fire classification of construction products and building elements Part 1: Classification using test data from reaction to fire tests Fire classification of construction products and building elements Part 2: Classification using test data from fire resistance tests

EN 1366-3:2009 EN 13501-1 EN 13501-2

A.2

Other reference documents:

EOTA TR 024

Characterisation, Aspects of Durability and Factory Production Control for Reactive Materials, Components and Products Material Safety Data Sheet according to 1907/2006/EC for PYROCOMB Tubes.

OIB-290-010/11-027

Page 13 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

ANNEX B DESCRIPTION OF PRODUCT(S) & PRODUCT LITERATURE B.1 PYROCOMB Tubes A detailed specification of the product is contained in document Identification/Product Specification and Control Plan relating to this European technical approval which is a non-public part of this ETA. Technical product literature: Technical data sheet and instructions for use PYROCOMB Tubes B.2 Gypsum plaster Any gypsum plaster suitable for use with flexible wall constructions or the intended type of rigid walls or floors may be used. B.3 Cementitious mortar Any cementitious mortar suitable for use with the intended type of rigid walls or floors may be used.

OIB-290-010/11-027

Page 14 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

ANNEX C RESISTANCE TO FIRE CLASSIFICATION OF PENETRATION SEALS MADE FROM PYROCOMB Tubes Flexible walls

A1

A2 A1

Collar Annular gap seal Bundle of conduits (open or occupied with cables) Building element Fixing of the collar

A2 C E

C E F

Rigid walls

A1

A2 A1

Collar Annular gap seal Bundle of conduits (open or occupied with cables) Building element Fixing of the collar

A2 C E

C E F

C.1

Installation in flexible and rigid walls according to 1.2.1, minimum wall thickness 100 mm

Penetration seal: Collar TCX on both sides (A1), annular gap filled with gypsum plaster (A2) over the entire thickness of the wall. In case of a rigid wall cementitious mortar may be used as an alternative to gypsum plaster. The smallest suitable fire protection collar for the particular conduit resp. conduit bundle has to be used. The maximum inner diameter of the collar may be 30 mm larger than the conduit resp. the conduit bundle. The maximum nominal diameter of the collar is 125 mm. The minimum distance between collars of this type is 100 mm. Conduits may be empty to fully occupied For single penetrations the maximum outer diameter of the conduit is 63 mm. For conduit bundles the maximum outer diameter is 125 mm. The minimum length of the conduits has to be 200 mm on both sides of the wall, measured from the wall surface. Collars fixed on both sides of the wall with rods M6 and nuts through the wall. In high density rigid walls alternatively metal anchors with minimum 6 mm may be used. Ends of conduits have to be sealed with the intumescending component Dmmschichtbildner DSX on both sides of the wall over a depth of minimum 10 mm or with plugs.

OIB-290-010/11-027

Page 15 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

PVC DN 16 DN 20 DN 25 DN 32 DN 40 DN 50 DN 63 Polyolefin DN 16 DN 20 DN 25 DN 32 DN 40 DN 50 DN 63 C.2

Conduit diameter dc (mm) 10,9 14,2 18,6 24,3 31,3 40,0 50,5 Conduit diameter dc (mm) 10,4 13,6 17,9 23,4 30,0 38,8 48,8

Conduit wall thickness (mm) 0,3 0,5 0,3 0,5 0,3 0,6 0,3 0,6 0,3 0,6 0,3 0,5 0,3 0,5 Conduit wall thickness (mm) 0,3 0,8 0,3 0,8 0,4 0,8 0,4 0,8 0,5 0,8 0,5 0,8 0,7 0,8

Classification EI 120 EI 120 EI 120 EI 120 EI 120 EI 120 EI 120 Classification EI 120 EI 120 EI 120 EI 120 EI 120 EI 120 EI 120

Rigid walls according to 1.2.1, minimum wall thickness 150 mm Collar TCX on both sides (A1), annular gap filled with cementitious mortar (A2) over the entire thickness of the wall. The smallest suitable fire protection collar for the particular conduit resp. conduit bundle has to be used. The maximum inner diameter of the collar may be 30 mm larger than the conduit resp. the conduit bundle. The maximum nominal diameter of the collar is 125 mm. The minimum distance between collars of this type is 100 mm. Conduits have to be either empty or fully occupied (total cross section of the cables is almost 100% of the inner Diameter of the conduit, no further cable may fit in the conduit). For single penetrations the maximum outer diameter of the conduit is 63 mm. For conduit bundles the maximum outer diameter is 125 mm. The minimum length of the conduits has to be 200 mm on both sides of the wall, measured from the wall surface. Collars fixed on both sides of the wall with rods M6 and nuts through the wall. In high density rigid walls alternatively metal anchors with minimum 6 mm may be used. Ends of conduits have to be sealed with the intumescending component Dmmschichtbildner DSX on both sides of the wall over a depth of minimum 10 mm or with plugs.

Penetration seal:

OIB-290-010/11-027

Page 16 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

PVC DN 16 DN 20 DN 25 DN 32 DN 40 DN 50 DN 63 Polyolefin DN 16 DN 20 DN 25 DN 32 DN 40 DN 50 DN 63 Rigid floor

Conduit diameter dc (mm) 10,9 14,2 18,6 24,3 31,3 40,0 50,5 Conduit diameter dc (mm) 10,4 13,6 17,9 23,4 30,0 38,8 48,8

Conduit wall thickness (mm) 0,3 0,5 0,3 0,5 0,3 0,6 0,3 0,6 0,3 0,6 0,3 0,5 0,3 0,5 Conduit wall thickness (mm) 0,3 0,8 0,3 0,8 0,4 0,8 0,4 0,8 0,5 0,8 0,5 0,8 0,7 0,8

Classification EI 120 EI 120 EI 120 EI 120 EI 120 EI 120 EI 120 Classification EI 120 EI 120 EI 120 EI 120 EI 120 EI 120 EI 120

C A2 F

A1 A2 C E F

Collar Annular gap seal Bundle of conduits (open or occupied with cables) Building element (floor) Fixing of the collar

A1

OIB-290-010/11-027

Page 17 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

C.3

Rigid floor according to 1.2.1

Penetration seal: Collar TCX (A1) on the underside of the floor, annular gap filled either with gypsum plaster or cementitious mortar (A2) over the entire thickness of the floor. The smallest suitable fire protection collar for the particular conduit resp. conduit bundle has to be used. The maximum inner diameter of the collar may be 30 mm larger than the conduit resp. the conduit bundle. The maximum nominal diameter of the collar is 125 mm. The minimum distance between collars of this type may be 0 mm. Conduits have to be either empty or fully occupied (total cross section of the cables is almost 100% of the inner Diameter of the conduit, no further cable may fit in the conduit). For single penetrations the maximum outer diameter of the conduit is 63 mm. For conduit bundles the maximum outer diameter is 125 mm. The minimum length of the conduits has to be 200 mm on both sides of the floor, measured from the floor surface. Collar fixed on the underside of the floor with rods M6 and nuts through the floor. In high density rigid floors alternatively metal anchors with minimum 6 mm may be used. Ends of conduits have to be sealed with the intumescending component Dmmschichtbildner DSX on both sides of the floor over a depth of minimum 10 mm or with plugs. PVC DN 16 DN 20 DN 25 DN 32 DN 40 DN 50 DN 63 Polyolefin DN 16 DN 20 DN 25 DN 32 DN 40 DN 50 DN 63 Conduit diameter dc (mm) 10,9 14,2 18,6 24,3 31,3 40,0 50,5 Conduit diameter dc (mm) 10,4 13,6 17,9 23,4 30,0 38,8 48,8 Conduit wall thickness (mm) 0,3 0,5 0,3 0,5 0,3 0,6 0,3 0,6 0,3 0,6 0,3 0,5 0,3 0,5 Conduit wall thickness (mm) 0,3 0,8 0,3 0,8 0,4 0,8 0,4 0,8 0,5 0,8 0,5 0,8 0,7 0,8 Classification EI 120 EI 120 EI 120 EI 120 EI 120 EI 120 EI 120 Classification EI 120 EI 120 EI 120 EI 120 EI 120 EI 120 EI 120

OIB-290-010/11-027

Page 18 of the European technical approval ETA-12/0207, with validity from 21.09.2012 to 07.11.2016

MemberINSTITUT of EOTA

STERRE FR BA

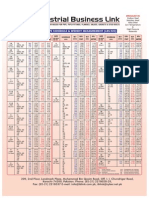

ANNEX D Pipe collar sizes

Collar 32 mm 40 mm 50 mm 63 mm 75 mm 90 mm 110 mm 125 mm

d (mm) 36 44 54 67 79 94 114 129

D (mm) 50 58 68 94 106 132 155 172

b (mm) 7,0 7,0 7,0 13,5 13,5 18,3 20,5 20,5

t (mm) 0,6 0,6 0,6 0,6 0,6 1,1 1,1 1,1

H (mm) 26,0 26,0 26,0 26,0 26,0 26,6 26,6 40,0

P (pcs) 2 2 2 4 4 4 4 4

h (mm) 25,4 25,4 25,4 25,4 25,4 25,4 25,4 38,1

a (mm) 6,4 0,5 6,4 0,5 6,4 0,5 12,8 1,0 12,8 1,0 17,1 1,0 19,2 1,5 19,2 1,5

B (mm) 6,0 6,0 6,0 6,0 6,0 9,0 9,0 9,0

OIB-290-010/11-027

MemberINSTITUT of EOTA

STERRE FR BA

n la

p k

e g a

MemberINSTITUT of EOTA

STERRE FR BA

n la

p k

e g a

Das könnte Ihnen auch gefallen

- Acoustic AssignmentDokument19 SeitenAcoustic AssignmentLaptuca Gabriel100% (1)

- HVAC and Psychrometric Charts SI TranscriptDokument15 SeitenHVAC and Psychrometric Charts SI TranscriptLaptuca GabrielNoch keine Bewertungen

- Gestiune Ape UzateDokument38 SeitenGestiune Ape UzateLaptuca GabrielNoch keine Bewertungen

- Alp General ACCESORIESDokument74 SeitenAlp General ACCESORIESsas_uu100% (1)

- USGS Wentworth Grain Size ChartDokument1 SeiteUSGS Wentworth Grain Size Chartetchplain100% (1)

- Alp General ACCESORIESDokument74 SeitenAlp General ACCESORIESsas_uu100% (1)

- New Zealand BIM HandbookDokument22 SeitenNew Zealand BIM HandbookLaptuca GabrielNoch keine Bewertungen

- Financial Analysis of Projects I PDFDokument14 SeitenFinancial Analysis of Projects I PDFgoyalmanojNoch keine Bewertungen

- V28 Catalogue Stormwater ManagementDokument22 SeitenV28 Catalogue Stormwater ManagementLaptuca GabrielNoch keine Bewertungen

- a-LIFE2 - 0102 - 1004 - 201306 - EN Rev05Dokument54 Seitena-LIFE2 - 0102 - 1004 - 201306 - EN Rev05Alex CorsauNoch keine Bewertungen

- CC1608 - Fire Systems Design GuideDokument20 SeitenCC1608 - Fire Systems Design GuidePhạm Thanh SơnNoch keine Bewertungen

- Thermal Insulation Materials Made of Rigid Polyurethane Foam (PURDokument33 SeitenThermal Insulation Materials Made of Rigid Polyurethane Foam (PURvtintin2006Noch keine Bewertungen

- EPA Well Design Ground Water Monitoring WwelldctDokument224 SeitenEPA Well Design Ground Water Monitoring Wwelldctintoyou2007Noch keine Bewertungen

- Cassette Fan Coil ManualDokument38 SeitenCassette Fan Coil ManualLaptuca GabrielNoch keine Bewertungen

- 1 - Pipe Schedule & Weight MeasurementDokument1 Seite1 - Pipe Schedule & Weight MeasurementSutrisno KlsNoch keine Bewertungen

- Gestiune Ape UzateDokument38 SeitenGestiune Ape UzateLaptuca GabrielNoch keine Bewertungen

- Catalog MasiniDokument13 SeitenCatalog MasiniLaptuca GabrielNoch keine Bewertungen

- Air Sparging Guidance DocumentDokument118 SeitenAir Sparging Guidance DocumentddadaraNoch keine Bewertungen

- BL Catalogue Ind 05 2014 EngDokument276 SeitenBL Catalogue Ind 05 2014 EngLaptuca GabrielNoch keine Bewertungen

- Gestiune Ape UzateDokument38 SeitenGestiune Ape UzateLaptuca GabrielNoch keine Bewertungen

- SQjanfeb 2012Dokument44 SeitenSQjanfeb 2012Laptuca GabrielNoch keine Bewertungen

- Air Sparging Guidance DocumentDokument118 SeitenAir Sparging Guidance DocumentddadaraNoch keine Bewertungen

- Fire Safety Risk Assessment 2006 Factories and WarehousesDokument148 SeitenFire Safety Risk Assessment 2006 Factories and Warehouses3582100% (1)

- Pipes For Civil and Industrial InstallationsDokument24 SeitenPipes For Civil and Industrial InstallationsLaptuca GabrielNoch keine Bewertungen

- Johnston Hydraulic Calculation PDFDokument40 SeitenJohnston Hydraulic Calculation PDFMalbec WallaceNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Dermatology Study Guide 2023-IvDokument7 SeitenDermatology Study Guide 2023-IvUnknown ManNoch keine Bewertungen

- CFO TagsDokument95 SeitenCFO Tagssatyagodfather0% (1)

- Public Private HEM Status AsOn2May2019 4 09pmDokument24 SeitenPublic Private HEM Status AsOn2May2019 4 09pmVaibhav MahobiyaNoch keine Bewertungen

- Composite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloDokument15 SeitenComposite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloSharan KharthikNoch keine Bewertungen

- Emergency Management of AnaphylaxisDokument1 SeiteEmergency Management of AnaphylaxisEugene SandhuNoch keine Bewertungen

- MQC Lab Manual 2021-2022-AutonomyDokument39 SeitenMQC Lab Manual 2021-2022-AutonomyAniket YadavNoch keine Bewertungen

- Aries Computer Repair SolutionsDokument9 SeitenAries Computer Repair SolutionsedalzurcNoch keine Bewertungen

- CBSE Class 6 Whole Numbers WorksheetDokument2 SeitenCBSE Class 6 Whole Numbers WorksheetPriyaprasad PandaNoch keine Bewertungen

- Checklist of Requirements For OIC-EW Licensure ExamDokument2 SeitenChecklist of Requirements For OIC-EW Licensure Examjonesalvarezcastro60% (5)

- GFS Tank Quotation C20210514Dokument4 SeitenGFS Tank Quotation C20210514Francisco ManriquezNoch keine Bewertungen

- Be It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledDokument2 SeitenBe It Enacted by The Senate and House of Representatives of The Philippines in Congress AssembledCesar ValeraNoch keine Bewertungen

- Breaking NewsDokument149 SeitenBreaking NewstigerlightNoch keine Bewertungen

- Technical Specification of Heat Pumps ElectroluxDokument9 SeitenTechnical Specification of Heat Pumps ElectroluxAnonymous LDJnXeNoch keine Bewertungen

- Strategies For StartupDokument16 SeitenStrategies For StartupRoshankumar BalasubramanianNoch keine Bewertungen

- Key Fact Sheet (HBL FreedomAccount) - July 2019 PDFDokument1 SeiteKey Fact Sheet (HBL FreedomAccount) - July 2019 PDFBaD cHaUhDrYNoch keine Bewertungen

- How To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Dokument31 SeitenHow To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Myster HighNoch keine Bewertungen

- TJUSAMO 2013-2014 Modular ArithmeticDokument4 SeitenTJUSAMO 2013-2014 Modular ArithmeticChanthana ChongchareonNoch keine Bewertungen

- Ratio Analysis of PIADokument16 SeitenRatio Analysis of PIAMalik Saad Noman100% (5)

- Meet Joe Black (1998) : A Metaphor of LifeDokument10 SeitenMeet Joe Black (1998) : A Metaphor of LifeSara OrsenoNoch keine Bewertungen

- Baobab MenuDokument4 SeitenBaobab Menuperseverence mahlamvanaNoch keine Bewertungen

- Business Case PresentationDokument27 SeitenBusiness Case Presentationapi-253435256Noch keine Bewertungen

- Paper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Dokument12 SeitenPaper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Hisham AlEnaiziNoch keine Bewertungen

- Cot 2Dokument3 SeitenCot 2Kathjoy ParochaNoch keine Bewertungen

- Joining Instruction 4 Years 22 23Dokument11 SeitenJoining Instruction 4 Years 22 23Salmini ShamteNoch keine Bewertungen

- Week 15 - Rams vs. VikingsDokument175 SeitenWeek 15 - Rams vs. VikingsJMOTTUTNNoch keine Bewertungen

- Corporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Dokument18 SeitenCorporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Lia asnamNoch keine Bewertungen

- 4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal DescisionDokument24 Seiten4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal Descisionmatteo mamaloNoch keine Bewertungen

- Gapped SentencesDokument8 SeitenGapped SentencesKianujillaNoch keine Bewertungen

- SBI Sample PaperDokument283 SeitenSBI Sample Paperbeintouch1430% (1)

- Draft SemestralWorK Aircraft2Dokument7 SeitenDraft SemestralWorK Aircraft2Filip SkultetyNoch keine Bewertungen