Beruflich Dokumente

Kultur Dokumente

Pelton Turbine

Hochgeladen von

HenDricky MagosiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pelton Turbine

Hochgeladen von

HenDricky MagosiCopyright:

Verfügbare Formate

Experiment 6 Memorial University of Newfoundland Faculty of Engineering and Applied Science Fluid Mechanics Laboratory HYDRAULIC TURBINE LAB

PELTON WHEEL TURBINE Objective The performance characteristics of a Pelton wheel hydraulic turbine are to be determined. Specifically, torque and power are to be presented as a function of turbine speed. Theoretically a Pelton Wheel turbine is most efficient when the speed of its buckets is half the speed of its water jet. The purpose of this lab is to check this prediction Apparatus A Pelton wheel with the following parts is employed to do this experiment. Figure 1 shows the wheel and its main components.

Figure 1. Pelton wheel components

Jet nozzle Torquemeter

Pelton wheel

V-Notch flowmeter

Tachometer

weir

Pressure gauge Figure 2. Schematic diagram of the experiment set-up

Pump

Figure 2 show as a schematic of the experiment. A water pumps drives water through a nozzle which creates a jet within the turbine body. The water jet hits the turbine buckets and the exchange of momentum causes the rotation. The brake power of the turbine is measured by a torque meter. Flow rate of water and pressure at the nozzle are measured using V notch flow meter and a pressure gauge. A handheld tachometer Theory The Pelton Wheel is a turbine to convert fluid energy to mechanical energy. The pressure due to a head of water in a reservoir above the turbine is converted into kinetic energy in the form of a jet, which then impinges on a series of targets mounted on a wheel transferring energy from the water into rotation of the wheel. For historical reasons, the type of turbine which operates with a jet of water at atmospheric pressure is known as impulse turbine. The targets on the rotating wheel are known as buckets, and the assembly of the wheel and buckets is called the runner. Theoretically a Pelton Wheel turbine is most efficient when the speed of its buckets is half the speed of its water jet. The purpose of this lab is to check this prediction. For the lab you will use just one flow rate of water and one jet speed. You will adjust the load on the turbine with a brake. You will adjust the load on the turbine with a brake. You will measure shaft rotational speed N using an optical tachometer and brake load L using a mercury bellows. For a Pelton Wheel the jet speed is: V=Cv(2gh) =Cv(2P/) =0.97(2P/) And the bucket speed is u=r. Its theoretical power is:

C = Q( V-u)(1-kcos) u The derivative of power with respect to turbine speed yields: dC/du=0 u=V/2 JET SPEED BUCKET SPEED BRAKE TORQUE ROTOR SPEED BRAKE POWER AVAILABLE POWER POWER ANGLE =165 V=0.97(2P/) u=r T = RL =2N/60 A =T B=PQ C = Q( V-u)(1-kcos) u FACTOR k=0.8

Where : r = distance from the axis of rotation down to the center of the bucket and jet u = bucket speed V = jet speed Q = volumetric flow rate of water N = shaft speed L = brake load A = brake power C = theoretical power D = pump motor brake power B = available power =165 and k=0.8: k accounts for friction losses. Experimental Procedures STEP1 : Use a ruler to estimate r the distance from the axis of rotation down to the center of the bucket and jet. This is needed to calculate the bucket speed u. Use a ruler to also estimate R the distance from the axis of rotation out to the center of load bellows. This is needed to calculate brake torque. STEP2: Turn on turbine and set the jet speed. Wait till transients settle. Then record P the pressure in the pipe from which the jet flows. This allows you to calculate the jet speed (V).Also record Q the volumetric flow rate of water using V notch weir. P and Q give you flow power. STEP3: Adjust the brake and record (1) the shaft speed N and (2) the brake load L. Repeat this step for many different closely spaced brake settings. Calculate the brake power A and the theoretical power C. Also calculate the available power B. Construct plots A/B and C/B versus u/V. Comment on plots. Measure the pump motor brake power D compare with available power B. Note that the available power in 3

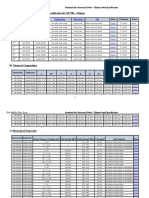

the flow is B=PQ. The brake power is A=T. The brake torque is T=RL. The rotor speed is = N/60 2 if N is in RPM. Record the following R = 0.160(m) Pump Speed = Brake Setting 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Reduce Shaft Speed by approx 150-200 rpm for each step. Start brake at full open r =0.06(m) Q= P =

Pump Bellows Load = Shaft Speed N (rpm) Turbine Bellows load L (Newton)

Das könnte Ihnen auch gefallen

- Coventry UniversityDokument20 SeitenCoventry UniversityDuncoh DunNoch keine Bewertungen

- Pelton Turbine Test Rig: BackgroundDokument4 SeitenPelton Turbine Test Rig: Backgroundanil chejara100% (1)

- Experiment 7 DiagramDokument7 SeitenExperiment 7 Diagramartemio john claveNoch keine Bewertungen

- EXP 6 Study of Impact of Free Water JetDokument11 SeitenEXP 6 Study of Impact of Free Water Jetsiva ramNoch keine Bewertungen

- Adiabatic Gas Law Apparatus Instruction ManualDokument10 SeitenAdiabatic Gas Law Apparatus Instruction ManualSyifauliyah AzmiNoch keine Bewertungen

- Pelton Turbine Efficiency Test (PTEDokument6 SeitenPelton Turbine Efficiency Test (PTENiall McInerneyNoch keine Bewertungen

- Technical-Specification-Rmu-Frtu (Bses) PDFDokument55 SeitenTechnical-Specification-Rmu-Frtu (Bses) PDFSanjay Kumar100% (1)

- Lab7-Phelton Turbine Experiment-UpdatedDokument7 SeitenLab7-Phelton Turbine Experiment-Updatedtomtoms92Noch keine Bewertungen

- Lab Guide - Pelton TurbineDokument22 SeitenLab Guide - Pelton TurbineBonifacioNoch keine Bewertungen

- Pelton Turbine LabDokument12 SeitenPelton Turbine LablufimanNoch keine Bewertungen

- Pelton TurbineDokument6 SeitenPelton Turbineendoparasite50% (2)

- Pelton Wheel TurbineDokument8 SeitenPelton Wheel TurbineSiew LynNoch keine Bewertungen

- Laboratory Manual MEC-325 Thermo Fluid Engineering LaboratoryDokument36 SeitenLaboratory Manual MEC-325 Thermo Fluid Engineering LaboratoryArpit Kumar Jain100% (1)

- Specific Energy Hydraulic Jumps WeirsDokument23 SeitenSpecific Energy Hydraulic Jumps WeirsHaris jugnooNoch keine Bewertungen

- Mka-03 Pelton and Francis TurbinesDokument11 SeitenMka-03 Pelton and Francis TurbineshasshosNoch keine Bewertungen

- Revised LabDokument18 SeitenRevised LabAbu AyemanNoch keine Bewertungen

- LAB SHEET For Pelton Wheel 21 Sept 2011Dokument3 SeitenLAB SHEET For Pelton Wheel 21 Sept 2011Mohd FazliNoch keine Bewertungen

- Francis TurbineDokument12 SeitenFrancis TurbinePraveen PagidiNoch keine Bewertungen

- Experiment 3Dokument9 SeitenExperiment 3Abigail RadubanNoch keine Bewertungen

- Experiment 3 Hydraulics LabDokument12 SeitenExperiment 3 Hydraulics LabMatt NashrudinNoch keine Bewertungen

- Measuring Momentum Forces on PlatesDokument4 SeitenMeasuring Momentum Forces on PlatesMunzirKhanNoch keine Bewertungen

- Hydraulic Turbines: General Layout of Hydro-Electric Power PlantDokument6 SeitenHydraulic Turbines: General Layout of Hydro-Electric Power PlantnarendraidealNoch keine Bewertungen

- Cam Jump Phenomenon-1Dokument10 SeitenCam Jump Phenomenon-1Dhairyasheel Bhutkar100% (1)

- Pelton Turbine Experiment ResultDokument2 SeitenPelton Turbine Experiment ResultShea Cheng KuangNoch keine Bewertungen

- Pelton Turbine (FM62)Dokument6 SeitenPelton Turbine (FM62)Mintesnot Abera100% (4)

- Study Surface Shape Forced Vortex FlowDokument12 SeitenStudy Surface Shape Forced Vortex FlowSaravin SelhvaduraiNoch keine Bewertungen

- Wheel N AxleDokument11 SeitenWheel N AxleCarey FernandesNoch keine Bewertungen

- Impact of A Water JetDokument5 SeitenImpact of A Water JetAnirban SardarNoch keine Bewertungen

- Impact of JetDokument12 SeitenImpact of JetShafizNoch keine Bewertungen

- Laboratory Teaching Exercises FM60 Impulse TurbineDokument6 SeitenLaboratory Teaching Exercises FM60 Impulse TurbineMintesnot AberaNoch keine Bewertungen

- Pelton Wheel Lab SheetDokument5 SeitenPelton Wheel Lab SheetHassan Ali0% (1)

- Orifice Jet Flow Experiment GuideDokument3 SeitenOrifice Jet Flow Experiment GuideshaneshaneshaneshaneNoch keine Bewertungen

- Lab Expt 04 - Investigation of Forced VorticesDokument5 SeitenLab Expt 04 - Investigation of Forced VorticesGIANNE MARIE AZURINNoch keine Bewertungen

- Free and Forced Vortices PDFDokument6 SeitenFree and Forced Vortices PDFdemiseNoch keine Bewertungen

- Water Turbines: Our SubtopicDokument28 SeitenWater Turbines: Our SubtopicVaish NaoNoch keine Bewertungen

- Sluice Gate ExperimentDokument1 SeiteSluice Gate Experimenttewodros getuNoch keine Bewertungen

- Force Balance Design For Educational Wind TunnelsDokument10 SeitenForce Balance Design For Educational Wind Tunnelsnarien kondamNoch keine Bewertungen

- Impact of JetDokument5 SeitenImpact of Jetميسرة33% (3)

- Experiment 3 Reaction TurbineDokument20 SeitenExperiment 3 Reaction TurbineAnonymous T7vjZG4ot100% (1)

- Jet ReactionDokument4 SeitenJet ReactionSelva RajNoch keine Bewertungen

- Impact of JetDokument7 SeitenImpact of JetHeng Xiu KohNoch keine Bewertungen

- Validates Bernoulli's Theorem in Tapered DuctDokument29 SeitenValidates Bernoulli's Theorem in Tapered DuctAnonymous NyvKBWNoch keine Bewertungen

- Measure Lift and Drag on an AirfoilDokument11 SeitenMeasure Lift and Drag on an AirfoilFanis VlazakisNoch keine Bewertungen

- Spiral Casing: The Spiral Casing Around The Runner of The Turbine Is Known As Volute Casing. AllDokument9 SeitenSpiral Casing: The Spiral Casing Around The Runner of The Turbine Is Known As Volute Casing. AllMuhammad Fauzan Ansari Bin AzizNoch keine Bewertungen

- Experiment No. 6: TitleDokument2 SeitenExperiment No. 6: TitleKamran AliNoch keine Bewertungen

- CavitationDokument3 SeitenCavitationTara JenkinsNoch keine Bewertungen

- Free VortexDokument3 SeitenFree VortexVrushiket Patil67% (3)

- Effect of Gyroscopic Couple on Naval ShipsDokument16 SeitenEffect of Gyroscopic Couple on Naval Shipsdada100% (1)

- Lab 1 - Fluid Flowmeters (Me) FinalDokument14 SeitenLab 1 - Fluid Flowmeters (Me) Finalizzahyahaya75% (4)

- Pelton Turbine CharacteristicsDokument10 SeitenPelton Turbine CharacteristicsViknesh MjNoch keine Bewertungen

- List of Experiments of Fluid LabDokument24 SeitenList of Experiments of Fluid LabGhufran Ahmed0% (1)

- Vortex FlowDokument21 SeitenVortex FlowLovely SinghNoch keine Bewertungen

- 4 Rough Draft2 Impact of A Water JetDokument14 Seiten4 Rough Draft2 Impact of A Water JetBrennan GenusaNoch keine Bewertungen

- Venturi meter experiment proceduresDokument2 SeitenVenturi meter experiment proceduresAnonymous mRBbdopMKf100% (1)

- Exp 1-Hele ShawDokument1 SeiteExp 1-Hele Shawadityain2003Noch keine Bewertungen

- Report On Pelton WheelDokument15 SeitenReport On Pelton WheelAwais100% (1)

- Practical Verification of Bernoulli'S Theorem: StructureDokument3 SeitenPractical Verification of Bernoulli'S Theorem: StructureVívék SâíNoch keine Bewertungen

- Pelton Turbine: I I H H I B B B B B 1 2Dokument2 SeitenPelton Turbine: I I H H I B B B B B 1 2Black CanaryNoch keine Bewertungen

- Performance Characteristics of Pelton Wheel Purpose: To Investigate The Performance Characteristics of An Impulse Turbine (Pelton Wheel)Dokument2 SeitenPerformance Characteristics of Pelton Wheel Purpose: To Investigate The Performance Characteristics of An Impulse Turbine (Pelton Wheel)Douglas FabrisNoch keine Bewertungen

- Exp 1 Pelton Wheel TurbineDokument8 SeitenExp 1 Pelton Wheel TurbineNabilahJasmiNoch keine Bewertungen

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Antidiabetic DrugsDokument24 SeitenAntidiabetic DrugsHenDricky MagosiNoch keine Bewertungen

- Epidermiology of HPV Disease 28jan2013-2Dokument33 SeitenEpidermiology of HPV Disease 28jan2013-2HenDricky MagosiNoch keine Bewertungen

- Preoprative EvaluationDokument24 SeitenPreoprative EvaluationHenDricky MagosiNoch keine Bewertungen

- School of MedicineDokument44 SeitenSchool of MedicineHenDricky MagosiNoch keine Bewertungen

- School of MedicineDokument44 SeitenSchool of MedicineHenDricky MagosiNoch keine Bewertungen

- Flow Through A Pipe Orifice Meter LabDokument8 SeitenFlow Through A Pipe Orifice Meter LabHenDricky MagosiNoch keine Bewertungen

- Mechanical EngineeringDokument17 SeitenMechanical EngineeringHenDricky MagosiNoch keine Bewertungen

- Flow Through A Pipe Orifice MeterDokument5 SeitenFlow Through A Pipe Orifice MeterHenDricky MagosiNoch keine Bewertungen

- WordDokument1 SeiteWordHenDricky MagosiNoch keine Bewertungen

- Corrosion Assessment in Reinforced Concrete StructuresDokument32 SeitenCorrosion Assessment in Reinforced Concrete Structuresdineshkumar rNoch keine Bewertungen

- IFR 101 ManualDokument28 SeitenIFR 101 ManualsunhuynhNoch keine Bewertungen

- LR Tech IntroDokument432 SeitenLR Tech Intromagellan_phineas100% (11)

- Articulado PDFDokument90 SeitenArticulado PDFMiguel Fuentes100% (1)

- Tulsion: Strong Acid Cation Exchange Resin Sodium CycleDokument2 SeitenTulsion: Strong Acid Cation Exchange Resin Sodium CycleKewl DudzNoch keine Bewertungen

- Guide To ExtrusionDokument26 SeitenGuide To ExtrusionThong Kin MunNoch keine Bewertungen

- IS-216 Queens Boiler Pit Leak RepairDokument8 SeitenIS-216 Queens Boiler Pit Leak RepairShamsherHussainNoch keine Bewertungen

- Cold Lime Soda Softening ProcessDokument10 SeitenCold Lime Soda Softening ProcessSaurabh JadhavNoch keine Bewertungen

- Ships: SEWAGE: MARPOL 4 - Prevention of Pollution by (SEWAGE) FromDokument2 SeitenShips: SEWAGE: MARPOL 4 - Prevention of Pollution by (SEWAGE) FromcanigetaccessNoch keine Bewertungen

- Schedule of Quantities: NIT No. 49/NIT/EE-I/CPWD/BBSR/2021-22Dokument11 SeitenSchedule of Quantities: NIT No. 49/NIT/EE-I/CPWD/BBSR/2021-22Ajit JenaNoch keine Bewertungen

- Floor ReportDokument4 SeitenFloor ReportStephen Gallagher0% (1)

- Definition of Tunnel BoringDokument13 SeitenDefinition of Tunnel BoringUji FauziahNoch keine Bewertungen

- Aqua Culture Brochure - Fusi TechDokument2 SeitenAqua Culture Brochure - Fusi Techsaradhi sravan kumarNoch keine Bewertungen

- Comparison Between Vacuum and SF6 Circuit BreakerDokument12 SeitenComparison Between Vacuum and SF6 Circuit BreakerecsanyiNoch keine Bewertungen

- First Part Lab ManualDokument6 SeitenFirst Part Lab ManualInfo EsocketNoch keine Bewertungen

- Layout Arrangement For Centrifugal Pump PipingDokument20 SeitenLayout Arrangement For Centrifugal Pump PipingKyaw Kyaw Aung50% (2)

- Fema 267Dokument164 SeitenFema 267chavico17100% (1)

- WWW - Osha.gov Pre Test Answer Key2Dokument3 SeitenWWW - Osha.gov Pre Test Answer Key2raul_bsu100% (6)

- 66 DuPont MECS Alloy AcidCoolersDokument2 Seiten66 DuPont MECS Alloy AcidCoolersMohamed Elayachi100% (1)

- PCM70140 Primer Epoxi PPGDokument1 SeitePCM70140 Primer Epoxi PPGMisaelNoch keine Bewertungen

- 04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesDokument1 Seite04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesRonaldNoch keine Bewertungen

- The Rheology Degradation Processing and Characterization of ReDokument261 SeitenThe Rheology Degradation Processing and Characterization of ReDeidra CadeNoch keine Bewertungen

- Pile Soil InteractionDokument250 SeitenPile Soil Interactionnallay1705100% (3)

- Manufacturer'S Test Certificate: National Builtech Trading and Contracting CoDokument1 SeiteManufacturer'S Test Certificate: National Builtech Trading and Contracting CoNBTC Tubes & PipesNoch keine Bewertungen

- PCL Handbook 2017 Lub1007eDokument228 SeitenPCL Handbook 2017 Lub1007eMahmoud MohamedNoch keine Bewertungen

- Standard Specification For GB 700Dokument12 SeitenStandard Specification For GB 700Ma'arif Nuzul AddibNoch keine Bewertungen

- Class 10 Social Science2Dokument15 SeitenClass 10 Social Science2Sumit BainNoch keine Bewertungen

- Cat 03a en Compact Conductor System VKS10Dokument25 SeitenCat 03a en Compact Conductor System VKS10quang.an185Noch keine Bewertungen