Beruflich Dokumente

Kultur Dokumente

Fab India

Hochgeladen von

Varun MehrotraCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fab India

Hochgeladen von

Varun MehrotraCopyright:

Verfügbare Formate

Introduction:

FabIndia is a well-known retail brand that sells various hand made products through its stores across India and overseas. They are probably the best-known urban middle class brand in India. It would not be wrong to say that they define the middle class look for Indians. Founded in 1960 by John Bissell to market the diverse craft traditions of India, Fabindia started out as a company exporting home furnishings. The first Fabindia retail store was opened in Greater Kailash, New Delhi fifteen years later. By the early eighties, Fabindia was already known for garments made from hand woven and hand printed fabrics. The non-textile range was added in 2000, while organic foods, which formed a natural extension of Fabindias commitment to traditional techniques and skills was added in 2004, with personal care products following in 2006. Handcrafted jewellery was introduced in 2008. Today, with a pan-India presence, Fabindia is the largest private platform for products that derive from traditional crafts and knowledge. A large proportion of these are sourced from villages across India where the company works closely with the artisans, providing various inputs including design, quality control, access to finance and raw materials. Fabindias endeavour is to bring customers a choice of products and lifestyle that offers an alternative to the mass-produced, while creating sustainable livelihoods in the rural sector. Fabindia links over 80,000 craft based rural producers to modern urban markets, thereby creating a base for skilled, sustainable rural employment, and preserving India's traditional handicrafts in the process. Fabindia's products are natural, craft based, contemporary, and affordable.

The FabIndia Ecosystem:

Fabindia enjoys a network of 175 retail stores across India, 2 stores in Mauritius, and 1 store each in Dubai, Italy, Nepal and Singapore. Its supply chain is based on Supply chain based on inclusive capitalism: co-option of 22,000 artisans and making them into shareholders through an elaborate communityowned model Designers and business experts are directly employed by Fabindia. Few of the designers work with the artisans while others form the product selection committee. The key responsibility of this committee is to select new artisans and weavers and ensure that the quality standards are met before ordering the products Fabindia created a fund, Artisans Micro Finance Private Limited (AMFPL), a fully owned subsidiary of Fabindia, that would bring these artisans into regional supplying companies spread across the country. By creating private limited companies it became easier for these companies to borrow money from banks against orders from Fabindia. Over the years, Fabindia has added several new product lines to its business - from apparel to furniture, jewelry and personal care products and even organic food. But it kept adding new SKUs (stock keeping units) in the existing space with the result that many of its stores are now packed to the brim.

Fabindia supply chain:

Fabindias suppliers are predominantly from rural India. The supply chain has 2 suppliers, the artisans and the fabricators. The artisans are the weavers or painters from a rural background so the designers are the ones who are responsible for communicating with the artisans and making them aware of urban needs and trends. The designers have a deep knowledge of textiles as well as the urban sensibilities.

Since most of the fabindia artisans are poor and illiterate there are few written contracts that exist and govern supplier behaviour. Each potential supplier comes through a reference from an existing supplier. Initially the supplier is given a trial order and based on the performance of the supplier, they get regular orders. The Fabindia supply chain has moved on from a centralized warehouse model to a more decentralized model. To shorten the supply chain and incorporate the artisans within the process in a greater way, fabindia introduced the concept of community owned companies. The weaver approaches the Supply regional company i.e. SRC with. At the SRC level the designer steps in to help artisans produce something relevant to the target market. The design is then approved by the PSC or the product selection committee. Here the fabrics and the quality of factors like color fastmess are determine and compared to the company set benchmarks. One the product is selected by the PSC the order is placed after price negotiation with the weaver. The orders are completed by the weaver and brought to the company warehouse. The fabric is delivered in the form of thaans. However there is no uniformity in terms of the length

of fabric incorporate in each of the thaan. It varies from 20m to 50m. The stock then moves from the SRC warehouse to the regional warehouse. The issue that fabindia faced in the initial stages was orchestrating the supply chain which would cater to the large volume of supplies as well as maintain quality. To resolve this the model of SRC s was introduced. The SRC are in direct contact with the artisans and serve as interfaces to the urban markets. The SRCs are also responsible for getting the artisans credit and capital that they require. 17 SRCs have been setup in different parts of the country to deal with suppliers across the length and breadth of the country. The artisans have a 26% stake in the SRCs and the rest is owned by the investors and the fabindia. Once the order has been received at the SRC warehouses it becomes a part of the fabindia online inventory system. The levels of stock and orders for a particular product can thus be moni tored online by the reatailer. As and when the retailers place their orders the products are moved from the SRC warehouses to the regional warehouses and distributor points. At each regional warehouse a continuous review model for inventory of products is followed. On the retailer side, each retailer orders as a single entrepreneurial entity. For various kinds of products bins or wallet sizes are defined and the retailer is allowed to stock up only upto a given wallet size. SRCs have evolved the supply chain of Fabindia from a centralized model to a regional supplier companies. Benefits of this novel approach:

Enabling it to create 100,000 sustainable rural jobs across India Access to working capital the main hurdle to capacity building Direct interface with artisans Closer to sourcing shortening the supply chain, better quality and pricing Enables the purchase of materials in bulk so as to get the best price

Key challenges in current supply chain:

The main problem for Fabindia is to maintain consistency of products since the suppliers and manufacturing locations are scattered over a large geographical area on a small scale. As these products are made in interior, rural locations in various locations, it has been difficult to maintain same level of quality due to lack of knowledge on urban customers and also cultural, behavioural differences in suppliers across different locations. In case of organic products, Market in not matured. So it targets customer with prior knowledge on this product. The major problem there is fickle delivery and product availability, which does lead to customer dissatisfaction. But this is a very small part of the customer base.

References 1. http://forbesindia.com/article/big-bet/fabindias-tightrope-walk/29762/0 2. http://www.fabindia.com/company/ 3. http://www.indianretailer.com/article/operations/logistics-and-supplychain/Empowering-Sustaining-through-Supply-Chain-280/

Das könnte Ihnen auch gefallen

- Fabindia - Intro & VMDokument37 SeitenFabindia - Intro & VMRoopas50% (4)

- Fab IndiaDokument16 SeitenFab IndiaArpita Mehta100% (2)

- Fabindia Marketing StrategyDokument5 SeitenFabindia Marketing StrategySoumya Ranjan PradhanNoch keine Bewertungen

- FabindiaDokument52 SeitenFabindiaGauravi Dhoble100% (4)

- Fabindia Final PresentationDokument17 SeitenFabindia Final PresentationShruti Singhal100% (1)

- Fab INdiaDokument15 SeitenFab INdiakomal aggy100% (1)

- Fabindia Merchandising ProjectDokument16 SeitenFabindia Merchandising ProjectindrascopeNoch keine Bewertungen

- Fab IndiaDokument16 SeitenFab IndiaDeepakh Arun100% (1)

- Lifestyle SIP ReportDokument5 SeitenLifestyle SIP ReportNikhil KumarNoch keine Bewertungen

- 7 P's of WestsideDokument10 Seiten7 P's of WestsidePallavi PatleNoch keine Bewertungen

- Retailing Mix of PantaloonsDokument27 SeitenRetailing Mix of PantaloonsRupal Patel0% (1)

- Industry Internship Report TommyDokument7 SeitenIndustry Internship Report TommydishaNoch keine Bewertungen

- Central VM DocumentDokument41 SeitenCentral VM Documentswati100% (1)

- Priyanka YadavDokument47 SeitenPriyanka YadavNANACY SHARMA100% (1)

- Global Desi Project Report: KhaleesiDokument11 SeitenGlobal Desi Project Report: KhaleesiAyush Bisht91% (11)

- Ucb ReportDokument50 SeitenUcb ReportlizaNoch keine Bewertungen

- West SideDokument44 SeitenWest SidesirgautamdubeyNoch keine Bewertungen

- Shoppers Stop Vs LifestyleDokument33 SeitenShoppers Stop Vs LifestyleDev Deep67% (3)

- Zarokha (Hypothetical Brand For Luxury BrandDokument13 SeitenZarokha (Hypothetical Brand For Luxury BrandShalu100% (1)

- Research FabindiaDokument76 SeitenResearch FabindiamadhusmitaNoch keine Bewertungen

- Marketing Strategy Analysis of FabIndiaDokument33 SeitenMarketing Strategy Analysis of FabIndiaAman P Jain100% (8)

- VISION ArvindDokument26 SeitenVISION ArvindPalak MehrotraNoch keine Bewertungen

- HidesignDokument15 SeitenHidesignAmanNoch keine Bewertungen

- Hypothetical Brand Identity PrismDokument4 SeitenHypothetical Brand Identity PrismRakshit JainNoch keine Bewertungen

- BibaDokument24 SeitenBibaPrachi Yash100% (1)

- Kavita SahuDokument57 SeitenKavita SahuPranav Jain100% (1)

- Peter England Presentation - Dipti PatelDokument48 SeitenPeter England Presentation - Dipti PatelDipti PatelNoch keine Bewertungen

- PANTALOONS - Store Layout, Design & Visual MerchandisingDokument20 SeitenPANTALOONS - Store Layout, Design & Visual MerchandisingPradip Kumar67% (3)

- West SideDokument10 SeitenWest SideSurya KumarNoch keine Bewertungen

- Brand Identity PrismDokument26 SeitenBrand Identity PrismVishakhaSharmaNoch keine Bewertungen

- Fabindia Strategy Management Complete OverviewDokument33 SeitenFabindia Strategy Management Complete OverviewShubham WaliaNoch keine Bewertungen

- Handloom Cluster Nuapatna and GopalpurDokument53 SeitenHandloom Cluster Nuapatna and Gopalpurvikash kumar100% (2)

- Internship. LifestyleDokument108 SeitenInternship. Lifestylefun_madurai67% (3)

- BibaDokument7 SeitenBibaTrisha Bhaumik100% (1)

- Craft Cluster Document PDFDokument119 SeitenCraft Cluster Document PDFShivam Nayar100% (1)

- STP, Marketing Mix of WestsideDokument17 SeitenSTP, Marketing Mix of WestsideAmrutha RP100% (2)

- Project Report On LifestyleDokument16 SeitenProject Report On LifestyleSwati Singh40% (5)

- Brand Portfolio of Peter EnglandDokument65 SeitenBrand Portfolio of Peter EnglandSourav Roy50% (4)

- STP of West SideDokument8 SeitenSTP of West SideApoorVaChandAkNoch keine Bewertungen

- 17MBA1028 - Summer Internship Report PDFDokument65 Seiten17MBA1028 - Summer Internship Report PDFNiyamathullahNoch keine Bewertungen

- A Project On Customer - Behaviour in PantaloonsDokument35 SeitenA Project On Customer - Behaviour in PantaloonsShweta ShrivasNoch keine Bewertungen

- HidesignDokument17 SeitenHidesignamankanojia1992Noch keine Bewertungen

- Brand Identity PrismDokument24 SeitenBrand Identity Prismarpit010380% (5)

- Triburg ReportDokument38 SeitenTriburg Reportluvlinamorya100% (4)

- Mini Project-EASY BUYDokument12 SeitenMini Project-EASY BUYLalithya Sannitha Meesala0% (2)

- Max Fashion Consumer BehaviourDokument35 SeitenMax Fashion Consumer Behavioursarika Rana67% (3)

- Nidhi BHATI PDFDokument92 SeitenNidhi BHATI PDFNikita Singh100% (2)

- On Arvind by VishalDokument34 SeitenOn Arvind by VishalVishal ShahNoch keine Bewertungen

- Max Fashion Summer Internship ReportDokument17 SeitenMax Fashion Summer Internship ReportABHIJITH V S100% (2)

- Research Report On The Retail Store Operations of Van HeusenDokument14 SeitenResearch Report On The Retail Store Operations of Van Heusenlikitha100% (2)

- Or InventoryDokument37 SeitenOr InventoryGreeshmaNoch keine Bewertungen

- Fabindia: Download PDFDokument3 SeitenFabindia: Download PDFShubhangi AgarwalNoch keine Bewertungen

- Case Studies - FabIndiaDokument4 SeitenCase Studies - FabIndiaPiyush PratikNoch keine Bewertungen

- Fabindia: Weaving Scale Into Hand Made ProductsDokument4 SeitenFabindia: Weaving Scale Into Hand Made ProductsAnkit AggarwalNoch keine Bewertungen

- Fabindia MerchandisingDokument21 SeitenFabindia MerchandisingShelly MistryNoch keine Bewertungen

- Fab IndiaDokument22 SeitenFab IndiaAnshumali BaruahNoch keine Bewertungen

- IndividualAssignment FabindiaDokument9 SeitenIndividualAssignment FabindiaPALLAVI DASHNoch keine Bewertungen

- FABINDIA ReportDokument20 SeitenFABINDIA ReportveenashreeNoch keine Bewertungen

- Fabindia: HistoryDokument36 SeitenFabindia: HistoryKanak GehlotNoch keine Bewertungen

- SL Fabindia Submission PDFDokument6 SeitenSL Fabindia Submission PDFMurali DharanNoch keine Bewertungen

- Busana Apparel Group - Tommy FH'17Dokument80 SeitenBusana Apparel Group - Tommy FH'17Varun MehrotraNoch keine Bewertungen

- Machine Health Evaluation SheetDokument4 SeitenMachine Health Evaluation SheetVarun MehrotraNoch keine Bewertungen

- All Shahi Employees: Anonymous Survey Online Easy To Fill OutDokument1 SeiteAll Shahi Employees: Anonymous Survey Online Easy To Fill OutVarun MehrotraNoch keine Bewertungen

- Threads: Training & Development/Od Shahi Exports PVT LTDDokument30 SeitenThreads: Training & Development/Od Shahi Exports PVT LTDVarun MehrotraNoch keine Bewertungen

- Boutique Manager - QPDokument29 SeitenBoutique Manager - QPVarun MehrotraNoch keine Bewertungen

- Date 22dec PDFDokument1 SeiteDate 22dec PDFVarun MehrotraNoch keine Bewertungen

- Scale Settings: Red 45 Amber 25 Green 30 Gap 100Dokument3 SeitenScale Settings: Red 45 Amber 25 Green 30 Gap 100Varun MehrotraNoch keine Bewertungen

- Total: Line 1 ITEM No.:-M675Dokument83 SeitenTotal: Line 1 ITEM No.:-M675Varun MehrotraNoch keine Bewertungen

- Yamata Fy 8500Dokument29 SeitenYamata Fy 8500yu7bx100% (1)

- SMEDA-Industry Support Program: Application of Lean ProductionDokument33 SeitenSMEDA-Industry Support Program: Application of Lean ProductionVarun MehrotraNoch keine Bewertungen

- Industrial Sewing Machine Needles Replacement Policy - Auto GarmentDokument4 SeitenIndustrial Sewing Machine Needles Replacement Policy - Auto GarmentVarun MehrotraNoch keine Bewertungen

- Date 21dec PDFDokument1 SeiteDate 21dec PDFVarun MehrotraNoch keine Bewertungen

- Managing Brand EquityDokument2 SeitenManaging Brand EquityVarun MehrotraNoch keine Bewertungen

- Faculty Mentor: Dr. PRABIR Jana Mr. Deepak Panghal Industry Mentor: Mr. UDAY N B (Sales & Technical Manager)Dokument2 SeitenFaculty Mentor: Dr. PRABIR Jana Mr. Deepak Panghal Industry Mentor: Mr. UDAY N B (Sales & Technical Manager)Varun MehrotraNoch keine Bewertungen

- EMR FormatDokument10 SeitenEMR FormatVarun MehrotraNoch keine Bewertungen

- Offer Letter - Shahi Exports Pvt. Ltd.Dokument1 SeiteOffer Letter - Shahi Exports Pvt. Ltd.Varun MehrotraNoch keine Bewertungen

- Feasibility of Using 3D Printed Sewing Machine Parts in Garment ManufacturingDokument7 SeitenFeasibility of Using 3D Printed Sewing Machine Parts in Garment ManufacturingVarun MehrotraNoch keine Bewertungen

- List of Hospitals/Diagnostic Centres Empanelled Under Cghs Delhi &Dokument29 SeitenList of Hospitals/Diagnostic Centres Empanelled Under Cghs Delhi &Varun MehrotraNoch keine Bewertungen

- AbstarctDokument2 SeitenAbstarctVarun MehrotraNoch keine Bewertungen

- Prototype: X A B YDokument7 SeitenPrototype: X A B YVarun MehrotraNoch keine Bewertungen

- Abs Suppliers in India: Spectrum 3D CreationsDokument2 SeitenAbs Suppliers in India: Spectrum 3D CreationsVarun MehrotraNoch keine Bewertungen

- ProductivityDokument13 SeitenProductivityVarun MehrotraNoch keine Bewertungen

- Arun Kumar Varun MehrotraDokument12 SeitenArun Kumar Varun MehrotraVarun MehrotraNoch keine Bewertungen

- Eton SystemDokument17 SeitenEton SystemVarun MehrotraNoch keine Bewertungen

- Organizational Behavior: Introduction ToDokument24 SeitenOrganizational Behavior: Introduction ToVarun MehrotraNoch keine Bewertungen

- Edita's Opertionalization StrategyDokument13 SeitenEdita's Opertionalization StrategyMaryNoch keine Bewertungen

- Allan ToddDokument28 SeitenAllan ToddBilly SorianoNoch keine Bewertungen

- Daraman vs. DENRDokument2 SeitenDaraman vs. DENRJeng GacalNoch keine Bewertungen

- GR L-38338Dokument3 SeitenGR L-38338James PerezNoch keine Bewertungen

- ADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementDokument33 SeitenADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementNURATIKAH BINTI ZAINOL100% (1)

- Schmidt Family Sales Flyer English HighDokument6 SeitenSchmidt Family Sales Flyer English HighmdeenkNoch keine Bewertungen

- Rebar Coupler: Barlock S/CA-Series CouplersDokument1 SeiteRebar Coupler: Barlock S/CA-Series CouplersHamza AldaeefNoch keine Bewertungen

- Historical Development of AccountingDokument25 SeitenHistorical Development of AccountingstrifehartNoch keine Bewertungen

- Intermediate Accounting (15th Edition) by Donald E. Kieso & Others - 2Dokument11 SeitenIntermediate Accounting (15th Edition) by Donald E. Kieso & Others - 2Jericho PedragosaNoch keine Bewertungen

- Lending OperationsDokument54 SeitenLending OperationsFaraz Ahmed FarooqiNoch keine Bewertungen

- TAS5431-Q1EVM User's GuideDokument23 SeitenTAS5431-Q1EVM User's GuideAlissonNoch keine Bewertungen

- Blade Torrent 110 FPV BNF Basic Sales TrainingDokument4 SeitenBlade Torrent 110 FPV BNF Basic Sales TrainingMarcio PisiNoch keine Bewertungen

- Are Groups and Teams The Same Thing? An Evaluation From The Point of Organizational PerformanceDokument6 SeitenAre Groups and Teams The Same Thing? An Evaluation From The Point of Organizational PerformanceNely Noer SofwatiNoch keine Bewertungen

- Ishares Core S&P/TSX Capped Composite Index Etf: Key FactsDokument2 SeitenIshares Core S&P/TSX Capped Composite Index Etf: Key FactsChrisNoch keine Bewertungen

- NOP PortalDokument87 SeitenNOP PortalCarlos RicoNoch keine Bewertungen

- M J 1 MergedDokument269 SeitenM J 1 MergedsanyaNoch keine Bewertungen

- EnerconDokument7 SeitenEnerconAlex MarquezNoch keine Bewertungen

- Capital Expenditure DecisionDokument10 SeitenCapital Expenditure DecisionRakesh GuptaNoch keine Bewertungen

- Phase 1: API Lifecycle (2 Days)Dokument3 SeitenPhase 1: API Lifecycle (2 Days)DevendraNoch keine Bewertungen

- Doterra Enrollment Kits 2016 NewDokument3 SeitenDoterra Enrollment Kits 2016 Newapi-261515449Noch keine Bewertungen

- Vinera Ewc1201Dokument16 SeitenVinera Ewc1201josue1965Noch keine Bewertungen

- Termination LetterDokument2 SeitenTermination Letterultakam100% (1)

- Hotel ManagementDokument34 SeitenHotel ManagementGurlagan Sher GillNoch keine Bewertungen

- BS 8541-1-2012Dokument70 SeitenBS 8541-1-2012Johnny MongesNoch keine Bewertungen

- JAZEL Resume-2-1-2-1-3-1Dokument2 SeitenJAZEL Resume-2-1-2-1-3-1GirlieJoyGayoNoch keine Bewertungen

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Dokument3 SeitenAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraNoch keine Bewertungen

- Lockbox Br100 v1.22Dokument36 SeitenLockbox Br100 v1.22Manoj BhogaleNoch keine Bewertungen

- ICSI-Admit-Card (1) - 230531 - 163936Dokument17 SeitenICSI-Admit-Card (1) - 230531 - 163936SanjayNoch keine Bewertungen

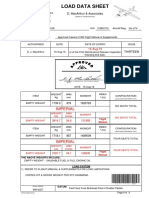

- Load Data Sheet: ImperialDokument3 SeitenLoad Data Sheet: ImperialLaurean Cub BlankNoch keine Bewertungen

- MMC Pipe Inspection RobotDokument2 SeitenMMC Pipe Inspection RobotSharad Agrawal0% (1)