Beruflich Dokumente

Kultur Dokumente

Group 2 Lead Project Final

Hochgeladen von

api-253503836Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Group 2 Lead Project Final

Hochgeladen von

api-253503836Copyright:

Verfügbare Formate

Diego Cardenas Mayra De Jesus-Rivas

Lynn Henderson Elizabeth Rains

Pratiksha Vaghela Mahamed Zogaj

MANUFACTURE OF LEADED STEEL

Lead as a Steel Improving Agent

MANUFACTURE OF LEADED STEEL

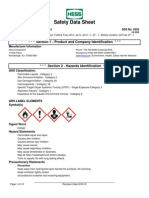

Naturally occurring element which cuts easily and is pliable. Used as a component of gasoline (banned), house paint (pre-1978), ceramics and crystal glass. Found in industrial practices: metalworking, soldering. Exposure can occur through inhalation and ingestion. If absorbed may attach to bone and calcified tissue, accumulate in

the gray matter of brain tissue.

Toxicity has been associated with reproductive effects, necrosis of brain tissue, OSHA (PEL) along with ACGIH (TLV) and NIOSH (REL) published occupational exposure limits to eliminate or reduce adverse health effects associated with lead exposure.

MANUFACTURE OF LEADED STEEL

Added as a steel improving agent. To improve machinability (ease of which a metal can be machined) Lends to the lubricant property of steel (which helps reduce wear and friction during processes increasing machine tool life)

Lead

Steel

Ease of Operations

MANUFACTURE OF LEADED STEEL

Ingot mold Poured Air-blast Gun

Lead Steel

Leaded Steel

MANUFACTURE OF LEADED STEEL

Exposure Limits

Health Effects

Action Level

Action Level (set at 30 g/m3) PEL (set at 50 g/m3)

No observable adverse health effects (precautionary) Gastrointestinal effects Acute encephalopathy (altered mental state) Reproductive Effects Anemia Peripheral, central, neuropathy PEL Severe lead colic (severe abdominal pain) Burtonian lines (blue lining of the gums)

PEL (Acute)

PEL (Chronic)

MANUFACTURE OF LEADED STEEL

Used as a steel improving agent. Occurs both naturally and from industrial practices such as copper mining. Added to steel to make it simpler to mill and machine. Exposure through the inhalation of fumes or dusts containing tellurium Linked to neurological disorders (affects nervous system), blood diseases (causes hemolysis), and respiratory problems (might cause exacerbation of pre-existing symptoms). Te (PEL)= 0.1 mg/m over an 8-hour work shift.

(OSHA)

Tellurium

* Exposure over limits promulgated by OSHA is very rare

MANUFACTURE OF LEADED STEEL

Occupational Exposure

Inhalation (most common rout) Skin contact

Eye contact Ingestion

MANUFACTURE OF LEADED STEEL

Possible air contaminants:

OSHA section 1926.55(a):

Exposure of the employee of inhalation, ingestion, skin absorption, or contact of any material or substance at a concentration above threshold level should be avoided.

Release of gases such as carbon monoxide and sulfur dioxide. Other toxic metals used: Lead, Tellurium, Nickel, and Cadmium.

MANUFACTURE OF LEADED STEEL

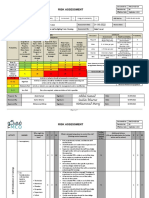

Per air sampling and biological blood analysis workers were found with lead levels exceeding PEL. Overhead crane operated by a worker w/o appropriate filter and respirator. The pouring crew in close proximity with lead. No barrier in between the workers. Workers not using respirators. A local exhaust ventilation is

being used.

Some of the fumes escaped ventilation capture.

The lateral local exhaust vent system was not flanged. Dust from metals shaken into bins. Lead debris should be wet-misted and placed into a sealed impermeable bag (OSHA, 1999).

Employer should provide the employee with appropriate respirator.

MANUFACTURE OF LEADED STEEL

Toxic dust has been blown and swept down.

Vacuuming is the most reliable method of cleaning dusty surfaces (OSHA, 1999).

Allowing workers to eat or smoke cigarettes while dealing with toxic dust material is a safety violation.

The worker will easily ingest lead by having contaminated hands. promote the vaporization of lead.

All workers involve in the collection of toxic dust should have respiratory protection and personal protective Burning of cigarettes clothing (OSHA, 1999).

MANUFACTURE OF LEADED STEEL

Workers were exposed to high levels of heat that can lead to heat stress during pouring operation.

Risk for workers to experience skin burns and risk of fire when shower of sparks was thrown up from the steel being poured hitting the ingot mold rim.

MANUFACTURE OF LEADED STEEL

Personnel Air Sample use small portable, battery operated pump.

MANUFACTURE OF LEADED STEEL

Calibration devices are now more portable. Bubble beret can also be used to calibrate the sampling pump flow rate, however this equipment is fragile and hard to use in the field.

MANUFACTURE OF LEADED STEEL

Three-stage

37-millimeter (mm), 0.8-micrometer (m) mixed cellulose ester filter (MCEF) cassette.

Flow rate 1-4 Liters Per Minute (LPM)

MANUFACTURE OF LEADED STEEL

Attach the sampling device in the employees breathing zone.

The sampling pump is attached to the employees waist to facilitate the sampling process.

MANUFACTURE OF LEADED STEEL

Air Samples

Exposure at or above PEL 14,000 g/m3 (Pitman-topping man)

Workplace Hygiene

Lack of shower facilities Candy bar wrappers & cigarettes butts

Ventilation System

Inadequate inspection and cleaning

Off center placement of hoods

MANUFACTURE OF LEADED STEEL

BLL and Hematology

7 BLL > 30 g/dL 5 BLL > 50g/dL

FEP

10 > the normal value Highest 358 g/dL (gun operator)

MANUFACTURE OF LEADED STEEL

Apparent overexposed Non-compliance

Workplace hygiene practices

Respiratory protection

Medical surveillance Exposure monitoring Written compliance program Workers training and education

MANUFACTURE OF LEADED STEEL

Short-term

Removal of worker Mean BLL at or > 50 g/dL or single BLL > 60 g/dL BLL at or > 30 g/dL if wish to bear children Medical evaluation Complete lab panel Chelation Strongly considered if BLLs between 80 and 99g/dL Possibly considered if BLLs between 50 and 79 g/dL in symptomatic workers

MANUFACTURE OF LEADED STEEL

Long-term

Employee Education Medical surveillance program

Biological monitoring Every 6 months if the last BLL was < 40 g/dL Every 2 months if the last BLL was between 40 g/dL and the levels requiring medical removal Every 1 month if the worker is medically removed

MANUFACTURE OF LEADED STEEL

Occupational Health Nursing

Educate and train employees on: Purpose and significance of the health monitoring program and Hazards of Lead results Written Safe Work Procedures Purpose and benefits of work Policy. scheduling and job Proper use, maintenance, and reassignment or rotation limitations of PPE.

Importance of safe hygiene and decontamination procedures. Purpose and significance of workplace lead dust monitoring and results (exposure data)

MANUFACTURE OF LEADED STEEL

Employees cannot be allowed to enter lunchroom facilities with protective work clothing or equipment

No Food in Work Areas

Employees must wash their hands and face prior to eating, drinking, smoking or applying cosmetics. No Smoking in Work Areas

Respirators protect the user in two basic ways. The first is by the removal of contaminants from the air. Respirators of this type include particulate respirators, which filter out airborne particles, and air-purifying respirators with cartridges/canisters which filter out chemicals and gases. Other respirators protect by supplying clean respirable air from another source. Respirators that fall into this category include airline respirators, which use compressed air from a remote source, and self-contained breathing apparatus (SCBA), which include their own air supply.

Regulated areas must be demarcated to show the necessary PPE required.

Eye protection

Aluminized Garments protect against heat

MANUFACTURE OF LEADED STEEL

Reduce take home exposures: Change out of work clothes and shoes, wash skin and hair by showering Take home exposures seen through ingestion of lead dust remaining on clothing or food brought home by exposed worker who did not practice safe hygiene practices before leaving work

MANUFACTURE OF LEADED STEEL

Workers treated for illnesses covered by workers compensation

1. 2012. Steel. [Photograph] http://www.romania-insider.com

2. 2012. Lead. [Photograph] http://images-ofelements.com/lead.php

3. 2013. Hazard Sign. [Photograph] http://work4youlaw.com

4. Robson, Greg. 2012. [Photograph] http://commons.wikimedia.org/wiki/Category:Electron_shell_di agrams

[Background]

Indoor air quality in commercial and institutional building (OSHA, 2011). www.osha.gov/publication/3430indoor-air-quality.

Occupational Safety and Health Administration (1999). Occupational safety and health standards. www.OSHA.gov

Plog, B.A. & Quilan, P.J. (2012). Fundamental of industry hygiene (6th ed.) . National Safety Council: United States of America.

Kosnett MJ. Lead. In: Poisoning and Drug Overdose (Olson KR, ed.). New York: Lange Medical Publishing/McGraw Hill. 2004, 238-242.

Medical Guidelines for the Lead-Exposed Worker. California Department of Public Health Occupational Lead Poisoning Prevention Program. Retrieved on 11/27/2013 from http://www.cdph.ca.gov/programs/olppp/Documents/medgdln.pdf Occupational Safety and Health Standards. Subpart Z: Medical surveillance guidelines. Retrieved on 11/27/2013 from https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_id=10033&p_table=STANDARD S Occupational Safety and Health Standards. Subpart Z: Toxic and Hazardous Substances-Lead. Retrieved on 11/24/2013 from https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=1003 0 Rosenstock, L and Cullen MR. Textbook of Clinical Occupational and Environmental Medicine. W.B. Saunders Company; Philadelphia, PA, 1994. Standard Interpretations. Standard Number: 1926.62; 1910.1025. Retrieved on 11/27/2013 from https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=INTERPRETATIONS&p_i d=22100

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Motoman XRC Controller Arm Interference Instruction ManualDokument31 SeitenMotoman XRC Controller Arm Interference Instruction ManualsunhuynhNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Competency Standard and Assessment Guide of Electrical Installation and MaintenanceDokument131 SeitenCompetency Standard and Assessment Guide of Electrical Installation and MaintenanceShaolin ShawonNoch keine Bewertungen

- Dequest® 2060S - MSDSDokument9 SeitenDequest® 2060S - MSDSDangnoi Shih Tzu DongNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- FMCO DR Potable Water and Fire Fighting Tank Cleaning - MSRADokument7 SeitenFMCO DR Potable Water and Fire Fighting Tank Cleaning - MSRASachin DharneNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Indian Standards For PPEDokument13 SeitenIndian Standards For PPESugun Kumar Pedapudi50% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Department of Labor: 2007 VOSH Conf BrochureDokument6 SeitenDepartment of Labor: 2007 VOSH Conf BrochureUSA_DepartmentOfLaborNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Dole RegulationsDokument5 SeitenDole Regulationsjuncos0729Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Transmission Axle 7 85W-140: Safety Data SheetDokument14 SeitenTransmission Axle 7 85W-140: Safety Data SheetDavid Loza PalmaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- SEC - 15 - Security Management at Industrial FacilitiesDokument42 SeitenSEC - 15 - Security Management at Industrial FacilitiesMohammed IrfanNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Running Heads: BOS 4601 UNIT III 1Dokument7 SeitenRunning Heads: BOS 4601 UNIT III 1etqmytriwwuzwdhbzzNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- CBC Form 1-Basic CompetenciesDokument17 SeitenCBC Form 1-Basic CompetenciesMarcus CambyNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- A Novel Study of Hazard Identification and Risk Assessment in Textile IndustryDokument42 SeitenA Novel Study of Hazard Identification and Risk Assessment in Textile IndustryIJRASETPublicationsNoch keine Bewertungen

- 2020.04.29 Letter To House and Senate Leadership On CHCs in C4Dokument6 Seiten2020.04.29 Letter To House and Senate Leadership On CHCs in C4Jenavieve HatchNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Operating Jig SawDokument2 SeitenOperating Jig SawgrantNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- List of PPE Is StandardsDokument2 SeitenList of PPE Is StandardstpchowoNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Imd 100 Integration Manual 4189360015 UkDokument243 SeitenImd 100 Integration Manual 4189360015 UkLUATNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Sikafloor - 261: System Data SheetDokument4 SeitenSikafloor - 261: System Data Sheetthe pilotNoch keine Bewertungen

- 2020 NFHS Guidance For High School Athletics & ActivitiesDokument16 Seiten2020 NFHS Guidance For High School Athletics & ActivitiesiBerkshires.comNoch keine Bewertungen

- Sibur-Khimprom CJSC Safety Data Sheet: According To 1907/2006/EC (REACH), 1272/2008 (CLP) & 453/2010Dokument32 SeitenSibur-Khimprom CJSC Safety Data Sheet: According To 1907/2006/EC (REACH), 1272/2008 (CLP) & 453/2010Игорь НарзуллаевNoch keine Bewertungen

- NTU ARF SOP Manual - V3Dokument94 SeitenNTU ARF SOP Manual - V3safit_rhyNoch keine Bewertungen

- 901 E Street, Suite 300 San Rafael, CA 94901 1 888 449 3872 (Toll Free) 1 415 339 2740 1 415 339 2722 (Fax)Dokument4 Seiten901 E Street, Suite 300 San Rafael, CA 94901 1 888 449 3872 (Toll Free) 1 415 339 2740 1 415 339 2722 (Fax)hg6ttnd478Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- SITE EMERGENCY NUMBER: 0534451256: ElectricityDokument1 SeiteSITE EMERGENCY NUMBER: 0534451256: ElectricityVenkataramanan S100% (2)

- Manual de Servicio Vantage 500Dokument110 SeitenManual de Servicio Vantage 500953997601100% (2)

- 0325 Jet Fuel Aand A1Dokument10 Seiten0325 Jet Fuel Aand A1VidyasenNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- MSDS0084UK SmokesabreDokument5 SeitenMSDS0084UK SmokesabreCristian Gonzalo Yaupe SilvaNoch keine Bewertungen

- LATAPOXY 300 Adhesive Part B SDS - US EnglishDokument7 SeitenLATAPOXY 300 Adhesive Part B SDS - US Englishpetersom 93Noch keine Bewertungen

- Viscosity - True Terpenes SDSDokument9 SeitenViscosity - True Terpenes SDSBen AdlinNoch keine Bewertungen

- Simazinc EP Primer 1402-01Dokument2 SeitenSimazinc EP Primer 1402-01Agung RiyantoNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Clearance LetterDokument1 SeiteClearance LetterMon HuaNoch keine Bewertungen

- HSE Global Training: Module No CMS-710-02-PR-01200 Safe Use of GrindersDokument49 SeitenHSE Global Training: Module No CMS-710-02-PR-01200 Safe Use of Grindersleopoldo medinaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)