Beruflich Dokumente

Kultur Dokumente

Stagecoach Model

Hochgeladen von

Jack ThomasCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stagecoach Model

Hochgeladen von

Jack ThomasCopyright:

Verfügbare Formate

.

, *11'

MODEL STAGECOACH

LTANDSOME

in a rugged way,

r r

with brieht yellow running

gear,

red coach body decorated

with

gilt

striping and outdoor

scenes

painted

in oil on the door

panel q-the prototype of thi s

eoach model weighed a ton and

a quarter empty and cost nearly

$2500.

Noteworthy features of

these old overland coaches were

the exceptionally hearry running

gear and the unique, mbthod of

springing the body as shorwr in

Figs. 7 and 9. This particular

coaeh was one of several owned

by the

"Overland

Stage Line"

which followed. the pony srpress

route behreen St. Josepb, Mo.,

and Sacramento, Calif., a service

that was operated on regular

schedules untilthe completion of

the first transcontineital rail-

way. Ben Holliday, whose name

alryears on the door panel of the

old coach, was a division super-

intendent of the 0verland Line.

Figs. 1, 2 and 6 rvilt give you a good idea

of the general

appearance of the finished

model. Consbuction begins with the body,

eomponent parts of which are shown in

Fig.3. lhe overall size of the body is easily

determined by laying out full-sized pat-

terns from the crosshatched views in Figs.

t - r '

\ i :

Photoc coudesy

Fon E:pre8sliluratE. Arcrdta. Crllf.

4 and 5. Before beginning work, notiqg the

position of the parts A-A,.right and'Ieft,

and the bottom, B, in Fig. 3. AIso note la

Fie. 5 that the sides of the body do not

slant inward at the top, Sideg front and

/ . \ |

seats are carved from balsa wood or tihit

--

oine and slued to the sides and bottom of

ihe bodv is shoutn in the cross section, Fig.

3. lbei the top is

glued

on and shaped to

the curves indicateil. Assembty of tlre lug-

s;se racks. top and rar,.ord fhe fitting of

the-driver'i se.it and

"boot"

finish the body

ready for the final sanding and application

of the trimmolding.

@

l ( r " X} t " SALSA

SANOPAPENED

HALF

NOUND

M

baek

parts of the body should-be eut from

%

-ir.-;tr*ood, prefeiably' a close-grained

wood iul{r as birch. Window openinq-s are

"nt "" ittaicated, and the doors are outlined

with a molding hrade by sandpapering-tbin

strips of balsi wood or rattan to a half'

"ouira section and

gluing in place.- Note

thatthe doors eachhave a single sash'

par-

U"U" i"*oed anil fitted witL a celluloid

Ue-il T.lr" sash frame is

gluedto the inside

of-the bodv

panel. The two small windows'

otte on e.dh-side of the door, have celluloid

liehts but no frames, while the large win-

ddws on bot.L sides are merely openings

curtained with !fiaki cloth rolled up as

indicated and secured with thin leather

strapi. In assenbling, begin wtth the bot-

torn and

glue the cun'ed side

pieces A-A

to the center

piece B, fi-g.3, qnd then fit

and

glue the sides and ends in place. Inside

fRO}IT ARE

16"

MATERIAI

BAtsA

ANM NEST

#

fi

'd^"-rffil

TEMPOTARY fITIING

Nort comes the running

gear, the frame

being detailed in Fig.s. 8 and 9 and the

qrheels

in Fig. 10. ltre latter are the trick-

iest of all to mahe as close duplication of a

number of parts is required.- n:lst, mahe

the longeron, or spring urrit which consists

of three lengthwise members rnortised

through end pieces as in Fig.9. Note that

the longerons slant to the rear, making the

il

GI.UED

SATS ARE SOLID

WHTTE PINE OR EAISA

BAI,SA

cusHroNs

CELIULOID

IBCESIiED PANEL

PAINIED BI.UE

czuutotD tEi{s

CEMENIED

KHAKI CIOTH

SECURCD w|T}I

ESCUTCHEON

PINS

DROP

wrNDow

r#@D

Stoct(

front a:rle the

"overhung"

t54pe while the

rear axle is of the conventional

"under-

slungt' construction. Use maple for all ttre

woodparts. Sheetmetal of 16-ga. thickness

and wir,e of approximately the same diam-

eter will serve in making most of the

"hard-

ware." Some of tbe

"ironingt'

can be simu-

lated by mere\r coating ttre area with black

pq+t

?s

in detail A, Fig. 9. Follow through

witlr tJre construetion as detailed in Figs. 8

atld

I

up t9 the whippletrees and tongue,

which can be left until later.

To make the wheel rims glue

two

pieces

of %s-in" hardwood togethefwith thderain

r h

LX

CRGS SECTION

IHROUGH CENTER

$

STJSPENSTON

spoke with a ternplate to assure unifornity.

Blanks for the spokes slmuld be cut slightly

oversize and aEout Ye in. longer than the

frnished leneth. After shaping' they are

-cut

to e:<act length- \flheel hubs are hrrned

to

thd dimensions

given and fitted with a

metal ferule, after which a hole'is drilled

in the srnall end of each spoke to take a

single brad. Before

eluing

the spokes into

t.be hub a trial assembly is made of each

wheel

'With

correct fit assured,

glue the

spokes into the hubs, trial-fit the wheel

rims and

glue and brad these in place. Make

sure that-the spokes are uniformly spaced

on the rim an4 before the

glue dries, slip

tlre wheel on ttre axle and check for true

running. If the rim is out at any pointt

EXAGGENAIED

ilAGNAN |ttus.

TRAIING SPRING ACfION

EIAKC.HANDIE

SKET

%" x l i " x 3 '

OVAI SECTIoN

NN STNAPS

mACrEl

ASSEiABY

o

IEATA

PEDAT

TAKE HANDIE

, { . " xW

so. sFcfroN

running at rieht ansles. Scroll saw the

rims to-finish slze, or,-if a lathe is available,

the rims'may be turned accurately. The

wheel spokes are of ovalsection and slight-

ty tapered toward the rim. IIae hub end of

the spoke is flat tapered, or wtdge-shaped,

and it is very itnportant to eheck each

clamp the wheel to the edge of a table top

and weight the portion of t}.e rim that is

out of true.

the tires are cut from 16-ga. sheet metal

to a ?6-in. \pidth and are bent cold around

a circular tronn of the same diameten as the

outside diameter of the wheel rim" the

DEfAIL'A'

Yr- XVt" X

%"36-

aorl

;f

th.-

FEnr0u

LFtr{o'

'ol\

GTUED W|rH GNA|N

AT. NIGHT ANGTGS

BRAZED AND

GROUND

'IUSH

12 SPOKE$fNONT WHEA

SEVEL

suGrmY

'O START

nnE

rtr

ends of the tire are overlapped

tzt

in. and

the

ioint

is brazed and

ground flush. Edges

oI the tire are then rounded slightly with

a file and smoothed with fine emerXr cloth.

Before shrinking the tire on the wheel rim

see that the l,atter is srrrootfi and true and

beveled slightly on the inside edge Then

heat the tire at several

points

and force it

carefully over the rim.- If necessarJr use

several snall C-clamps

-equdly

spaeed

about the rim.

Paint the running gear

before assem-

bling the body and gear.

A neat

job

of

painting always emphasizes fine workman-

ship and on work of this kindmostmodel-

makers use tinting eolors ground

in oil for

the primer. Some craftsmen even

go

so

far as to assemble the iob completelv for

trial fit of all pab, theh disass-emble and

paint each part separately. This method

assures- a-paint

job

,of

professional quality.

Most of the easily detaehed hardware and

the smaller wooden parts

of the nrnning

gear

can be dipped in the pgint

and hung

to dry on a wili or separate hooks. tr aoy

case continue dipping the parts until three

coats of paint have been applied in this

manner. For dipping, tlre paint should be

thinned to a priming-coat

consistency. Al-

low the excess paint

to drain back into the

container before hangrng the part to dry.

Be sure that you use a prepared thinner

recommended by the manufacturer of the

paint Of course, on this particular job

it

is not practical to disassemble the body for

dip-painting. Follow Figs. 3 and 4 and

use colors gfound in oil or sign-painters'

colors and apply with small round brusftres,

faklng great care on the flat surfaces to tray

on a thin uniform coating. Seats and inte-

rior are

painted

a medium brown to simu-

late khal<i-colored upholstery and body

lining.

Pick up any ercess paint in ttre

corners and at the edges with an extra dr57

brush and carefully srnooth out any laps or

sags that may develop on the verticafsur-

faees. Allow each coat

plenty

of time to

dry thoroughly, and before

iainting

any

parts on which an acid-soldering flux has

been used, FiS. 11, neutralize the acid by

washing the parts in hot water.

After the last coat of

paint

has had time

to dry asserrble the iunning gear

and

mount the body. firen make and fit the

Iamps,fig..3, and the tongue and whippl+.

tregs. Dip these parts in paint successively

in the same manner as described and allow

to dry before fastening them permanently

in plice.

ff yorr

do not feel iqual to th;

lettering and the fine-line stripins on the

wheels it's a

good

idea to obtarn 6e senv-

ices of a sigrr painter. Ilowever, the land-

scapes on the door panels

can be eut from

duplieate colored iliusbatioas and pasted

on.

The model should be mounted oa a base

as shown in Figs. l and 2. A\e base adds

eonsiderably to the attractiveness of the

model and helps to safeguard it from darn-

age. Attach the model

permanentlv

to the

base with sall metal- clips bent- to the

shape of the wheel rims andfastened to the

base with mall screws. Staia and finish

the base with slpar varnish.

r4 sPorcs

lN nEAn

Das könnte Ihnen auch gefallen

- Masonic Lodge Symbols EducationDokument10 SeitenMasonic Lodge Symbols Educationedpoli5205100% (2)

- Douglas DB-7 BomberDokument8 SeitenDouglas DB-7 BomberAviation/Space History Library50% (2)

- Mario S Frog Suit - pdf4Dokument13 SeitenMario S Frog Suit - pdf4Carla OlivieriNoch keine Bewertungen

- Alter Ego #5Dokument30 SeitenAlter Ego #5Eduardo PereiraNoch keine Bewertungen

- Sketching Faces FasterDokument16 SeitenSketching Faces FasterOla Gf Olamit97% (30)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideVon EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNoch keine Bewertungen

- Home Broadcast Tube AM Transmitter Kit: About ConstructionDokument5 SeitenHome Broadcast Tube AM Transmitter Kit: About ConstructionA Daniel LazarescuNoch keine Bewertungen

- Digital Navy USS Arizona (2002 Ver. 1-250) PDFDokument44 SeitenDigital Navy USS Arizona (2002 Ver. 1-250) PDFbamboobuckNoch keine Bewertungen

- C&NW RS36 HO Scale ModelDokument12 SeitenC&NW RS36 HO Scale ModelpwmvsiNoch keine Bewertungen

- CartoonDokument256 SeitenCartoonBarnali Dutta100% (1)

- RFFS-100 Micro Pitts SpecialDokument6 SeitenRFFS-100 Micro Pitts Specialmam73Noch keine Bewertungen

- Kid-Powered "Squaris" WheelDokument6 SeitenKid-Powered "Squaris" WheelzebrazeroNoch keine Bewertungen

- Vintage Playground Plans 1950s PDFDokument39 SeitenVintage Playground Plans 1950s PDFAlexandre Mello100% (1)

- Motor A Vapor (Vapeur - Vertical Steam Engine)Dokument16 SeitenMotor A Vapor (Vapeur - Vertical Steam Engine)migss1074Noch keine Bewertungen

- 15 Foot SailboatDokument4 Seiten15 Foot SailboatAntónio OliveiraNoch keine Bewertungen

- Aquarail JetskiDokument6 SeitenAquarail Jetskitony_williams_4Noch keine Bewertungen

- Gee Bee Super SportsterDokument8 SeitenGee Bee Super SportsterAviation/Space History LibraryNoch keine Bewertungen

- Curtiss P-40 WarhawkDokument9 SeitenCurtiss P-40 WarhawkAviation/Space History LibraryNoch keine Bewertungen

- Amazing Stories v04n08 (1929-11.experimenter) (Coverless) (AKv1.0)Dokument95 SeitenAmazing Stories v04n08 (1929-11.experimenter) (Coverless) (AKv1.0)williamNoch keine Bewertungen

- Woodworking Plans Farm Truck ToyDokument11 SeitenWoodworking Plans Farm Truck Toyfrankcorbet100% (6)

- 16 Foot Apache Outboard - PlansDokument8 Seiten16 Foot Apache Outboard - PlansRolando DaclanNoch keine Bewertungen

- 3 in Shaper PDFDokument5 Seiten3 in Shaper PDFRob NairNoch keine Bewertungen

- Taylorcraft L-2 GrasshopperDokument10 SeitenTaylorcraft L-2 GrasshopperAviation/Space History Library100% (1)

- Cards OldDokument2 SeitenCards OldfxtmrjmmorkdvqcjiyNoch keine Bewertungen

- AirHopper - A Free-Flight Model Airplane (Glider)Dokument7 SeitenAirHopper - A Free-Flight Model Airplane (Glider)Bob KowalskiNoch keine Bewertungen

- Culver Cadet MonoplaneDokument5 SeitenCulver Cadet MonoplaneAviation/Space History LibraryNoch keine Bewertungen

- A Lai of The Dying Cow Hand's Lamentation'Dokument54 SeitenA Lai of The Dying Cow Hand's Lamentation'Guigno SchmuerzNoch keine Bewertungen

- s4 History of Music Homework AssignmentsDokument5 Seitens4 History of Music Homework AssignmentsJonathan Scott100% (1)

- Adventures in High FantasyDokument180 SeitenAdventures in High FantasyxnexusNoch keine Bewertungen

- Build This Brewster F2A-1 Flying Scale ModelDokument10 SeitenBuild This Brewster F2A-1 Flying Scale ModelJose Antonio Lobo Gerardino100% (1)

- ERCO 415-A ErcoupeDokument8 SeitenERCO 415-A ErcoupeAviation/Space History LibraryNoch keine Bewertungen

- Daredevil's Delight PDFDokument7 SeitenDaredevil's Delight PDFJun VargasNoch keine Bewertungen

- 3 in 1 MachineDokument5 Seiten3 in 1 Machinemarandan85100% (1)

- Gyro Skipper PlansDokument5 SeitenGyro Skipper PlansJayantha KandegamaNoch keine Bewertungen

- Stephen Baker - Visual Persuasion (1961)Dokument268 SeitenStephen Baker - Visual Persuasion (1961)momir6856100% (4)

- N12electricalexperi06gern 1206 PDFDokument92 SeitenN12electricalexperi06gern 1206 PDFljubazNoch keine Bewertungen

- Junior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build DiggerDokument5 SeitenJunior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build Diggermagatsu2099Noch keine Bewertungen

- (1903) Driving: Stage-Coaching in Early TimesDokument459 Seiten(1903) Driving: Stage-Coaching in Early TimesHerbert Hillary Booker 2nd100% (1)

- House & Home DefinedDokument33 SeitenHouse & Home DefinedMaria Riza Maaya Laurdaus100% (1)

- Mini Super Am Radio (Modern Mechanix v18n03 (1937.07)Dokument5 SeitenMini Super Am Radio (Modern Mechanix v18n03 (1937.07)Peeters Guy100% (1)

- Station Wagon SkiffDokument8 SeitenStation Wagon SkiffJim100% (3)

- Submarine / From Mechanix IllustratedDokument9 SeitenSubmarine / From Mechanix IllustratedboomixNoch keine Bewertungen

- Bensen b8 PDFDokument8 SeitenBensen b8 PDFmaxNoch keine Bewertungen

- A Guide To Weapon SmithDokument41 SeitenA Guide To Weapon SmithYato LeoNoch keine Bewertungen

- Campus Paper Sections ExplainedDokument25 SeitenCampus Paper Sections Explainedmaria cielo bataanon88% (8)

- Cessna 140Dokument18 SeitenCessna 140getuliobraiaNoch keine Bewertungen

- Bonnie Two SailboatDokument18 SeitenBonnie Two SailboatJim96% (27)

- Foot-Powered Scroll SawDokument8 SeitenFoot-Powered Scroll SawJan Steinman100% (1)

- Catalog UbertiDokument60 SeitenCatalog UbertiRoberto Cisneros Mendoza100% (1)

- Chinese pagodas and the Chicago Tribune TowerDokument8 SeitenChinese pagodas and the Chicago Tribune TowerJehan Mohamad100% (1)

- Old Steam LocomotiveDokument55 SeitenOld Steam LocomotivemmkattaNoch keine Bewertungen

- Toa QuestionnaireDokument6 SeitenToa QuestionnaireIsha AguileraNoch keine Bewertungen

- G0355Dokument52 SeitenG0355sjdarkman1930100% (1)

- VRB TS1Dokument448 SeitenVRB TS1MangBedjo100% (1)

- Rizal's Brindis Speech: Honoring Philippine Artists Luna and HidalgoDokument3 SeitenRizal's Brindis Speech: Honoring Philippine Artists Luna and HidalgoArnold Venturina100% (1)

- Interstate Cadet MonoplaneDokument7 SeitenInterstate Cadet MonoplaneAviation/Space History LibraryNoch keine Bewertungen

- The Stinson Reliant SR-6 - A Free-Flight Model AirplaneDokument13 SeitenThe Stinson Reliant SR-6 - A Free-Flight Model AirplaneBob KowalskiNoch keine Bewertungen

- Baby DurationDokument5 SeitenBaby DurationWilmer Chinomes PinzónNoch keine Bewertungen

- Curtiss R-6 RacerDokument9 SeitenCurtiss R-6 RacerAviation/Space History LibraryNoch keine Bewertungen

- 12thpak InstrutionsDokument5 Seiten12thpak InstrutionsJavier Rodriguez PaezNoch keine Bewertungen

- Cessna 195Dokument2 SeitenCessna 195MehdiNoch keine Bewertungen

- Curtiss O-52 - A Free-Flight Model AirplaneDokument5 SeitenCurtiss O-52 - A Free-Flight Model AirplaneBob KowalskiNoch keine Bewertungen

- Vultee A-31 VengeanceDokument4 SeitenVultee A-31 VengeanceAviation/Space History LibraryNoch keine Bewertungen

- Full Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full ChapterDokument22 SeitenFull Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full Chapterhomer.owens120100% (24)

- 1/10 Scale Sport Hydro 1969 Notre DameDokument2 Seiten1/10 Scale Sport Hydro 1969 Notre Damewidian rienandaNoch keine Bewertungen

- North American BC-1 TrainerDokument7 SeitenNorth American BC-1 TrainerAviation/Space History LibraryNoch keine Bewertungen

- De Havilland DH4Dokument3 SeitenDe Havilland DH4RosanaNoch keine Bewertungen

- The Pacemaker - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Dokument11 SeitenThe Pacemaker - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Bob KowalskiNoch keine Bewertungen

- Full Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full ChapterDokument22 SeitenFull Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full Chaptermary.grooms166100% (27)

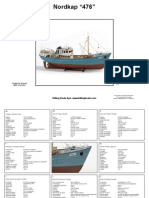

- BB476 Nordkap InstructionDokument19 SeitenBB476 Nordkap InstructionMunteanuCNoch keine Bewertungen

- GSAS V2.1 DES IE 09 Low Emitting MaterialsDokument2 SeitenGSAS V2.1 DES IE 09 Low Emitting MaterialsManiKandanNoch keine Bewertungen

- The History and Practice of Production DesignDokument8 SeitenThe History and Practice of Production DesignKissBalázsNoch keine Bewertungen

- Ongole Bypass Cost Estimation 11.08.2017Dokument34 SeitenOngole Bypass Cost Estimation 11.08.2017BhavaniPrasad100% (1)

- Sketch Your Dreams Lesson PlanDokument5 SeitenSketch Your Dreams Lesson Planapi-356117490100% (1)

- Bernstein - 99 PoetsDokument277 SeitenBernstein - 99 PoetsJulián Herbert100% (2)

- Toyo Springs LTD (Action Plan Lucknow)Dokument9 SeitenToyo Springs LTD (Action Plan Lucknow)Abhishek ChauhanNoch keine Bewertungen

- Renaissance Web Quest 2Dokument2 SeitenRenaissance Web Quest 2api-260397974Noch keine Bewertungen

- History of Urban Planning in 40 CharactersDokument1 SeiteHistory of Urban Planning in 40 CharactersKarla AmarNoch keine Bewertungen

- Module On Art History and Art Movements (Part 1)Dokument8 SeitenModule On Art History and Art Movements (Part 1)Paul macaraegNoch keine Bewertungen

- DINH, Giang - Origami-B-21Dokument1 SeiteDINH, Giang - Origami-B-21Zebek McKlauNoch keine Bewertungen

- Title: Bedsheet TensionerDokument6 SeitenTitle: Bedsheet TensionerRA Mikael Master MindNoch keine Bewertungen

- Advertisng Design & PrinciplesDokument48 SeitenAdvertisng Design & PrinciplesDiana Burns100% (11)

- IKEA Catalogue 2011Dokument189 SeitenIKEA Catalogue 2011Ahmed SamiNoch keine Bewertungen

- Material and Equipment Standard: IPS-M-TP-165Dokument8 SeitenMaterial and Equipment Standard: IPS-M-TP-165RezaNoch keine Bewertungen

- ARK Survival Evolved CheatsDokument8 SeitenARK Survival Evolved CheatsEss GintokiNoch keine Bewertungen

- Architectural Building MaterialsDokument239 SeitenArchitectural Building MaterialsLaurence CalpoturaNoch keine Bewertungen

- Ge6 Act 7Dokument2 SeitenGe6 Act 7Dummdz SreenNoch keine Bewertungen

- Modern Art: Ars Libri LTDDokument47 SeitenModern Art: Ars Libri LTDju1976Noch keine Bewertungen

- S.Curcic-VISIBLE AND INVISIBLE ASPECTS OF BUILDINGDokument17 SeitenS.Curcic-VISIBLE AND INVISIBLE ASPECTS OF BUILDINGMarija ObradovicNoch keine Bewertungen