Beruflich Dokumente

Kultur Dokumente

PQR Format

Hochgeladen von

ravi0009880%(5)80% fanden dieses Dokument nützlich (5 Abstimmungen)

3K Ansichten2 SeitenCopyright

© © All Rights Reserved

Verfügbare Formate

XLS, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

80%(5)80% fanden dieses Dokument nützlich (5 Abstimmungen)

3K Ansichten2 SeitenPQR Format

Hochgeladen von

ravi00098Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

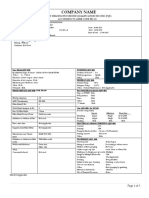

Procedure Qualification Record No : Revision: Dated:

WPS No (Draft) : Revision: Dated:

Welding Process(es) :

:

JOINTS (QW - 402)

Joint Design :

Backing :

Backing Material (Type) :

BASE METAL (QW -403) POST WELD HEAT TREATMENT (QW-407)

Material Spec. : Temperature :

Type or Grade : Soaking Time :

P. No : to P. No. : Heating Rate :

Thickness of Test Coupon : Cooling Rate :

Diameter of Test Coupon : Loading Temp. :

Other : Unloading Temp. :

FILLER METALS (QW-404) GAS (QW -408)

GTAW SMAW Gas %Composition Flow Rate

SFA Specification : 5.18 5.1 Shielding :

AWS Classification : ER 70S-2 E 7018 Trailing :

Filler Metal F.No. : 6 4 Backing :

Weld Metal Analysis A.No: 1 1 ELECTRICAL CHARACTERISTICS (QW-409)

Size of Filler Metal : 2.5 mm 2.5&3.15mm Current :

Other : NONE NONE Polarity :

Weld Metal Thickness : 4 mm 6 mm Amps. :

Max. weld reinforcement : NONE 2.4 mm Volts :

POSITION (QW-405) Tungsten Electrode Size :

Position of Groove : and type

: TECHNIQUE (QW-410)

Other : Travel Speed :

String or Weave Bead :

PREHEAT (QW - 406) Oscillation :

Preheat Temp. : Multipass or Single Pass (per side) :

Interpass Temp. : Single or Multiple Electrodes :

Other : Other :

NEO STRUCTO CONSTRUCTION LTD,

SURAT.

Types (Manual, Automatic, Semi-Auto)

PROCEDURE QUALIFICATION RECORD(PQR)

(As per ASME Section IX)

Weld Progression (Uphill /Downhill)

PQR-01 Page 1 of 2 NSC/QA/PQR/01 R0

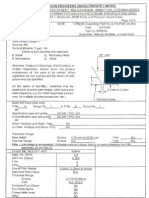

NEO STRUCTO CONSTRUCTION LTD,

SURAT.

PROCEDURE QUALIFICATION RECORD(PQR)

(As per ASME Section IX)

T1 21.00 202.65

T2 20.70 194.58

Root Bend test (RB-1)

Root Bend test (RB-2)

Face Bend test (RB-2)

Face Bend test (RB-2)

TOUGHNESS TEST (QW -170)

Joules Mils

FILLET WELD TEST (QW -180)

Result Satisfactory YES / NO

Penetration into Parent Metal YES / NO

Macro Result

Welder Name: . Stamp No: .

Test Conducted by: . Laboratory Test No. .

Note(s):

We certify that the statements in this record are correct and that the test welds were prepared, welded and

tested in accordance with the requirements of Section IX of the ASME Code.

Signature

Name

Date

TENSILE STRENGTH (QW-150)

NSCL CLIENT THIRD PARTY INSP.

Area (mm

2

)

545.3

552.5

110,500

Specimen No

Width

(mm)

Thickness

(mm)

GUIDED-BEND TEST (QW-160)

Type and Figure No. Result

Drop Weight

Break (Y/N)

9.65

9.40

Specimen

Size

Test Temp.

% Shear

Impact Value

Specimen No

Notch

Location

Broken on

Parent Metal

Ultimate Load

(N)

107,500

Broken on

Parent Metal

Ultimate

Tensile

Strength

(N/mm

2

)

Type of Failure

& Location

PQR-01 Page 2 of 2 NSC/QA/PQR/01 R0

Das könnte Ihnen auch gefallen

- Fundamental Theories of PhysicsDokument881 SeitenFundamental Theories of Physicscibercafejava100% (4)

- PQR Asme BlankDokument3 SeitenPQR Asme Blankamirul8686Noch keine Bewertungen

- WPS For Different Materail by BhelDokument176 SeitenWPS For Different Materail by Bhelsaisssms911691% (46)

- WPS For Structure Mild Steel Fillet WeldDokument2 SeitenWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- Welding Procedure Specification - TemplateDokument2 SeitenWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (3)

- WPS-46 - Gtaw & Smaw Tig + SmawDokument8 SeitenWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNoch keine Bewertungen

- Procedure Qualification Record (PQR)Dokument3 SeitenProcedure Qualification Record (PQR)Senthil KumaranNoch keine Bewertungen

- Welder Qualification Test Certificate for Mohan ReddyDokument2 SeitenWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- Welding Procedure Specification Pipe - 6GDokument3 SeitenWelding Procedure Specification Pipe - 6Gdndudc96% (27)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDokument1 Seite193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- Blyton Enid Noddy 5 Well Done Noddy! 1952Dokument71 SeitenBlyton Enid Noddy 5 Well Done Noddy! 1952carlosathinopolos75% (12)

- Weld Joint 1Dokument81 SeitenWeld Joint 1rajibali27100% (1)

- Weld MapDokument4 SeitenWeld MapSatish Keskar50% (2)

- Impact TestingDokument27 SeitenImpact Testingapi-3764139100% (2)

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Dokument5 SeitenWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazNoch keine Bewertungen

- WPS TITLEDokument2 SeitenWPS TITLERichard Periyanayagam86% (14)

- Paint DefectsDokument129 SeitenPaint Defectsmohammad100% (6)

- WPS (AsmeDokument8 SeitenWPS (AsmeMohammad Elhedaby100% (6)

- WPS Format For ASME IX - PQR-AllDokument3 SeitenWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Dokument48 SeitenQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- WPS PQR WPQ PeiplDokument16 SeitenWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- WPS For Structure Mild Steel Fillet Weld PDFDokument2 SeitenWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNoch keine Bewertungen

- GTAW Welding Procedure SpecificationDokument3 SeitenGTAW Welding Procedure SpecificationVimin Prakash100% (1)

- Fundamentals of Professional WeldingDokument213 SeitenFundamentals of Professional Weldingapi-3856939Noch keine Bewertungen

- EC3 - Steel-Prof WalkerDokument42 SeitenEC3 - Steel-Prof WalkerAhmad Farhan HamzahNoch keine Bewertungen

- PQRDokument2 SeitenPQRalokbdasNoch keine Bewertungen

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Dokument6 SeitenMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNoch keine Bewertungen

- WPS Multi GMAW FCAW PDFDokument2 SeitenWPS Multi GMAW FCAW PDFwentroprem75% (4)

- QW-483 BlankDokument2 SeitenQW-483 BlankCraftyBob100% (1)

- WPS 316 LDokument4 SeitenWPS 316 Llaz_k100% (2)

- Welder Id SampleDokument1 SeiteWelder Id Sampledevendrasingh202157% (7)

- WQT Record for Pipeline Welder QualificationDokument99 SeitenWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- Using Excel For Soil TestingDokument18 SeitenUsing Excel For Soil TestingQaiser Abbas100% (3)

- Welder Performance Qualification-Interactive Form QW-484ADokument1 SeiteWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- According To ASME IX: Welding Procedure Specification (W.P.S)Dokument4 SeitenAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNoch keine Bewertungen

- Coating Faults AADokument82 SeitenCoating Faults AAAbrianto Akuan100% (5)

- WPSDokument3 SeitenWPSKhurram Burjees100% (1)

- WPS PQR A36.20Dokument5 SeitenWPS PQR A36.20gchaves504100% (2)

- PQR Gmaw3gDokument4 SeitenPQR Gmaw3gdevendrasingh2021100% (3)

- ESAB Puls Mig Welding Hand BookDokument20 SeitenESAB Puls Mig Welding Hand BookLeonardo De La HudiNoch keine Bewertungen

- WPS & PQRDokument46 SeitenWPS & PQRJohn Candidate CIns88% (8)

- WPS PQRDokument23 SeitenWPS PQRHashim Khan88% (8)

- WPSDokument6 SeitenWPSNur Wijianto100% (1)

- Coating Failure Presentation 01 PDFDokument32 SeitenCoating Failure Presentation 01 PDFravi00098Noch keine Bewertungen

- Einstein, Albert - A New Determination of Molecular Dimensions - 1905Dokument16 SeitenEinstein, Albert - A New Determination of Molecular Dimensions - 1905nicopanzNoch keine Bewertungen

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Dokument5 SeitenWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Valves and PipingDokument118 SeitenValves and PipingMahdi Daly100% (1)

- 6GR WPS PQRDokument15 Seiten6GR WPS PQRKiukStaks100% (6)

- WPS-PQR (Er309l Mo)Dokument4 SeitenWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS and PQRDokument4 SeitenWPS and PQRdandiar1Noch keine Bewertungen

- WPS for 316L Pipe WeldingDokument3 SeitenWPS for 316L Pipe WeldingRichard Periyanayagam100% (3)

- WPS PQR FormatDokument1 SeiteWPS PQR FormatJatin Kamdar100% (2)

- 20 Welding RevisedDokument104 Seiten20 Welding Revisedravi00098Noch keine Bewertungen

- 20 Welding RevisedDokument104 Seiten20 Welding Revisedravi00098Noch keine Bewertungen

- PQRDokument2 SeitenPQRSreenivas Kamachi Chettiar100% (1)

- Fortin, Sebastian - Holik, Federico - Lombardi, Olimpia - López, Cristian - Quantum Worlds - Perspectives On The Ontology of Quantum Mechanics-Cambridge University Press (2019)Dokument411 SeitenFortin, Sebastian - Holik, Federico - Lombardi, Olimpia - López, Cristian - Quantum Worlds - Perspectives On The Ontology of Quantum Mechanics-Cambridge University Press (2019)hecaicedo77100% (2)

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDokument4 SeitenWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNoch keine Bewertungen

- Wps Gmaw SawDokument2 SeitenWps Gmaw Sawupedro26Noch keine Bewertungen

- Kou2003 PDFDokument6 SeitenKou2003 PDFGe EffgenNoch keine Bewertungen

- Fcaw 16 THKDokument5 SeitenFcaw 16 THKparesh2387Noch keine Bewertungen

- Val Caraig WPQTDokument1 SeiteVal Caraig WPQTMark Jason M. BrualNoch keine Bewertungen

- WPS E6013+e7018Dokument2 SeitenWPS E6013+e7018Anvesh Vaddi100% (1)

- A 36 WPSDokument2 SeitenA 36 WPSNaqqash Sajid100% (1)

- PT Kuwera Karya Me: PanduDokument2 SeitenPT Kuwera Karya Me: PanduGalang Pratama PutraNoch keine Bewertungen

- SS WPSDokument1 SeiteSS WPSMOHAMEDABBASNoch keine Bewertungen

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDokument6 SeitenProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNoch keine Bewertungen

- WPQ 282Dokument1 SeiteWPQ 282proxywarNoch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNoch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Noch keine Bewertungen

- PQR FormatDokument2 SeitenPQR FormatBE GNoch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNoch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNoch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNoch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Noch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Noch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNoch keine Bewertungen

- Barbara Delinsky-The Wedding Night PDFDokument217 SeitenBarbara Delinsky-The Wedding Night PDFravi00098Noch keine Bewertungen

- Con AirDokument156 SeitenCon Airravi00098Noch keine Bewertungen

- Hotel Sales Strategies To Effectively Increase RevenueDokument38 SeitenHotel Sales Strategies To Effectively Increase Revenueravi00098Noch keine Bewertungen

- NDT Radio Graphy Notes PDFDokument18 SeitenNDT Radio Graphy Notes PDFravi00098Noch keine Bewertungen

- RadioGraph Book 1Dokument33 SeitenRadioGraph Book 1Vicky SinghNoch keine Bewertungen

- 009 The Great Airport MysteryDokument67 Seiten009 The Great Airport Mysteryomar omarNoch keine Bewertungen

- Practices PipeDokument4 SeitenPractices PipeParag Naik100% (2)

- Stainless Pocket GuideDokument36 SeitenStainless Pocket GuidePukhraj DagaNoch keine Bewertungen

- Weld Chart 1Dokument4 SeitenWeld Chart 1ravi00098Noch keine Bewertungen

- Welding of Duplex SSDokument20 SeitenWelding of Duplex SSHermansyah PutraNoch keine Bewertungen

- Welding Reference To Sec-IXDokument22 SeitenWelding Reference To Sec-IXVijayananda AnandaNoch keine Bewertungen

- An Introduction To RadiographyDokument52 SeitenAn Introduction To RadiographyAmit PalaliyaNoch keine Bewertungen

- Measure Optical Density of X-Ray FilmsDokument2 SeitenMeasure Optical Density of X-Ray FilmsthisisghostactualNoch keine Bewertungen

- Schubert PDFDokument66 SeitenSchubert PDFdattu33Noch keine Bewertungen

- PaintCure PDFDokument8 SeitenPaintCure PDFmahendraNoch keine Bewertungen

- W Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523Dokument18 SeitenW Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523ravi00098Noch keine Bewertungen

- Husain Al Muslim Saudi Aramco PDFDokument34 SeitenHusain Al Muslim Saudi Aramco PDFravi00098Noch keine Bewertungen

- Welding Power SourcesDokument6 SeitenWelding Power SourcesM.IBRAHEEMNoch keine Bewertungen

- Elcometer 456 User Manual PDFDokument76 SeitenElcometer 456 User Manual PDFchaparal100% (1)

- Freeboard Guidelines for DamsDokument11 SeitenFreeboard Guidelines for DamsSouvik DasNoch keine Bewertungen

- Failure Analysis of Gas Compressor Bolt PistonDokument5 SeitenFailure Analysis of Gas Compressor Bolt PistonBenget Manullang100% (1)

- Nuclear Physics Boson Expansion ComparisonDokument16 SeitenNuclear Physics Boson Expansion Comparisonarturo_C_MNoch keine Bewertungen

- 01 - Cryogenics - Nakai PDFDokument63 Seiten01 - Cryogenics - Nakai PDFSaumya RanjanNoch keine Bewertungen

- Ch01 1Dokument33 SeitenCh01 1Sumihar SimangunsongNoch keine Bewertungen

- Chemical Basbvbms of Pharmacology An Introduction To Pharmacodynamics 1000160027Dokument394 SeitenChemical Basbvbms of Pharmacology An Introduction To Pharmacodynamics 1000160027Andres ZareNoch keine Bewertungen

- AccelerationDokument8 SeitenAccelerationSteveNoch keine Bewertungen

- U2 - L10 Stress Isobar or Pressure Bulb PDFDokument6 SeitenU2 - L10 Stress Isobar or Pressure Bulb PDFศิวาเวช อบมาNoch keine Bewertungen

- The Bernoulli Equation & Crocco’s TheoremDokument4 SeitenThe Bernoulli Equation & Crocco’s TheoremJohn BirdNoch keine Bewertungen

- MATLABDokument227 SeitenMATLABRohit DNoch keine Bewertungen

- CHP 2 Electric PotentialDokument21 SeitenCHP 2 Electric PotentialSyahshaiNoch keine Bewertungen

- Maths TUT 7Dokument1 SeiteMaths TUT 7Rahul SehgalNoch keine Bewertungen

- M.Sc. Physics SyllabusDokument26 SeitenM.Sc. Physics SyllabusRevolution WorldNoch keine Bewertungen

- Biology Exam 4 Study GuideDokument12 SeitenBiology Exam 4 Study GuideKhusbu PatelNoch keine Bewertungen

- Tame Process BasicsDokument10 SeitenTame Process BasicsD'Bayour Toke OsuolaleNoch keine Bewertungen

- LESSON Plan in Science (TTL2)Dokument5 SeitenLESSON Plan in Science (TTL2)Rosa LegaraNoch keine Bewertungen

- Ch5 - 2 Relative VelocityDokument22 SeitenCh5 - 2 Relative Velocitym_er100Noch keine Bewertungen

- P525/2 Chemistry Paper 2: Uganda Advanced Certificate of Education Page 1Dokument8 SeitenP525/2 Chemistry Paper 2: Uganda Advanced Certificate of Education Page 1ArthurNoch keine Bewertungen

- Moment of Inertia - Study Materials: WWW - Examsdaily.In ExamsdailyDokument3 SeitenMoment of Inertia - Study Materials: WWW - Examsdaily.In ExamsdailymaanuNoch keine Bewertungen

- First Semester Engineering Degree Examination: Subject Title 21PHY12/22Dokument3 SeitenFirst Semester Engineering Degree Examination: Subject Title 21PHY12/22Nanditha ONoch keine Bewertungen

- Flow of Real FluidDokument52 SeitenFlow of Real FluidADIL BAHNoch keine Bewertungen

- Electric PotentialDokument26 SeitenElectric PotentialGlitchNoch keine Bewertungen

- Som 4Dokument11 SeitenSom 4Ronaldo Ulisi100% (1)

- Chapter 2 (Part A) Components of Instrument For Optical SpectrosDokument28 SeitenChapter 2 (Part A) Components of Instrument For Optical SpectrosaisyahNoch keine Bewertungen