Beruflich Dokumente

Kultur Dokumente

ASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied Linings

Hochgeladen von

Amanda Ariesta ApriliaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied Linings

Hochgeladen von

Amanda Ariesta ApriliaCopyright:

Verfügbare Formate

ASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With

Corrosion Resistant Integral Cladding Weld Metal !verla" Cladding or With A##lied

Linings

The rules in Part UCL are applicable to pressure vessels or vessel parts that are constructed of

base material with corrosion resistant integral or weld metal overlay cladding and to vessels and

vessel parts that are fully or partially lined inside or outside with corrosion resistant plate, sheet,

or strip, attached by welding to the base plates before or after forming or to the shell, heads,

and other parts during or after assembly into the completed vessel.1 These rules shall be used

in conjunction with the general reuirements in !ubsection " and with the specific reuirements

in the applicable Parts of !ubsection #.

Methods of $a%rication

$essels and vessel parts of base material with corrosion resistant integral or weld metal overlay

cladding construction shall be fabricated by welding. Corrosion resistant linings may be attached

by welding to vessels fabricated by any method of construction permitted under the rules of this

section.

Conditions of Service

!pecific chemical compositions, heat treatment procedures, fabrication reuirements, and

supplementary tests may be reuired to assure that the vessel will be suitable for the intended

service. This is particularly true for vessels subject to severe corrosive conditions, and also

those vessels operating in a cyclic temperature service. These rules do not indicate the

selection of an alloy suitable for the intended service or the amount of the corrosion allowance

to be provided. !ee also informative and nonmandatory guidance regarding metallurgical

phenomena in "ppendi% & of !ection '', Part (.

't is recommended that users assure themselves by appropriate tests, or otherwise, that the

alloy material selected and its heat treatment during fabrication will be suitable for the intended

service.

NOTE: Attention is called to the difficulties that have been experienced in welding materials

differing greatly in chemical composition.

)i%tures of uncertain chemical composition and physical properties are produced at the line of

fusion. !ome of these mi%tures are brittle and may give rise to crac*s during solidification or

afterward. To avoid weld embrittlement, special care is reuired in the selection of lining

material and welding electrodes, and in the application of controls over the welding process and

other fabrication procedures.

Materials

The base materials used in the construction of clad vessels and of those having applied

corrosion linings shall comply with the reuirements for materials given in UC!+,, U-+,, U.T+,,

or UL/+,.

'ntegral and /eld )etal 0verlay Clad )aterial

1a2 Clad material used in constructions in which the design calculations are based on the total

thic*ness including cladding 3see UCL+451c26 shall conform to one of the following specifications7

!"+4&5, Corrosion+8esisting Chromium9!teel Clad

Plate, !heet and !trip !"+4&:, Corrosion+8esisting Chromium9;ic*el !teel Clad Plate,

!heet and !trip

!"+4&,, ;ic*el and ;ic*el9#ase "lloy Clad !teel Plate.

'n addition to the above, weld metal overlay cladding may be used as defined in this Part.

1b2 #ase material with corrosion resistant integral or weld metal overlay cladding used in

constructions in which the design calculations are based on the base material thic*ness,

e%clusive of the thic*ness of the cladding material, may consist of any base material satisfying

the reuirements of UCL+1< and any metallic corrosion resistant integral or weld metal overlay

cladding material of weldable uality that in the judgment of the user is suitable for the intended

service.

1c2 #ase material with corrosion resistant integral cladding in which any part of the cladding is

included in the design calculations, as permitted in UCL+451c2, shall show a minimum shear

strength of 4<,<<< psi 115= )Pa2 when tested in the manner described in the clad plate

specification. 0ne shear test shall be made on each such clad plate as rolled, and the results

shall be reported on the certified material test report.

/hen the composite thic*ness of the clad material is 5>: in. 11? mm2 or less, and@or when the

cladding metal thic*ness is nominally <.<A, in. 11.? mm2 or less, the B#ond !trengthC test, as

described in !"+4&5, !"+4&:, or !"+4&,, may be used in lieu of the bond B!hear !trengthC test

to fulfill the criteria for acceptable minimum shear strength, e%cept that the bend test specimen

shall be 11>4 in. 15= mm2 wide by not more than 5>: in. 11? mm2 in thic*ness and shall be bent,

at room temperature, through an angle of 1=< deg to the bend diameter provided for in the

material specifications applicable to the bac*ing metal. The results of the B#ond !trengthC test

shall be reported on the certified material test report.

1d2 " shear or bond strength test is not reuired for weld metal overlay cladding.

1e2 /hen any part of the cladding thic*ness is specified as an allowance for corrosion, such

added thic*ness shall be removed before mill tension tests are made.

/hen corrosion of the cladding is not e%pected, no part of the cladding need be removed before

testing, even though e%cess thic*ness seems to have been provided or is available as corrosion

allowance.

Lining

)aterial used for applied corrosion resistant lining may be any metallic material of weldable

uality that in the judgment of the user is suitable for the intended purpose.

Visit our site to do&nload http://code-pdf.com/asme-viii-div-1-part-ucl

Das könnte Ihnen auch gefallen

- Basics of Shell and Tube Heat Exchangers With PDFDokument12 SeitenBasics of Shell and Tube Heat Exchangers With PDFtruong cong truc100% (1)

- Miller RMDDokument4 SeitenMiller RMDRony Lesbt100% (1)

- NPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Dokument4 SeitenNPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Mr. ANoch keine Bewertungen

- Flange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartDokument6 SeitenFlange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartArya0% (1)

- Approved Weld Procedure SpecificationsDokument38 SeitenApproved Weld Procedure SpecificationsJohan0001Noch keine Bewertungen

- WeldDokument3 SeitenWeldSenthil SubramanianNoch keine Bewertungen

- Manage Structural Steel Production Using BarcodesDokument10 SeitenManage Structural Steel Production Using BarcodesajaymrNoch keine Bewertungen

- Travelling Band ScreensDokument2 SeitenTravelling Band ScreensIngénérie traitement des eauxNoch keine Bewertungen

- Swire Mini Containers Spec SheetDokument2 SeitenSwire Mini Containers Spec Sheetsopian320Noch keine Bewertungen

- This Is Very Common in Tank ConstructionDokument11 SeitenThis Is Very Common in Tank ConstructionsbmmlaNoch keine Bewertungen

- Wrought Carbon Steel Sleeve-Type Pipe Couplings: Standard Specification ForDokument5 SeitenWrought Carbon Steel Sleeve-Type Pipe Couplings: Standard Specification ForDeen ew100% (1)

- IIT Hyderabad Faculty Housing Design CalculationsDokument33 SeitenIIT Hyderabad Faculty Housing Design CalculationssmijusNoch keine Bewertungen

- PreheatDokument2 SeitenPreheatScott TrainorNoch keine Bewertungen

- Field Manual For Structural Bolting 5 5x8 5pdf 468332 7Dokument50 SeitenField Manual For Structural Bolting 5 5x8 5pdf 468332 7Mahmoud FawzyNoch keine Bewertungen

- IND 902 Product Selection GuideDokument8 SeitenIND 902 Product Selection Guideibson045001256Noch keine Bewertungen

- Manufacturing Head Types for Pressure Vessels and TanksDokument6 SeitenManufacturing Head Types for Pressure Vessels and TanksJohn MaldonadoNoch keine Bewertungen

- Pipe Wall Thickness ChartDokument0 SeitenPipe Wall Thickness ChartSiddiqui Abdul KhaliqNoch keine Bewertungen

- Demo Weld Cost Calc XL-UnprotectedDokument10 SeitenDemo Weld Cost Calc XL-UnprotectedA R0% (1)

- Flow Chart For SubsidyDokument1 SeiteFlow Chart For SubsidyAvinash MaheshwariNoch keine Bewertungen

- Coating or hydrotestingDokument4 SeitenCoating or hydrotestinggigiphi1Noch keine Bewertungen

- NDT of WeldsDokument4 SeitenNDT of WeldsVu Tung Linh100% (1)

- Ptfe Torque Chart Aps KitsDokument2 SeitenPtfe Torque Chart Aps KitsJo KingsNoch keine Bewertungen

- ASME B31.3 Piping Design - Part ADokument46 SeitenASME B31.3 Piping Design - Part AA_Uossef100% (1)

- Smith Tank & Steel: Leader in Above Ground Steel Tank ConstructionDokument5 SeitenSmith Tank & Steel: Leader in Above Ground Steel Tank ConstructionRinia DurrsakeNoch keine Bewertungen

- API Standard 1104 - Welding Guidelines and Inspection RequirementsDokument94 SeitenAPI Standard 1104 - Welding Guidelines and Inspection Requirementsmedkom2000Noch keine Bewertungen

- P 192.727 Abandonment or Inactivation of Facilities RevisionsDokument4 SeitenP 192.727 Abandonment or Inactivation of Facilities RevisionsnguyenNoch keine Bewertungen

- Stainless Steel 316l (SA240)Dokument2 SeitenStainless Steel 316l (SA240)Sugiarto SaptomoNoch keine Bewertungen

- ASME Sec I Cylinder Thickness and Pressure Calculation FormulasDokument1 SeiteASME Sec I Cylinder Thickness and Pressure Calculation Formulasramananrv123Noch keine Bewertungen

- Pipe & Mechanical InsulationDokument36 SeitenPipe & Mechanical InsulationMiguel Martinez GuerreroNoch keine Bewertungen

- Cu Ni CatalogDokument48 SeitenCu Ni CatalogbureqqNoch keine Bewertungen

- Heating With Coils and Jackets - Spirax SarcoDokument14 SeitenHeating With Coils and Jackets - Spirax SarcoWEN GIE KONGNoch keine Bewertungen

- Duplex Material PDFDokument4 SeitenDuplex Material PDFmengelito almonteNoch keine Bewertungen

- Requirement in EN ISO 1442 2017Dokument6 SeitenRequirement in EN ISO 1442 2017Sơn Nguyễn TháiNoch keine Bewertungen

- Catalogue Pipe Hangers SupportsDokument111 SeitenCatalogue Pipe Hangers SupportsIlija Runjajic100% (1)

- Bleed Ring - ANSI Class 150-2500 (In)Dokument2 SeitenBleed Ring - ANSI Class 150-2500 (In)ulfatNoch keine Bewertungen

- AGC Plibrico Monolithic RefractoriesDokument15 SeitenAGC Plibrico Monolithic RefractoriesUmashankar Govindappa0% (1)

- S o P-PipingDokument17 SeitenS o P-PipingPrakash TiwariNoch keine Bewertungen

- Pipeline Transportation Systems GuideDokument3 SeitenPipeline Transportation Systems GuideUmar KidaNoch keine Bewertungen

- U Tube BendDokument1 SeiteU Tube BendMangesh BanaleNoch keine Bewertungen

- BS 4504 Slip On Flanges PDFDokument7 SeitenBS 4504 Slip On Flanges PDFMaclean ArthurNoch keine Bewertungen

- Tank Specification ReferenceDokument13 SeitenTank Specification ReferenceA.Subin DasNoch keine Bewertungen

- Anaerobic Digester CoversDokument2 SeitenAnaerobic Digester CoversChris QueroNoch keine Bewertungen

- PIPING DESIGN & PLANT LAYOUT MANUAL SPECIFICATIONDokument24 SeitenPIPING DESIGN & PLANT LAYOUT MANUAL SPECIFICATIONzsmithNoch keine Bewertungen

- KL UHP Catalog 2011-02 PDFDokument30 SeitenKL UHP Catalog 2011-02 PDFaconibet9040Noch keine Bewertungen

- Codes For Vessels/Heat ExchangersDokument23 SeitenCodes For Vessels/Heat Exchangersegy pureNoch keine Bewertungen

- Optimum pipe purging for economy and qualityDokument3 SeitenOptimum pipe purging for economy and qualityshridharbshenoyNoch keine Bewertungen

- 07 Piping BOQDokument54 Seiten07 Piping BOQHRK65Noch keine Bewertungen

- CV Mechanical Engineer Muhammad Shafeeq highlights experienceDokument4 SeitenCV Mechanical Engineer Muhammad Shafeeq highlights experienceAzhar HussainNoch keine Bewertungen

- Basics of Pressure Vessel FabricationDokument50 SeitenBasics of Pressure Vessel Fabricationavik100% (1)

- Floating Flange Rubber Expansion Joints: Series 980Dokument8 SeitenFloating Flange Rubber Expansion Joints: Series 980Roland Bon IntudNoch keine Bewertungen

- Construction Supervisor II: Passbooks Study GuideVon EverandConstruction Supervisor II: Passbooks Study GuideNoch keine Bewertungen

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionVon EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNoch keine Bewertungen

- Painting Inspector: Passbooks Study GuideVon EverandPainting Inspector: Passbooks Study GuideNoch keine Bewertungen

- Corrosion Failures: Theory, Case Studies, and SolutionsVon EverandCorrosion Failures: Theory, Case Studies, and SolutionsNoch keine Bewertungen

- Fab & Erection Pro 20000klR1Dokument17 SeitenFab & Erection Pro 20000klR1Gandhi OnoNoch keine Bewertungen

- Quality Control Procedure Strcture-SSDokument16 SeitenQuality Control Procedure Strcture-SSKamran AliNoch keine Bewertungen

- Specification For Stainless Chromium-Nickel Steel-Clad Plate, Sheet, and StripDokument11 SeitenSpecification For Stainless Chromium-Nickel Steel-Clad Plate, Sheet, and Stripomsingh1988Noch keine Bewertungen

- specSPCT00rev01 PDFDokument10 SeitenspecSPCT00rev01 PDFharsh_1582Noch keine Bewertungen

- ASTM B165 Standard Specification of Nickel-Copper Alloy Seamless Pipe and TubeDokument2 SeitenASTM B165 Standard Specification of Nickel-Copper Alloy Seamless Pipe and TubeAmanda Ariesta ApriliaNoch keine Bewertungen

- ABS Part 2 Materials and WeldingDokument2 SeitenABS Part 2 Materials and WeldingAmanda Ariesta ApriliaNoch keine Bewertungen

- RINA Part B Chapter 2Dokument2 SeitenRINA Part B Chapter 2Amanda Ariesta ApriliaNoch keine Bewertungen

- ASTM E96 Standard Test Methods For Water Vapor Transmission of MaterialsDokument2 SeitenASTM E96 Standard Test Methods For Water Vapor Transmission of MaterialsAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM E8M Standard Test Methods For Tension Testing of Metallic MaterialsDokument3 SeitenASTM E8M Standard Test Methods For Tension Testing of Metallic MaterialsAmanda Ariesta Aprilia0% (1)

- ASME VIII Div I Part ULW Pressure Vessels Fabricated by Layered ConstructionDokument2 SeitenASME VIII Div I Part ULW Pressure Vessels Fabricated by Layered ConstructionAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM E84 Standard Test Method For Surface Burning Characteristics of Building MaterialsDokument2 SeitenASTM E84 Standard Test Method For Surface Burning Characteristics of Building MaterialsAmanda Ariesta Aprilia0% (1)

- Astm A216Dokument2 SeitenAstm A216Amanda Ariesta ApriliaNoch keine Bewertungen

- Corrosion Control by Modern Weld Overlay TechnologyDokument3 SeitenCorrosion Control by Modern Weld Overlay TechnologyAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM C150 Standard Specification For Portland CementDokument2 SeitenASTM C150 Standard Specification For Portland CementAmanda Ariesta Aprilia100% (1)

- ASTM B164 Nickel-Copper Alloy Rod, Bar, and WireDokument3 SeitenASTM B164 Nickel-Copper Alloy Rod, Bar, and WireAmanda Ariesta ApriliaNoch keine Bewertungen

- Process Design For Chemical EngineerDokument2 SeitenProcess Design For Chemical EngineerAmanda Ariesta ApriliaNoch keine Bewertungen

- Fundamentals of Physical GeologyDokument2 SeitenFundamentals of Physical GeologyAmanda Ariesta ApriliaNoch keine Bewertungen

- RINA Part B Chapter 1Dokument3 SeitenRINA Part B Chapter 1Amanda Ariesta ApriliaNoch keine Bewertungen

- ABS Part 1 Scope and Conditions of ClassificationDokument2 SeitenABS Part 1 Scope and Conditions of ClassificationAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME IIA SA 47 Ferritic Malleable Iron CastingsDokument2 SeitenASME IIA SA 47 Ferritic Malleable Iron CastingsAmanda Ariesta ApriliaNoch keine Bewertungen

- RINA Structural Rules For Bulk Chapter 3 - Carriers Structural Design PrinciplesDokument2 SeitenRINA Structural Rules For Bulk Chapter 3 - Carriers Structural Design PrinciplesAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM B151 Copper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and BarDokument2 SeitenASTM B151 Copper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and BarAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME I Part PMB Requirements For Miniature BoilersDokument2 SeitenASME I Part PMB Requirements For Miniature BoilersAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM A193 A193M Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceDokument2 SeitenASTM A193 A193M Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM C139 Concrete Masonry Units For Construction of Catch Basins and ManholesDokument2 SeitenASTM C139 Concrete Masonry Units For Construction of Catch Basins and ManholesAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME V Article 5 Ultrasonic Examination Methods For MaterialsDokument2 SeitenASME V Article 5 Ultrasonic Examination Methods For MaterialsAmanda Ariesta Aprilia100% (1)

- ASTM D1265 Sampling Liquefied Petroleum Gases (Manual Method)Dokument2 SeitenASTM D1265 Sampling Liquefied Petroleum Gases (Manual Method)Amanda Ariesta Aprilia100% (1)

- Standard Specifications For Road, Bridge, and Municipal ConstructionDokument1 SeiteStandard Specifications For Road, Bridge, and Municipal ConstructionAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM A184 Welded Deformed Steel Bar Mats For Concrete ReinforcementDokument2 SeitenASTM A184 Welded Deformed Steel Bar Mats For Concrete ReinforcementAmanda Ariesta Aprilia100% (1)

- Fundamentals of Metallurgy by Seshadri SeetharamanDokument1 SeiteFundamentals of Metallurgy by Seshadri SeetharamanAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM A185 Standard Specification For Steel Welded Wire Reinforcement, Plain, For ConcreteDokument2 SeitenASTM A185 Standard Specification For Steel Welded Wire Reinforcement, Plain, For ConcreteAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME I Part PG General Requirements For All Methods of ConstructionDokument2 SeitenASME I Part PG General Requirements For All Methods of ConstructionAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME VIII Div 1 Part UCS Pressure Vessels Constructed of Carbon and Low Alloy SteelsDokument2 SeitenASME VIII Div 1 Part UCS Pressure Vessels Constructed of Carbon and Low Alloy SteelsAmanda Ariesta ApriliaNoch keine Bewertungen

- Kalzip FC Rainscreen SystemDokument8 SeitenKalzip FC Rainscreen SystemClef GonadanNoch keine Bewertungen

- Jaypee Cement Project ReportDokument29 SeitenJaypee Cement Project ReportPurnendu MishraNoch keine Bewertungen

- Study of The Reasons For Blocking C S Formation in The Presence of SO and Finding Ways To Overcome BlockagesDokument10 SeitenStudy of The Reasons For Blocking C S Formation in The Presence of SO and Finding Ways To Overcome BlockagesSyed Kazam RazaNoch keine Bewertungen

- Soil Liquefaction: A Critical State ApproachDokument7 SeitenSoil Liquefaction: A Critical State Approachvisio2004Noch keine Bewertungen

- Fundamentals of Fluid Mechanics: November 2015Dokument6 SeitenFundamentals of Fluid Mechanics: November 2015Sonam Lhendup DorjiNoch keine Bewertungen

- Archtechnik Bolt-On Balcony CatalogueDokument15 SeitenArchtechnik Bolt-On Balcony CatalogueSlinky BillNoch keine Bewertungen

- Air Conditioning: Working, and TypesDokument31 SeitenAir Conditioning: Working, and TypesVaibhav KudtalkarNoch keine Bewertungen

- Cold Bridge Free: Central Air Handling UnitDokument23 SeitenCold Bridge Free: Central Air Handling UnitErwin MaldoNoch keine Bewertungen

- "Room To Breathe" Kitchen and Bath Ideas 12.10Dokument6 Seiten"Room To Breathe" Kitchen and Bath Ideas 12.10Drury DesignNoch keine Bewertungen

- Chapter 1 - Basics of Heat Transfer PDFDokument14 SeitenChapter 1 - Basics of Heat Transfer PDFalhussenyNoch keine Bewertungen

- Current Trends and Industrial Applications of Polymer CompositesDokument85 SeitenCurrent Trends and Industrial Applications of Polymer CompositesSampath PSNoch keine Bewertungen

- Timber SeasoningDokument3 SeitenTimber SeasoningEllz LahCe Gimotea BaluyutNoch keine Bewertungen

- STRESS AND STRAIN DEFINITIONS AND CALCULATIONSDokument2 SeitenSTRESS AND STRAIN DEFINITIONS AND CALCULATIONSCalvin Jude GoveiaNoch keine Bewertungen

- Terrain Below Ground Drainage Dimensional DataDokument16 SeitenTerrain Below Ground Drainage Dimensional DatamealysrNoch keine Bewertungen

- Aashto - LRFD of Steel Beam Bridges Fatigue and FractureDokument56 SeitenAashto - LRFD of Steel Beam Bridges Fatigue and Fractureg401992100% (1)

- FLV 07 ISO Valve For FCV I/L I/L 40 800# 9032195Dokument7 SeitenFLV 07 ISO Valve For FCV I/L I/L 40 800# 9032195Manikandan elumalaiNoch keine Bewertungen

- 40RBW - Catalog - Single SkinDokument12 Seiten40RBW - Catalog - Single SkinPhuNguyenHoangNoch keine Bewertungen

- Ayesha KausarDokument27 SeitenAyesha KausarEstudiante2346Noch keine Bewertungen

- Experimental and Numerical Investigations of Athletic Prosthetic Feet Made of Fiber Glass Reinforced EpoxyDokument6 SeitenExperimental and Numerical Investigations of Athletic Prosthetic Feet Made of Fiber Glass Reinforced EpoxyMohsin NooriNoch keine Bewertungen

- SmartRHEO SeriesDokument2 SeitenSmartRHEO Seriesrajesh_rbpNoch keine Bewertungen

- Handbook Damage Models For ConcreteDokument13 SeitenHandbook Damage Models For ConcreteMilmxmenNoch keine Bewertungen

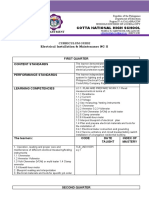

- Competencies Taught Updated g11 Eim NC IIDokument3 SeitenCompetencies Taught Updated g11 Eim NC IIfrancisco macatugobNoch keine Bewertungen

- FIVDokument60 SeitenFIVSaurabh Shukla100% (2)

- Model Series S, Din: Sempell Safety ValveDokument17 SeitenModel Series S, Din: Sempell Safety ValveKiattisak JaemjunNoch keine Bewertungen

- Precast HandbookDokument179 SeitenPrecast HandbookFernando LopezNoch keine Bewertungen

- Effect of Excess Air on Boiler EfficiencyDokument5 SeitenEffect of Excess Air on Boiler EfficiencyGovindarajan Chandrasekaran100% (1)

- Journal of Building Engineering: Tatheer Zahra, Julian Thamboo, Mohammad AsadDokument13 SeitenJournal of Building Engineering: Tatheer Zahra, Julian Thamboo, Mohammad AsadShafieNoch keine Bewertungen

- Production Service HookupDokument40 SeitenProduction Service Hookupray mojicaNoch keine Bewertungen

- CH 6 - Earthing Systems 2010-2011 A4Dokument27 SeitenCH 6 - Earthing Systems 2010-2011 A4norhaidarNoch keine Bewertungen