Beruflich Dokumente

Kultur Dokumente

ASTM B164 Nickel-Copper Alloy Rod, Bar, and Wire

Hochgeladen von

Amanda Ariesta ApriliaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASTM B164 Nickel-Copper Alloy Rod, Bar, and Wire

Hochgeladen von

Amanda Ariesta ApriliaCopyright:

Verfügbare Formate

ASTM B164 Nickel-Copper Alloy Rod, Bar, and Wire

This specification covers nickel-copper alloys UNS N04400 and N04405 in the form of hot-

worked and coldworked rod and bar in the conditions shown in Table 1 and cold-worked wire in

the conditions shown in Table 2

The val!es stated in inch-po!nd !nits are to be re"arded as the standard The val!es "iven in

parentheses are for information only

Referenced Documen!

ASTM Sandard!"

# 12$ Specification for Nickel-%opper &lloy 'UNS N04400( )late* Sheet* and Strip

+ , Test -ethods for Tension Testin" of -etallic -aterials

+ 1, Test -ethods for .ockwell /ardness and .ockwell S!perficial /ardness of -etallic

-aterials

+ 20 )ractice for Usin" Si"nificant 1i"its in Test 1ata to 1etermine %onformance with

Specifications

+ $2 Test -ethods for %hemical &nalysis of Nickel-%opper &lloys

+ 140 /ardness %onversion Tables for -etals

Miliary Sandard!"

-34-ST1-120 -arkin" for Shipment and Stora"e

-34-ST1-2$1 Nondestr!ctive Testin" .e5!irements for -etals

Terminolo#y

1efinitions of Terms Specific to This Standard6

$ar7material of rectan"!lar 'flats(* he8a"onal* or s5!are solid section !p to and

incl!din" 10 in '254 mm( in width and 19, in ':2 mm( and over in thickness in strai"ht

len"ths

rod7material of ro!nd solid section f!rnished in strai"ht len"ths

%ire7a cold-worked solid prod!ct of !niform ro!nd cross section alon" its whole len"th*

s!pplied in coiled form

NOTEHot-worked rectangular bar in widths 10 in. and under may be furnished as hot-rolled

late with sheared or cut edges in accordance with !ecification " 1#$% ro&ided the

mechanical roerty re'uirements of !ecification " 1() are met.

C&emical Compo!iion

The material shall conform to the composition limits specified in Table :

3f a prod!ct 'check( analysis is performed by the p!rchaser* the material shall conform to the

prod!ct 'check( analysis variations in Table :

Mec&anical 'roperie!

Mec&anical 'roperie!7The material shall conform to the mechanical properties specified in

Table 1 for rod or bar* or in Table 2 for wire

Dimen!ion! and 'ermi!!i$le (ariaion!

Diameer, T&ickne!!, or Wid&7The permissible variations from the specified dimensions as

meas!red on the diameter or between parallel s!rfaces of cold-worked rod and bar shall be as

prescribed in Table 4* and of hot-worked rod and bar as prescribed in Table 5 The permissible

variations in diameter of cold-worked wire shall be as prescribed in Table 2

)u-of-Round7/ot-worked rods and cold-worked rods 'e8cept ;for"in" 5!ality<( all si=es* in

strai"ht len"ths* shall not be o!t-of-ro!nd by more than one half the total permissible variations

in diameter shown in Table 4 and Table 5* e8cept for hot-worked rods 192 in '12$ mm( in

diameter and !nder* which may be o!t-of-ro!nd by the total permissible variations in diameter

shown in Table 5 >ire shall not be o!t-of-ro!nd by more than one-half the total permissible

variations shown in Table 2

Corner!7%old-worked bars will have practically e8act an"les and sharp corners

Mac&inin# Allo%ance! for *o-Worked Maerial!7 >hen the s!rfaces of hot-worked

prod!cts are to be machined* the allowances prescribed in Table $ are recommended for

normal machinin" operations

+en#&7The permissible variations in len"th of coldworked and hot-worked rod and bar shall

be as prescribed in Table ,

.ods and bars ordered to random or nominal len"ths will be f!rnished with either cropped or

saw-c!t ends? material ordered to c!t len"ths will be f!rnished with s5!are saw-c!t or machined

ends

Srai#&ne!!"

The permissible variations in strai"htness of cold worked rod and bar as determined by the

depart!re from strai"htness shall be as prescribed in Table 0

The permissible variations in strai"htness of precision strai"htened cold-worked rod as

determined by the depart!re from strai"htness shall be as prescribed in Table 10

3n determinin" strai"htness in the standard 42-in '10$-m( distance between s!pports or* when

specified* in determinin" strai"htness in len"ths not in e8cess of those shown in Table 10* the

rod shall be placed on a precision table e5!ipped with ball-bearin" rollers and a micrometer or

dial indicator The rod shall then be rotated slowly a"ainst the indicator* and the deviation from

strai"htness in any portion of the rod between the s!pports shall not e8ceed the permissible

variations prescribed in Table 10 The deviation from strai"htness 'throw in one revol!tion( is

defined as the difference between the ma8im!m and minim!m readin"s of the dial indicator in

one complete revol!tion of the rod

The permissible variations in strai"htness of hot worked rod and bar as determined by the

depart!re from strai"htness shall be as specified in Table 11

(i!i our !ie o do%nload http://goo.gl/Dpj74X

Das könnte Ihnen auch gefallen

- ASTM A127 Standard Specification For NickelDokument2 SeitenASTM A127 Standard Specification For NickelAmanda Ariesta ApriliaNoch keine Bewertungen

- Astm B 865 (Monel k500)Dokument7 SeitenAstm B 865 (Monel k500)Jarbas MoraesNoch keine Bewertungen

- ASTM B165 Standard Specification of Nickel-Copper Alloy Seamless Pipe and TubeDokument2 SeitenASTM B165 Standard Specification of Nickel-Copper Alloy Seamless Pipe and TubeAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME IIA SA 47 Ferritic Malleable Iron CastingsDokument2 SeitenASME IIA SA 47 Ferritic Malleable Iron CastingsAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM B127 Nickel-Copper Alloy Plate, Sheet, and StripDokument2 SeitenASTM B127 Nickel-Copper Alloy Plate, Sheet, and StripAmanda Ariesta ApriliaNoch keine Bewertungen

- Specification For Nickel-Copper Alloy Rod, Bar, and WireDokument12 SeitenSpecification For Nickel-Copper Alloy Rod, Bar, and WireAnilNoch keine Bewertungen

- Jis G3466Dokument9 SeitenJis G3466魏雨辰Noch keine Bewertungen

- Section B7 Steel Reinforcement For StructuresDokument4 SeitenSection B7 Steel Reinforcement For StructuresMehmet Lezgin BucakNoch keine Bewertungen

- Asme2b sb-160Dokument8 SeitenAsme2b sb-160jsskj12122Noch keine Bewertungen

- Nickel Rod and Bar: Standard Specification ForDokument6 SeitenNickel Rod and Bar: Standard Specification ForSrinivasan KrishnamoorthyNoch keine Bewertungen

- Low-Alloy Steel Deformed and Plain Bars For Concrete ReinforcementDokument6 SeitenLow-Alloy Steel Deformed and Plain Bars For Concrete ReinforcementEdisonCorderoNoch keine Bewertungen

- Scroll Confidential: Product Engineering SpecificationDokument5 SeitenScroll Confidential: Product Engineering SpecificationMike Fioren100% (1)

- B 134 PDFDokument5 SeitenB 134 PDFGrato Jr SingcoNoch keine Bewertungen

- Piping Shop Fabrication SpecificationDokument20 SeitenPiping Shop Fabrication SpecificationAnonymous NIICRJNoch keine Bewertungen

- ASME VIII Div 1 Part UCS Pressure Vessels Constructed of Carbon and Low Alloy SteelsDokument2 SeitenASME VIII Div 1 Part UCS Pressure Vessels Constructed of Carbon and Low Alloy SteelsAmanda Ariesta ApriliaNoch keine Bewertungen

- Astm b16 1992Dokument8 SeitenAstm b16 1992sansagithNoch keine Bewertungen

- Is 1239 - (2004) Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specification Steel TubeDokument14 SeitenIs 1239 - (2004) Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specification Steel TubevetrikamalNoch keine Bewertungen

- Astm A36 1977Dokument6 SeitenAstm A36 1977Ben Yie Min100% (1)

- Astm b127 (Monel 400)Dokument10 SeitenAstm b127 (Monel 400)Jarbas MoraesNoch keine Bewertungen

- B5-11 Standard Specification For High Conductivity Tough-Pitch Copper Refinery Shapes PDFDokument5 SeitenB5-11 Standard Specification For High Conductivity Tough-Pitch Copper Refinery Shapes PDFislamakthamNoch keine Bewertungen

- Astm A570 1979Dokument5 SeitenAstm A570 1979set_ltdaNoch keine Bewertungen

- Astm A0036 PDFDokument3 SeitenAstm A0036 PDFsuheilbugsNoch keine Bewertungen

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDokument19 SeitenSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13Noch keine Bewertungen

- ASTM A131 Standard Specification For Structural Steel For ShipsDokument1 SeiteASTM A131 Standard Specification For Structural Steel For ShipsAmanda Ariesta ApriliaNoch keine Bewertungen

- PCPL 0532 4 407 04 10Dokument9 SeitenPCPL 0532 4 407 04 10tceterexNoch keine Bewertungen

- Standard Specification For Threaded Couplings, Steel, Black or Zinc-Coatedi (Galvanized) Welded or Seamless, For Use in Steel PipeDokument1 SeiteStandard Specification For Threaded Couplings, Steel, Black or Zinc-Coatedi (Galvanized) Welded or Seamless, For Use in Steel PipeDavid Francisco Plata DuranNoch keine Bewertungen

- Astm B163 PDFDokument12 SeitenAstm B163 PDFSuellen FerreiraNoch keine Bewertungen

- Astm A178Dokument0 SeitenAstm A178flaviodellatorre0% (1)

- Astm B164 (1998) PDFDokument9 SeitenAstm B164 (1998) PDFElmerNoch keine Bewertungen

- Ti SPC Ohe Fasteners 0120Dokument31 SeitenTi SPC Ohe Fasteners 0120guri317Noch keine Bewertungen

- Astm A31 (1995)Dokument4 SeitenAstm A31 (1995)gsb2100% (1)

- Astm 510Dokument7 SeitenAstm 510Arnold Bohorquez Acevedo100% (1)

- Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)Dokument5 SeitenCartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)LUISALBERTO06011985Noch keine Bewertungen

- Is 1570 P1 - 1978Dokument13 SeitenIs 1570 P1 - 1978praveen_pattemNoch keine Bewertungen

- Astm b152 1997Dokument12 SeitenAstm b152 1997Jose Carlos Vaz CarneiroNoch keine Bewertungen

- Asme2b sb-171 DDFDokument8 SeitenAsme2b sb-171 DDFzingalehe25464Noch keine Bewertungen

- Steel Wire, High Tensile Strength, Cold Drawn: Standard Specification ForDokument3 SeitenSteel Wire, High Tensile Strength, Cold Drawn: Standard Specification ForJosé Ramón GutierrezNoch keine Bewertungen

- Specification For Stainless Chromium-Nickel Steel-Clad Plate, Sheet, and StripDokument11 SeitenSpecification For Stainless Chromium-Nickel Steel-Clad Plate, Sheet, and Stripomsingh1988Noch keine Bewertungen

- ASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedDokument1 SeiteASME IIA SA29 SA29M Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-FinishedAmanda Ariesta ApriliaNoch keine Bewertungen

- Asme2b sb-187Dokument8 SeitenAsme2b sb-187kkskasdkk12Noch keine Bewertungen

- RR S 550D. Spelter SocketsDokument17 SeitenRR S 550D. Spelter SocketsJustin FetterNoch keine Bewertungen

- Asme2b sb-151Dokument6 SeitenAsme2b sb-151asjkhjshdjkashdashNoch keine Bewertungen

- Wire, Deformed, For Concrete Reinforcement': Standard Specification For SteelDokument5 SeitenWire, Deformed, For Concrete Reinforcement': Standard Specification For SteelSidharth MahajanNoch keine Bewertungen

- JisDokument23 SeitenJisĐào_hải_10100% (1)

- Astm A216Dokument2 SeitenAstm A216Amanda Ariesta ApriliaNoch keine Bewertungen

- ASTM StandardsDokument27 SeitenASTM StandardsTran Thanh Hao100% (2)

- ASTM A193 A193M Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceDokument2 SeitenASTM A193 A193M Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceAmanda Ariesta ApriliaNoch keine Bewertungen

- A125 96 PDFDokument6 SeitenA125 96 PDFJohano AraújoNoch keine Bewertungen

- ASTM A123 - Zinc Hot Dip Galvanised Coatings On Iron and Steel ProductsDokument4 SeitenASTM A123 - Zinc Hot Dip Galvanised Coatings On Iron and Steel ProductsPisut LeelalumlertNoch keine Bewertungen

- Astm Standart A416.1974Dokument7 SeitenAstm Standart A416.1974SetyasasmitaNoch keine Bewertungen

- Asme2b sb-152Dokument6 SeitenAsme2b sb-152kkskasdkk12Noch keine Bewertungen

- Part Viii List Bis CodeDokument9 SeitenPart Viii List Bis Codejoydeep_d3232Noch keine Bewertungen

- A 48 - A 48M - 03 Qtq4l0e0oe0Dokument6 SeitenA 48 - A 48M - 03 Qtq4l0e0oe0metalgikanuNoch keine Bewertungen

- Standard Specification For Copper, Bus Bar, Rod, and Shapes and General Purpose Rod, Bar, and Shapes ASTM B187 - B187M - 11Dokument8 SeitenStandard Specification For Copper, Bus Bar, Rod, and Shapes and General Purpose Rod, Bar, and Shapes ASTM B187 - B187M - 11Mauricio Leyton OtarolaNoch keine Bewertungen

- TurnbucklesDokument2 SeitenTurnbuckleschondroc11Noch keine Bewertungen

- Asme Section II A Sa-358 Sa-358mDokument10 SeitenAsme Section II A Sa-358 Sa-358mAnonymous GhPzn1xNoch keine Bewertungen

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Astm A216Dokument2 SeitenAstm A216Amanda Ariesta ApriliaNoch keine Bewertungen

- RINA Part B Chapter 2Dokument2 SeitenRINA Part B Chapter 2Amanda Ariesta ApriliaNoch keine Bewertungen

- Fundamentals of Physical GeologyDokument2 SeitenFundamentals of Physical GeologyAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM C150 Standard Specification For Portland CementDokument2 SeitenASTM C150 Standard Specification For Portland CementAmanda Ariesta Aprilia100% (1)

- ABS Part 2 Materials and WeldingDokument2 SeitenABS Part 2 Materials and WeldingAmanda Ariesta ApriliaNoch keine Bewertungen

- Corrosion Control by Modern Weld Overlay TechnologyDokument3 SeitenCorrosion Control by Modern Weld Overlay TechnologyAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsDokument3 SeitenASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM E96 Standard Test Methods For Water Vapor Transmission of MaterialsDokument2 SeitenASTM E96 Standard Test Methods For Water Vapor Transmission of MaterialsAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM E8M Standard Test Methods For Tension Testing of Metallic MaterialsDokument3 SeitenASTM E8M Standard Test Methods For Tension Testing of Metallic MaterialsAmanda Ariesta Aprilia0% (1)

- ASTM B151 Copper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and BarDokument2 SeitenASTM B151 Copper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and BarAmanda Ariesta ApriliaNoch keine Bewertungen

- RINA Part B Chapter 1Dokument3 SeitenRINA Part B Chapter 1Amanda Ariesta ApriliaNoch keine Bewertungen

- ASME VIII Div I Part ULW Pressure Vessels Fabricated by Layered ConstructionDokument2 SeitenASME VIII Div I Part ULW Pressure Vessels Fabricated by Layered ConstructionAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM E84 Standard Test Method For Surface Burning Characteristics of Building MaterialsDokument2 SeitenASTM E84 Standard Test Method For Surface Burning Characteristics of Building MaterialsAmanda Ariesta Aprilia0% (1)

- ASTM D1265 Sampling Liquefied Petroleum Gases (Manual Method)Dokument2 SeitenASTM D1265 Sampling Liquefied Petroleum Gases (Manual Method)Amanda Ariesta Aprilia100% (1)

- ASTM C139 Concrete Masonry Units For Construction of Catch Basins and ManholesDokument2 SeitenASTM C139 Concrete Masonry Units For Construction of Catch Basins and ManholesAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM A193 A193M Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceDokument2 SeitenASTM A193 A193M Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM A185 Standard Specification For Steel Welded Wire Reinforcement, Plain, For ConcreteDokument2 SeitenASTM A185 Standard Specification For Steel Welded Wire Reinforcement, Plain, For ConcreteAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME V Article 5 Ultrasonic Examination Methods For MaterialsDokument2 SeitenASME V Article 5 Ultrasonic Examination Methods For MaterialsAmanda Ariesta Aprilia100% (1)

- ASME VIII Div 1 Part UCS Pressure Vessels Constructed of Carbon and Low Alloy SteelsDokument2 SeitenASME VIII Div 1 Part UCS Pressure Vessels Constructed of Carbon and Low Alloy SteelsAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME I Part PMB Requirements For Miniature BoilersDokument2 SeitenASME I Part PMB Requirements For Miniature BoilersAmanda Ariesta ApriliaNoch keine Bewertungen

- RINA Chapter 2 Common Structural Rules For Bulk CarriersDokument2 SeitenRINA Chapter 2 Common Structural Rules For Bulk CarriersAmanda Ariesta ApriliaNoch keine Bewertungen

- ASTM A184 Welded Deformed Steel Bar Mats For Concrete ReinforcementDokument2 SeitenASTM A184 Welded Deformed Steel Bar Mats For Concrete ReinforcementAmanda Ariesta Aprilia100% (1)

- ASME IIA SA36 SA36M Specification For Carbon Structural SteelDokument1 SeiteASME IIA SA36 SA36M Specification For Carbon Structural SteelAmanda Ariesta Aprilia100% (1)

- ASTM D 1143 Test Method For Piles Under Static Axial Compressive LoadDokument2 SeitenASTM D 1143 Test Method For Piles Under Static Axial Compressive LoadAmanda Ariesta Aprilia100% (1)

- ASME I Part PG General Requirements For All Methods of ConstructionDokument2 SeitenASME I Part PG General Requirements For All Methods of ConstructionAmanda Ariesta ApriliaNoch keine Bewertungen

- Fundamentals of Metallurgy by Seshadri SeetharamanDokument1 SeiteFundamentals of Metallurgy by Seshadri SeetharamanAmanda Ariesta ApriliaNoch keine Bewertungen

- Bootstrap Geologist by Gene ShinnDokument1 SeiteBootstrap Geologist by Gene ShinnAmanda Ariesta ApriliaNoch keine Bewertungen

- ASME V Article 10 Leak TestingDokument2 SeitenASME V Article 10 Leak TestingAmanda Ariesta Aprilia0% (1)

- Bosch KE-Jetronic System DescriptionDokument3 SeitenBosch KE-Jetronic System DescriptionJack Tang50% (2)

- EXPERIMENT 1 - Bendo Marjorie P.Dokument5 SeitenEXPERIMENT 1 - Bendo Marjorie P.Bendo Marjorie P.100% (1)

- Bilateral Transfer of LearningDokument18 SeitenBilateral Transfer of Learningts2200419Noch keine Bewertungen

- READMEDokument2 SeitenREADMEtushar patelNoch keine Bewertungen

- The Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesDokument456 SeitenThe Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesAnna D.Noch keine Bewertungen

- MGNM801 Ca2Dokument19 SeitenMGNM801 Ca2Atul KumarNoch keine Bewertungen

- Chemical Engineering & Processing: Process Intensi Fication: ArticleinfoDokument9 SeitenChemical Engineering & Processing: Process Intensi Fication: Articleinfomiza adlinNoch keine Bewertungen

- Lennox IcomfortTouch ManualDokument39 SeitenLennox IcomfortTouch ManualMuhammid Zahid AttariNoch keine Bewertungen

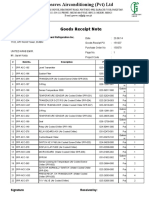

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDokument4 SeitenGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNoch keine Bewertungen

- Customer Service Metrics CalculatorDokument28 SeitenCustomer Service Metrics CalculatorSelma Regita MahardiniNoch keine Bewertungen

- Sustainable Development Precautionary PR 2Dokument12 SeitenSustainable Development Precautionary PR 2PramodNoch keine Bewertungen

- Naca Duct RMDokument47 SeitenNaca Duct RMGaurav GuptaNoch keine Bewertungen

- Empowerment Series Social Work With Groups Comprehensive Practice and Self Care 10Th Edition Charles Zastrow Full ChapterDokument67 SeitenEmpowerment Series Social Work With Groups Comprehensive Practice and Self Care 10Th Edition Charles Zastrow Full Chapterruby.levi441100% (5)

- KARAKTERISTIK GEOTERMAL SUMUR EKSPLORASI AT-1, LAPANGAN PANAS BUMI ATADEI, KABUPATEN LEMBATA NTT. Kastiman Sitorus Dan Arif Munandar SUBDIT PANAS BUMIDokument7 SeitenKARAKTERISTIK GEOTERMAL SUMUR EKSPLORASI AT-1, LAPANGAN PANAS BUMI ATADEI, KABUPATEN LEMBATA NTT. Kastiman Sitorus Dan Arif Munandar SUBDIT PANAS BUMIItTo MakinoNoch keine Bewertungen

- World Trends in Municipal Solid Waste ManagementDokument11 SeitenWorld Trends in Municipal Solid Waste ManagementNeima EndrisNoch keine Bewertungen

- Unit 3Dokument5 SeitenUnit 3Narasimman DonNoch keine Bewertungen

- Formulae HandbookDokument60 SeitenFormulae Handbookmgvpalma100% (1)

- Effect of Minor and Trace Elements in Cast IronDokument2 SeitenEffect of Minor and Trace Elements in Cast IronsachinguptachdNoch keine Bewertungen

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryDokument19 SeitenAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000Noch keine Bewertungen

- Electronic Parts Catalog - Option Detail Option Group Graphic Film Card DateDokument2 SeitenElectronic Parts Catalog - Option Detail Option Group Graphic Film Card DatenurdinzaiNoch keine Bewertungen

- Drsent PT Practice Sba OspfDokument10 SeitenDrsent PT Practice Sba OspfEnergyfellowNoch keine Bewertungen

- 2018-2019 Annual Algebra Course 1 Contest: InstructionsDokument2 Seiten2018-2019 Annual Algebra Course 1 Contest: InstructionsNaresh100% (1)

- Analyst - Finance, John Lewis John Lewis PartnershipDokument2 SeitenAnalyst - Finance, John Lewis John Lewis Partnershipsecret_1992Noch keine Bewertungen

- Mathematics4 q4 Week4 v4Dokument11 SeitenMathematics4 q4 Week4 v4Morales JinxNoch keine Bewertungen

- Teachers Guide Lower Secondary Science PDFDokument141 SeitenTeachers Guide Lower Secondary Science PDFNuzhat IbrahimNoch keine Bewertungen

- ResumeDokument3 SeitenResumeAstig Kuging63% (8)

- LQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQDokument5 SeitenLQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQSAJAL KOIRALANoch keine Bewertungen

- TOEFL-Reading Question Type Definitions and ExplanationDokument5 SeitenTOEFL-Reading Question Type Definitions and ExplanationSamara SampaioNoch keine Bewertungen

- GE Uno Downlight Backlit BLDokument2 SeitenGE Uno Downlight Backlit BLChen KengloonNoch keine Bewertungen

- MidsemDokument6 SeitenMidsemAravind SomasundaramNoch keine Bewertungen