Beruflich Dokumente

Kultur Dokumente

2010 Uit Congress Estimation of Effectiveness of Using Nanofluids Flowing Inside A Circular Tube For Heat Transfer Applications

Hochgeladen von

eldwin_dj72160 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

6 Ansichten1 SeiteProceeding in UIT 2010 conference. The topic of the paper is heat transfer in nanofluids.

Originaltitel

2010 Uit Congress Estimation of Effectiveness of Using Nanofluids Flowing Inside a Circular Tube for Heat Transfer Applications

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenProceeding in UIT 2010 conference. The topic of the paper is heat transfer in nanofluids.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

6 Ansichten1 Seite2010 Uit Congress Estimation of Effectiveness of Using Nanofluids Flowing Inside A Circular Tube For Heat Transfer Applications

Hochgeladen von

eldwin_dj7216Proceeding in UIT 2010 conference. The topic of the paper is heat transfer in nanofluids.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

XXVIII Congresso UIT sulla Trasmissione del Calore

Brescia, 21-23 Giugno 2010

1. INTRODUCTION

As recent technology has made it possible to produce

nano-sized particles, researchers tried to disperse this size

(determined to be < 100 nm) of particles, instead of millimeter

or micrometer-sized ones, inside conventional heat transfer

fluids such as water, oil, and ethylene glycol. These new class

of fluids are called nanofluids. A nanofluid can be defined as a

fluid in which solid particles with sizes below 100 nm are

suspended stably and dispersed uniformly. The base fluid used

is usually a traditional heat transfer fluid, e.g., water, oil, and

ethylene glycol.

A lot of researchers observed the phenomenon of higher

thermal conductivity of various nanofluids compared to that of

the base fluids. However, there is a main difference between

the results, i.e., some results showed that the increase of

thermal conductivity of nanofluids is an anomaly that cannot

be predicted by the existing conventional model for calculating

the effective thermal conductivity of liquids containing

suspended solid particles [1 - 4] while some others showed that

the increase is not an anomaly and can be predicted by using

the existing model [5, 6]. Thus, the research regarding thermal

conductivity increase of nanofluids needs to be extended until

the physical phenomena responsible for it are known.

It is true that increase in thermal conductivity will improve

the heat transfer behavior of fluid. However, a number of other

variables also play key roles such as in convection heat transfer

cases. Convection heat transfer, beside the thermophysical

properties of the fluid, is also influenced by the velocity of the

flow and by the geometry of the system through which the fluid

is flowing. Hence, the heat transfer performance/behavior of

nanofluids must be tested directly under flow conditions.

Xuan and Li [7] reported that in turbulent forced convection,

the heat transfer coefficient of Cu-water nanofluids flowing

inside a uniformly heated tube remarkably increased. The heat

transfer coefficient increased by around 39% for 2 vol.%

nanoparticle concentration compared to that of water.

Furthermore, it was observed that the increase of nanoparticle

concentration would also increase the heat transfer coefficient.

For the same Reynolds number, the heat transfer coefficient

increase ranged from 6% to 39% with the increase of particle

concentration from 0.5 vol.% to 2 vol.% respectively.

Interestingly, the experimental results showed that, for

nanoparticle volume concentration of 1%, 1.2%, 1.5%, and

2%, no significant increase in pressure drop compared to that

of water. Thus, it is no need to be worried about the drawback

of pumping power increase.

Maiga et al. [8] investigated, numerically, laminar and

turbulent forced convection of water-

2

O

3

and ethylene

glycol-

2

O

3

nanofluids inside a uniformly heated circular

tube. It was found that heat transfer at the tube wall was

enhanced for both laminar and turbulent flow compared to that

of base fluids. The enhancement increased with the increase of

particle loading. However, this also resulted in the increase of

wall shear stress which causes the undesirable increase of

pumping power and contradicts the results of Xuan and Li [7].

The particle volume concentrations used in this numerical

study were 1%, 2.5%, 5%, 7.5%, and 10%.

ESTIMATION OF EFFECTIVENESS OF USING NANOFLUIDS FLOWING

INSIDE A CIRCULAR TUBE FOR HEAT TRANSFER APPLICATIONS

Eldwin Djajadiwinata

a

*, Hany al-Ansary

b

, Khalid al-Dakkan

c

, Abdulaziz al-Jariwi

c

a

Graduate Study of Department of Mechanical Engineering, King Saud University, P.O. Box 800, Riyadh 11421,

Kingdom of Saudi Arabia

b

Department of Mechanical Engineering, King Saud University, P.O. Box 800, Riyadh 11421,

Kingdom of Saudi Arabia

c

National Nanotechnology Center (NNC), King Abdulaziz City for Science and Technology (KACST),

P. O. Box 6086, Riyadh 11442, Kingdom of Saudi Arabia

*

Corresponding author, email address: eldwin_dj@yahoo.com

ABSTRACT

This study assesses the heat transfer application of nanofluids, particularly Al

2

O

3

-water, CuO-water, Al

2

O

3

-EG/water mixture

(60:40wt), and CuO-EG/water mixture (60:40wt), flowing turbulently (Re around 5000 to 15000) inside a circular tube. The

h/P)

n

/(h/P)

b

h P

convection heat transfer coefficient and the pumping power, respectivel

base fluids, respectively. It is found that for mass flow rate of 0.1 kg/s and mean bulk temperature of 25C, CuO-water nanofluids

reached maximum and minimum effectiveness of 1.106 at 1.5 vol.% nanoparticles and 1.093 at 3 vol.% nanoparticles,

respectively, while Al

2

O

3

-water nanofluids reached maximum and minimum effectiveness of 1.087 at 2.5 vol.% nanoparticles

and 1.067 at 1% vol. nanoparticles, respectively.

outperforms that of Al

2

O

3

nanofluids. On the other hand, for EG/water mixture based nanofluids, with mass flow rate of 0.3 kg/s

and various mean bulk temperature and particle volume concentration, generally the Al

2

O

3

outperforms that of This paper also shows that heat transfer application of nanofluids mainly depends on their

thermophysical properties and the assessment must be done by observing the ratio between h and P.

Keywords: Nanofluids, copper oxide, alumina, pressure drop, pumping power, convection coefficient

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Buckling of Columns: Buckling & Stability Critical LoadDokument29 SeitenBuckling of Columns: Buckling & Stability Critical LoadShumaila KhanNoch keine Bewertungen

- Flexural Analysis and Design - Doubly Reinforced BeamsDokument23 SeitenFlexural Analysis and Design - Doubly Reinforced BeamsJhe Taguines100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Equivalent Single Wheel LoadDokument12 SeitenEquivalent Single Wheel LoadRajesh Khadka100% (1)

- Col Interaction Diagram 6 PDFDokument35 SeitenCol Interaction Diagram 6 PDFkhawaldeh jamalNoch keine Bewertungen

- Wood Shear Wall and Diaphragm DeflectionDokument17 SeitenWood Shear Wall and Diaphragm DeflectionNameNoch keine Bewertungen

- Wellbore Stability PDFDokument71 SeitenWellbore Stability PDFanavabi3440Noch keine Bewertungen

- Some Critical Issues 4 Injection MoldingDokument280 SeitenSome Critical Issues 4 Injection MoldingMiralles Martínez JordiNoch keine Bewertungen

- Back To Top: Rahul - LeslieDokument12 SeitenBack To Top: Rahul - LeslieMukhlish AkhatarNoch keine Bewertungen

- Stress DistributionDokument25 SeitenStress DistributionMoyukh De100% (2)

- Design For Fracture: Lecture Two Lect. Dr. Hind B. Al-AttraqchiDokument35 SeitenDesign For Fracture: Lecture Two Lect. Dr. Hind B. Al-AttraqchiTRNADEWNoch keine Bewertungen

- GEA Steam-Jet-Vacuum-Pumps Brochure EN tcm11-22950 PDFDokument8 SeitenGEA Steam-Jet-Vacuum-Pumps Brochure EN tcm11-22950 PDFeldwin_dj7216Noch keine Bewertungen

- Fatigue Analysis of Leaf SpringDokument14 SeitenFatigue Analysis of Leaf SpringylionkingxNoch keine Bewertungen

- Good Design Practice: A Guideline For Fatigue DesignDokument53 SeitenGood Design Practice: A Guideline For Fatigue DesignANUSSBAUMERNoch keine Bewertungen

- Kaeser Compressors ASD 37 T - ME Dept OwnedDokument11 SeitenKaeser Compressors ASD 37 T - ME Dept Ownedeldwin_dj7216Noch keine Bewertungen

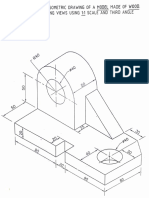

- Projection: Draw The Following Views Using 11 Scale and Third AngleDokument1 SeiteProjection: Draw The Following Views Using 11 Scale and Third Angleeldwin_dj7216Noch keine Bewertungen

- Pressure Loss Experiment Gunt Hamburg HM 150.29Dokument2 SeitenPressure Loss Experiment Gunt Hamburg HM 150.29eldwin_dj7216Noch keine Bewertungen

- 2012 MIT KFUPM McGovern Ejector Efficiency PDFDokument12 Seiten2012 MIT KFUPM McGovern Ejector Efficiency PDFeldwin_dj7216Noch keine Bewertungen

- Northvale Steam Ejector Basics. 1Dokument16 SeitenNorthvale Steam Ejector Basics. 1eldwin_dj7216Noch keine Bewertungen

- Comparison of Turbulence Models On 2D Backward Facing StepDokument16 SeitenComparison of Turbulence Models On 2D Backward Facing Stepeldwin_dj7216Noch keine Bewertungen

- 2D Airfoil Meshing Tutorial in ICEM CFDDokument11 Seiten2D Airfoil Meshing Tutorial in ICEM CFDsvkindiaNoch keine Bewertungen

- Radiative Heat Transfer ProblemsDokument10 SeitenRadiative Heat Transfer Problemseldwin_dj7216Noch keine Bewertungen

- ELDWIN Term Paper Boundary Layer Flow of A Nanofluid Over A Stretching SurfaceDokument15 SeitenELDWIN Term Paper Boundary Layer Flow of A Nanofluid Over A Stretching Surfaceeldwin_dj7216Noch keine Bewertungen

- Heat Transfer PHD Qualifying ExamDokument13 SeitenHeat Transfer PHD Qualifying Exameldwin_dj7216Noch keine Bewertungen

- Lid Driven Cavity Flow OK Final EldwinDokument33 SeitenLid Driven Cavity Flow OK Final Eldwineldwin_dj7216Noch keine Bewertungen

- 2011 Sanjeeva - Ding - Ref - Stability of Nano Fluids in Quiescent and Shear Flow FieldsDokument6 Seiten2011 Sanjeeva - Ding - Ref - Stability of Nano Fluids in Quiescent and Shear Flow Fieldseldwin_dj7216Noch keine Bewertungen

- JMST Journal EldwinDokument10 SeitenJMST Journal Eldwineldwin_dj7216Noch keine Bewertungen

- Mathematics Extension 2 HSC LevelDokument250 SeitenMathematics Extension 2 HSC LevelkalstarNoch keine Bewertungen

- CSAT 2019 Spe3D Duguid - Andrew PDFDokument111 SeitenCSAT 2019 Spe3D Duguid - Andrew PDFdocturboNoch keine Bewertungen

- High Temperature Service Equipment and Piping Maintenance in PlantDokument22 SeitenHigh Temperature Service Equipment and Piping Maintenance in Plantvaratharajan g rNoch keine Bewertungen

- Concrete Industrial Floor Design - Engineers EdgeDokument1 SeiteConcrete Industrial Floor Design - Engineers EdgeNeil WilsnachNoch keine Bewertungen

- ME6019-Non Destructive Testing and MaterialsDokument14 SeitenME6019-Non Destructive Testing and MaterialscamilaskishoreNoch keine Bewertungen

- Lode Dependences Pressure-Sensitive Materials For Isotropic ElastoplasticDokument9 SeitenLode Dependences Pressure-Sensitive Materials For Isotropic Elastoplasticaasc1981Noch keine Bewertungen

- Viscocity and Plasticity in Rubber CompoundingDokument1 SeiteViscocity and Plasticity in Rubber CompoundingBharat ChatrathNoch keine Bewertungen

- (Shirvani 1998) Behavior of Tensile Anchors in Concrete Statistical Analysis and Design RecommendationsDokument450 Seiten(Shirvani 1998) Behavior of Tensile Anchors in Concrete Statistical Analysis and Design RecommendationsmanoelmangabeiraNoch keine Bewertungen

- Op 2 PDFDokument252 SeitenOp 2 PDFjecarilloNoch keine Bewertungen

- Behavior Analysis of Stiffened Slender Plate Girders: January 2012Dokument9 SeitenBehavior Analysis of Stiffened Slender Plate Girders: January 2012Asr FlowerNoch keine Bewertungen

- Powder Metallurgy SintekDokument4 SeitenPowder Metallurgy SintekKatina PrattNoch keine Bewertungen

- Steam TurbineDokument17 SeitenSteam TurbinebobyNoch keine Bewertungen

- Excess Carriers and Junction Concepts: Unit IIIDokument48 SeitenExcess Carriers and Junction Concepts: Unit IIIThamizharasanNoch keine Bewertungen

- Fermi EnergyDokument20 SeitenFermi EnergyMukund BihariNoch keine Bewertungen

- 1993 JoSG Strain Kinematic Analysis General Shear Zones PDFDokument20 Seiten1993 JoSG Strain Kinematic Analysis General Shear Zones PDFLalit JoshiNoch keine Bewertungen

- Jominy TestDokument13 SeitenJominy Testihulme_2006139Noch keine Bewertungen

- Qualifying The Technology of The Aluminothermic Welding of Tramway Rails On The Basis of Quality Assurance System Requirements in Welding EngineeringDokument7 SeitenQualifying The Technology of The Aluminothermic Welding of Tramway Rails On The Basis of Quality Assurance System Requirements in Welding Engineeringhesti1405Noch keine Bewertungen

- Nonlinear Analysis of Reinforced Concrete Continuous Deep Beams Using Stringer - Panel ModelDokument16 SeitenNonlinear Analysis of Reinforced Concrete Continuous Deep Beams Using Stringer - Panel ModelBrandon LevineNoch keine Bewertungen