Beruflich Dokumente

Kultur Dokumente

Stabilization and Characterization of Heavy Crude Oilin

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stabilization and Characterization of Heavy Crude Oilin

Copyright:

Verfügbare Formate

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org 489

STABILIZATION AND CHARACTERIZATION OF HEAVY CRUDE OIL-

IN-WATER (O/W) EMULSIONS

Liyana M.S

1

, Abdurahman H. Nour

2

, Rizauddin D

3

, Gimbun J

4

, Nurdin S

5

Abstract

There has been much interest in alternative to transport viscous crude oil from reservoir which is much more abundant than

conventional oil. There are many authors hard to find the stable of oil-in-water (o/w) emulsion condition which has been considered

as critical analysis. In order to reduce the viscosity, the heavy oil is required to modify for reducing their viscosity. Applying diluent

and forming o/w emulsion are the selected as alternative for reducing viscosity. The purpose for this investigation is to study factors

that influencing stability and viscosity of o/w emulsion. From the observation, o/w emulsions reduced almost six (6) times less than

original heavy oil. However, the addition of 40% of light oil reduced oil viscosity from 478.10 mPa.sto 113.40 mPa.s. Thus, the

knowledge and understanding factors that influencing the stability and viscosity of o/w emulsion is important due to avoiding of

occurring phase inversion phenomena.

Keywords: Crude oil, Stability, Heavy oil, Viscosity, Emulsion, Shear Rate, Shear Stress.

---------------------------------------------------------------------***---------------------------------------------------------------------

1. INTRODUCTION

Demanding for crude oil will be increase in the future and this

will exert pressure on oil exploration companies throughout

the whole world. Indeed, there are various companies that are

still focusing on the oil reservoir within their boundaries in the

hopes that they might develop and increase their economic

growth in the future. The important of crude oil has been

focused by developer oil and gas industry. The pipeline

transportation by using water and present of surfactant to form

oil-in-water emulsion that has been suggested by authors (Zaki

1997; Azodi and Solaimany, 2013; Ashrafizadeh and Kamran,

2010). However, the difficulty to find stability between oil and

water which is require knowledge in order to reduce the heavy

oil viscosity(Crandall and Wise, 1984; Gillies and Shook,

1992; Hardy et al., 1989; Zakin et al., 1979).Besides, adding

light oil as diluent also promotes in reducing viscosity of

heavy oil. Unfortunately, the availability of diluent reserves at

the production site indicates major difficulties to obtain.

From literature survey, the crude oil worlds which has been

discover deep in the wellhead is associated with water which

is produced as water-in-oil (w/o) emulsion (Steinhauff, 1962;

Alvarado and Marsden, 1979). This fact are also mention by

Abdurahman et al., (2007) where the hydrocarbon oils are

normally present with water or is injected as steam to

stimulate oil production. Thus, w/o emulsion is consider as

normal emulsion while o/w emulsions indicate reverse

emulsion in oil and gas industries.

Shiffert et al., (1984) reported there are three (3) requirements

to form or prepare an emulsion; 1) two immiscible liquid, 2)

enough agitation to disperse one liquid into small drops, 3) the

present of surfactant to stabilize the dispersed drops. The

applying of homogenizer forces is to break the dispersed

liquid up into many small droplets. According to Dukhin and

Goetz (2005), an emulsion are depending on the several

factors including liquid properties, surfactant content,

temperature, and mixing conditions during preparing the

emulsion. In this investigation, there are several variables that

influencing preparation of a stable heavy crude o/w emulsion

such as, mixing speed, duration time mixing, concentration

surfactant, and volume fraction of oil and water. Basically, an

emulsion can be categorized into two (2) major phases which

is classified as o/w and w/o. The term of o/w emulsion refer to

oil as discontinues phase being dispersed in continuous water

phase. While term w/o emulsion refer to water as discontinues

phase being dispersed in continuous oil phase. In other words,

the continuous phase is also referred as the dispersion

medium, while the liquid in form of droplets are called as the

dispersed phase. The stability of emulsion is an essential

valuable knowledge for both academic and industrial points of

views. The term of stability is defined as the combination

between two immiscible liquid which are not separated for

long period time and also reduced amount of droplet to be

coalescence. Other authors determine the stable emulsions as

water droplets are not settle out from oil phase due to their

small size and surface tension (Stewart and Arnold, 2009).

Besides, emulsions stability is verify by analysis of their drop

size, rheological properties, and other factor that effecting

stability (Mandal, et al., 2010). This factor has been explained

by Mandal et al. (2010) where the stability is dependents on

the stirring speed and time during formation. Other than that,

Murray et al. (2009) reported the stability of emulsion is effect

from small droplet size which has strong interfacial lm

around oil droplets. In addition, the mixed of oil and water

will easily break and form clearly double layer because of

IJRET: International Journal of Research in Engineering and Technology

_______________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @

different density between oil and water. Besides, Stew

Arnold (2009) stated that the most stable emulsions often

required additional special treatment which is involved the

sufficient agitation to disperse the discontinuous phase into

continuous phase and the present of surfactant

2. EXPERIMENTAL PROCEDURE

2.1 Sample Preparation

Two types of crude oil samples were used in this study which

has been obtained heavy oil from PETRONAS Refinery

Melaka and blended with forty per cent (40%) of light crude

oil from PETRONAS Kerteh. In order to investigate the

effective surfactant, five (5) different types of emulsifiers

willused in this study, namely SDDS, Triton X

Tween 80, and Coco-Amide. The oil ratio was varied from

50%-70% by total volume. The surfactant concentration is

varied from 0.5-1% and homogenized at varied mixing speed

from 10,000-15,000 rpm. The oil as dispersed phase was

added slowly in water (continuous phase) at 5

other hand, the rheological measurements for all samples

carried out by using Brookfield Rotational Digital Viscometer

with UL adaptor and spindles 31 for measuring viscosity,

shear rate and shear stress. Figure 1 demonstrated

experiment for this investigation.

Fig 1: Overview experiment set

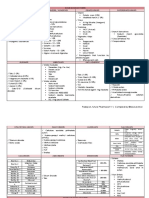

Table 1 shows the summarizing physical properties for both

types of crude oil. Meanwhile Table 2 displayed the chemical

properties according to ASTM D-2007 by applying Open

Column Chromatography method.

Table 1

Analysis Heavy

Oil

Physical Properties

Density at 25 C (g/cm

3

)

a

0.9372

API gravity (API )

b

19.48

Apparent viscosity at 25 C, (mPas)

c

478.1

Surface tension at 25 C (mN/m)

d

33.2

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319

_______________________________________________________________________________________

2014, Available @ http://www.ijret.org

different density between oil and water. Besides, Stewart and

Arnold (2009) stated that the most stable emulsions often

required additional special treatment which is involved the

sufficient agitation to disperse the discontinuous phase into

continuous phase and the present of surfactant.

ypes of crude oil samples were used in this study which

has been obtained heavy oil from PETRONAS Refinery

Melaka and blended with forty per cent (40%) of light crude

oil from PETRONAS Kerteh. In order to investigate the most

effective surfactant, five (5) different types of emulsifiers

S, Triton X-100, Span 83,

Amide. The oil ratio was varied from

70% by total volume. The surfactant concentration is

1% and homogenized at varied mixing speed

15,000 rpm. The oil as dispersed phase was

nuous phase) at 5-10 min. On the

other hand, the rheological measurements for all samples were

carried out by using Brookfield Rotational Digital Viscometer

with UL adaptor and spindles 31 for measuring viscosity,

nstrated the set-up

: Overview experiment set-up

Table 1 shows the summarizing physical properties for both

types of crude oil. Meanwhile Table 2 displayed the chemical

2007 by applying Open

Heavy

Oil

Blend

Oil

0.9372 0.8977

19.48 26.12

478.1 113.4

33.2 25.7

Interfacial tension at 25 C (mN/m)

Pour Point (

0

C)

f

Cloud Point (

0

C)

g

a. Determined by using MicromeriticsPycnometer device in

the range 0.91.0 kg/m3.

b Calculated according to the relation API = (141.5/Specific

Gravity) - 131.5

c. Determined by using

Viscometer.

d.&e.Measured using SEO DST30 Tensiometer by applying

the du Nuoy ring method.

f&g. Determined by using pour point and clould point device

Analysis

Chemical Properties (wt%)

Asphaltenes

Resin

Aromatics

Saturates

3. EXPERIMENTALRESULTS

3.1 Comparison between

Diluent Alternative

Technique

This interesting idea was apply since only 10

used to produce emulsion compared to

The diluent required to be recovered at the end of pipe and

need to be pumped back to the field hundreds of miles away

(Salager et al., 2001). These diluent usually demand high cost

and more valuable due to hydrocarbon fractions or light crude

oils would be sacrificed in the process (Salager et al., 2001).

O/W emulsion can be generating a much better result rather

than dilution as illustrat

commodity is an advantage of this technique. The water is

used to reduce viscosity heavy oil by present of surfactant as

active agent to produce stable o/w emulsion (Langevin et al.,

2004). The o/w emulsion has been proof to reduce viscosity

and make it easier delivering oil during transportation. Hence,

it is necessary to develop further research and built knowledge

about characteristic of crude oil.

eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

490

Interfacial tension at 25 C (mN/m)

e

37.7 18.73

-12 15

-8.95 20.6

a. Determined by using MicromeriticsPycnometer device in

b Calculated according to the relation API = (141.5/Specific

c. Determined by using Brookfield Rotational Digital

using SEO DST30 Tensiometer by applying

Determined by using pour point and clould point device

Table 2

Heavy

Oil

Blend

Oil

Chemical Properties (wt%)

16.54 10.32

18.31 7.58

18.63 49.71

46.52 32.39

EXPERIMENTALRESULTS

between Influence Light Oil as

and Oil-in-Water Emulsion

This interesting idea was apply since only 10-30 % of water

used to produce emulsion compared to adding 40% light oil.

he diluent required to be recovered at the end of pipe and

need to be pumped back to the field hundreds of miles away

001). These diluent usually demand high cost

hydrocarbon fractions or light crude

oils would be sacrificed in the process (Salager et al., 2001).

can be generating a much better result rather

than dilution as illustrated in Figure 2. The low cost

commodity is an advantage of this technique. The water is

used to reduce viscosity heavy oil by present of surfactant as

e stable o/w emulsion (Langevin et al.,

2004). The o/w emulsion has been proof to reduce viscosity

and make it easier delivering oil during transportation. Hence,

it is necessary to develop further research and built knowledge

about characteristic of crude oil.

IJRET: International Journal of Research in Engineering and Technology

_______________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @

Fig 2: Viscosity as a function of temperature f

oil, its mixture with 40% diluent, and its emulsion with 30 %

water content.

3.2 Stability of O/W Emulsion

The stability between oil and water phase are very important

during pipeline transportation.The highest

stability is selected as the suitable surfactant to form

stable o/w emulsion. From Figure 3, its clearly

Triton X-100 is the best surfactant to form o/w emulsion.

Heavy oil is stable by present of Triton X

separation indicates less than 3 mL after 14 days. Besides that,

Table 3 also demonstrated Triton X-100 promotes hig

stability with 94%. Octyl phenol ethoxylate (Triton X

a hydrophilic group where it has a water loving portion with

13.5 value of HLB.

Fig 3: Effect of surfactant types on the stability heavy

emulsion.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319

_______________________________________________________________________________________

2014, Available @ http://www.ijret.org

function of temperature for a heavy crude

its mixture with 40% diluent, and its emulsion with 30 %

The stability between oil and water phase are very important

he highest percentage of

selected as the suitable surfactant to form the most

3, its clearly shown that

100 is the best surfactant to form o/w emulsion.

Triton X-100 where the

less than 3 mL after 14 days. Besides that,

100 promotes highest

Octyl phenol ethoxylate (Triton X-100) is

a hydrophilic group where it has a water loving portion with

on the stability heavy o/w

Table 3: Stability for different types of surfactant

Types Surfactant

Triton X-100

Span 83

Tween 80

SDDS

Coca-Amide

The stability of emulsion is evaluated according to less

amount of water separated. In other word, the high stability of

emulsion indicates the minimum percentage of water

separation from o/w emulsion. The stability of emulsion was

calculated by using Equation

generated by Abdurahman et al. (2012).

Emulsion Stability= 1

The second highest percentage of stability is Span 83 (88 %

Heavy) followed by Tween

(85% Heavy), and SDDS (84% Heavy). Sodium dedocyl

sulphate (SDS) from anionic group obtained the lowest

stability compared to other non

ionic surfactants can be impart the interactive particles with

the steric stabilization mechanism, while anionic surfactants

can be provide repulsive force between similarly charged

electric double layers to the particles (Chen et al., 1997). The

non-ionic surfactant was covered well the thin film droplet to

provide less time the emulsion to be coalesce.

ionic surfactant is suitable to use as stabilizer for o/w

emulsion.

Generally, non-ionic surfactants such as Triton X

a good selection as emulsifiers because they are not afflicted

by the salinity of the water, low cost, and not change the oil

properties (Rivas et al., 1998). Triton X

soluble in water and miscible in most polar organic solvents

and aromatic hydrocarbons (Hait and Moulik, 2001). Besides,

it is suitable to form o/w emulsio

in the industry.

3.3 Influence of Surfactant

Stability and Viscosity of

Surfactant concentration promotes significant factors that

influence the stability and viscosity of emulsions. An effective

technique to reduce the viscosity of heavy oil is the formation

of o/w emulsions with the influence of surfactant agents

(Martinez-Palou et al. 2011). Other than that, the surfactant

concentration strongly influence emulsion stability (Ostberg et

eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

491

Stability for different types of surfactant

Types Surfactant Stability

Heavy o/w

emulsion

94%

88%

86%

85%

84%

The stability of emulsion is evaluated according to less

amount of water separated. In other word, the high stability of

emulsion indicates the minimum percentage of water

separation from o/w emulsion. The stability of emulsion was

ted by using Equation 1 as below. This equation is

generated by Abdurahman et al. (2012).

1 -

watcr scparatcd (%)

watcr contcnt (%)

1uu (1)

The second highest percentage of stability is Span 83 (88 %

Heavy) followed by Tween 80 (86% Heavy), Coco-Amide

DS (84% Heavy). Sodium dedocyl

sulphate (SDS) from anionic group obtained the lowest

stability compared to other non-ionic group. Besides, non-

ionic surfactants can be impart the interactive particles with

tabilization mechanism, while anionic surfactants

can be provide repulsive force between similarly charged

double layers to the particles (Chen et al., 1997). The

ionic surfactant was covered well the thin film droplet to

emulsion to be coalesce. Therefore, non-

ionic surfactant is suitable to use as stabilizer for o/w

ionic surfactants such as Triton X-100 indicate

a good selection as emulsifiers because they are not afflicted

he water, low cost, and not change the oil

properties (Rivas et al., 1998). Triton X-100 is the most

soluble in water and miscible in most polar organic solvents

and aromatic hydrocarbons (Hait and Moulik, 2001). Besides,

it is suitable to form o/w emulsion and commercially available

Influence of Surfactant Concentration on

and Viscosity of O/W Emulsion

Surfactant concentration promotes significant factors that

influence the stability and viscosity of emulsions. An effective

technique to reduce the viscosity of heavy oil is the formation

of o/w emulsions with the influence of surfactant agents

alou et al. 2011). Other than that, the surfactant

concentration strongly influence emulsion stability (Ostberg et

IJRET: International Journal of Research in Engineering and Technology

_______________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @

al., 1995). As it can be observed from Figure

the increasing of actual emulsifiers concentration in the liquid

phase will increases emulsion stability and viscosity

respectively

Fig 4: Effect of influence surfactant concentration on the

stability of heavy o/w emulsion

Fig 5: Effect of influence surfactant concentration on the

viscosity ofheavy o/w emulsion

From the graph, emulsion stability is increased as surfactant

concentration increased from 0.5% to 0.9%. This observation

is explained by Zaki (1997) where the addition of emulsifiers

demonstrated in an increase in the amount of emulsifier

molecules adsorbed at the oil/water interface.

viscosity has signicantly increased when the concentration of

emulsifier increase. Eirong and Lempe (2006) found that the

addition of surfactant concentration in the emulsion will

increases along the viscosity of the emulsion. The o/w

emulsion becomes more stable by increasing th

of surfactant. The high amount of surfactant promotes

droplet was covered well to avoid the droplets from coalesce.

The adsorbed emulsifier between oil and water molecules

because of their non-ionic nature contribute a steric obstacle to

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319

_______________________________________________________________________________________

2014, Available @ http://www.ijret.org

Figure 4 and Figure 5

the increasing of actual emulsifiers concentration in the liquid

reases emulsion stability and viscosity,

surfactant concentration on the

emulsion.

surfactant concentration on the

emulsion.

stability is increased as surfactant

concentration increased from 0.5% to 0.9%. This observation

is explained by Zaki (1997) where the addition of emulsifiers

demonstrated in an increase in the amount of emulsifier

ed at the oil/water interface. Meanwhile, the

cantly increased when the concentration of

emulsifier increase. Eirong and Lempe (2006) found that the

addition of surfactant concentration in the emulsion will

of the emulsion. The o/w

more stable by increasing the concentration

of surfactant. The high amount of surfactant promotes each

avoid the droplets from coalesce.

The adsorbed emulsifier between oil and water molecules

ionic nature contribute a steric obstacle to

droplet oil (dispersed phase) to

Singh and Pandey, 1991). Furthermore, Ashrafizadeh and

Kamran, (2010) reported the increasing of emulsifiers

concentration are effect an increments of obstacle between the

two phases and promotes a good distribution of oil droplets

(dispersed phase) in the water (continuous phase).

3.4 Influence of Mixing

Homogenizer on Stability

Emulsion

The inuence of mixing speed on the viscosity and stability of

o/w emulsions has been thoroughly studied. The stability of

heavy o/w emulsions have been

mixing speeds of 10,000, 12,000 and 15,000 rpm. Results are

shown in Figure 6 and Figure

speed homogenizer with stability and viscosity for

emulsions.

Fig 6: Influence of mixing speed on the stability

blend

Fig 7: Influence of mixing speed on the viscosity of heavy o/w

eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

492

droplet oil (dispersed phase) to be coalescence (Singh, 1994;

Singh and Pandey, 1991). Furthermore, Ashrafizadeh and

ported the increasing of emulsifiers

concentration are effect an increments of obstacle between the

two phases and promotes a good distribution of oil droplets

(dispersed phase) in the water (continuous phase).

Mixing Speed and Duration Time of

on Stability and Viscosity of O/W

uence of mixing speed on the viscosity and stability of

emulsions has been thoroughly studied. The stability of

heavy o/w emulsions have been investigated at different

mixing speeds of 10,000, 12,000 and 15,000 rpm. Results are

Figure 7 demonstrated relationship

speed homogenizer with stability and viscosity for heavy o/w

Influence of mixing speed on the stability of heavyand

blend o/w emulsion.

Influence of mixing speed on the viscosity of heavy o/w

emulsion.

IJRET: International Journal of Research in Engineering and Technology

_______________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @

From the graph illustrated the increasing mixing speed was

slightly increased the stability and viscosity. This fact

agreed by Zaki (1997) where the increasing the mixing speed

results in an increase in the viscosity of the emulsion.

Ashrazadeh and Kamran, (2010) also agree with the above

statement where increasing speed of mixing has a similar

effect on the emulsions quality. The stability at 70% oil

content showed 100% stable when 15,000 rpm apply during

preparing o/w emulsion. The increasing of mixing speed

promotes decreasing in the oil droplet size and increasing the

viscosity of the emulsion.However, 15,000 rpm is considered

very high speed compared to 10,000 rpm. From the

observation, the emulsion will require more than 4% of

surfactant when mixing speed below than 2,000 rpm was

applied and also need more than 20 min to agitate the

emulsion. From this condition, the o/w emulsion

quality in term of stability. Ashrazadeh and Kamran (2010)

has observed when applying mixing speed lower than 3,000

rpm and mixing time less than 10 min, would signi

reduce the quality of the emulsions.

From the observation, there is no separation w

word, the emulsion show 100% stable for 70% oil

Besides, 10K rpm is considered as high speed of mixing and

homogenizing for more than 8 min are not efficient because

the emulsion become more viscous and creamy. These

observations are explained by highly speed homogenized and

a longer mixing time will lead an o/w emulsion facing the

phase inversion. The observation has been shown that the

efficient time for high speed homogenizing at 10,000 rpm is

required maximum time at 7 min agitation for 0.9% of Triton

X-100. However, the concentration at 0.5% of Triton X

require less time of mixing because after 4 min agitated, the

emulsion change to w/o emulsion.

3.5 Effect of Temperature on Stability and Viscosity

of O/W Emulsion.

Temperature is another factors that is promotes strong

influence to reduce of heavy oils viscosity (Abdurahman et

al., 2012; Martnez-Palou et al.; 2011; Ilia and Abdurahman,

2010). Besides, the insulating of the pipeline is usually only a

solution for a small distance due to the temperature losses

reduction (Martnez-Palou et al., 2011). Ther

different studied mixing temperatures, namely, 27

96C while the other parameters are kept constant

shows a plot of the influence mixing speed on the viscosity of

o/w emulsions.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319

_______________________________________________________________________________________

2014, Available @ http://www.ijret.org

From the graph illustrated the increasing mixing speed was

slightly increased the stability and viscosity. This fact is

agreed by Zaki (1997) where the increasing the mixing speed

results in an increase in the viscosity of the emulsion.

zadeh and Kamran, (2010) also agree with the above

statement where increasing speed of mixing has a similar

quality. The stability at 70% oil

000 rpm apply during

he increasing of mixing speed

promotes decreasing in the oil droplet size and increasing the

viscosity of the emulsion.However, 15,000 rpm is considered

very high speed compared to 10,000 rpm. From the

observation, the emulsion will require more than 4% of

surfactant when mixing speed below than 2,000 rpm was

applied and also need more than 20 min to agitate the

emulsion. From this condition, the o/w emulsion exhibit low

zadeh and Kamran (2010)

mixing speed lower than 3,000

rpm and mixing time less than 10 min, would signicantly

From the observation, there is no separation water or in other

100% stable for 70% oil content.

0K rpm is considered as high speed of mixing and

homogenizing for more than 8 min are not efficient because

the emulsion become more viscous and creamy. These

observations are explained by highly speed homogenized and

emulsion facing the

phase inversion. The observation has been shown that the

efficient time for high speed homogenizing at 10,000 rpm is

required maximum time at 7 min agitation for 0.9% of Triton

100. However, the concentration at 0.5% of Triton X-100

equire less time of mixing because after 4 min agitated, the

Effect of Temperature on Stability and Viscosity

Temperature is another factors that is promotes strong

viscosity (Abdurahman et

Palou et al.; 2011; Ilia and Abdurahman,

2010). Besides, the insulating of the pipeline is usually only a

solution for a small distance due to the temperature losses

Palou et al., 2011). There are four (4)

d mixing temperatures, namely, 27, 60, 90, and

96C while the other parameters are kept constant.Figure 8

mixing speed on the viscosity of

Fig 8: Influence of temperature on

blend o/w emulsion

It is clear from this plot that the viscosity of the emulsion is

increased as the temperature is raised (Zaki, 1997; Sanchez

and Zakin, 1994; Abdurahman et al., 2012).

temperature promotes in

between oil and water. Consequently, t

energy of the molecules may increase the pressure required to

induce the interfacial film thinning, and eventually reduces the

coalescence time (Isaaka et al., 2

with high temperature, the o/w emulsions are available to

transport via pipeline.As been discussed previously, the

present of surface active agent promotes an increasing of

stability and viscosity of the emulsions. However, the

solubility of the surfactant normally invert when temperature

changes, the stability of emulsion also change.

of temperature cause the flow molecules through the interfaces

also increased resulting in a decrease in emulsion stability (Ilia

and Abdurahman, 2010). These flow molecules correlated

with viscosity where the increasing temperature results in

decreasing the viscosity.

velocity is increase as viscosity decreased. Furthermore, Ilia

and Abdurahman (2010)

sensitive to temperature due to the high temperature promotes

to reduce emulsion stability

3.7 Oil Droplet Measurement

The droplet size of an emulsion is important variables which

are affecting the colloidal stability and rheological properties

such as the flow and deformations of the emulsion (Han et al.,

2011). The droplet size distribution for the emulsions was

determined as a function of different mixing speeds and

concentration of surfactant using Carl Zeiss research

microscope equipped with the digital camera and AxioVission

AC image analysis software. The average of droplet size

distribution of emulsion is measured b

approximately eight to ten different droplet size images. The

influence of average droplet size emulsions on the mixing

eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

493

Influence of temperature on the viscosity of heavy and

blend o/w emulsion

It is clear from this plot that the viscosity of the emulsion is

increased as the temperature is raised (Zaki, 1997; Sanchez

and Zakin, 1994; Abdurahman et al., 2012). The increasing of

increasing the interfacial tension

between oil and water. Consequently, the increase of internal

energy of the molecules may increase the pressure required to

induce the interfacial film thinning, and eventually reduces the

coalescence time (Isaaka et al., 2010). As viscosity decrease

with high temperature, the o/w emulsions are available to

As been discussed previously, the

present of surface active agent promotes an increasing of

stability and viscosity of the emulsions. However, the

solubility of the surfactant normally invert when temperature

bility of emulsion also change. The increasing

of temperature cause the flow molecules through the interfaces

also increased resulting in a decrease in emulsion stability (Ilia

nd Abdurahman, 2010). These flow molecules correlated

with viscosity where the increasing temperature results in

decreasing the viscosity. AccordingStokes Law theory, the

velocity is increase as viscosity decreased. Furthermore, Ilia

found that the viscosity is very

sensitive to temperature due to the high temperature promotes

stability.

Oil Droplet Measurement

The droplet size of an emulsion is important variables which

are affecting the colloidal stability and rheological properties

such as the flow and deformations of the emulsion (Han et al.,

2011). The droplet size distribution for the emulsions was

ed as a function of different mixing speeds and

concentration of surfactant using Carl Zeiss research

microscope equipped with the digital camera and AxioVission

AC image analysis software. The average of droplet size

distribution of emulsion is measured by taking randomly,

approximately eight to ten different droplet size images. The

influence of average droplet size emulsions on the mixing

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org 494

speed and emulsifier concentration are illustrated in Figure 9

and Figure 10. From both figure, it is clear shown that the

average droplet size distribution of the emulsions decreases as

the speed of homogenizer and concentration emulsifier is

increased.

Fig 9: Influence of mixing speed on the average droplet size

of heavy o/w emulsion

Fig 10: Influence of concentration on the average droplet size

of heavy o/w emulsion

This observation has been explained by increasing mixing

speed and surfactant concentration will be reducing to droplet

oil size. The increasing the surfactant concentration will

increase an amount of obstacle between two phases to be

separate and improved the distribution of dispersed droplets in

the continuous phase (Ashrazadeh and Kamran, 2010). This

ndings are also agreed with some authors where the adsorbed

molecules of surfactant provide a strong barrier of oil droplet

to be the coalescence (Singh and Pandey, 1991; Singh, 1994).

Besides, the high surfactant concentration provide well

protection to each droplet surface, thus the uncovered droplet

surface area with water (continuous phase) is

thermodynamically unfavourable (Huda, 2011). The increment

of volume surfactant in the emulsion would reduce the

interfacial tension which promotes the breakage of droplets

into smaller ones and the interaction between particles is

increases. Consequently, the droplet between oil and water

become more tight relation and hard to break due to high

mixing speed and present of high amount of surfactant. At the

same time, the increasing mixing speed and mixing time also

could cause small droplet size which is nally increase the

stability of the emulsion (Ashrazadeh and Kamran, 2010).

Parkinson et al. (1970) considered the influence of droplet size

distribution on the stability and viscosity of the emulsion. This

fact are already discussed by Azodiand Solaimany(2013) and

Abdurahman et al., (2012) where the increasing of surfactant

concentration and mixing speed will reduces average oil

droplets size leading to an increase of the viscosity of o/w

emulsion. The other author also agree by the decreasing of oil

droplets size (dispersed phase) results in a slight increase in

the viscosity of the emulsions (Stachurski and Michaek,

1996; Zaki, 1997; Pal et al, 1992). This observation is

explained by an increase in the mixing speed produced the

smaller size of oil droplets, thus influence the increasing of

viscosity (Pal et al., 1992; Briceno et al. 2001; Zaki, 1997).

The application of homogenizer may cause the formation of

oil droplets having a diameter less than 10 m. According to

the droplet result, macro-emulsion and micro-emulsion (2.9

0.08 m) had successfully applied by homogenizer

(10,000rpm-15,000rpm). Amorim (2007) also agree by

applying homogenizer are produced small size and stabilized

the emulsion. However, the droplet size have more than 1.2

m are found as unstable emulsion due to coalesces process

are easy to occur (Jafari et al., 2008).

CONCLUSIONS

According to the result, it can be concluded that, o/w emulsion

influence various factor in order to find the stabilize condition.

This is due to the physical and chemical properties of types

crude oil which can beaffecting especially need to consider on

phase inversion phenomena. The less water separate indicate

the most stable o/w emulsion. Applying homogenizer proof

the droplet become smallest and displayed tight relation

between oil and water.

REFFERENCES

[1]. Abdurahman, H. N., Yunus, R. M., Jemaat, Z. 2007.

Chemical demulsification of water-in-crude oil emulsions.

Journal of Applied Sciences, 7(2): 196-201.

[2]. Abdurahman, N.H., Rosli, Y.M., Azhari, N.H.

Hayder,B.A. 2012. Pipeline transportation of viscous crudes as

concentrated oil-in-water emulsions. Journal of Petroleum

Science and Engineering, 9091: 139-144.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org 495

[3] Alvarado, D., and Marsden, S.S. 1979. Flow of oil-in-

water emulsions through tubes and porous media. Old SPE

Journal, 19(6): 369-377.

[4]. Amorim, F.A., Welz, B., Costa, A., Lepri, F. G., Vale, M.

G. R., Ferreira, S.L. 2007. Determination of vanadium in

petroleum and petroleum products using atomic spectrometric

techniques.Talanta, 72(2): 349-359.

[5]. Ashrafizadeh, S.N. and Kamran, M. 2010. Emulsification

of heavy crude oil in water for pipeline transportation. Journal

of Petroleum Science and Engineering, 71(34): 205-211.

[6]. Azodi, M., and Solaimany, N.A.R. 2013. An experimental

study on factors affecting the heavy crude oil in water

emulsions viscosity. Journal of Petroleum Science and

Engineering, 106: 1-8.

[7]. Briceno, M., Salager, J. L., & Bertrand, J. 2001. Influence

of dispersed phase content and viscosity on the mixing of

concentrated oil-in-water emulsions in the transition flow

regime. Chemical Engineering Research and Design, 79(8):

943-948.

[8]. Chen, L.-J., Lin, S.-Y. Chern, C-S., Wu, S-C. 1997.

Critical micelle concentration of mixed surfactant SDS/NP

(EO) 40 and its role in emulsion polymerization. Colloids and

Surfaces A: Physicochemical and Engineering Aspects,

122(13): 161-168.

[9]. Crandall, G.R., and Wise, T.H., 1984. Availability of

diluent may inhibit heavy oil exports. Can. Pet, 25: 3740.

[10]. Dukhin, A., and Goetz, P. 2005. Evolution of water-

in-oil emulsion controlled by droplet- bulk ion

exchange: acoustic, electroacoustic, conductivity and

image analysis. Colloids and Surfaces A:

Physicochemical and Engineering Aspects, 253(1): 51-64.

[11]. Eirong, J.I. and Lempe, D.A. 2006. Calculation of

viscosities of liquid mixtures using Eyring's theory in

combination with cubic equations of state. J. Chem. Eng., 14

(6) : 770779

[12]. Gillies, KG. and Shook, C.A. 1992. Emulsions for Short

Distance Transportation of Heavy Oil: Pipeloop Test Results,

J. Canad. Pet. Tech., 31 (9): 41-47.

[13]. Hait, S.K. and Moulik, S.P. 2001. Determination of

critical micelle concentration (CMC) of non-ionic surfactants

by donoracceptor interaction with iodine and correlation of

CMC with hydrophilelipophile balance and other

parameters of the surfactants. Journal of Surfactants and

Detergents, 4(3).

[14]. Han, N. S., Basri, M., Abd. Rahman, M.B., ZalihaRaja

Abd. Rahman, R.N., Salleh, A.B., Ismail, Z. 2011. Phase

behavior and formulation of palm oil esters o/w

nanoemulsionsstabilized by hydrocolloid gums for

cosmeceuticalsapplication. Journal of Dispersion Science

andTechnology, 32(10), 1428-1433.

[15]. Hardy, W.A., Sit, S.P., Stockwell, A., 1989. Heavy-oil-

emulsion pipeline tests meet targets. Oil and Gas J. (March),

39 43.

[16]. Huda, S.N. 2011. Stabilization and optimization of heavy

crude oil emulsion transportation using response surface

methodology. Master dissertation thesis, Universiti Malaysia

Pahang

[17]. Ilia, A.A.N. and Abdurahman, H.N. 2010. Affect of

Viscosity and Droplet Diameter on water-in-oil (w/o)

Emulsions: An Experimental Study. World Academy of

Science, Engineering and Technology, 38 :691-694

[18]. Issaka, S.A., Nour, A.H., Yunus, R.M. 2010.

Decolorization and characterization of petroleum emulsions.

Journal of Applied Sciences, 10: 215-220.

[19]. Jafari, S.M., Assadpoor, E., He, Y., Bhandari, B. 2008.

Re-coalescence of emulsion droplets during high-energy

emulsification. Food Hydrocolloids, 22(7): 1191-1202.

[20]. Langevin, D., Poteau, S., Hnaut, I., and Argillier, J.F.

2004.Crude oil emulsion properties and their application to

heavy oil transportation. Oil & Gas Science and Technology,

59(5): 511-521.

[21]. Mandal, A., Samanta, A., Bera, A., Ojha, K. 2010.

Characterization of Oil Water Emulsion and Its Use in

Enhanced Oil Recovery. Industrial &Engineering Chemistry

Research, 49(24): 12756-12761.

[22]. Martinez-Palou, R., Mosqueira, M.d.L. Zapata- Rendn,

B., Mar-Jurez, E., Bernal-Huicochea, C., Clavel-Lpez,

J.d.L.C., Aburto, J. 2011. Transportation of heavy and extra-

heavy crude oil by pipeline: A review. Journal of Petroleum

Science and Engineering, 75(34): 274-282.

[23]. Murray, B.S. Dickinson, E. Wang, Y. 2009. Bubble

stability in thepresence of oil-in-water emulsion droplets:

Inuence of surface shear versusdilatational rheology. Food

Hydrocolloids, 23 (4): 11981208.

[24]. Ostberg, G., Bergenstahl, B., Hulden, M. 1995. Colloids

and Surfaces.A Physicochemical and Engineering Aspects, 94

(2-3): 161171.

[25]. Pal, R., Yan, Y., Masliyah, J. 1992. L.L. Schramm (Ed.),

Emulsions Fundamentals and Applications in the Petroleum

Industry, American Chemical Society, Washington, DC,

Chapter 4, p. 141.

[26]. Parkinson, C., Matsumoto, S., Sherman, P. 1970. The

influence of particle-size distribution on the apparent viscosity

of non-newtoniandispersed systems. Journal of Colloid and

Interface Science, 33(1): 150-160.

[27]. Rivas, H., Gutierrez, X., Cardenas, A.E., Morles, A.

1998. U.S. Patent No. 5,792,223. Washington, DC: U.S.

Patent and Trademark Office.

[28]. Salager, J. L., Briceo, M. I., Bracho, C. L. 2001. Heavy

hydrocarbon emulsions. Making use of the state of the art in

formulation engineering.Encyclopedic Handbook of Emulsion

Technology, 20: 455-495.

[29]. Sanchez, L.E., and Zakin, J.L. 1994. Transport of viscous

crudes as concentrated oil-in-water emulsions. Industrial &

engineering chemistry research, 33(12): 3256-3261.

[30]. Silset, A. 2008. Emulsions (w/o and o/w) of HeavyCrude

Oils.Characterization, Stabilization, Destabilization and

ProducedWater Quality (Doctoral dissertation, Norwegian

University of Science and Technology).

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Issue: 02 | Feb-2014, Available @ http://www.ijret.org 496

[31]. Singh, B.P., and Pandey, B.P. 1991. Physical

characteristics of natural films formed at crude oil-water

interfaces. Indian Journal of Technology, 29(9): 443-447

[32]. Singh, B.P. 1994. Chemical resolution of petroleum

emulsion. Chemical Engineering World, 29: 203.

[33]. Shiffert., B., Bourgeois, C., Papirer, E. 1984. Structure

and water-oil emulsifying properties of asphaltenes.Fuel, 63:

835-837.

[34]. Steinhauff, F. 1962. Modern Oilfield Demulsification.art

I. Petroleum, 25: 294.

[35]. Steward, M., and Arnold K. 2009. Emulsions and Oil

treating Equipment, selection, sizing, and troubleshoot.

Elsivier Publishing.

[36]. Stachurski, J., and Michaek, M., 1996. The effect of the

potential on the stability of a non-polar oil-in-water

emulsion. J. Colloid Interface Sci, 184 (2), 433436.

[37]. Zaki, N.N. 1997. Surfactant stabilized crude oil-in-water

emulsions for pipeline transportation of viscous crude oils.

Colloids and Surfaces A: Physicochemical and Engineering

Aspects, 125(1): 19-25.

[38]. Zakin, J.L., Pinaire, R., Borgmeyer, M.E., 1979.

Transporationof oils as oil-in-water emulsions.J. Fluids Eng.

101: 100 104

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Shear Strength of RC Deep Beam Panels - A ReviewDokument15 SeitenShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDokument8 SeitenFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDokument5 SeitenImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDokument8 SeitenEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDokument9 SeitenEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDokument11 SeitenWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDokument6 SeitenRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDokument5 SeitenGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDokument5 SeitenLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDokument3 SeitenLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDokument4 SeitenChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDokument10 SeitenWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDokument3 SeitenMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDokument10 SeitenComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDokument8 SeitenHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Review Study On Performance of Seismically Tested Repaired Shear WallsDokument7 SeitenReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Assessment of Seismic Susceptibility of RC BuildingsDokument4 SeitenAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDokument9 SeitenDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Cyclone Disaster On Housing and Coastal AreaDokument7 SeitenCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDokument4 SeitenEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Disaster Recovery Sustainable HousingDokument4 SeitenDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDokument4 SeitenCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDokument5 SeitenA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDokument6 SeitenCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDokument6 SeitenDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDokument5 SeitenCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Analytical Solutions For Square Shape PressureDokument4 SeitenAnalytical Solutions For Square Shape PressureInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDokument4 SeitenBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDokument5 SeitenRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- Neem PatentDokument9 SeitenNeem PatentPriyank JivaniNoch keine Bewertungen

- Silicones Additives 2017Dokument36 SeitenSilicones Additives 2017Bilson ShuklaNoch keine Bewertungen

- Chemistry and Technology of The Cosmetics and Toiletries Industry (PDFDrive)Dokument411 SeitenChemistry and Technology of The Cosmetics and Toiletries Industry (PDFDrive)Audrey Ann100% (1)

- Areviewon Self Emulsifying Drug Delivery SystemDokument6 SeitenAreviewon Self Emulsifying Drug Delivery SystemAhmed RedaNoch keine Bewertungen

- Dry Syrup 2Dokument7 SeitenDry Syrup 2meiliadiana48Noch keine Bewertungen

- MicellsDokument12 SeitenMicellsZunairaNoch keine Bewertungen

- SATDokument13 SeitenSATPrikshit HoodaNoch keine Bewertungen

- Jo GradeDokument40 SeitenJo GradeEvonne TanNoch keine Bewertungen

- DS Tegopren 5878 0715Dokument2 SeitenDS Tegopren 5878 0715Wessel WesselsNoch keine Bewertungen

- TDS Rheobyk-7420 Es enDokument4 SeitenTDS Rheobyk-7420 Es enjravi781043Noch keine Bewertungen

- 2 - 2021 KW40 E Wasser Surface and Wax SharedDokument61 Seiten2 - 2021 KW40 E Wasser Surface and Wax SharedThanh VuNoch keine Bewertungen

- SOFTILT AS-L LeafletDokument2 SeitenSOFTILT AS-L LeafletTrần Yến NhiNoch keine Bewertungen

- Solid Dosage Forms Diluents Binders / Adhesives Disintegrants SuperdisintegrantsDokument4 SeitenSolid Dosage Forms Diluents Binders / Adhesives Disintegrants SuperdisintegrantsMargaret RNoch keine Bewertungen

- Nanoemulsions of Essential Oils To Improve Solubility, Stability and Permeability: A ReviewDokument19 SeitenNanoemulsions of Essential Oils To Improve Solubility, Stability and Permeability: A ReviewHector LeónNoch keine Bewertungen

- Dowfax Muy BuenoDokument20 SeitenDowfax Muy Buenohugogauna100% (1)

- Pcos311 LabDokument4 SeitenPcos311 LabsherilleNoch keine Bewertungen

- Lesson III:: Otc DrugsDokument42 SeitenLesson III:: Otc DrugsKhara TeanoTanNoch keine Bewertungen

- 11.20 Innospec - Sodium Methyl Acyl Taurates Give High Performing Sulfate-FreeDokument29 Seiten11.20 Innospec - Sodium Methyl Acyl Taurates Give High Performing Sulfate-FreeSầu VeNoch keine Bewertungen

- A Comprehensive Review of Recent Advances On Surfactant Architectures and Their Applications For Unconventional ReservoirsDokument47 SeitenA Comprehensive Review of Recent Advances On Surfactant Architectures and Their Applications For Unconventional ReservoirsRuth Santos NaranjoNoch keine Bewertungen

- Surfactant SDokument630 SeitenSurfactant Sadyrobert21100% (11)

- Personal Care & Cosmetic Grade HECDokument3 SeitenPersonal Care & Cosmetic Grade HECrafaeldelperu1982Noch keine Bewertungen

- Us5877138 PDFDokument5 SeitenUs5877138 PDFMamoon ShahidNoch keine Bewertungen

- Clariant Product Fact Sheet PRAEPAGEN HY 201305 enDokument7 SeitenClariant Product Fact Sheet PRAEPAGEN HY 201305 enVasanthakumar VenkatesanNoch keine Bewertungen

- Pesticide FormulationDokument70 SeitenPesticide FormulationPrathap G M100% (1)

- Shampoo Volume Pro Age (Formulation # HB-DE-10-209-11)Dokument1 SeiteShampoo Volume Pro Age (Formulation # HB-DE-10-209-11)Martin AvagyanNoch keine Bewertungen

- Astm PDFDokument9 SeitenAstm PDFFelipe Marçal MorgantiniNoch keine Bewertungen

- Surfactants, Anionic, (Detergents), Method 8028, 02-2009, 9th Ed PDFDokument4 SeitenSurfactants, Anionic, (Detergents), Method 8028, 02-2009, 9th Ed PDFCorinne MartinNoch keine Bewertungen

- 100 Quesions With AnswerDokument15 Seiten100 Quesions With Answernabil heddadNoch keine Bewertungen

- Multi Functional AdditivesDokument5 SeitenMulti Functional AdditivesHafiz TanveerNoch keine Bewertungen