Beruflich Dokumente

Kultur Dokumente

Lincoln Notes On Weld Distortion

Hochgeladen von

ansarALLAAHOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lincoln Notes On Weld Distortion

Hochgeladen von

ansarALLAAHCopyright:

Verfügbare Formate

4/28/2014 Weld Distortion

http://www.lincolnelectric.com/en-us/support/welding-how-to/pages/weld-distortion-detail.aspx 1/5

Weld Distortion

Beginning welders and even those that are more experienced commonly struggle with the problem of weld distortion, (warping of the base plate caused by heat

f rom the welding arc). Distortion is troublesome f or a number of reasons, but one of the most critical is the potential creation of a weld that is not structurally

sound. This article will help to def ine what weld distortion is and then provide a practical understanding of the causes of distortion, ef f ects of shrinkage in various

types of welded assemblies and how to control it, and f inally look at methods f or distortion control.

What is Weld Distortion?

Distortion in a weld results f rom the expansion and contraction of the weld metal and adjacent base metal during the heating and cooling cycle of the welding

process. Doing all welding on one side of a part will cause much more distortion than if the welds are alternated f rom one side to the other. During this heating and

cooling cycle, many f actors af f ect shrinkage of the metal and lead to distortion, such as physical and mechanical properties that change as heat is applied. For

example, as the temperature of the weld area increases, yield strength, elasticity, and thermal conductivity of the steel plate decrease, while thermal expansion

and specif ic heat increase (Fig. 3-1). These changes, in turn, af f ect heat f low and unif ormity of heat distribution.

Fig. 3-1 Changes in the properties of steel with

increases in temperature complicate analysis of what

happens during the welding cycle - and, thus,

understanding of the f actors contributing to weldment

distortion.

Reasons for Distortion

To understand how and why distortion occurs during heating and cooling of a metal, consider the bar of steel shown in Fig. 3-2. As the bar is unif ormly heated, it

expands in all directions, as shown in Fig. 3-2(a). As the metal cools to room temperature it contracts unif ormly to its original dimensions.

Fig. 3-2 If a steel bar is unif ormly heated while

unrestrained, as in (a), it will expand in all directions and

return to its original dimentions on cooling. If restrained,

as in (b), during heating, it can expand only in the vertical

direction - become thicker. On cooling, the def ormed bar

contracts unif ormly, as shown in (c), and, thus, is

permanently def ormed. This is a simplif ied explanation of

basic cause of distortion in welding assemblies.

But if the steel bar is restrained -as in a vise - while it is heated, as shown in Fig. 3-2(b), lateral expansion cannot take place. But, since volume expansion must

occur during the heating, the bar expands in a vertical direction (in thickness) and becomes thicker. As the def ormed bar returns to room temperature, it will still

tend to contract unif ormly in all directions, as in Fig. 3-2 (c). The bar is now shorter, but thicker. It has been permanently def ormed, or distorted. (For simplif ication,

the sketches show this distortion occurring in thickness only. But in actuality, length is similarly af f ected.)

In a welded joint, these same expansion and contraction f orces act on the weld metal and on the base metal. As the weld metal solidif ies and f uses with the base

metal, it is in its maximum expanded f rom. On cooling, it attempts to contract to the volume it would normally occupy at the lower temperature, but it is restrained

f rom doing so by the adjacent base metal. Because of this, stresses develop within the weld and the adjacent base metal. At this point, the weld stretches (or

yields) and thins out, thus adjusting to the volume requirements of the lower temperature. But only those stresses that exceed the yield strength of the weld metal

are relieved by this straining. By the time the weld reaches room temperature - assuming complete restraint of the base metal so that it cannot move - the weld will

contain locked-in tensile stresses approximately equal to the yield strength of the metal. If the restraints (clamps that hold the workpiece, or an opposing shrinkage

f orce) are removed, the residual stresses are partially relieved as they cause the base metal to move, thus distorting the weldment.

Shrinkage Control - What You Can Do to Minimize Distortion

To prevent or minimize weld distortion, methods must be used both in design and during welding to overcome the ef f ects of the heating and cooling cycle.

Shrinkage cannot be prevented, but it can be controlled. Several ways can be used to minimize distortion caused by shrinkage:

4/28/2014 Weld Distortion

http://www.lincolnelectric.com/en-us/support/welding-how-to/pages/weld-distortion-detail.aspx 2/5

1. Do not overweld

The more metal placed in a joint, the greater the shrinkage f orces. Correctly sizing a weld f or the requirements of the joint not only minimizes distortion, but also

saves weld metal and time. The amount of weld metal in a f illet weld can be minimized by the use of a f lat or slightly convex bead, and in a butt joint by proper

edge preparation and f itup. The excess weld metal in a highly convex bead does not increase the allowable strength in code work, but it does increase shrinkage

f orces.

When welding heavy plate (over 1 inch thick) bevelling or even double bevelling can save a substantial amount of weld metal which translates into much less

distortion automatically.

In general, if distortion is not a problem, select the most economical joint. If distortion is a problem, select either a joint in which the weld stresses balance each

other or a joint requiring the least amount of weld metal.

2. Use intermittent welding

Another way to minimize weld metal is to use intermittent rather than continuous welds where possible, as in Fig. 3-7(c). For attaching stif f eners to plate, f or

example, intermittent welds can reduce the weld metal by as much as 75 percent yet provide the needed strength.

Fig. 3-7 Distortion can be prevented or minimized by

techniques that def eat - or use constructively - the ef f ects

of the heating and cooling cycle.

3. Use as few weld passes as possible

Fewer passes with large electrodes, Fig. 3-7(d), are pref erable to a greater number of passes with small electrodes when transverse distortion could be a

problem. Shrinkage caused by each pass tends to be cumulative, thereby increasing total shrinkage when many passes are used.

4. Place welds near the neutral axis

Distortion is minimized by providing a smaller leverage f or the shrinkage f orces to pull the plates out of alignment. Figure 3-7(e) illustrates this. Both design of the

weldment and welding sequence can be used ef f ectively to control distortion.

Fig. 3-7 Distortion can be prevented or minimized by

techniques that def eat - or use constructively - the ef f ects

of the heating and cooling cycle.

5. Balance welds around the neutral axis

This practice, shown in Fig. 3-7(f ), of f sets one shrinkage f orce with another to ef f ectively minimize distortion of the weldment. Here, too, design of the assembly

and proper sequence of welding are important f actors.

6. Use backstep welding

In the backstep technique, the general progression of welding may be, say, f rom lef t to right, but each bead segment is deposited f rom right to lef t as in Fig. 3-

7(g). As each bead segment is placed, the heated edges expand, which temporarily separates the plates at B. But as the heat moves out across the plate to C,

expansion along outer edges CD brings the plates back together. This separation is most pronounced as the f irst bead is laid. With successive beads, the plates

expand less and less because of the restraint of prior welds. Backstepping may not be ef f ective in all applications, and it cannot be used economically in

automatic welding.

4/28/2014 Weld Distortion

http://www.lincolnelectric.com/en-us/support/welding-how-to/pages/weld-distortion-detail.aspx 3/5

Fig. 3-7 Distortion can be prevented or minimized by

techniques that def eat - or use constructively - the ef f ects

of the heating and cooling cycle.

7. Anticipate the shrinkage forces

Presetting parts (at f irst glance, I thought that this was ref erring to overhead or vertical welding positions, which is not the case) bef ore welding can make

shrinkage perf orm constructive work. Several assemblies, preset in this manner, are shown in Fig. 3-7(h). The required amount of preset f or shrinkage to pull the

plates into alignment can be determined f rom a f ew trial welds.

Prebending, presetting or prespringing the parts to be welded, Fig. 3-7(i), is a simple example of the use of opposing mechanical f orces to counteract distortion

due to welding. The top of the weld groove - which will contain the bulk of the weld metal - is lengthened when the plates are preset. Thus the completed weld is

slightly longer than it would be if it had been made on the f lat plate. When the clamps are released af ter welding, the plates return to the f lat shape, allowing the

weld to relieve its longitudinal shrinkage stresses by shortening to a straight line. The two actions coincide, and the welded plates assume the desired f latness.

Another common practice f or balancing shrinkage f orces is to position identical weldments back to back, Fig. 3-7(j), clamping them tightly together. The welds are

completed on both assemblies and allowed to cool bef ore the clamps are released. Prebending can be combined with this method by inserting wedges at suitable

positions between the parts bef ore clamping.

In heavy weldments, particularly, the rigidity of the members and their arrangement relative to each other may provide the balancing f orces needed. If these

natural balancing f orces are not present, it is necessary to use other means to counteract the shrinkage f orces in the weld metal. This can be accomplished by

balancing one shrinkage f orce against another or by creating an opposing f orce through the f ixturing. The opposing f orces may be: other shrinkage f orces;

restraining f orces imposed by clamps, jigs, or f ixtures; restraining f orces arising f rom the arrangement of members in the assembly; or the f orce f rom the sag in a

member due to gravity.

8. Plan the welding sequence

A well-planned welding sequence involves placing weld metal at dif f erent points of the assembly so that, as the structure shrinks in one place, it counteracts the

shrinkage f orces of welds already made. An example of this is welding alternately on both sides of the neutral axis in making a complete joint penetration groove

weld in a butt joint, as in Fig. 3-7(k). Another example, in a f illet weld, consists of making intermittent welds according to the sequences shown in Fig. 3-7(l). In

these examples, the shrinkage in weld No. 1 is balanced by the shrinkage in weld No. 2.

Fig. 3-7 Distortion can be prevented or minimized by

techniques that def eat - or use constructively - the ef f ects

of the heating and cooling cycle.

4/28/2014 Weld Distortion

http://www.lincolnelectric.com/en-us/support/welding-how-to/pages/weld-distortion-detail.aspx 4/5

Clamps, jigs, and f ixtures that lock parts into a desired position and hold them until welding is f inished are probably the most widely used means f or controlling

distortion in small assemblies or components. It was mentioned earlier in this section that the restraining f orce provided by clamps increases internal stresses in

the weldment until the yield point of the weld metal is reached. For typical welds on low-carbon plate, this stress level would approximate 45,000 psi. One might

expect this stress to cause considerable movement or distortion af ter the welded part is removed f rom the jig or clamps. This does not occur, however, since the

strain (unit contraction) f rom this stress is very low compared to the amount of movement that would occur if no restraint were used during welding.

9. Remove shrinkage forces after welding

Peening is one way to counteract the shrinkage f orces of a weld bead as it cools. Essentially, peening the bead stretches it and makes it thinner, thus relieving

(by plastic def ormation) the stresses induced by contraction as the metal cools. But this method must be used with care. For example, a root bead should never

be peened, because of the danger of either concealing a crack or causing one. Generally, peening is not permitted on the f inal pass, because of the possibility of

covering a crack and interf ering with inspection, and because of the undesirable work-hardening ef f ect. Thus, the utility of the technique is limited, even though

there have been instances where between-pass peening proved to be the only solution f or a distortion or cracking problem. Bef ore peening is used on a job,

engineering approval should be obtained.

Another method f or removing shrinkage f orces is by thermal stress relieving - controlled heating of the weldment to an elevated temperature, f ollowed by

controlled cooling. Sometimes two identical weldments are clamped back to back, welded, and then stress-relieved while being held in this straight condition. The

residual stresses that would tend to distort the weldments are thus minimized.

10. Minimize welding time

Since complex cycles of heating and cooling take place during welding, and since time is required f or heat transmission, the time f actor af f ects distortion. In

general, it is desirable to f inish the weld quickly, bef ore a large volume of surrounding metal heats up and expands. The welding process used, type and size of

electrode, welding current, and speed of travel, thus, af f ect the degree of shrinkage and distortion of a weldment. The use of mechanized welding equipment

reduces welding time and the amount of metal af f ected by heat and, consequently, distortion. For example, depositing a given-size weld on thick plate with a

process operating at 175 amp, 25 volts, and 3 ipm requires 87,500 joules of energy per linear inch of weld (also known as heat input). A weld with approximately

the same size produced with a process operating at 310 amp, 35 volts, and 8 ipm requires 81,400 joules per linear inch. The weld made with the higher heat input

generally results in a greater amount of distortion. (note: I don't want to use the words "excessive" and "more than necessary" because the weld size is, in f act,

tied to the heat input. In general, the f illet weld size (in inches) is equal to the square root of the quantity of the heat input (kJ/in) divided by 500. Thus these two

welds are most likely not the same size.

Other Techniques for Distortion Control

Water-Cooled Jig

Various techniques have been developed to control distortion on specif ic weldments. In sheet-metal welding, f or example, a water-cooled jig (Fig. 3-33) is usef ul

to carry heat away f rom the welded components. Copper tubes are brazed or soldered to copper holding clamps, and the water is circulated through the tubes

during welding. The restraint of the clamps also helps minimize distortion.

Fig. 3-33 A water-cooled jig f or rapid removal of

heat when welding sheet meta.

Strongback

The "strongback" is another usef ul technique f or distortion control during butt welding of plates, as in Fig. 3-34(a). Clips are welded to the edge of one plate and

wedges are driven under the clips to f orce the edges into alignment and to hold them during welding.

Fig. 3-34 Various strongback arrangements to

control distortion during butt-welding.

4/28/2014 Weld Distortion

http://www.lincolnelectric.com/en-us/support/welding-how-to/pages/weld-distortion-detail.aspx 5/5

Thermal Stress Relieving

Except in special situations, stress relief by heating is not used f or correcting distortion. There are occasions, however, when stress relief is necessary to

prevent f urther distortion f rom occurring bef ore the weldment is f inished.

Summary: A Checklist to Minimize Distortion

Follow this checklist in order to minimize distortion in the design and f abrication of weldments:

Do not overweld

Control f itup

Use intermittent welds where possible and consistent with design requirements

Use the smallest leg size permissible when f illet welding

For groove welds, use joints that will minimize the volume of weld metal. Consider double-sided joints instead of single-sided joints

Weld alternately on either side of the joint when possible with multiple-pass welds

Use minimal number of weld passes

Use low heat input procedures. This generally means high deposition rates and higher travel speeds

Use welding positioners to achieve the maximum amount of f lat-position welding. The f lat position permits the use of large-diameter electrodes and high-

deposition-rate welding procedures

Balance welds about the neutral axis of the member

Distribute the welding heat as evenly as possible through a planned welding sequence and weldment positioning

Weld toward the unrestrained part of the member

Use clamps, f ixtures, and strongbacks to maintain f itup and alignment

Prebend the members or preset the joints to let shrinkage pull them back into alignment

Sequence subassemblies and f inal assemblies so that the welds being made continually balance each other around the neutral axis of the section

Following these techniques will help minimize the ef f ects of distortion and residual stresses.

Das könnte Ihnen auch gefallen

- Beeline Timing BeltsDokument1 SeiteBeeline Timing BeltsansarALLAAHNoch keine Bewertungen

- ISO Hole Limits TolerancesDokument3 SeitenISO Hole Limits TolerancesansarALLAAHNoch keine Bewertungen

- Synchro FlexDokument19 SeitenSynchro FlexsilvaroneNoch keine Bewertungen

- List of CNC Machine CodesDokument5 SeitenList of CNC Machine CodesansarALLAAHNoch keine Bewertungen

- How R Boxes MadeDokument6 SeitenHow R Boxes MadeKeka SomaiahNoch keine Bewertungen

- Lifting Lug Design Per ASME BTH-1-2005: InputDokument4 SeitenLifting Lug Design Per ASME BTH-1-2005: InputcoolkaisyNoch keine Bewertungen

- Tempil Preheating ChartDokument1 SeiteTempil Preheating ChartansarALLAAHNoch keine Bewertungen

- NOK Packing Seal - GeneralDokument9 SeitenNOK Packing Seal - GeneralansarALLAAHNoch keine Bewertungen

- Paadeye S TypeDokument148 SeitenPaadeye S TypeansarALLAAHNoch keine Bewertungen

- DOS CommandDokument6 SeitenDOS CommandManoj PandeyNoch keine Bewertungen

- Fluid Power Seal GuideDokument424 SeitenFluid Power Seal GuideDillibabu RNoch keine Bewertungen

- Viking Energy PresentationDokument8 SeitenViking Energy PresentationansarALLAAHNoch keine Bewertungen

- LOLER NSL Inspection MetricDokument1 SeiteLOLER NSL Inspection MetricbudygmoodNoch keine Bewertungen

- Precision Engineering Directory Singapore 2009Dokument60 SeitenPrecision Engineering Directory Singapore 2009ansarALLAAH100% (1)

- TDS - Barrier 90 - English (Uk) - Issued.05.10.2011Dokument4 SeitenTDS - Barrier 90 - English (Uk) - Issued.05.10.2011ansarALLAAHNoch keine Bewertungen

- Strandjack H-140 - Connecting Piece CP-140Dokument1 SeiteStrandjack H-140 - Connecting Piece CP-140ansarALLAAHNoch keine Bewertungen

- Weld Assure GasPurifiersDokument2 SeitenWeld Assure GasPurifiersansarALLAAHNoch keine Bewertungen

- LR Soot Blow PDFDokument35 SeitenLR Soot Blow PDFvtbk100% (1)

- Strandjack H 140Dokument1 SeiteStrandjack H 140ansarALLAAHNoch keine Bewertungen

- Strandjack H 300Dokument1 SeiteStrandjack H 300ansarALLAAHNoch keine Bewertungen

- Stainless SteelDokument8 SeitenStainless SteelAlvaro Alexis Mendoza PradaNoch keine Bewertungen

- American Structural ShapesDokument16 SeitenAmerican Structural ShapesAlfonsoNoch keine Bewertungen

- Vector Techlok BrochureDokument34 SeitenVector Techlok BrochureRobert Murray100% (2)

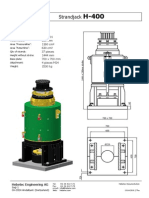

- Strandjack H-400 PDFDokument1 SeiteStrandjack H-400 PDFansarALLAAHNoch keine Bewertungen

- Rotary SootDokument8 SeitenRotary SootAnoop Kumar AllankiNoch keine Bewertungen

- Zaclon Galvanizing HandbookDokument127 SeitenZaclon Galvanizing HandbookMohammed Abdallah100% (2)

- Zeron100 Welding GuidelinesDokument8 SeitenZeron100 Welding GuidelinesansarALLAAHNoch keine Bewertungen

- ARC-23066 ST-23A Spool Gun DataDokument2 SeitenARC-23066 ST-23A Spool Gun DataansarALLAAHNoch keine Bewertungen

- ZS Customer and Project-NewDokument3 SeitenZS Customer and Project-NewansarALLAAHNoch keine Bewertungen

- ZinkPower Batam - Company BrochureDokument6 SeitenZinkPower Batam - Company BrochureansarALLAAHNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- EDAG0007Dokument5 SeitenEDAG0007krunalNoch keine Bewertungen

- Citrus Information Kit-Update: Reprint - Information Current in 1998Dokument53 SeitenCitrus Information Kit-Update: Reprint - Information Current in 1998hamsa sewakNoch keine Bewertungen

- The Teacher Research Movement: A Decade Later: Cite This PaperDokument13 SeitenThe Teacher Research Movement: A Decade Later: Cite This PaperAlexandre NecromanteionNoch keine Bewertungen

- MCFKTP G3 S2 SC Number Pattern PuzzlesDokument5 SeitenMCFKTP G3 S2 SC Number Pattern PuzzlesEric GoNoch keine Bewertungen

- Some Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsDokument5 SeitenSome Studies On Structure and Properties of Wrapped Jute (Parafil) YarnsVedant MahajanNoch keine Bewertungen

- P D P: C I D, C M: Design of Coastal RoadsDokument55 SeitenP D P: C I D, C M: Design of Coastal RoadsMohammedNoch keine Bewertungen

- Chudamani Women Expecting ChangeDokument55 SeitenChudamani Women Expecting ChangeMr AnantNoch keine Bewertungen

- What Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?Dokument11 SeitenWhat Is The Difference Between Newtonian and Non-Newtonian Fluid and Give Example For Each Case?MOHAMED ABD ELGHANYNoch keine Bewertungen

- Chapter 1 INTRODUCTION TO LITERATUREDokument4 SeitenChapter 1 INTRODUCTION TO LITERATUREDominique TurlaNoch keine Bewertungen

- Department of Education: Republic of The PhilippinesDokument2 SeitenDepartment of Education: Republic of The PhilippinesISMAEL KRIS DELA CRUZNoch keine Bewertungen

- Unit 20: TroubleshootingDokument12 SeitenUnit 20: TroubleshootingDongjin LeeNoch keine Bewertungen

- Nationalism, Feminism, and Modernity in PalestineDokument26 SeitenNationalism, Feminism, and Modernity in PalestinebobandjoerockNoch keine Bewertungen

- Construction Claims and Contract Admin CPDDokument40 SeitenConstruction Claims and Contract Admin CPDCraig FawcettNoch keine Bewertungen

- 2023 2024 Syllabus PDFDokument23 Seiten2023 2024 Syllabus PDFRika DianaNoch keine Bewertungen

- Swift As A MisanthropeDokument4 SeitenSwift As A MisanthropeindrajitNoch keine Bewertungen

- 3DS 2017 GEO GEMS Brochure A4 WEBDokument4 Seiten3DS 2017 GEO GEMS Brochure A4 WEBlazarpaladinNoch keine Bewertungen

- LT3845ADokument26 SeitenLT3845Asoft4gsmNoch keine Bewertungen

- PID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDokument7 SeitenPID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDenisNoch keine Bewertungen

- Week 1 Familiarize The VmgoDokument10 SeitenWeek 1 Familiarize The VmgoHizzel De CastroNoch keine Bewertungen

- Grua Grove 530e 2 Manual de PartesDokument713 SeitenGrua Grove 530e 2 Manual de PartesGustavo100% (7)

- 12 Logarithm Approximate FloatingDokument6 Seiten12 Logarithm Approximate FloatingPhilippe Englert VelhaNoch keine Bewertungen

- An Introduction To Routine and Special StainingDokument13 SeitenAn Introduction To Routine and Special StainingBadiu ElenaNoch keine Bewertungen

- Mossbauer SpectrosDokument7 SeitenMossbauer SpectroscyrimathewNoch keine Bewertungen

- Sub-Wings of YuvanjaliDokument2 SeitenSub-Wings of Yuvanjalin_tapovan987100% (1)

- On The Wings of EcstasyDokument79 SeitenOn The Wings of Ecstasygaya3mageshNoch keine Bewertungen

- Abdominal Migraine and HomoeopathyDokument17 SeitenAbdominal Migraine and HomoeopathyDr. Rajneesh Kumar Sharma MD HomNoch keine Bewertungen

- When SIBO & IBS-Constipation Are Just Unrecognized Thiamine DeficiencyDokument3 SeitenWhen SIBO & IBS-Constipation Are Just Unrecognized Thiamine Deficiencyps piasNoch keine Bewertungen

- P6 - TT2 - Revision Test 2021-2022 Page 1 of 11Dokument11 SeitenP6 - TT2 - Revision Test 2021-2022 Page 1 of 11Nilkanth DesaiNoch keine Bewertungen

- Linux and The Unix PhilosophyDokument182 SeitenLinux and The Unix PhilosophyTran Nam100% (1)

- RESEARCHDokument5 SeitenRESEARCHroseve cabalunaNoch keine Bewertungen