Beruflich Dokumente

Kultur Dokumente

Fluid Machinery

Hochgeladen von

aadhanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fluid Machinery

Hochgeladen von

aadhanCopyright:

Verfügbare Formate

INTRODUCTION

A fluid machine is a device which converts the energy stored by a fluid into

mechanical energy or vice versa . The energy stored by a fluid mass aears in

the form of otential! "inetic and intermolecular energy. The mechanical

energy! on the other hand! is usually transmitted by a rotating shaft. #achines

using li$uid %mainly water! for almost all ractical uroses& are termed as

hydraulic machines. In this chater we shall discuss! in general! the basic fluid

mechanical rincile governing the energy transfer in a fluid machine and also

a brief descrition of different "inds of hydraulic machines along with their

erformances. Discussion on machines using air or other gases is beyond the

scoe of the chater.

C'A((I)ICAITON( O) )'UID #AC*IN+(

The fluid machines may be classified under different categories as follows,

Classification -ased on Direction of +nergy Conversion.

The device in which the "inetic! otential or intermolecular energy held by the

fluid is converted in the form of mechanical energy of a rotating member is

"nown as a turbine . The machines! on the other hand! where the mechanical

energy from moving arts is transferred to a fluid to increase its stored energy

by increasing either its ressure or velocity are "nown as ums! comressors!

fans or blowers .

Classification -ased on .rincile of Oeration

The machines whose functioning deend essentially on the change of volume

of a certain amount of fluid within the machine are "nown as ositive

dislacement machines . The word ositive dislacement comes from the fact

that there is a hysical dislacement of the boundary of a certain fluid mass as

a closed system. This rincile is utili/ed in ractice by the recirocating

motion of a iston within a cylinder while entraing a certain amount of fluid

in it. Therefore! the word recirocating is commonly used with the name of the

machines of this "ind. The machine roducing mechanical energy is "nown as

recirocating engine while the machine develoing energy of the fluid from the

mechanical energy is "nown as recirocating um or recirocating

comressor.

The machines! functioning of which deend basically on the rincile of fluid

dynamics! are "nown as rotodynamic machines . They are distinguished from

ositive dislacement machines in re$uiring relative motion between the fluid

and the moving art of the machine. The rotating element of the machine

usually consisting of a number of vanes or blades! is "nown as rotor or imeller

while the fi0ed art is "nown as stator. Imeller is the heart of rotodynamic

machines! within which a change of angular momentum of fluid occurs

imarting tor$ue to the rotating member.

)or turbines! the wor" is done by the fluid on the rotor! while! in case of um!

comressor! fan or blower! the wor" is done by the rotor on the fluid element.

Deending uon the main direction of fluid ath in the rotor! the machine is

termed as radial flow or a0ial flow machine . In radial flow machine! the main

direction of flow in the rotor is radial while in a0ial flow machine! it is a0ial. )or

radial flow turbines! the flow is towards the centre of the rotor! while! for

ums and comressors! the flow is away from the centre. Therefore! radial

flow turbines are sometimes referred to as radially inward flow machines and

radial flow ums as radially outward flow machines. +0amles of such

machines are the )rancis turbines and the centrifugal ums or comressors.

The e0amles of a0ial flow machines are 1alan turbines and a0ial flow

comressors. If the flow is arty radial and artly a0ial! the term mi0ed2flow

machine is used. )igure 3.3 %a& %b& and %c& are the schematic diagrams of

various tyes of imellers based on the flow direction.

Classification -ased on )luid Used

The fluid machines use either li$uid or gas as the wor"ing fluid deending uon

the urose. The machine transferring mechanical energy of rotor to the

energy of fluid is termed as a um when it uses li$uid! and is termed as a

comressor or a fan or a blower! when it uses gas. The comressor is a

machine where the main ob4ective is to increase the static ressure of a gas.

Therefore! the mechanical energy held by the fluid is mainly in the form of

ressure energy. )ans or blowers! on the other hand! mainly cause a high flow

of gas! and hence utili/e the mechanical energy of the rotor to increase mostly

the "inetic energy of the fluid. In these machines! the change in static ressure

is $uite small.

)or all ractical uroses! li$uid used by the turbines roducing ower is water!

and therefore! they are termed as water turbines or hydraulic turbines .

Turbines handling gases in ractical fields are usually referred to as steam

turbine! gas turbine! and air turbine deending uon whether they use steam!

gas %the mi0ture of air and roducts of burnt fuel in air& or air.

ROTOD5NA#IC #AC*IN+(

In this section! we shall discuss the basic rincile of rotodynamic machines

and the erformance of different "inds of those machines. The imortant

element of a rotodynamic machine! in general! is a rotor consisting of a

number of vanes or blades. There always e0ists a relative motion between the

rotor vanes and the fluid. The fluid has a comonent of velocity and hence of

momentum in a direction tangential to the rotor. 6hile flowing through the

rotor! tangential velocity and hence the momentum changes.

The rate at which this tangential momentum changes corresonds to a

tangential force on the rotor. In a turbine! the tangential momentum of the

fluid is reduced and therefore wor" is done by the fluid to the moving rotor. -ut

in case of ums and comressors there is an increase in the tangential

momentum of the fluid and therefore wor" is absorbed by the fluid from the

moving rotor.

-asic +$uation of +nergy Transfer in Rotodynamic #achines

The basic e$uation of fluid dynamics relating to energy transfer is same for all

rotodynamic machines and is a simle form of 7 Newton 8s 'aws of #otion7

alied to a fluid element traversing a rotor. *ere we shall ma"e use of the

momentum theorem as alicable to a fluid element while flowing through

fi0ed and moving vanes. )igure 3.9 reresents diagrammatically a rotor of a

generalised fluid machine! with :2: the a0is of rotation and the angular

velocity. )luid enters the rotor at 3! asses through the rotor by any ath and

is discharged at 9. The oints 3 and 9 are at radii and from the centre of the

rotor! and the directions of fluid velocities at 3 and 9 may be at any arbitrary

angles. )or the analysis of energy transfer due to fluid flow in this situation! we

assume the following,

%a& The flow is steady! that is! the mass flow rate is constant across any

section %no storage or deletion of fluid mass in the rotor&.

%b& The heat and wor" interactions between the rotor and its surroundings

ta"e lace at a constant rate.

%c& ;elocity is uniform over any area normal to the flow. This means that the

velocity vector at any oint is reresentative of the total flow over a finite area.

This condition also imlies that there is no lea"age loss and the entire fluid is

undergoing the same rocess.

The velocity at any oint may be resolved into three mutually erendicular

comonents as shown in )ig 3.9. The a0ial comonent of velocity is directed

arallel to the a0is of rotation ! the radial comonent is directed radially

through the a0is to rotation! while the tangential comonent is directed at

right angles to the radial direction and along the tangent to the rotor at that

art.

The change in magnitude of the a0ial velocity comonents through the rotor

causes a change in the a0ial momentum. This change gives rise to an a0ial

force! which must be ta"en by a thrust bearing to the stationary rotor casing.

The change in magnitude of radial velocity causes a change in momentum in

radial direction.

*owever! for an a0isymmetric flow! this does not result in any net radial force

on the rotor. In case of a non uniform flow distribution over the erihery of the

rotor in ractice! a change in momentum in radial direction may result in a net

radial force which is carried as a 4ournal load. The tangential comonent only

has an effect on the angular motion of the rotor. In consideration of the entire

fluid body within the rotor as a control volume! we can write from the moment

of momentum theorem

3.3

where T is the tor$ue e0erted by the rotor on the moving fluid! m is the mass

flow rate of fluid through the rotor. The subscrits 3 and 9 denote values at

inlet and outlet of the rotor resectively. The rate of energy transfer to the fluid

is then given by

3.9

where

is the angular velocity of the rotor and

which reresents the linear velocity of the rotor. Therefore

and

are the linear velocities of the rotor at oints 9 %outlet & and 3 %inlet&

resectively %)ig. 3.9&. The +$! %3.9& is "nown as +uler8s e$uation in relation to

fluid machines. The +$. %3.9& can be written in terms of head gained 8*8 by the

fluid as

3.<

In usual convention relating to fluid machines! the head delivered by the fluid

to the rotor is considered to be ositive and vice2versa. Therefore! +$. %3.<&

written with a change in the sign of the right hand side in accordance with the

sign convention as

3.=

Comonents of +nergy Transfer It is worth mentioning in this conte0t that

either of the +$s. %3.9& and %3.=& is alicable regardless of changes in density

or comonents of velocity in other directions. #oreover! the shae of the ath

ta"en by the fluid in moving from inlet to outlet is of no conse$uence. The

e0ression involves only the inlet and outlet conditions. A rotor! the moving

art of a fluid machine! usually consists of a number of vanes or blades

mounted on a circular disc. )igure 3.<a shows the velocity triangles at the inlet

and outlet of a rotor. The inlet and outlet ortions of a rotor vane are only

shown as a reresentative of the whole rotor.

;ector diagrams of velocities at inlet and outlet corresond to two velocity

triangles! where

is the velocity of fluid relative to the rotor and

are the angles made by the directions of the absolute velocities at the inlet and

outlet resectively with the tangential direction! while

and

and are the angles made by the relative velocities with the tangential

direction. The angles and should match with vane or blade angles at inlet and

outlet resectively for a smooth! shoc"less entry and e0it of the fluid to avoid

undersirable losses. Now we shall aly a simle geometrical relation as

follows,

)rom the inlet velocity triangle!

or

3.>

(imilarly from the outlet velocity triangle.

or

3.?

Invo"ing the e0ressions of

and

in +$. %3.=&! we get * %6or" head! i.e. energy er unit weight of fluid!

transferred between the fluid and the rotor as& as

3.@

The +$ %3.@& is an imortant form of the +uler8s e$uation relating to fluid

machines since it gives the three distinct comonents of energy transfer as

shown by the air of terms in the round brac"ets. These comonents throw

light on the nature of the energy transfer. The first term of +$. %3.@& is readily

seen to be the change in absolute "inetic energy or dynamic head of the fluid

while flowing through the rotor. The second term of +$. %3.@& reresents a

change in fluid energy due to the movement of the rotating fluid from one

radius of rotation to another.

Das könnte Ihnen auch gefallen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- S3 VMRDokument12 SeitenS3 VMRaadhanNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- SpiceJet - E-Ticket - PNR J2CT7Y - 23 Nov 2015 Chennai-Delhi For MRS. KANAGARAJDokument2 SeitenSpiceJet - E-Ticket - PNR J2CT7Y - 23 Nov 2015 Chennai-Delhi For MRS. KANAGARAJaadhanNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Bharat Sanchar Nigam Limited: Receipt DetailsDokument1 SeiteBharat Sanchar Nigam Limited: Receipt DetailsaadhanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Mech Syllabus PDFDokument162 SeitenMech Syllabus PDFaadhanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Design of Machine ElementsDokument53 SeitenDesign of Machine ElementsSrks Kondal Reddy100% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- DTS PDFDokument18 SeitenDTS PDFaadhan100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Design of Machine ElementsDokument53 SeitenDesign of Machine ElementsSrks Kondal Reddy100% (2)

- Dynamics of Machinery PDFDokument18 SeitenDynamics of Machinery PDFThomas VictorNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Design of Machine ElementsDokument53 SeitenDesign of Machine ElementsSrks Kondal Reddy100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Dynamics of Machinery PDFDokument18 SeitenDynamics of Machinery PDFThomas VictorNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

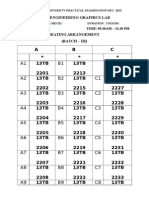

- P-103 Engineering Graphics Lab: DATE: 26-12-2013 TIME: 09.30AM - 12.30 PMDokument3 SeitenP-103 Engineering Graphics Lab: DATE: 26-12-2013 TIME: 09.30AM - 12.30 PMaadhanNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Classificaitons of Fluid MachinesDokument4 SeitenClassificaitons of Fluid MachinesaadhanNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Diverter Damper SystemsDokument8 SeitenDiverter Damper SystemsSajjad Ahmed100% (1)

- Gas Turbine & GeneratorDokument37 SeitenGas Turbine & GeneratorONURNoch keine Bewertungen

- Fluid Mechanics and Hydraulic Machine PDFDokument3 SeitenFluid Mechanics and Hydraulic Machine PDFChaudhary Rahul SinghNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Airfoil Database PDFDokument119 SeitenAirfoil Database PDFmurjass85Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Performance Test On Francis Turbine and Pelton TurbineDokument21 SeitenPerformance Test On Francis Turbine and Pelton TurbineSyf100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Asme 19.23 1980 PDFDokument86 SeitenAsme 19.23 1980 PDFPopescu AlinNoch keine Bewertungen

- Capacity Expansion PlanningDokument42 SeitenCapacity Expansion PlanningAkif Zia KhanNoch keine Bewertungen

- 7FA Flex Seal Upgrade - LetterDokument2 Seiten7FA Flex Seal Upgrade - LetterPeter_Phee_341Noch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Turbo ShaftDokument10 SeitenTurbo ShaftMarco MendezNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidroturbinas en Brazil. - Tiago FilhoDokument2 SeitenHidroturbinas en Brazil. - Tiago Filhodm311Noch keine Bewertungen

- BTech - 5th - 6th - Sem MEDokument9 SeitenBTech - 5th - 6th - Sem MEN KumarNoch keine Bewertungen

- GRPTS TurbochargersDokument65 SeitenGRPTS TurbochargersFaur RahmanNoch keine Bewertungen

- Fluid Mechanics Objective Type QuestionsDokument223 SeitenFluid Mechanics Objective Type Questionsshivi_shivendraNoch keine Bewertungen

- Once Through Boiler Recirculation PumpDokument6 SeitenOnce Through Boiler Recirculation Pumpபிரசன்னகுமார் ஆனந்தன்Noch keine Bewertungen

- Turbo Chargers T3-T4Dokument1 SeiteTurbo Chargers T3-T4Andries FerreiraNoch keine Bewertungen

- Underwater - Windmill 2Dokument9 SeitenUnderwater - Windmill 2Yadnyesh TaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Certification Testing For Small Wind Turbines: D. Corbus, H. Link, S. Butterfield, C. Stork, and C. Newcomb T. SasseenDokument10 SeitenCertification Testing For Small Wind Turbines: D. Corbus, H. Link, S. Butterfield, C. Stork, and C. Newcomb T. SasseenAmlan DasNoch keine Bewertungen

- Automatically Regulated C.V.T. in Wind PDFDokument12 SeitenAutomatically Regulated C.V.T. in Wind PDFمهيمن فالح حمدNoch keine Bewertungen

- Vdocuments - MX - Cooling and Sealing Air SystemDokument17 SeitenVdocuments - MX - Cooling and Sealing Air Systemmohammad mortazavi100% (1)

- Initialization of Wind Turbine Dynamic ModelDokument6 SeitenInitialization of Wind Turbine Dynamic ModelEléctrico IngenieríaNoch keine Bewertungen

- Paper - MDPI-Energies.2021.Review On Dynamics of Offshore Floating Wind Turbine PlatformsDokument31 SeitenPaper - MDPI-Energies.2021.Review On Dynamics of Offshore Floating Wind Turbine PlatformstaigerasNoch keine Bewertungen

- An Iterative CFD and Mechanical Brush Seal Model and Comparison With Experimental ResultsDokument7 SeitenAn Iterative CFD and Mechanical Brush Seal Model and Comparison With Experimental ResultsНиколайNoch keine Bewertungen

- M.tech SyllabusDokument41 SeitenM.tech SyllabusRushikeshKatkarNoch keine Bewertungen

- Lecture17 Energybalance OpenDokument31 SeitenLecture17 Energybalance Opennurul syamimieNoch keine Bewertungen

- ch05 PDFDokument8 Seitench05 PDFAkash ThummarNoch keine Bewertungen

- Utilities Plant Description: Presented byDokument46 SeitenUtilities Plant Description: Presented byAWAIS50% (2)

- Wind Energy Basics Definition of Wind EnergyDokument4 SeitenWind Energy Basics Definition of Wind EnergyPartha BaruahNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Compre JamDokument2 SeitenCompre Jammarlo ignacioNoch keine Bewertungen

- FMHM Phase 1Dokument3 SeitenFMHM Phase 1KUNAL PATELNoch keine Bewertungen