Beruflich Dokumente

Kultur Dokumente

Centrifugal Pump Script

Hochgeladen von

cgjp120391Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Centrifugal Pump Script

Hochgeladen von

cgjp120391Copyright:

Verfügbare Formate

E21 Characteristics if a Centrifugal Pump

JContext

A centrifugal pump converts the input power to kinetic energy in the liquid by accelerating the liquid by an

impeller

Centrifugal pumps are used to move liquids through a piping system

The efficiency of a centrifugal pump is important as a pump running at a low efficiency increases costs

APurpose of Experiment

To determine the change in pressure against flow rate

To find out the overall efficiency of a centrifugal pump from the output power and the input power

JDiagram

This is a diagram of the apparatus

Water is pumped through the centrifugal pump from the tank and around the system

The flow rate is varied using the two rotameters

At each flow rate the delivery pressure on the pressure gauge and the power consumption of the pump is

recorded

The pressure gauge measures the gauge pressure this is the absolute pressure minus the standard pressure

AResults

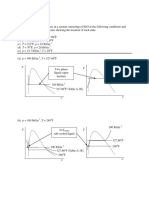

1)

The flow rate was first set to 2l/min using the rotameter on the right. It was then increased by 2l/min up to

10l/min. Above this the flow rate was increased by 10l/min.

The graph shows that as the flow rate increases the delivery pressure decreases.

2)

To measure the power consumption of the pump the same pattern of flow rate were used.

As the flow rate increases the efficiency of the pump increases up a flow rate of 1.67*10

-3

m

3

/s where the

efficiency starts to decrease.

J3)

Velocity of a liquid can be calculated by using continuity equation which is Q=UA.

The output power equation is derived from Bernoullis equation. Rho 1 equals rho 2 as water is the only liquid used.

V

2

is less than V

1

which means V

2

2

is a lot less that V

1

2

. H is the difference between z

2

and z

1

.Also the difference in

P

1

and P

2

is the gauge pressure reading. Therefore the Bernoullis equation can be simplified to ........ It is then

multiplied through by the liquid flow rate.

One of the sources of error was that the power reading was constantly changing which means that the correct

power consumption as not always recorded. Also at flow rates above 10l/min the water was leaking out of the valve

casing a break in the system

AConclusion

The maximum efficiency of the pump is 27.2% at a flow rate of 1.67*10

-3

m

3

/s. This efficiency is fairly low which

means it cant be used in a continuous process as the efficacy will decrease further.

As the flow rate increases the delivery pressure decreases. This is because the velocity increases so there is more

friction causing a decrease in pressure.

When a choosing a centrifugal pump, the flow rate has to considered. From the flow rate required a pump with the

maximum efficiency should be selected. This can be found out by examining the pumps performance curve.

J)Net positive suction head is the useful head available to push the liquid through the suction side pipework, and is

very important in the design of pumping systems.

j)The suitability of a centrifugal pump for a particular application can be determined by the desired suction head and

discharge head required.

Das könnte Ihnen auch gefallen

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesVon EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesBewertung: 5 von 5 Sternen5/5 (1)

- Note About Hydraulic PumpDokument0 SeitenNote About Hydraulic PumpzakiannuarNoch keine Bewertungen

- Chapter 9: Pumps, Compressors and Turbines: 9.1 Positive Displacement PumpDokument27 SeitenChapter 9: Pumps, Compressors and Turbines: 9.1 Positive Displacement PumpMukesh BohraNoch keine Bewertungen

- Tutorial 02 - Hydraulic PumpsDokument11 SeitenTutorial 02 - Hydraulic Pumpswouter_mae100% (1)

- Figure1.1: U-Tube ManometerDokument5 SeitenFigure1.1: U-Tube Manometeraydn_89Noch keine Bewertungen

- Ce 370 - Centrifugal Pump CharacteristicsDokument29 SeitenCe 370 - Centrifugal Pump CharacteristicsLeon SanchezNoch keine Bewertungen

- 302-Exp7 S13Dokument10 Seiten302-Exp7 S13Anurag KashyapNoch keine Bewertungen

- 336 TB 03metricsforimprovingwatermanagementinagricultureDokument4 Seiten336 TB 03metricsforimprovingwatermanagementinagricultureمؤمن سعيد طلحةNoch keine Bewertungen

- Efficiency and Input Power of The PumpDokument14 SeitenEfficiency and Input Power of The PumpMohammed BrashdiNoch keine Bewertungen

- Pumps & Pumping SystemDokument4 SeitenPumps & Pumping SystemAjay kunwar singhNoch keine Bewertungen

- Open Ended Lab Report (Wed G-4)Dokument9 SeitenOpen Ended Lab Report (Wed G-4)Osama RaheelNoch keine Bewertungen

- Hemanth Karmali & Deepak Pai - FomentoDokument46 SeitenHemanth Karmali & Deepak Pai - FomentoNileshNoch keine Bewertungen

- Design of Hydraulic Piezoelectric PumpDokument4 SeitenDesign of Hydraulic Piezoelectric PumpdhineshpNoch keine Bewertungen

- Ijert Ijert: Design and Experimental Setup of Pedal Operated Water PumpDokument5 SeitenIjert Ijert: Design and Experimental Setup of Pedal Operated Water PumpSri LekhaNoch keine Bewertungen

- 10 - Review Notes - Water Pumping EquipmentDokument12 Seiten10 - Review Notes - Water Pumping EquipmentPeter John Asaytona GalamitonNoch keine Bewertungen

- Lab 1 Series Parallel PumpsDokument16 SeitenLab 1 Series Parallel PumpsSasys Rgl100% (11)

- Lab 4 (Flowmeter Demonstration)Dokument23 SeitenLab 4 (Flowmeter Demonstration)Muhamad Baihakhi ShamsudinNoch keine Bewertungen

- Hydraulic PumpsDokument6 SeitenHydraulic PumpsSriram SastryNoch keine Bewertungen

- B21ME030 Lab3 PDFDokument8 SeitenB21ME030 Lab3 PDFJaydeep Prajapati (B21ME030)Noch keine Bewertungen

- Ebae 161 92 Ram Pump JenningsDokument6 SeitenEbae 161 92 Ram Pump JenningsGaguk Triosona PraditaNoch keine Bewertungen

- FM-II Week 5Dokument28 SeitenFM-II Week 5khizeraftab1018Noch keine Bewertungen

- Flow Meter MeasurementDokument12 SeitenFlow Meter Measurementrahman75% (8)

- ELEC3320 Lab ReportDokument16 SeitenELEC3320 Lab ReportTameem MithaiwalaNoch keine Bewertungen

- Pump CharacteristicsDokument8 SeitenPump CharacteristicsgeocaustasNoch keine Bewertungen

- Centrifugal Pump Performance Characteristics For DDokument6 SeitenCentrifugal Pump Performance Characteristics For DPinaki SankarNoch keine Bewertungen

- Water Metering MechanismDokument6 SeitenWater Metering MechanismMuhammad saqibNoch keine Bewertungen

- Fluid Mechanic XP 3Dokument12 SeitenFluid Mechanic XP 3Alimah AzeliNoch keine Bewertungen

- Sun Xiao1, Wu Shang1,, Hu Weilin1,, Wu Yulong1Dokument4 SeitenSun Xiao1, Wu Shang1,, Hu Weilin1,, Wu Yulong1Khalid ChrisNoch keine Bewertungen

- Sun Xiao1, Wu Shang1,, Hu Weilin1,, Wu Yulong1Dokument4 SeitenSun Xiao1, Wu Shang1,, Hu Weilin1,, Wu Yulong1Khalid ChrisNoch keine Bewertungen

- Lec 2 Ceng80Dokument4 SeitenLec 2 Ceng80Syrille alarconNoch keine Bewertungen

- (Chemical Engineering Laboratory Ii) : Segi University Experiment 4: Centrifugal PumpDokument9 Seiten(Chemical Engineering Laboratory Ii) : Segi University Experiment 4: Centrifugal Pumpgongweejie93Noch keine Bewertungen

- Centrifugal PumpsDokument20 SeitenCentrifugal PumpsBabylyn AustriaNoch keine Bewertungen

- Centrifugal Pump - VSD On TestDokument6 SeitenCentrifugal Pump - VSD On TestaurinkokelloNoch keine Bewertungen

- Unit VIII Reciprocating PumpsDokument16 SeitenUnit VIII Reciprocating PumpsRICHARD VALIENTENoch keine Bewertungen

- Analisys of Hidram Pump Perfomance On Variation Nof Waterfall AnglesDokument4 SeitenAnalisys of Hidram Pump Perfomance On Variation Nof Waterfall AnglesJose Gerardo Lopez LopezNoch keine Bewertungen

- Pitot Static TubeDokument4 SeitenPitot Static TubeVrushiket PatilNoch keine Bewertungen

- Centrifugal Pumps PDFDokument5 SeitenCentrifugal Pumps PDFWilliam SalazarNoch keine Bewertungen

- Influence of Produced Fluid Parameters On The UseDokument7 SeitenInfluence of Produced Fluid Parameters On The UseAlexander Aristizábal PeñalozaNoch keine Bewertungen

- Chapter 6 Pumps and CompressorDokument48 SeitenChapter 6 Pumps and CompressorIndiran SelvanNoch keine Bewertungen

- Hydraulic Machines LaboratoryDokument27 SeitenHydraulic Machines LaboratoryAnonymous f1UCK4Noch keine Bewertungen

- Numerical Calculation of Energy Performance and Transient Characteristics of Centrifugal Pump Under Gas-Liquid Two-Phase ConditionDokument14 SeitenNumerical Calculation of Energy Performance and Transient Characteristics of Centrifugal Pump Under Gas-Liquid Two-Phase Conditionoussema baddediNoch keine Bewertungen

- Experiment 7-Pump Performance - Single PumpDokument12 SeitenExperiment 7-Pump Performance - Single PumpVasanthan Rao0% (1)

- Performance and Experimentation On Centrifugal PumpDokument10 SeitenPerformance and Experimentation On Centrifugal PumpLohith AcharyaNoch keine Bewertungen

- Santosh G Kelshekar - AssortedDokument10 SeitenSantosh G Kelshekar - AssortedscemanjuNoch keine Bewertungen

- Experiment No. 7 Pump Performance - Single Pump: MEHB221 Fluids Mechanics Lab 2016Dokument6 SeitenExperiment No. 7 Pump Performance - Single Pump: MEHB221 Fluids Mechanics Lab 2016Syahmi ShahimanNoch keine Bewertungen

- Energy Equation & Its ApplicationsDokument47 SeitenEnergy Equation & Its ApplicationsRopah ChihuriNoch keine Bewertungen

- The Mathematics of Pumping Water: AECOM Design BuildDokument9 SeitenThe Mathematics of Pumping Water: AECOM Design BuildAdel SharifiNoch keine Bewertungen

- Sesion 5 FLOW MEASUREMENTDokument32 SeitenSesion 5 FLOW MEASUREMENTmuh amarNoch keine Bewertungen

- Flow MeasurementDokument40 SeitenFlow MeasurementPradyumna Dhamangaonkar100% (2)

- Theory2 2Dokument14 SeitenTheory2 2Yamama 1Noch keine Bewertungen

- Slides 5 Hydraulic MachineryDokument18 SeitenSlides 5 Hydraulic MachineryTing Wee KietNoch keine Bewertungen

- Centrifugal Pump TestDokument7 SeitenCentrifugal Pump TestiJeng RalluNoch keine Bewertungen

- Efficiency of Pumps in Parallel Operation On Long-Distance Water PipelinesDokument12 SeitenEfficiency of Pumps in Parallel Operation On Long-Distance Water Pipelinessimu84Noch keine Bewertungen

- Chapter Fluid MachineryDokument50 SeitenChapter Fluid MachineryWan AimanNoch keine Bewertungen

- 2 Pump-Pipeline SysDokument39 Seiten2 Pump-Pipeline SysAdelChNoch keine Bewertungen

- Analysis On Centrifugal Pump Performance in Single, Serial, and ParallelDokument8 SeitenAnalysis On Centrifugal Pump Performance in Single, Serial, and ParallelFaiz AkbarsyahNoch keine Bewertungen

- Discussion (Meant by Pump Characteristic)Dokument5 SeitenDiscussion (Meant by Pump Characteristic)Akmal ShaariNoch keine Bewertungen

- Safety Data Sheet: Di Deionised WaterDokument4 SeitenSafety Data Sheet: Di Deionised Watercgjp120391Noch keine Bewertungen

- Absorption of Carbon Dioxide Into WaterDokument13 SeitenAbsorption of Carbon Dioxide Into WaterPetronela CozmaNoch keine Bewertungen

- ATEX 2014-34-EU Guidelines - 2nd Edition December 2017Dokument238 SeitenATEX 2014-34-EU Guidelines - 2nd Edition December 2017ARTURONoch keine Bewertungen

- Liquid-Liquid Copper Extraction Process Perfected ExperimentsDokument4 SeitenLiquid-Liquid Copper Extraction Process Perfected Experimentscgjp120391Noch keine Bewertungen

- Unit Lab Manual 2011Dokument114 SeitenUnit Lab Manual 2011cgjp120391Noch keine Bewertungen

- Mod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot PlantDokument2 SeitenMod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot Plantcgjp120391Noch keine Bewertungen

- Armfield Oregon State PosterDokument1 SeiteArmfield Oregon State Postercgjp120391Noch keine Bewertungen

- Perfected Experiments RigsDokument3 SeitenPerfected Experiments Rigscgjp120391Noch keine Bewertungen

- UsefulCalculations PDFDokument3 SeitenUsefulCalculations PDFhbithoNoch keine Bewertungen

- LleDokument12 SeitenLlecgjp120391Noch keine Bewertungen

- Gas Cyclones: Eloise Jackson and Jigar PatelDokument24 SeitenGas Cyclones: Eloise Jackson and Jigar Patelcgjp120391Noch keine Bewertungen

- Lab ManualDokument155 SeitenLab ManualKieu Phuong PhamNoch keine Bewertungen

- Exbatrea PDFDokument6 SeitenExbatrea PDFNurhazimah IsmailNoch keine Bewertungen

- Ecre CD-CH13 PDFDokument78 SeitenEcre CD-CH13 PDFPadmesh TvnNoch keine Bewertungen

- Experimental InvestigationDokument6 SeitenExperimental Investigationcgjp120391Noch keine Bewertungen

- Armfield Dryer PriceDokument5 SeitenArmfield Dryer Pricecgjp120391Noch keine Bewertungen

- Teky's Tips: Mix Fluids As You Pump Them Through A Pipe LineDokument1 SeiteTeky's Tips: Mix Fluids As You Pump Them Through A Pipe Linecgjp120391Noch keine Bewertungen

- Ex MixingDokument7 SeitenEx Mixingcgjp120391Noch keine Bewertungen

- Teky's Tips: Mix Fluids As You Pump Them Through A Pipe LineDokument1 SeiteTeky's Tips: Mix Fluids As You Pump Them Through A Pipe Linecgjp120391Noch keine Bewertungen

- Tray Dryer LabDokument6 SeitenTray Dryer Labcgjp120391Noch keine Bewertungen

- Concentration To ConductivitycurvesDokument30 SeitenConcentration To Conductivitycurvescgjp120391Noch keine Bewertungen

- Unit Lab Manual 2011Dokument114 SeitenUnit Lab Manual 2011cgjp120391Noch keine Bewertungen

- UsefulCalculations PDFDokument3 SeitenUsefulCalculations PDFhbithoNoch keine Bewertungen

- Mass TransferDokument4 SeitenMass Transfercgjp120391Noch keine Bewertungen

- CoalescerDokument18 SeitenCoalescer112dharmesh0% (1)

- 1997 JFE p269 TsampDokument24 Seiten1997 JFE p269 Tsampcgjp120391Noch keine Bewertungen

- Mod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot PlantDokument2 SeitenMod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot Plantcgjp120391Noch keine Bewertungen

- LAB8Dokument6 SeitenLAB8cgjp120391Noch keine Bewertungen

- Chemical Compatibility Chart Metallic Materials Used in Bal Seal ProductsDokument28 SeitenChemical Compatibility Chart Metallic Materials Used in Bal Seal Productscgjp120391Noch keine Bewertungen

- Excstr PDFDokument7 SeitenExcstr PDFcgjp120391Noch keine Bewertungen

- Cost Classifications For Preparing External Financial StatementsDokument4 SeitenCost Classifications For Preparing External Financial StatementsEduNoch keine Bewertungen

- GemDokument9 SeitenGemRam Prasidh AnaswaraNoch keine Bewertungen

- Automotive Connectors: BAB Connector SISC ConnectorDokument13 SeitenAutomotive Connectors: BAB Connector SISC ConnectorPrabhansh PandeyNoch keine Bewertungen

- Compliance Options For UL 1446 BrochureDokument10 SeitenCompliance Options For UL 1446 BrochureNeoZeruelNoch keine Bewertungen

- Lecture 6Dokument36 SeitenLecture 6keiNoch keine Bewertungen

- 303-W1-Rb-0632-1-Rdl-Num Det of Sup STR PDFDokument1 Seite303-W1-Rb-0632-1-Rdl-Num Det of Sup STR PDFJkkhyhNoch keine Bewertungen

- Magnum Composite Plug Catalog 06-30-10Dokument21 SeitenMagnum Composite Plug Catalog 06-30-10Emad JamshidiNoch keine Bewertungen

- Comitrol Processor Model 1700: Controlled Particle Size ReductionDokument2 SeitenComitrol Processor Model 1700: Controlled Particle Size ReductionNguyễn Lê Anh KhoaNoch keine Bewertungen

- Speed TripleDokument379 SeitenSpeed TriplecsavargaNoch keine Bewertungen

- ME 231 Montazami Whharris 9-10-18 SOLUTIONDokument4 SeitenME 231 Montazami Whharris 9-10-18 SOLUTIONEduardo Perez UriegasNoch keine Bewertungen

- Codigos FordDokument66 SeitenCodigos FordavffNoch keine Bewertungen

- enDokument40 SeitenenRegistr Registr91% (11)

- Wa320 5Dokument228 SeitenWa320 5Felipe Naxo Becerra Arriagada50% (2)

- Chapter 11 CACCDHDokument60 SeitenChapter 11 CACCDHmeda012Noch keine Bewertungen

- Fragmentation and Its Impact On Downstream ProcessingDokument4 SeitenFragmentation and Its Impact On Downstream Processingalvaroaac4Noch keine Bewertungen

- FBHVN 1117 DDokument6 SeitenFBHVN 1117 DkhairolNoch keine Bewertungen

- Chapter 8: Failure: How Do Materials Break?Dokument40 SeitenChapter 8: Failure: How Do Materials Break?Leann FarleyNoch keine Bewertungen

- D6372-15-Design, Testing, and Construction of Micro SurfacingDokument8 SeitenD6372-15-Design, Testing, and Construction of Micro SurfacingEveling Vanegas NarváezNoch keine Bewertungen

- Lecture 21 PDFDokument14 SeitenLecture 21 PDFMehmet Arvasi100% (1)

- DPWH - Guard HouseDokument180 SeitenDPWH - Guard HouseErnest BelmesNoch keine Bewertungen

- Joint Operating Body: Pertamina Medco E&P SkkmigasDokument2 SeitenJoint Operating Body: Pertamina Medco E&P SkkmigasAriNoch keine Bewertungen

- K SpanDokument36 SeitenK SpanMerve MerveNoch keine Bewertungen

- Beam Design To BS 5400 Part 3Dokument6 SeitenBeam Design To BS 5400 Part 3Tamil SelviNoch keine Bewertungen

- Lesson 6-GlassDokument32 SeitenLesson 6-Glasslewis imaNoch keine Bewertungen

- M.tech Ise (2021-23) - List of Topics For PresentationDokument2 SeitenM.tech Ise (2021-23) - List of Topics For PresentationAmarnath Reddy RagipindiNoch keine Bewertungen

- Heat Gain Due To InfiltrationDokument18 SeitenHeat Gain Due To InfiltrationNg Swee Loong Steven100% (2)

- W7 Smith CapacitorsDokument31 SeitenW7 Smith CapacitorsyjandeNoch keine Bewertungen

- ModifiedProposedProvisionsforSeismicDesignofLiquidStorageTanks PartII PDFDokument14 SeitenModifiedProposedProvisionsforSeismicDesignofLiquidStorageTanks PartII PDFJaime CoronellNoch keine Bewertungen

- VCMStudy UOP Advanced MTO Tehran ConferenceDokument21 SeitenVCMStudy UOP Advanced MTO Tehran ConferenceUsamah ZakiNoch keine Bewertungen