Beruflich Dokumente

Kultur Dokumente

Transformer Losses

Hochgeladen von

supermannon0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

147 Ansichten11 SeitenTransformer Losses

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTransformer Losses

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

147 Ansichten11 SeitenTransformer Losses

Hochgeladen von

supermannonTransformer Losses

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 11

This article is excerpted from "Premium-Efficiency Motors and Transformers", a CD-ROM available from

CDA by calling 888/480-MOTR, or through the Publications List.

Transformer losses are produced by the electrical current flowing in the coils and the magnetic field

alternating in the core. The losses associated with the coils are called the load losses, while the losses

produced in the core are called no-load losses.

What Are Load Losses?

Load losses vary according to the loading on the transformer. They include heat losses and eddy currents in

the primary and secondary conductors of the transformer.

Heat losses, or I

2

R losses, in the winding materials contribute the largest part of the load losses. They are

created by resistance of the conductor to the flow of current or electrons. The electron motion causes the

conductor molecules to move and produce friction and heat. The energy generated by this motion can be

calculated using the formula:

Watts = (volts)(amperes) or VI.

According to Ohms law, V=RI, or the voltage drop across a resistor equals the amount of resistance in the

resistor, R, multiplied by the current, I, flowing in the resistor. Hence, heat losses equal (I)(RI) or I

2

R.

Transformer designers cannot change I, or the current portion of the I

2

R losses, which are determined by the

load requirements. They can only change the resistance or R part of the I

2

R by using a material that has a

low resistance per cross-sectional area without adding significantly to the cost of the transformer. Most

transformer designers have found copper the best conductor considering the weight, size, cost and

resistance of the conductor. Designers can also reduce the resistance of the conductor by increasing the

cross-sectional area of the conductor.

What Are No-load Losses?

No-load losses are caused by the magnetizing current needed to energize the core of the transformer, and

do not vary according to the loading on the transformer. They are constant and occur 24 hours a day, 365

days a year, regardless of the load, hence the term no-load losses. They can be categorized into five

components: hysteresis losses in the core laminations, eddy current losses in the core laminations, I

2

R

losses due to no-load current, stray eddy current losses in core clamps, bolts and other core components,

and dielectric losses. Hysteresis losses and eddy current losses contribute over 99% of the no-load losses,

while stray eddy current, dielectric losses, and I

2

R losses due to no-load current are small and consequently

often neglected. Thinner lamination of the core steel reduces eddy current losses.

The biggest contributor to no-load losses is hysteresis losses. Hysteresis losses come from the molecules in

the core laminations resisting being magnetized and demagnetized by the alternating magnetic field. This

resistance by the molecules causes friction that results in heat. The Greek word, hysteresis, means "to lag"

and refers to the fact that the magnetic flux lags behind the magnetic force. Choice of size and type of core

material reduces hysteresis losses.

Values of Transformer Losses (A and B Values)

The values of transformer losses are important to the purchaser of a transformer who wants to select the

most cost-effective transformer for their application. The use of A and B factors is a method followed by

most electric utilities and many large industrial customers to capitalize the future value of no-load losses

(which relate to the cost to supply system capacity) and load losses (which relate to the cost of incremental

energy). Put another way, A values provide an estimate of the equivalent present cost of future no-load

losses, while B values provide an estimate of the equivalent present cost of future load losses. Most utilities

regularly update their avoided cost of capacity and energy (typically on an annual basis), and use A and

B values when specifying a transformer. Most smaller end users typically use life-cycle -cost evaluation

methods, discussed in another article on this web site.

When evaluating various transformer designs, the assumed value of transformer losses (A and B values) will

contribute to determining the efficiency of transformer to be purchased. Assuming a high value for

transformer losses will generally result in purchase of a more efficient unit; assuming a lower value of losses

will result in purchase of a less efficient unit. What value of losses should be assumed?

The total owning cost (TOC) method provides an effective way to evaluate various transformer initial

purchase prices and cost of losses. The goal is to choose a transformer that meets specifications and

simultaneously has the lowest TOC. The A and B values include the cost of no-load and load losses in the

TOC formula:

TOC = NLL x A + LL x B + C

Where,

TOC = capitalized total owning cost,

NLL = no-load loss in watts,

A = capitalized cost per rated watt of NLL (A value),

LL = load loss in watts at the transformer's rated load,

B = capitalized cost per rated watt of LL (B value),

C = the initial cost of the transformer including transportation, sales tax, and other costs to prepare it for service.

What Is the A Value?

The A value is an estimate of the present value of future capital cost (nonload- dependent) items at a given

point in time. It can vary over time as utilities re-evaluate their costs on a periodic basis. (In other words, the

A value is the answer to the question, what is a watt of no-load loss over the life of the transformer worth

to me today?) Even if there is no load, there is capital that is devoted to fixed capacity to generate, transmit

and distribute electricity, which contribute to the A value. The loading that may change daily on the

transformer does not affect the no-load loss value. It is calculated using the following formula:

A = [SC + (EC x 8760)] x 0.001 / [FC]

= Cost of No-Load Loss in $/watt

Where,

SC = Annual Cost of System Capacity in $/kW-year (SC is the levelized annual cost of generation, transmission

and primary distribution capacity required to supply one watt of load to the distribution transformer coincident with

the peak load).

EC = Energy Cost (EC is the levelized annual cost per kWh of fuel, including inflation, escalation, and any other

fuel related components of operation or maintenance costs that are proportional to the energy output of the

generating units).

8,760 = hours per year

FC = Fixed Charge on capital per year (FC is the levelized annual revenue required to carry and repay the

transformer investment obligation and pay related taxes, all expressed as a per-unit quantity of the original).

0.001 = conversion from kilowatts to watts.

What Is the B Value?

Similar to the way the A value is determined, the B value is an estimate of the present value of future

variable, or load-dependent, cost items at a given point in time. (In other words, the B value is the answer

to the question, what is a watt of load loss over the life of the transformer worth to me today?) The B

value can also change over time as utilities revaluate their costs on a periodic basis, but once determined, it

is a constant value for a given transformer purchase. The cost of load losses, or B value, is calculated

using the following formula:

B = [(SC x RF) + (EC x 8,760 x LF)] (PL)

2

(0.001) / (FC)

= Cost of Load Loss Cost $/watt

Where,

RF = Peak Loss Responsibility Factor (RF is the composite responsibility factor that reduces the system capacity

requirements for load losses since the peak transformer losses do not necessarily occur at peak time).

LF = Annual Loss Factor (LF is the ratio of the annual average load loss to the peak value of the load loss in the

transformer).

PL = Uniform Equivalent Annual Peak Load (PL is the levelized peak load per year over the life of the transformer.

Transformer life cycle is defined as the useful life of the asset and is usually assumed to be 30-35 years).

Specifying A and B Values

For custom-designed transformers, manufacturers optimize the design of the unit to the specified A and B

values resulting in a transformer designed to the lowest total owning cost, rather than one designed for

cheapest first cost.

In situations where A and B values have not been determined (or the enduser does not utilize or specify

them), such as occur in commercial or small industrial applications, the suggested technique to maximize

transformer efficiency is to obtain the no-load and full-load loss values of a specific transformer, in watts.

This method is discussed in the article Transformer Life-Cycle Cost, elsewhere on this web site.

Proper Transformer Sizing and Copper Windings Mean Lowest Total

Owning Cost, Fastest Payback

Transformers are used in virtually every commercial and industrial building, from the service transformer

reducing the distribution voltage to a more usable voltage for the building, to step-down transformers serving

individual floors, to small transformers for individual apparatus or functions. Typically a transformer is a long-

lived device that can be in service for decades.

Over such a long life span, the operating cost of a transformer can greatly exceed the initial price, so

selection of the right transformer for economic performance involves looking at proper size (capacity) and

efficiency.

And efficiency means looking at both the core steel and the winding material.

Transformer Losses

In the simplest terms, there are two components to transformer losses: core losses (also called no-load

losses); and coil losses (called load losses).

The core losses originate in the steel core of the transformer, caused by the magnetizing current needed to

energize the core. They are constant, irrespective of the load on the transformer (thus the name no-load).

They continue to waste energy as long as the transformer is energized. No-load losses do, however, vary

with the size (kVA) of the transformer, and the core steel selected; hence the emphasis on proper sizing.

The coil losses (load losses) originate in the primary and secondary coils of the transformer, and are a result

of the resistance of the winding material. That's where selection of copper windings can make a difference in

losses.

Proper Sizing

Transformers are sometimes placed into a speculative setting in advance of occupancy, so the engineer

does not necessarily know the load that will be placed on the unit. As the installer is often not the party

paying the electric bill, there can be a tendency to oversize the transformer capacity relative to the load it will

actually see. Since the no-load loss is a function of the kVA capacity of the transformer, careful selection of

the transformer capacity closer to the intended task will ensure lowest core loss.

Energy Star (TP-1) Transformers May Not be Efficient Enough

The Energy Star label is applied to transformers that meet a certain minimal standard for efficiency known

as NEMA TP-1 (NEMA stands for the National Electrical Manufacturers Association.) The full name of the

standard is "Guide for Determining Energy Efficiency for Distribution Transformers"

1

or "NEMA Standards

Publication TP-1-1996." It is intended to promote the manufacture and use of energy efficient transformers

by establishing minimum efficiency standards, albeit with certain assumptions built-in. It contains a simplified

method for evaluating the first cost of transformers along with the costs of core and load losses. It also

presents tables of minimum transformer efficiencies based on kVA size, voltages, and liquid or dry-type.

Unfortunately, there is nothing especially efficient nor cutting-edge about transformers that meet TP-1. Yes,

they are an improvement over so-called "standard" transformers, still made and sold widely, and they are

conditionally required in certain states for new construction. However, many transformers are available from

various manufacturers that exceed the efficiency levels of TP-1, and may provide a fast payback of their

purchase price.

The efficiency standards in NEMA TP-1 are based on certain assumptions that may result in the selection of

less-than-optimally efficient transformers. One key assumption is that low voltage (600-volt class) dry-type

(typical commercial or industrial) transformers are loaded at 35 per cent of their nameplate rating. For

medium voltage and liquid-filled transformers the assumed loading is 50% of nameplate rating. Another

underlying part of the economic rational for the standard is an assumed electricity cost of 6 cents per kWh.

Both these assumptions may be too low for industrial and commercial users, who often can more accurately

predict their load requirements, or who may be paying more than 6 cents per kWh, particularly at peak

times. In fact, recommended loading for economic sizing of a transformer is typically around 75% of

nameplate (35% load, if constant, means the transformer is oversized and wasting core loss as well as well

as higher purchase price.)

The table below, provided by Olsun Electrics, compares a "standard efficiency" 75 kVA transformer to an

aluminum-wound TP-1 model, a copper-wound TP-1 model, and a "premium efficiency" copper-wound unit,

at various loading levels. As the table shows, choosing a more efficient, copper-wound transformer that

exceeds the minimal efficiencies of TP-1 (and Energy Star) can pay back its price premium in as little as one

year.

Noteworthy is the fact that the TP-1 (Energy Star) efficiency, copper-wound unit, loaded at 75% of its

nameplate capacity (column 7), saves over $88 per year compared to an aluminum-wound TP-1 model

(column 6), but costs only $85 more initially. At only 50% loading, the copper TP-1 unit (column 11) saves

about $50 per year compared to the same aluminum unit (column 10). No-load loss (core) is reduced from

350 to 320 watts because the greater conductivity of copper windings allows a smaller core to be used, so

energy continues to be saved even at light loading levels.

For even greater savings, the premium efficiency, copper-wound unit saves over $401 per year at 75%

loading (column 8), compared to the aluminum TP-1 model (column 6), and costs only $1235 additional. In

fact, over a 20-year life (neglecting the time value of money), the total owning cost of the premium efficiency,

copper-wound model is $12,399.60 compared to $25,447.00 for the standard efficiency model. The 20-year

total ownership cost to buy and operate the premium efficiency transformer is less than one-half the cost of

the standard model.

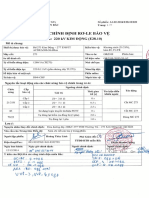

Payback time comparison for 75kVA Dry-Type transformers

(1) (2) (3) (4) (5) (6) (7) (8)

Standard

(Aluminum)

TP-1

(Aluminum)

TP-1

(Copper)

Premium

(Copper)

Standard

(Aluminum)

TP-1

(Aluminum)

TP-1

(Copper)

Premium

(Copper)

100 100 100 100 75 75 75 75 % of name

plate load

Core loss

(w)

Conductor

loss (w)

Total loss

(w)

Efficiency

(%)

375

2829

3204

95.9

350

1874

2224

97.12

320

1670

1990

97.42

190

993

1183

98.45

375

1591

1966

96.62

350

1054

1404

97.56

320

940

1260

97.81

190

559

749

98.69

Transformer

cost ($)

1336 1979 2064 3214 1336 1979 2064 3214

Additional

cost

compared

with

standard

unit ($)

643 728 1878 643 728 1878

Energy

cost/year

($)

1964.69 1363.76 1220.27 725.42 1205.55 860.93 772.63 459.29

Annual

energy cost

saving

compared

with

standard

unit ($)

600.94 744.42 1239.28 344.62 432.92 746.26

Payback 1.07 0.98 1.52 1.87 1.68 2.52

(9) (10) (11) (12) (13) (14) (15) (16)

Standard

(Aluminum)

TP-1

(Aluminum)

TP-1

(Copper)

Premium

(Copper)

Standard

(Aluminum)

TP-1

(Aluminum)

TP-1

(Copper)

Premium

(Copper)

50 50 50 50 35 35 35 35

% of name

plate load

Core loss

(w)

Conductor

loss (w)

Total loss

(w)

Efficiency

(%)

375

707

1082

97.19

350

469

819

97.86

320

418

738

98.07

190

248

438

98.84

375

1591

1966

96.62

350

176

526

98.04

320

157

477

98.04

190

113

303

98.86

Transformer

cost ($)

1336 1979 2064 3214 1336 1979 2064 3214

Additional

cost

compared

with

standard

unit ($)

643 728 1878 643 728 1878

Energy

cost/year

($)

663.48 502.21 452.54 268.58 1205.55 322.54 292.50 185.80

Annual

energy cost

saving

compared

with

standard

unit ($)

161.27 210.94 394.90 69.90 99.95 206.65

Payback

period (yrs)

3.99 3.45 4.76 9.20 7.28 9.09

Courtesy: Olsun Electrics, Richmond, IL.

Notes:

1. Standard and Aluminum TP-1 units are 150C rise, copper TP-1 unit is 115C rise, Premium unit is 80 C rise.

2. Loss values at 100%, 75% and 50% nameplate load are at reference temperature.

3. Loss values at 35% nameplate load are at 75C in accordance with TP-1.

4. Energy cost assumed to be $0.07/kWh.

Specifying to Minimize Owning Cost

Whenever possible, always compare competing transformer models by asking for the load and no-load

losses, in watts, and look at the total cost of ownership. If possible, perform life cycle cost analysis

(discussed elsewhere on this Web site). Remember that no-load losses are constant whenever the

transformer is energized. Specifying copper windings can minimize both the load loss and the no-load loss,

by allowing for a smaller core. If the load is known or can be predicted, choose a transformer that will be

loaded to about 75% of its nameplate rating. Oversizing the unit increases the no-load losses, as well as the

purchase price, unnecessarily.

If the actual losses in watts are not available, and you are seeking the transformer with the lowest losses,

choose a transformer with 80 C rise, core of grade M 6 steel or better, and copper windings. Specifying a

lower temperature rise transformer results in a unit with higher overload capability. For example, an 80C

rise dry-type unit using 220C insulation, has 70C reserve capacity. This allows the 80C unit to operate

with an overload capability of 15-30% without affecting the transformer life expectancy. Also, a cooler

running transformer means a more reliable unit, and more up-time.

Overcoming Transformer Losses

By Philip J.A. Ling, P.E., Powersmiths Corp.

Aug 29, 2003 12:00 PM

A more efficient transformer can pay for itself many

times over during its 25-year lifespan

The transformer plays a key role in an electrical

systems efficiency and power quality, yet 95% of

buying decisions are based solely on first cost. Buying

based on life cycle cost would save literally hundreds of

thousands of dollars in operating losses over the

installed life for transformers in a typical facility. In fact,

the United States Environmental Protection Agency (EPA) estimates that 60 to 80 billion kWh

annually can be attributed to transformer losses. These losses cost end-users $3 to $4 billion, and

can tie up nine days of U.S.

generating capacity annually.

When feeding the increasingly

electronic nature of connected

equipment, distortion of the voltage

waveform can reduce the operating

reliability of both the electrical

system and the connected

equipment. Users can lower energy

rates and avoid high transformer

losses by investing in energy-

efficient transformers. This article

compares the efficiency of different

transformer types including low

temperature rise, Energy Star, K-

rated, as well as new transformers

that are designed to minimize life

cycle cost.

Underestimating loss data.

Electronic equipment and other nonlinear loads now make up most of the load on transformers in

many facilities. Even in the average office, many individuals plug in mostly computers, printers,

scanners, and other electronics to 120V receptacles. The load profile of electronic equipmentfrom

the computer in the office to the variable speed drive in the factorydrives both additional losses

and unwanted distortion, according to IEEE Standard 519-1992. Since transformer manufacturers

test only under ideal (linear) conditions, as called for in present construction standards, a

substantial gap exists between published loss data and actual losses incurred after installation (Fig.

1). In fact, test results published in a 1996 IEEE Transaction paper documented an almost tripling of

transformer losses when feeding 60kW of computer load rather than linear load.

Transformers have two major components that drive losses: the core and the coils. The typical core

is an assembly of laminated steel. Core losses are mostly related to magnetizing or energizing the

core. These losses, also known as no-load losses, are present the entire time the transformer is

powered on, regardless of whether theres any load or not.

Core losses are roughly constant from no-load to full-load when feeding linear loads. They represent

a continuous cost, 24/7, for the 25- to 40-year life of the transformer. A common 75kVA

commercial transformer has about 400W in no-load losses. At $.10/kWh, this represents a

continuous cost of $350/yr or $14,000 over a 40-year life, eclipsing the purchase cost many times

over. And remember, this is just the cost for powering the unit. The cost of powering the load itself

far exceeds this cost.

The coil losses, commonly referred

to as load losses, are associated with

feeding power to the connected load.

For linear loads, these losses are

predominately I2R losses. In other

words, load losses increase by the

square of current from no-load to

full-load, driven by the resistance of

the coil. Fig. 2 shows a graphical

representation of how transformer

losses increase with loading.

Since a wide variety of transformers

serve different purposes, actual

losses incurred in the field will vary

substantially from one installation to

another. Load level varies widely,

with some installations running very heavily loaded and others more lightly loaded. This difference

substantially affects actual losses incurred.

To calculate the cost of these losses, one must refer to the billing structure of the electric utility.

This varies across the country and may involve kWh, kW peak demand, and kVA charges. Taking an

example from Fig. 2, at 60% load the transformer has about 1,500W of losses. If the user is being

billed only on kilowatt-hour consumption at a rate of $.10/kWh, the operating cost would be 1.5kW

x $.10/kWh, which equals $.15/hr or roughly $1,300/yearthe same order of magnitude as the

purchase price of the transformer. Although some utilities charge by kVA or kW, most charge a

combination of a kWh rate and a peak demand charge. Additional distribution or environmental

costs are also common surcharges included in electrical bills, so be sure to look beyond the cost per

kWh.

Comparing transformer losses. Only a limited amount of field data is available on transformer

losses due to the high cost of gathering detailed data from a reasonable number of individual

transformers. Faced with this lack of comprehensive field data, the remaining graphs in this article

represent our years of field experience with a combination of published efficiency data under linear

and nonlinear load conditions and independent testing, as well as before/after field measurements

to build a series of representative loss curves for different transformers as accurately as possible

with the data available.

Standard transformerThe standard transformer is built to deliver its nameplate kVA rating under

linear load only and is UL Listed on this basis. As it has the lowest purchase price on the market, it

represents the majority of transformer purchases made across the country. When feeding electronic

equipment, substantial derating is requiredon the order of 50% or moreto prevent overheating

and premature failure, according to IEEE Standard 1100-1992. Along with its high operating cost,

other factors include a substantial loss in capacity and distortion of the voltage to connected

equipment.

Low temperature rise transformerTransformers with a low operating temperature rise have often

been purchased with energy savings in mind, as published full load losses are substantially lower

than those of many other transformers. These transformers are traditionally available in either 80C

or 115C operating temperature rise, as opposed to the standard 150C rise that represents the

majority of low-voltage, 3-phase, dry-type transformer sales.

The low temperature rise transformer is designed to run cooler than a standard transformer when

fully loaded. To meet this objective, manufacturers typically use a larger core and winding set,

resulting in higher no-load losses (more core), but lower load losses (more coil). Since total losses

are the sum of both core and coil losses, the low rise transformer will have higher losses than other

transformers at low load levels where core losses predominate, but lower losses when heavily

loaded, since coil losses predominate

at high load levels.

From Fig. 3, its evident that at less

than 60% load, it actually costs

more to operate the 80C rise

transformer than the standard 150C

rise transformer. Depending on the

size and manufacturer, the break-

even point can be as high as 80%.

Since many transformers are loaded

to less than 50% capacity, use of an

80C rise transformer is often a

commitment to higher energy

coststhe exact opposite of what

was intended. Another limitation with

the low temperature rise transformer

is that its UL Listing applies when

feeding linear loads only.

Energy Star transformer In 1998, the EPA included a high-efficiency transformer program under

the Energy Star banner. For a reference document, the EPA settled on NEMA TP-1 Guide for

Determining Energy Efficiency for Distribution Transformers. The NEMA TP-1 standard establishes

required efficiencies at 35% load for low-voltage, dry-type transformers, and at 50% load for liquid-

filled and medium-voltage, dry-type transformers. In a bid to move the first-cost driven market to

higher efficiency transformers, several states including New York, California, Minnesota, and

Massachusetts, adopted NEMA TP-1

into law.

However, NEMA TP-1/ENERGY STAR

transformer efficiencies reference

test data under linear load

conditions. This results in published

efficiencies that are much higher

than experienced in the real world

due to the additional losses

associated with the widespread use

of electronic equipment. Ironically,

transformers feeding harmonic-rich

loads are exempt from meeting

NEMA TP-1 benchmark efficiencies.

Like the standard transformer, the

Energy Star transformer is built to

deliver its nameplate kVA rating

under linear load and is UL Listed on

this basis. And like standard

transformers, Energy Star transformers exhibit increased losses, loss of capacity, and increased

voltage distortion when feeding electronic equipment. The Energy Star-compliant transformer is

more efficient than the standard transformer as shown in Fig. 4 (linear loading).

K-rated transformerUnlike standard transformers, which are designed to feed linear loads only

and lose capacity when feeding nonlinear loads, K-rated transformers are designed to feed nonlinear

loads with harmonic content up to their nameplate rating. The UL Listing is maintained as long as

the load profile has a K-factor lower than the K-rating of the transformer. Industry standard ratings

include K4, K13, and K20, with K4 and K13 being the most frequently specified. A higher K-rating

represents the capability to withstand higher harmonic content.

K-rating is a heat survival rating, not

a treatment of associated power

quality issues like voltage distortion,

and efficiency isnt typically

discussed. Surviving the extra heat

means using more core and coil

material, and sometimes use of

different construction techniques.

Depending on the manufacturers

design, harmonic losses may be

reduced to varying degrees.

Ironically, even though the

designated use of the K-rated

transformer is to feed nonlinear load,

manufacturers publish their loss data

under linear load conditions.

The need for commissioning.

When energy savings are driving part or all of the justification for selecting a particular transformer,

its important that these savings are indeed present once the transformer is installed. This means

commissioning the transformer for energy performance after installation. In fact, some rebate

programs and other life cycle-oriented programs like Leadership in Efficiency and Environmental

Design call for ongoing product commissioning.

As electronic equipment has become more integrated into our daily lives, transformer losses have

added a substantial hidden energy cost to the overall operating costs of many buildings. If properly

applied, energy-efficient transformers can help deliver substantial energy savings and power quality

improvements.

Ling is vice president technology of Powersmiths Corp. in Irving, Texas.

Sidebar: Pay Me Now or Pay Me Later

Electric utilities have traditionally purchased their distribution transformers based on life cycle

costing, or total cost of ownership (TCO), where the cost of losses is factored into the buying

processas they understand the cost of ongoing operating losses. As a result, the trend in this

market segment is the use of higher efficiency transformers.

The opposite trend is in place in the commercial/industrial world, where the standard low voltage

step-down transformer is widely considered a commodity. The only perceived differentiator is

upfront cost, or purchase price, since the lowest first cost wins.

Commercial transformer specifications rarely set a minimum efficiency requirement. As you would

expect, building a less efficient transformer is cheaper than building a more efficient one, so a

typical low-first-cost transformer will have a low upfront cost but substantially higher operating

cost. And the lifetime cost of the operating losses far exceeds the purchase cost.

The typical buying process makes the situation worse. Traditionally, the consulting engineer

specifies a generic transformer, and a contractor purchases it from a wholesaler. The contractor

typically focuses on first cost since the winning bidder is based on providing the lowest bid. The end

user, who pays the electricity bill for the next 40 years, is neither involved in the selection process

nor educated about the true operating cost of the unit or the potential savings from using a more

efficient unit. As a result, the fight is over first cost, which for the transformer is on the order of 4%

of the life cycle cost. In the end, the end user is stuck with high operating cost, the other 96% of

the life cycle cost.

Das könnte Ihnen auch gefallen

- Are Harmonics Still A Problem in Data CentersDokument11 SeitenAre Harmonics Still A Problem in Data CentersAnonymous dM4QtbCJ0Noch keine Bewertungen

- PP 159-168 Optimal Design of Transformer A CompressiveDokument10 SeitenPP 159-168 Optimal Design of Transformer A CompressiveEditorijset IjsetNoch keine Bewertungen

- Various Routine Test of Power Transformer - (Part-3)Dokument8 SeitenVarious Routine Test of Power Transformer - (Part-3)supermannonNoch keine Bewertungen

- CFD analysis of heat transfer in a dry type transformerDokument7 SeitenCFD analysis of heat transfer in a dry type transformerEnriqueGD100% (1)

- Star Delta StarterDokument40 SeitenStar Delta Startersupermannon100% (1)

- Fundamentals of HV Circuit-BreakersDokument22 SeitenFundamentals of HV Circuit-BreakersBastian OspinaNoch keine Bewertungen

- Various Routine Test of Power Transformer - (Part-1)Dokument10 SeitenVarious Routine Test of Power Transformer - (Part-1)supermannonNoch keine Bewertungen

- mrp11 Catalogue PDFDokument3 Seitenmrp11 Catalogue PDFab_s5036Noch keine Bewertungen

- Electrical Q&A Part-1: Understanding Electrical Components & SystemsDokument44 SeitenElectrical Q&A Part-1: Understanding Electrical Components & SystemsSlardarRadrals0% (1)

- A Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyDokument67 SeitenA Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyGunjan VarshneyNoch keine Bewertungen

- Auto Transformer Insulation Coordination StudyDokument6 SeitenAuto Transformer Insulation Coordination StudyrajfabNoch keine Bewertungen

- System Earthings in LV PDFDokument29 SeitenSystem Earthings in LV PDFGilberto SanchezNoch keine Bewertungen

- Cable Size Calculation For LT & HT MotorsDokument14 SeitenCable Size Calculation For LT & HT MotorssupermannonNoch keine Bewertungen

- 14 - Bergmann - HV TR PDFDokument45 Seiten14 - Bergmann - HV TR PDFbcqbao100% (1)

- Voltage Unbalance and It's Impact On The Performance of Three Phase Induction Motor: A ReviewDokument6 SeitenVoltage Unbalance and It's Impact On The Performance of Three Phase Induction Motor: A ReviewSunil SinghNoch keine Bewertungen

- Core Laminations SelectionDokument10 SeitenCore Laminations SelectionJavo CoreNoch keine Bewertungen

- Transformer Winding Layer Vs DiskDokument33 SeitenTransformer Winding Layer Vs Diskbibhoo100% (1)

- RF Controlled Stepper MotorDokument20 SeitenRF Controlled Stepper MotorDurgesh ShuklaNoch keine Bewertungen

- On Transformer ManufacturingDokument25 SeitenOn Transformer ManufacturingThakur Dhananjay Singh Gaur100% (1)

- Temp Rise Dry Type TransformerDokument8 SeitenTemp Rise Dry Type TransformerAnonymous sAmJfcVNoch keine Bewertungen

- K-Factor Rated Transformer For Deal With Harmonic Generating LoadsDokument4 SeitenK-Factor Rated Transformer For Deal With Harmonic Generating Loadsp41005679Noch keine Bewertungen

- 1500kVA-3 Phase LSA 50.2 L8 - 440V - 60HzDokument2 Seiten1500kVA-3 Phase LSA 50.2 L8 - 440V - 60HzsupermannonNoch keine Bewertungen

- Trafo Spec PDFDokument56 SeitenTrafo Spec PDFMohammad Fadhil KoesputraNoch keine Bewertungen

- Final Report Transformer Design Section A PDFDokument68 SeitenFinal Report Transformer Design Section A PDFThabiso Kyle100% (1)

- Introduction to Electric Power Systems: History, Generation, Transmission, Smart GridDokument17 SeitenIntroduction to Electric Power Systems: History, Generation, Transmission, Smart GridsohaibNoch keine Bewertungen

- History of Power SystemDokument6 SeitenHistory of Power SystemAmr Diaa El-Din El-FawalNoch keine Bewertungen

- Temperature RiseDokument31 SeitenTemperature Rise2ander100% (3)

- 24/30 MVA Transformer SpecsDokument1 Seite24/30 MVA Transformer Specsram krishnanNoch keine Bewertungen

- Electrical Q&A Part-4Dokument15 SeitenElectrical Q&A Part-4supermannonNoch keine Bewertungen

- Electrical Q&A Part-3Dokument18 SeitenElectrical Q&A Part-3supermannon100% (1)

- Power Transformer Tests Guide - Voltage Ratio, Turns Ratio, Polarity Vector GroupDokument7 SeitenPower Transformer Tests Guide - Voltage Ratio, Turns Ratio, Polarity Vector GroupsupermannonNoch keine Bewertungen

- Aluminum Vs Copper in TrafoDokument6 SeitenAluminum Vs Copper in TrafosamuraivickyNoch keine Bewertungen

- Earthing System - Schneider ElectricDokument8 SeitenEarthing System - Schneider ElectricAnne Kelley100% (1)

- MV Design Guide PDFDokument83 SeitenMV Design Guide PDFClaro Dal PianNoch keine Bewertungen

- Dry transformer failure analysisDokument33 SeitenDry transformer failure analysisPetranthosNoch keine Bewertungen

- High-Voltage and High Current Testing Standards: Past, Present and Future of IEC and IEEEDokument4 SeitenHigh-Voltage and High Current Testing Standards: Past, Present and Future of IEC and IEEERomany AllamNoch keine Bewertungen

- Transformers - App Guide 2015Dokument6 SeitenTransformers - App Guide 2015Florin AdrianNoch keine Bewertungen

- Brochure ANSIDokument40 SeitenBrochure ANSIDaniel PalaciosNoch keine Bewertungen

- Transformer PD OnlineDokument12 SeitenTransformer PD Onlinesumpeno enoNoch keine Bewertungen

- Transformer Database ReserchDokument8 SeitenTransformer Database ReserchJignesh100% (1)

- Power Transformer Protection PresentationDokument11 SeitenPower Transformer Protection PresentationOmpa AcharyaNoch keine Bewertungen

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsVon EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNoch keine Bewertungen

- Dry-Type Transformers For Railways Brochure A4 - vFINALDokument18 SeitenDry-Type Transformers For Railways Brochure A4 - vFINALYusuke Okudaira100% (1)

- Diagnosis of The Short Circuit Duty of Power TransformersDokument6 SeitenDiagnosis of The Short Circuit Duty of Power TransformerscisnatelNoch keine Bewertungen

- ENPAY Shunt Reactor Cores GuideDokument16 SeitenENPAY Shunt Reactor Cores Guideemy1188Noch keine Bewertungen

- Transformer Viva QuestionDokument9 SeitenTransformer Viva QuestionAvro AronnoNoch keine Bewertungen

- Insulators: Properties, Types and EfficiencyDokument18 SeitenInsulators: Properties, Types and EfficiencyGurpreet UppalNoch keine Bewertungen

- Vector Group Code ExplainedDokument8 SeitenVector Group Code ExplainedSuraj Kumar GuptaNoch keine Bewertungen

- 80-85 Standards Relevant To Transformers - P. RamachandranDokument6 Seiten80-85 Standards Relevant To Transformers - P. RamachandranAnderson Jair Velandia PiraquiveNoch keine Bewertungen

- CRGODokument15 SeitenCRGOipraoNoch keine Bewertungen

- Losses in TransformerDokument15 SeitenLosses in TransformerAnkit SrivastavaNoch keine Bewertungen

- Power Transformer Construction CoreDokument4 SeitenPower Transformer Construction CoreJayadevDamodaran0% (1)

- TransformerDokument9 SeitenTransformerSamPolancosNoch keine Bewertungen

- Transformer Design AnalysisDokument6 SeitenTransformer Design AnalysisAkash VermaNoch keine Bewertungen

- A2.24 Thermal PerformancesID55VER20Dokument15 SeitenA2.24 Thermal PerformancesID55VER20Fajar Adi PrabowoNoch keine Bewertungen

- Distribution Transformer TestingDokument2 SeitenDistribution Transformer TestingjamilsoriaNoch keine Bewertungen

- Dual Three-Winding Transformer Equivalent Circuit Matching Leakage MeasurementsDokument9 SeitenDual Three-Winding Transformer Equivalent Circuit Matching Leakage MeasurementsDiegoNoch keine Bewertungen

- Transformers ConnectionsDokument6 SeitenTransformers Connectionsgeorgel1980Noch keine Bewertungen

- Why Transformer Does Not Work On DC Supply Instead of ACDokument4 SeitenWhy Transformer Does Not Work On DC Supply Instead of ACAHMED YOUSEFNoch keine Bewertungen

- Sri RamachandranDokument7 SeitenSri RamachandranNavaneethakrishnan MurugesanNoch keine Bewertungen

- Transformer Design PrinciplesDokument3 SeitenTransformer Design Principlesacport2809Noch keine Bewertungen

- Transformers: Understanding the Heart of AC Power SystemsDokument28 SeitenTransformers: Understanding the Heart of AC Power SystemsGirish Shankar MishraNoch keine Bewertungen

- S2-4-SC Withstand Test of - EHV - Transformer - Learnings - Challenges-C Jayasenan-Siemens - Rev1Dokument8 SeitenS2-4-SC Withstand Test of - EHV - Transformer - Learnings - Challenges-C Jayasenan-Siemens - Rev1MallikarjunNoch keine Bewertungen

- DGA Ebook WebDokument16 SeitenDGA Ebook Webjulio cesar silvaNoch keine Bewertungen

- TransformerDokument81 SeitenTransformerMuluken FilmonNoch keine Bewertungen

- IEEMA-Basics of Dual Ratio TransformersDokument3 SeitenIEEMA-Basics of Dual Ratio TransformersHari Krishna.MNoch keine Bewertungen

- S2-6-Calculating Circulating Currents in Clamping Strucure and Preventing Gassing Problem - Manan Pandya-Siemens - Rev1Dokument3 SeitenS2-6-Calculating Circulating Currents in Clamping Strucure and Preventing Gassing Problem - Manan Pandya-Siemens - Rev1MallikarjunNoch keine Bewertungen

- Product: Complete Diagnostic SolutionsDokument8 SeitenProduct: Complete Diagnostic SolutionsbhpNoch keine Bewertungen

- Arcing HornDokument2 SeitenArcing HornSureshraja9977100% (1)

- Switching impulse test of transformer insulationDokument3 SeitenSwitching impulse test of transformer insulationBashar MatloobNoch keine Bewertungen

- Course Outline: 1. Introduction To WECC 2. Fundamentals of ElectricityDokument51 SeitenCourse Outline: 1. Introduction To WECC 2. Fundamentals of ElectricityWoldemariam WorkuNoch keine Bewertungen

- Power-system protection A Complete GuideVon EverandPower-system protection A Complete GuideBewertung: 1 von 5 Sternen1/5 (1)

- General Method For Cable Sizing - Electrical Installation GuideDokument10 SeitenGeneral Method For Cable Sizing - Electrical Installation GuidesupermannonNoch keine Bewertungen

- PESO Approval ProcessDokument8 SeitenPESO Approval ProcesssanthoshkumarplNoch keine Bewertungen

- Effect of Soil Thermal Resistivity On Underground Cable InstallationDokument4 SeitenEffect of Soil Thermal Resistivity On Underground Cable InstallationRamesh VrNoch keine Bewertungen

- Isgec-Cell Booster Sizing PDFDokument1 SeiteIsgec-Cell Booster Sizing PDFsupermannonNoch keine Bewertungen

- Battery Overview: Types and CharacteristicsDokument45 SeitenBattery Overview: Types and CharacteristicssupermannonNoch keine Bewertungen

- Selection of Surge Protective Device (SPD) - (Part 1)Dokument5 SeitenSelection of Surge Protective Device (SPD) - (Part 1)supermannonNoch keine Bewertungen

- K01 000 09Dokument338 SeitenK01 000 09arfeemNoch keine Bewertungen

- Various Routine Test of Power Transformer - (Part-4)Dokument9 SeitenVarious Routine Test of Power Transformer - (Part-4)supermannon100% (1)

- Protection of Rotating MachinesDokument13 SeitenProtection of Rotating MachinessupermannonNoch keine Bewertungen

- Over Load Relay & Contactor For StarterDokument13 SeitenOver Load Relay & Contactor For StartersupermannonNoch keine Bewertungen

- Electrical Motor ConnectionDokument5 SeitenElectrical Motor ConnectionsupermannonNoch keine Bewertungen

- Tpd1586e6 - 4012-46tag1a 2aDokument18 SeitenTpd1586e6 - 4012-46tag1a 2asupermannonNoch keine Bewertungen

- Building Lighting Protection CalculationDokument5 SeitenBuilding Lighting Protection CalculationsupermannonNoch keine Bewertungen

- Calculation For Class-Ps CT - 1500kva (DG) : Used CT Rating, Primary in Amp 2000 Used CT Rating, SEC. IN AMP 1Dokument1 SeiteCalculation For Class-Ps CT - 1500kva (DG) : Used CT Rating, Primary in Amp 2000 Used CT Rating, SEC. IN AMP 1supermannonNoch keine Bewertungen

- System Monitoring RelaysDokument8 SeitenSystem Monitoring RelayssupermannonNoch keine Bewertungen

- Push Button & Indication Lamps CatalogueDokument4 SeitenPush Button & Indication Lamps CataloguesupermannonNoch keine Bewertungen

- REFERRAL GUIDE FOR ELECTROMECHANICAL & NUMERICAL RELAYSDokument16 SeitenREFERRAL GUIDE FOR ELECTROMECHANICAL & NUMERICAL RELAYSAhmed TarekNoch keine Bewertungen

- Specifying CBCTDokument3 SeitenSpecifying CBCTkarthikumarNoch keine Bewertungen

- QSR InstrumentationControl PDFDokument275 SeitenQSR InstrumentationControl PDFDonny FitradiNoch keine Bewertungen

- G9 TosDokument3 SeitenG9 TosJuniel BarriosNoch keine Bewertungen

- Ceiling Fans: Only 1 Out of These Justifies The Five-Star RatingDokument7 SeitenCeiling Fans: Only 1 Out of These Justifies The Five-Star RatingSurbhi SabharwalNoch keine Bewertungen

- Prezentare Fluke 1550CDokument30 SeitenPrezentare Fluke 1550CsayedmhNoch keine Bewertungen

- Resistor Color CodeDokument17 SeitenResistor Color CodeKatrina Cassandra EscovillaNoch keine Bewertungen

- The Metal-Insulator Transition in V2O4 Lee (1994)Dokument6 SeitenThe Metal-Insulator Transition in V2O4 Lee (1994)Jonggyu LeeNoch keine Bewertungen

- Catalogo SEIDokument88 SeitenCatalogo SEIamjbNoch keine Bewertungen

- Ae430 450MC 144Dokument2 SeitenAe430 450MC 144RafiurRahmanNoch keine Bewertungen

- Chapter 3 MethodologyDokument14 SeitenChapter 3 MethodologyNagarajan Govindan0% (1)

- Basic Semiconductor TheoryDokument224 SeitenBasic Semiconductor TheoryJackie JonesNoch keine Bewertungen

- A Long Flashover ArresterDokument10 SeitenA Long Flashover ArresterNAMEER999100% (1)

- Shunt Reactor - 230-001Dokument26 SeitenShunt Reactor - 230-001winston11Noch keine Bewertungen

- PhieuCD A1-02-2014 E20.10 220Dokument7 SeitenPhieuCD A1-02-2014 E20.10 220Khắc Biên NgôNoch keine Bewertungen

- Light Intensity Meter Project ReportDokument25 SeitenLight Intensity Meter Project Reportzubairkhan100% (1)

- Activity 2 (DC & AC Circuits)Dokument6 SeitenActivity 2 (DC & AC Circuits)Adrian PrinceNoch keine Bewertungen

- Electric Charges and Fields Mind MapDokument48 SeitenElectric Charges and Fields Mind Mapharsh dugharNoch keine Bewertungen

- Overload y CapacitoresDokument30 SeitenOverload y Capacitores100046384Noch keine Bewertungen

- Can We Achieve Ultra-Low Resistivity in Carbon Nanotube-Based Metal Composites?Dokument5 SeitenCan We Achieve Ultra-Low Resistivity in Carbon Nanotube-Based Metal Composites?tao fanNoch keine Bewertungen

- Users Manual: Earth Ground ClampDokument30 SeitenUsers Manual: Earth Ground Clamptesya konelaNoch keine Bewertungen

- EE SetaDokument30 SeitenEE SetaAbas AcmadNoch keine Bewertungen

- 01 REFRESHER EE 1 - CLB - CompressedDokument12 Seiten01 REFRESHER EE 1 - CLB - CompressedJuphil PletoNoch keine Bewertungen

- Field Effect Transistor PDFDokument2 SeitenField Effect Transistor PDFChristinaNoch keine Bewertungen

- Circuito Integrado Del Rele de Luz de Cruce Del Accent 1.5Dokument10 SeitenCircuito Integrado Del Rele de Luz de Cruce Del Accent 1.5SAMMYF1Noch keine Bewertungen

- A01 Series Pushbutton Switches & Indicators Specification GuideDokument6 SeitenA01 Series Pushbutton Switches & Indicators Specification Guideayxworks eurobotsNoch keine Bewertungen

- Thermometry: There Are Triple Points For Many Other Substances Besides WaterDokument7 SeitenThermometry: There Are Triple Points For Many Other Substances Besides WaterIMJ JNoch keine Bewertungen

- Sheet1 product code document with resistors, capacitors, transistorsDokument106 SeitenSheet1 product code document with resistors, capacitors, transistorsBelajar IlmuNoch keine Bewertungen

- EE21L-2 - Basic Electrical Engineering, LabDokument7 SeitenEE21L-2 - Basic Electrical Engineering, LabCedric Arcel CruzNoch keine Bewertungen

- Project Based Lab Report On MEASURING TEDokument23 SeitenProject Based Lab Report On MEASURING TERaja VenkateshNoch keine Bewertungen

- HRS1H S DC5V C2Dokument3 SeitenHRS1H S DC5V C2Hama AieaNoch keine Bewertungen