Beruflich Dokumente

Kultur Dokumente

GEIT 60008GB Phasedarrays

Hochgeladen von

Tintu ViswamCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GEIT 60008GB Phasedarrays

Hochgeladen von

Tintu ViswamCopyright:

Verfügbare Formate

Ultrasonics

GE Inspection Technologies

Array probes with Array control electronics

Krautkramer Testing Machines

Phased Arrays

Phased Arrays bring a new dimension

to weld or tube testing. With arrays and

time-delay electronics an ultrasonic

beam can be focused and steered ex-

actly to the requirements, i.e. the sound

beam will be slued.

Furthermore, having determined the

optimum setting, arrays allow for virtual

scanning of the weld area to give an

optimum test despite weld wander and

to give a thickness prole of the weld

area, all without any mechanical probe

movement.

Because the system uses a water delay

line between the probe and the tube,

this means that one array can accomo-

date a range of tube sizes with no me-

chanical adjustments being necessary.

In this case the phased array is used for

ERW tubes. The following applications

are possible, so that weld defects and

defects in the adjacent parent material

of the Heat Affected Zone (HAZ) can be

detected.

Examples for angular beaming

(left) and straight beaming (right)

left: for weld seam testing

right: for wall thickness measuring

In addition to that, wall thickness meas-

urement and out of this a ash trimming

monitoring as well as a determination of

the tube saw-off length are possible.

A Phased Array system consists of the

following primary components:

Transducers in Phased Array

assembly

Array control electronics linked to the

pulser receiver channels

Array-timing control for phasing

Ultrasonic evaluation electronics

Mechanic system to position array

probes

Arrays are constructed in industrial

housings and with up to 128 elements.

They can plug directly into the Array

Module.

Alternatively, the array transducers can

also be operated in some distance from

the Array Electronic Module (with cables

of max. 2 m length).

The Array Head Module includes 128

pulsers and preampliers for each Array

which can be switched into groups of 16

selected Array Elements from the Array

itself.

GE Inspection Technologies

Ultrasonics

We reserve the right to technical modications without prior notice.

GEInspectionTechnologies.com

2004 General Electric Company. All rights reserved.

GEIT-60008GB (11/04)

From the 128 elements 16 adjacent

elements as a group can be activated si-

multaneously. These 16 elements create

the virtual scanning transducer during a

clock cycle. Through the selection of 16

out of 128 elements the sound eld can

be scanned. For example during the rst

clock cycle, elements number 1 through

16 are active, and during the second

clock cycle, elements 2 through 17 are

active, in the third clock cycle elements

3 through 18 are active etc. until clock

cycle 113 activates elements 113 through

128. In this way it is possible to move the

sound eld by several centimeters with-

out any mechanical displacement of the

probe.

The main electronics for the system is

contained in an industrial cabinet suit-

able for harsh environments.

The test mechanism mainly consists of

the following units:

Elevation table with manual adjust-

ment (Adaptation to the tube dia-

meter to be tested) or a portal with

lifting and lowering device

A test with water jet probes or a divi-

dable water chamber for mounting the

array probes incl.on-site electronics

Second water chamber (only lower

part incl. water connections) for the

service and setting positions

Divided guiding bushes and rubber

sealings

Water connections and corresponding

water distributors

Water collecting trough with hose

connection for water return

Water circulation system

(optional)

Test principles

Closed Water Chamber

Open Water Chamber

Phased Array Mechanism

Das könnte Ihnen auch gefallen

- Digital Billboard Agreement Terms and Conditions: PartiesDokument4 SeitenDigital Billboard Agreement Terms and Conditions: PartiesTintu ViswamNoch keine Bewertungen

- Clear Channel Outdoor Lease Agreement: Lease No. Lease Rep. Effective DateDokument28 SeitenClear Channel Outdoor Lease Agreement: Lease No. Lease Rep. Effective DateTintu ViswamNoch keine Bewertungen

- Pipeline Inspection Company LTD.: Portable Holiday DetectorsDokument12 SeitenPipeline Inspection Company LTD.: Portable Holiday DetectorsTintu ViswamNoch keine Bewertungen

- Abbreviations of Legal DocumentsDokument10 SeitenAbbreviations of Legal DocumentsTintu ViswamNoch keine Bewertungen

- Interview invitation for vacancyDokument1 SeiteInterview invitation for vacancyHarshit ShahNoch keine Bewertungen

- FreeCertificateTemplate ServiceDokument1 SeiteFreeCertificateTemplate ServiceTintu ViswamNoch keine Bewertungen

- GestaltDokument1 SeiteGestaltAnthony CerdasNoch keine Bewertungen

- Indulekha (First Novel of Malayalam) PDFDokument210 SeitenIndulekha (First Novel of Malayalam) PDFMunniNoch keine Bewertungen

- Microsoft Access 2007 Tutorial: Getting StartedDokument49 SeitenMicrosoft Access 2007 Tutorial: Getting Startedaqjabbar_pkNoch keine Bewertungen

- Access 07 BasicsDokument31 SeitenAccess 07 BasicsTintu ViswamNoch keine Bewertungen

- Indulekha (First Novel of Malayalam) PDFDokument210 SeitenIndulekha (First Novel of Malayalam) PDFMunniNoch keine Bewertungen

- Aquarium Blue Tang P MsDokument0 SeitenAquarium Blue Tang P MsTintu ViswamNoch keine Bewertungen

- GEIT 20113US Linear Phasedarray ProbesDokument2 SeitenGEIT 20113US Linear Phasedarray ProbesTintu ViswamNoch keine Bewertungen

- Routing and Transmittal Slip: Building, Agency/PostDokument1 SeiteRouting and Transmittal Slip: Building, Agency/PostTintu ViswamNoch keine Bewertungen

- Transmittal Letter: XYZ Architecture XX-XX Thomson Avenue Long Island City, NY 11101Dokument1 SeiteTransmittal Letter: XYZ Architecture XX-XX Thomson Avenue Long Island City, NY 11101Tintu ViswamNoch keine Bewertungen

- Routing and Transmittal Slip: Building, Agency/PostDokument1 SeiteRouting and Transmittal Slip: Building, Agency/PostTintu ViswamNoch keine Bewertungen

- PreamplifiersDokument2 SeitenPreamplifiersTintu ViswamNoch keine Bewertungen

- Malayalam CalenderDokument12 SeitenMalayalam CalenderTintu ViswamNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Model Answer: Winter-2018Dokument13 SeitenModel Answer: Winter-2018lionNoch keine Bewertungen

- Ultrasonic Phased Array: Techniques, Apps, Advantages & FutureDokument25 SeitenUltrasonic Phased Array: Techniques, Apps, Advantages & FutureAntony Bruno GenewinNoch keine Bewertungen

- AST-NDE-UT-R-500-4-2 Rev.01 Ultrasonic Testing ReportDokument7 SeitenAST-NDE-UT-R-500-4-2 Rev.01 Ultrasonic Testing Reportpankaj ranaNoch keine Bewertungen

- AI Advanced NDT MethodsDokument2 SeitenAI Advanced NDT MethodspermanahendNoch keine Bewertungen

- ME 6019 Non Destrictive Testing and Materials SyllabusDokument2 SeitenME 6019 Non Destrictive Testing and Materials Syllabusbalaguru780% (2)

- Small Diameter Tube and Pipe Inspection With Phased ArrayDokument1 SeiteSmall Diameter Tube and Pipe Inspection With Phased Arraypon sharonNoch keine Bewertungen

- Department of Electronics and Communication Engineering: Head of Deparment: Dr. Shelly Garg MENTOR: Mr. Shiv Narain GuptaDokument17 SeitenDepartment of Electronics and Communication Engineering: Head of Deparment: Dr. Shelly Garg MENTOR: Mr. Shiv Narain GuptaSourabh ChakrabartyNoch keine Bewertungen

- Notes: Physics (Grade 10) Unit:11 (Sound) Conceptual QuestionsDokument3 SeitenNotes: Physics (Grade 10) Unit:11 (Sound) Conceptual QuestionskhadijaNoch keine Bewertungen

- Dental Ultrasound ImagingDokument51 SeitenDental Ultrasound ImagingAmira RNoch keine Bewertungen

- 000 SA E 50308 - RevBDokument94 Seiten000 SA E 50308 - RevBDurga Jagan Puppala100% (1)

- Ultrasonics DemoDokument315 SeitenUltrasonics Demozubairsarwar912100% (1)

- Audio SpotlightDokument31 SeitenAudio SpotlightcheguweraNoch keine Bewertungen

- Determination of Resonant Frequency of A Piezoelectric Ring For Generation of Ultrasonic WavesDokument8 SeitenDetermination of Resonant Frequency of A Piezoelectric Ring For Generation of Ultrasonic WavesiisteNoch keine Bewertungen

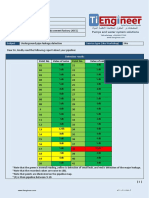

- Case Study TiEngineer مؤسسة المهندس الدولية Pipe Leakage Detection Elnahda ASEC CementDokument8 SeitenCase Study TiEngineer مؤسسة المهندس الدولية Pipe Leakage Detection Elnahda ASEC CementMohamed Abdulrahman IbrahimNoch keine Bewertungen

- Medical Electronics Surgical DiathermyDokument29 SeitenMedical Electronics Surgical DiathermysenthilvlNoch keine Bewertungen

- Types of Biomedical Instruments and Their UsesDokument12 SeitenTypes of Biomedical Instruments and Their Usesgzb0120% (2)

- Rife Ray TubeDokument43 SeitenRife Ray TubezonetrekNoch keine Bewertungen

- Ultrasonic PDFDokument8 SeitenUltrasonic PDFMOHAMED SHARKAWINoch keine Bewertungen

- 69 - 1 s2.0 S1350417718312422 Main PDFDokument7 Seiten69 - 1 s2.0 S1350417718312422 Main PDFfungiman88Noch keine Bewertungen

- Iiw Doc Viii 1576 10Dokument12 SeitenIiw Doc Viii 1576 10Marjan SubanNoch keine Bewertungen

- PAUT Ultrasonic Testing Procedure ASME - SVDN Rev 01EDokument29 SeitenPAUT Ultrasonic Testing Procedure ASME - SVDN Rev 01ETrung Tinh Ho100% (2)

- Indian Standard: Recommended Practice Straight Beam Ultrasonic of Steel Plates (FOR TestingDokument10 SeitenIndian Standard: Recommended Practice Straight Beam Ultrasonic of Steel Plates (FOR TestingAMITaXWINoch keine Bewertungen

- Smart: NDE 4.0 in Manufacturing: Challenges and Opportunities For NDE in The 21st CenturyDokument10 SeitenSmart: NDE 4.0 in Manufacturing: Challenges and Opportunities For NDE in The 21st CenturyHyujeii MceNoch keine Bewertungen

- Research Literature Pack RL 1 Lit A4Dokument46 SeitenResearch Literature Pack RL 1 Lit A4aidylNoch keine Bewertungen

- L-12 Sound Notes In-Text Questions NCERT Textbook For Class 9 Science - Page 162Dokument9 SeitenL-12 Sound Notes In-Text Questions NCERT Textbook For Class 9 Science - Page 162Sai Uday Shankar BommakantiNoch keine Bewertungen

- BES - IsO - UT - 12 - Ultrasonic Test - Rev 00Dokument43 SeitenBES - IsO - UT - 12 - Ultrasonic Test - Rev 00Ciety Ma100% (1)

- Ultrasonic Array Imaging Through An Anisotropic Austenitic Steel Weld Using An Efficient Ray-Tracing AlgorithmDokument11 SeitenUltrasonic Array Imaging Through An Anisotropic Austenitic Steel Weld Using An Efficient Ray-Tracing AlgorithmpjhollowNoch keine Bewertungen

- Sound IXDokument35 SeitenSound IXarpankrishna739Noch keine Bewertungen

- E+l ElguiderDokument36 SeitenE+l ElguiderHR Enríquez0% (1)

- Clinical Electrotherapy Modalities GuideDokument46 SeitenClinical Electrotherapy Modalities Guidehuxley2378100% (2)