Beruflich Dokumente

Kultur Dokumente

Wooden Clock Plans

Hochgeladen von

nk1869Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Wooden Clock Plans

Hochgeladen von

nk1869Copyright:

Verfügbare Formate

Woodenclocks

Clock1

The drawings on the following pages contain plans to build the

wooden clock shown above.

For further information and more detailed rendered images visit

www.woodenclocks.co.uk

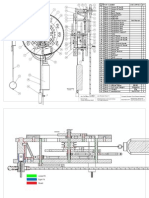

GENERALASSEMBLY 1 SHT OF 10 SHTS

NTS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

J AN 2000

Designed by:

BRLAW

www.woodenclocks.co.uk

20

35

25

43

9

35

33

48

12

47

49

34

36

35

28

27

37

32

29

38

40

45

46

44

23

24

22

27

28

30

30

11

11

26

25

4

10

1

33

8

2

3

31

5

EXPLODED VIEW

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 back

2 1 cross

3 1 Angled brace

4 1 front

5 1 squarespacer top

6 1 Pendulum hanger

7 2 Wall spacer

8 1 squarespacer bottom

9 2 Front pin

10 2 cover pin

11 3 Securing pin

12 1 Clock dial

13 2 Dial spacer

14 1 Pendulum head

15 1 Pendulum pivot

16 1 Pendulum rod

17 1 Pendulum bob

18 1 Pendulum nut

19 6 Shaft cover

20 1 Shaft151

21 1 yoke

22 1 escape

23 1 Pallet2

24 1 Pallet1

25 1 Timing

26 1 16teeth

27 2 Shaft140

28 2 Sleeve119

29 1 Shaft175

30 2 15teeth_1.5

31 1 Pawl

32 1 Sleeve70

33 2 15teeth

34 1 drum

35 3 60teeth

36 1 Ratchet

37 1 Pawl pin

38 1 32teeth

39 1 10teeth

40 1 sleeve18

41 8 ropering

42 1 rope

43 1 Weight

44 1 shaft30

45 1 8teeth

46 1 30teeth

47 1 Key shaft

48 1 Minute hand

49 1 Hour hand

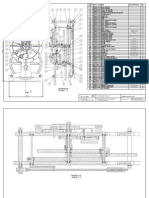

SHT 2 OF 10 SHTS

NTS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN2000

Designed by:

BRLAW

www.woodenclocks.co.uk

1

0

1

0

1

0

1

0

3

9

.

7

5

39 DIAL NOT SECTIONED

SHT 3 OF 10 SHTS

NTS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN 2000

Designed by:

BRLAW

www.woodenclocks.co.uk

CENTRELINE CROSS SECTION

5 1

4

9

19

12

16

19

3

FRAMESUB ASSY

10

6

19

8

2

14

15

16

13

13

7

7

B

C

15

14

16

B(1: 2)

C (1: 2)

18

17

SHT 4 OF 10 SHTS

NTS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN2000

Designed by:

BRLAW

www.woodenclocks.co.uk

R62.5

87.3

664

81 87.4 49 86.7 90.8

42x5mm DEEP

60

10

50

62.3

12.6

R3 13 6 6 6 6 20

P

P

1

20 6 10

R62.5

502

8.6

6.1

42 50

55.5

6 8

6

6 6 10 20

50 49 42.4 38.6 36.2 51.3 46 40.7 39.3 51.6

81

86.7

4

50 75 75

252

50

42 50

6.1

20

R2

R62.5

57

25

130

90

40

120

20 30SQ

40

20

120

40

20

30SQ

13

10

3

R9

R37.5

4.3

20

3

48

13

13 6

30 13

25

15

10

30

20

98

48

12 12

A

A

6

5

12

A-A (1: 1)

30 20

50

58

23

12

5

30 20

58

48

18

P-P(1: 2)

BACK 1-off

SCALE1:2

WALLSPACER2-off

CROSSFRAME1-off

SCALE1:2

ANGLEDBRACE1-off

SQUARESPACERTOP1-off

SCALE1:2

FRONT 1-off

SCALE1:2

FRONTPIN 2-off

SHAFTCOVER 5-off

SECURING PIN 3-off

SHAFTCOVER 1-off

PENDULUM HANGER1-OFF

COVERPIN 2-off

2

3

SQUARESPACERBOTTOM 1-off

SCALE1:2

8

5

7

9

11

19

FRAMEDETAILS

SHT5 OF 10 SHTS

SCALE1:1 UOS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN2000

Designed by:

BRLAW

www.woodenclocks.co.uk

55

75

PENDULUM HEAD 1-off 14

6

40

21.8

30

6

20

6.5

20

20

TAP M6

28

1076

6

Thread M6

10

20

10

25

10

10

300

210

10

252

CLOCKDIAL1-off

SCALE1:2

2holesDRILLEDFROM

THEBACK6MM DEEP

12

10

49

6

48

120

59

17

PENDULUM ROD 1-off

PENDULUM NUT 1-off

DIALSPACER 2-off

PENDULUM PIVOT 1_off

DIALAND PENDULUM DETAILS

HOURHAND1-off

2mmTHICK

MINUTEHAND1-off

2mmTHICK

PENDULUM BOB 1-off

18

16

15

13

SHT6 OF10 SHTS

SCALE1:1 UOS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN2000

Designed by:

BRLAW

www.woodenclocks.co.uk

R1.6

6

17.2

23

10

R1.6

28.7

34.5

R2.4

43.1

13

51.8

R1.6

10

31

36.8

73.6

R5

3.2

63.2

6.1

69

N

N

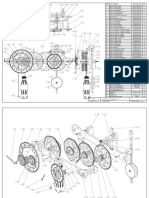

30TEETH1-off

32TEETH1-off

15TEETH1.5 1-off

30 15teeth1.5 1-off

8TEETH 1-off

10TEETH 1-off

16TEETH 1-off

15 TEETH 1-off

15 TEETH 1-off

46

78

R5

3.2

10

67.9

73

I

I

I-I

R1.6

6.1

12.6

18.4

43.1

8

R2.4

51.8

30

N-N 33

33

45

39

26

38

SHT7 OF10SHTS

SCALE1:1

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN2000

Designed by:

BRLAW

www.woodenclocks.co.uk

GEARS

35

35

6

53

6

10

R6

142.6

132.2

10

3.2

135.7

60TEETH2-OFF

60TEETH1-OFF

GEARSLARGE

35

60TEETH1-OFF

SHT8 OF10SHTS

SCALE1:1 UOS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN2000

Designed by:

BRLAW

www.woodenclocks.co.uk

Tight fit on shaft

R6

10

258

1

12

126

148.1

138.4

O

O

O-O (1: 1)

15

1.9

13

50

10

6

20.3

23.3

2.2

R25.5

7

24.9

53

27.53

125

37

31

25 TIMING WHEEL1-OFF

PAWLPIN 1-OFF

PAWL 1-OFF

36 RATCHET 1-OFF

TIMING WHEELAND RATCHET SHT9 OF 10 SHTS

SCALE1:1 UOS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN2000

Designed by:

BRLAW

www.woodenclocks.co.uk

9

30

6

54

15

0.6

ESCAPEMENT 1-OFF

PALLET2 1-OFF PALLET11-OFF

9

30

6

1

55

15

6

44.63

6.8

4.7

69.17

36.3

37.1

TRUER3 TRUER3

10

19.8

92

8.6

74.3 10

90

6 20

R7.5

6

R5

13 38 13

6.1

19.5

39.5

KEYSHAFT1-OFF

DRUM 1-OFF

9.5

9.5

13

9.5 8

32

2

20

6 30

6

151

6

175

18

70

119.5

10

6.1

6.1 10

10

6.1

Shafts and sleeves

YOKE1-off

SLEEVE119 2-OFF

32

28

SLEEVE70 12-OFF

SLEEVE18 1-OFF

44

20

29

SHAFT30 1-OFF

SHAFT151 1-OFF

SHAFT175 1-OFF

27 SHAFT140 2-OFF

40

34

21

22

23 24

47

SHT10 OF10SHTS

SCALE1:1 UOS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN2000

Designed by:

BRLAW

www.woodenclocks.co.uk

SCALE1:1 UOS

LAW WOODEN CLOCK 1

ALL DIMENSIONSIN MM

3rd ANGLEPROJ ECTION

UNTOLERANCED DIMS+/- 0.5

JAN2000

Designed by:

BRLAW

www.woodenclocks.co.uk

Notes

Woodenclock Clock l

Notes

1. Use close-grained timber such as Beech planed down to a thickness of 1

10 mm for all components unless otherwise stated.

2. All shafts for spindles should be made from 6 mm diameter bar.

3. Any suitable material can be used for the weight. The mass of the weight

will need to be established by experiment, but a good starting point would

be 6 lbs.

4. Details of the dial numerals are shown for guidance only, the actual form

of the numerals is left to your own discretion. They can be applied by

painting or as relief numerals cut from thin sheet.

5. The hands are again given for guidance only, although in this instance

they are drawn to size so that you can copy these if you wish. They should

in any event be cut from thin sheet.

6. Where the components are drawn to 1:1 scale you can attach the drawing

to the timber using a low tack adhesive, and cut around the profiles. Great

care should be taken with this approach when cutting the gear teeth

because they need to be cut very accurately to avoid problems when

assembling the clock

7. The frame is held together using 3 pins fitted through holes cross-drilled

after assembly.

8. Care should be taken to adjust the pallets (23 & 24) relative to the timing

wheel. They should operate to allow the timing wheel to move

incrementally forward when swinging through a small arc of movement of

the pendulum. (<10).

9. The pitch of the gears is controlled by the drilling of the hole centres in the

front and back frames. It may help to delay the drilling of these holes in

the frames until after the gears are first cut and then linished to size. At

this point it would help to mount them on two separate pieces of wood and

test there free movement one to the other and measure the centre

distance between them, so that the hole centres can be drilled at this

dimension rather than the theoretical dimension on the drawing.

10. The winder used is not drawn on the plans but a simple 'T' bar with a

square hole in the end to engage over the end of the square end of the

shaft holding the winding gears.

Fits between components

Loose Tight Bond

1 & 20 11 & 5 1 & 19

1 & 7 11 & 8 1 & 2

1 & 29 12 & 13 1 & 3

16 & 17 20 & 21 1 & 8

27 & 28 20 & 22 14 & 15

29 & 32 22 & 23 14 & 16

31 & 37 25 & 28 4 & 13

32 & 29 26 & 28 4 & 19

4 &20 30 & 34 7 & 2

4 & 27 32 & 33 45 & 46

4 & 29 32 & 34

4 & 44 32 & 35

4 & 47 35 & 37

45 & 4 38 & 40

46 & 4 44 & 4

44 & 45

44 & 46

47 & 30

6 & 5

9 & 5

9 & 8

11. The profiling of the larger gears is not necessary to the functioning of the

clock, and can be carried out at the discretion of the clock builder.

28 & 35

29 & 35

22 & 24 3 & 8

Das könnte Ihnen auch gefallen

- Clock 5Dokument0 SeitenClock 5jjtex100% (5)

- How to Build a Wooden ClockDokument9 SeitenHow to Build a Wooden Clockpejotage100% (2)

- Clock 7Dokument21 SeitenClock 7Jose Antonio Torres del Rio100% (3)

- Compact Wooden Clock AssemblyDokument11 SeitenCompact Wooden Clock Assemblykreitzz100% (1)

- Wooden Clock 1Dokument21 SeitenWooden Clock 1strokealpha80% (5)

- Clock 4Dokument10 SeitenClock 4pejotage100% (1)

- Clock 4Dokument10 SeitenClock 4Jose Antonio Torres del Rio100% (1)

- Clock 9Dokument12 SeitenClock 9Jose Antonio Torres del Rio100% (8)

- Wooden Gear ClocksDokument157 SeitenWooden Gear ClocksFranco Mauricio87% (240)

- Clock6 1PRDokument0 SeitenClock6 1PRMarco Muñoz ANoch keine Bewertungen

- Clock 12 Skeleton-Wind Up-Detail Drawings-PRDokument14 SeitenClock 12 Skeleton-Wind Up-Detail Drawings-PRTimothy Clark80% (5)

- Dial Removed For Clarity: Item QTY Part No. DescriptionDokument8 SeitenDial Removed For Clarity: Item QTY Part No. DescriptionThanh BinhNoch keine Bewertungen

- Dial Removed For Clarity: Item QTY Part No. DescriptionDokument8 SeitenDial Removed For Clarity: Item QTY Part No. DescriptionDaniel Andres Bolaños Gonzalez100% (1)

- Clock 38 InstructionsDokument20 SeitenClock 38 InstructionsCanNoch keine Bewertungen

- Turret Clock GuidelinesDokument48 SeitenTurret Clock Guidelinesmaccione431150% (4)

- Worlds Simplest Clock Assy 6may04 PDFDokument3 SeitenWorlds Simplest Clock Assy 6may04 PDFLucianoAlmeidaNoch keine Bewertungen

- Woodenclock Gears-Pl PDFDokument8 SeitenWoodenclock Gears-Pl PDFstaticfactory928178% (9)

- Envisionlabs Wood ClocksDokument22 SeitenEnvisionlabs Wood ClocksAlfonso100% (1)

- Build Your Own Wooden Clock PlansDokument12 SeitenBuild Your Own Wooden Clock Planszotsenko85% (20)

- 01-02-1 Assembly, Gears Ratio Clock WoodDokument1 Seite01-02-1 Assembly, Gears Ratio Clock Woodjgokey100% (1)

- Wooden Gear Clock - Clock Instructions 9Dokument66 SeitenWooden Gear Clock - Clock Instructions 9bird100% (1)

- Wooden clock assembly drawingsDokument24 SeitenWooden clock assembly drawingsJose Antonio Torres del Rio100% (2)

- Penguin Clock Assembly DrawingsDokument25 SeitenPenguin Clock Assembly Drawingsbird100% (8)

- Wooden Gear ClockDokument10 SeitenWooden Gear ClockLuca Alberti0% (1)

- CW5 TotalDokument101 SeitenCW5 TotalPierre799es88% (26)

- Wooden Gear Clock Instructions 10-2 PDFDokument78 SeitenWooden Gear Clock Instructions 10-2 PDFLuca Alberti50% (2)

- Patron para Hacer Reloj de Madera CaladoDokument9 SeitenPatron para Hacer Reloj de Madera Caladomauxer76% (33)

- Ascent Plan ManualDokument48 SeitenAscent Plan Manualkaka_0246878% (9)

- Clock 31-Drawings Iss 2Dokument9 SeitenClock 31-Drawings Iss 2Gmayuso Gma Gma0% (1)

- ScrollSaw Woodworking & Crafts 51 (Summer 2013)Dokument100 SeitenScrollSaw Woodworking & Crafts 51 (Summer 2013)bird100% (9)

- Assembly (Rev 1)Dokument31 SeitenAssembly (Rev 1)Ceci_SunshineNoch keine Bewertungen

- Wooden Clock 1 PDFDokument21 SeitenWooden Clock 1 PDFAntonio Antonio NuñezNoch keine Bewertungen

- Mystery ClockDokument88 SeitenMystery ClockVương Ngọc Khánh100% (1)

- Wooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockDokument25 SeitenWooden Gear Clocks UK: Build Manual For "Clockerel" Electromechanical Wooden Geared ClockKovačević Darko100% (1)

- Hackaday Io Project 163814 3d Printed Pendulum ClockDokument17 SeitenHackaday Io Project 163814 3d Printed Pendulum ClockMihai Daniel100% (1)

- #P574 - Pendulum Clock: 15"H. Order Movement #C131 & Hands #C137 or #C138Dokument11 Seiten#P574 - Pendulum Clock: 15"H. Order Movement #C131 & Hands #C137 or #C138eruadan100% (3)

- Book Woodenclock Design and Build Imperial SampleDokument24 SeitenBook Woodenclock Design and Build Imperial Sampleariel marinNoch keine Bewertungen

- WC5 Parts Fabrication: Author: J. RandleDokument48 SeitenWC5 Parts Fabrication: Author: J. RandleCarlos Gabriel Estergaard100% (1)

- Book Woodenclock Design and Build SampleDokument16 SeitenBook Woodenclock Design and Build SampleFernando BentancorNoch keine Bewertungen

- HorlogeDokument12 SeitenHorlogearwa bouazaouiNoch keine Bewertungen

- Easy To Make Wooden SundialsDokument46 SeitenEasy To Make Wooden SundialsJosé João Roseira80% (10)

- Clock 40 InstructionsDokument20 SeitenClock 40 Instructionsabraham maldonadoNoch keine Bewertungen

- Miniature Marble Machine For WEB 259013455Dokument2 SeitenMiniature Marble Machine For WEB 259013455Squinkle78% (9)

- Clock Gear Calculator InstructionsDokument2 SeitenClock Gear Calculator InstructionsDaksh Dhingra0% (1)

- Automata PlansDokument10 SeitenAutomata PlansSquinkle100% (1)

- Herramientas para Trazar y Medir2Dokument88 SeitenHerramientas para Trazar y Medir2Franco Mauricio60% (5)

- Vintage Playground Plans 1950s PDFDokument39 SeitenVintage Playground Plans 1950s PDFAlexandre Mello100% (1)

- Woodenclocks Journal-V1Dokument173 SeitenWoodenclocks Journal-V1jekRaffio100% (1)

- Wooden Gear Clock DIYDokument13 SeitenWooden Gear Clock DIYDaboomNoch keine Bewertungen

- Woodenclocks: Clock2Dokument9 SeitenWoodenclocks: Clock2g_ciocanNoch keine Bewertungen

- Complete Guide to Making Wooden Clocks, 3rd Edition: 37 Woodworking Projects for Traditional, Shaker & Contemporary DesignsVon EverandComplete Guide to Making Wooden Clocks, 3rd Edition: 37 Woodworking Projects for Traditional, Shaker & Contemporary DesignsNoch keine Bewertungen

- TB-2855 Edit-Sd-17Dokument1 SeiteTB-2855 Edit-Sd-17Enabulele OsakpamwanNoch keine Bewertungen

- Design AidsDokument28 SeitenDesign Aidsresurrection786Noch keine Bewertungen

- Hydraulic Cylinder Parker 3lDokument48 SeitenHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- CBTTT Sales Leaflet PDFDokument2 SeitenCBTTT Sales Leaflet PDFElmer RaulNoch keine Bewertungen

- Steinel Helicalfjedre EngDokument7 SeitenSteinel Helicalfjedre Engsmhea123Noch keine Bewertungen

- Roller Screw BrochureDokument8 SeitenRoller Screw BrochureRjgandhi65Noch keine Bewertungen

- 37° Flared Tube Fitting GuideDokument13 Seiten37° Flared Tube Fitting GuidehernychtNoch keine Bewertungen

- Mega Chad RefsDokument1 SeiteMega Chad Refsnk1869Noch keine Bewertungen

- TestDokument1 SeiteTestnk1869Noch keine Bewertungen

- Foot Scrollsaw1Dokument4 SeitenFoot Scrollsaw1Frenchwolf420100% (1)

- Arcoy DovetailerDokument8 SeitenArcoy Dovetailernk186967% (3)

- Will This DoDokument1 SeiteWill This Donk1869Noch keine Bewertungen

- Will This DoDokument1 SeiteWill This Donk1869Noch keine Bewertungen

- Will This DoDokument1 SeiteWill This Donk1869Noch keine Bewertungen

- Kennedy Cutting ToolsDokument150 SeitenKennedy Cutting ToolsFarhan AizatNoch keine Bewertungen

- Ridce de Tail: ToorseDokument4 SeitenRidce de Tail: ToorseTriveni TriveniNoch keine Bewertungen

- LAB REPORT of Filling OperationDokument4 SeitenLAB REPORT of Filling OperationAhtisham AmjadNoch keine Bewertungen

- @bonaobra EIM 9 TLE-AS-MELC's #1W 1Q 1Dokument8 Seiten@bonaobra EIM 9 TLE-AS-MELC's #1W 1Q 1Editha BonaobraNoch keine Bewertungen

- Fire Performance of Mass TimberDokument5 SeitenFire Performance of Mass TimberciviliiiNoch keine Bewertungen

- Shandong Huawei Intelligent Equipment Co., LTD.: CS6266C 2000/3000MMDokument5 SeitenShandong Huawei Intelligent Equipment Co., LTD.: CS6266C 2000/3000MMEdgar Rojas EspejoNoch keine Bewertungen

- Build Your Own Corning Machine: Tool Tip..Dokument9 SeitenBuild Your Own Corning Machine: Tool Tip..Olindo D'AndreaNoch keine Bewertungen

- VentureDeckingInstallationInstructions LRDokument13 SeitenVentureDeckingInstallationInstructions LRGhislainTremblayNoch keine Bewertungen

- Lembar Penilaian CIS LKS - Jateng 2023Dokument3 SeitenLembar Penilaian CIS LKS - Jateng 2023adichNoch keine Bewertungen

- 20MEP-155 - Workshop Practice Sample Viva Questions With AnswersDokument12 Seiten20MEP-155 - Workshop Practice Sample Viva Questions With AnswersVerbala RastogiNoch keine Bewertungen

- Electrical Tools and Equipment Lesson for Middle School StudentsDokument4 SeitenElectrical Tools and Equipment Lesson for Middle School StudentsJoni GalarritaNoch keine Bewertungen

- Forest Products Classification and Definitions - New ProposalDokument36 SeitenForest Products Classification and Definitions - New ProposalJayvee LauretaNoch keine Bewertungen

- List of Thai Exporter MDF and Plywood Products: Medium Density Fibreboard (MDF) HardboardDokument3 SeitenList of Thai Exporter MDF and Plywood Products: Medium Density Fibreboard (MDF) HardboardVlas BogdănNoch keine Bewertungen

- Woodworker's Journal Vol38 #02 April 2014Dokument84 SeitenWoodworker's Journal Vol38 #02 April 2014Engineer3DNoch keine Bewertungen

- Unit 2 - Drilling 29Dokument41 SeitenUnit 2 - Drilling 29normanjames966Noch keine Bewertungen

- Se1 - Collection of Handtools and Equipment Used For The Woodworking Shop FinalDokument46 SeitenSe1 - Collection of Handtools and Equipment Used For The Woodworking Shop FinalGabriel DiuyanNoch keine Bewertungen

- Stationary Power Tools: 10" Deluxe Bench Saw 10" Table SawDokument43 SeitenStationary Power Tools: 10" Deluxe Bench Saw 10" Table Sawusmanghani17201Noch keine Bewertungen

- Boot Basket in EnglishDokument2 SeitenBoot Basket in Englishyeruar 07Noch keine Bewertungen

- Francis Xavier Engineering College Manufacturing Technology Lab ManualDokument101 SeitenFrancis Xavier Engineering College Manufacturing Technology Lab ManualSiva RamanNoch keine Bewertungen

- SMTCL Cak CNC LatheDokument7 SeitenSMTCL Cak CNC Lathes_barriosNoch keine Bewertungen

- 12 Types of CNC MachinesDokument8 Seiten12 Types of CNC MachinesVirnic FarmNoch keine Bewertungen

- BLK 20 Lot 7 Agabus ST., Annex 35, Better Living Subdivision, Parañaque CityDokument7 SeitenBLK 20 Lot 7 Agabus ST., Annex 35, Better Living Subdivision, Parañaque CityAlexander MasongsongNoch keine Bewertungen

- Taper and Deburring CountersinkersDokument32 SeitenTaper and Deburring CountersinkersTuyenNoch keine Bewertungen

- Effect of Immersion on Strength and Durability of Ulin WoodDokument20 SeitenEffect of Immersion on Strength and Durability of Ulin WoodHidayatus SadriNoch keine Bewertungen

- Unit 3 - Multi Point CuttersDokument92 SeitenUnit 3 - Multi Point CuttersNeo TarunNoch keine Bewertungen

- Pulp and Paper - Wood SourcesDokument5 SeitenPulp and Paper - Wood SourcesEvansChombaNoch keine Bewertungen

- Project Milestone Achievment WIP Facility Deconstraint Stage 2 - Complete Shelter and MCC BuildingDokument4 SeitenProject Milestone Achievment WIP Facility Deconstraint Stage 2 - Complete Shelter and MCC BuildingNofrizal HasanNoch keine Bewertungen

- Fabricate and Install Wooden CABINETDokument30 SeitenFabricate and Install Wooden CABINETsam jeaNoch keine Bewertungen

- Brasive Industries: Wood Coating & Paint ProductsDokument2 SeitenBrasive Industries: Wood Coating & Paint ProductsPrince KumarNoch keine Bewertungen

- Install Selkie shower panels in 2 or 3 sidesDokument4 SeitenInstall Selkie shower panels in 2 or 3 sidesAva LeeNoch keine Bewertungen