Beruflich Dokumente

Kultur Dokumente

Key - Ductile Iron Pipes & Fittings Catalogue

Hochgeladen von

DFOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Key - Ductile Iron Pipes & Fittings Catalogue

Hochgeladen von

DFCopyright:

Verfügbare Formate

1

Good manufacturing and quality controlling system can assure to make perfect products

2

Centrifugal casting machine with

wat er - cool i ng met al moul d.

High quality molten iron with its

low content of sulphur, phosphorus

and other trace elements, together

with the Delavaud Process of the

world advanced level, combines to

produce perfect quality iron pipes.

3

The annealing furnace of

horizontal type performs the

treatment ductile cast iron pipes

75 meter long with 45 meters

effective working length and

equipped with computerized

control system up from siemens

in Germany. The furnace is up

to now the most advance in the

wo r l d t e c h n o l o g i c a l l y .

No leakage will be appeared on the socket and

spigot when tested under specified pressure.

4

During finishing processes, the pipes will pass through visual

Inspection, Zinc spraying (if necessary), Roundness checking,

internal grinding of spigot and socket, hydraulic pressure testing (or

air test), Ring test chamfering, grinding, dimension checking and

mechanical properties test etc, in order to assure the quality of pipes.

5

After the precise quality inspecting, Ductile Cast Iron Pipes possess

reliable strength, correct dimensions, uniform wall thickness, smoothly

surface of inside and outside.

6

Chemical components Ductile iron pipe Steel pipe Grey cast iron pipe

Carbon 3.5-4.0 0.1-0.2 3.2-3.8

Silicon 1.9-2.6 0.15-0.4 1.4 -2.2

Manganese 0.15-0.45 0.3-0.6 0.4 -0.6

Phosphorus <=0.06 0.02-0.03 <=0.3

Sulfur <=0.02 0.02-0.03 <=0.1

C

h

e

m

i

c

a

l

c

o

m

p

o

s

i

t

i

o

n

Magnesium 0.03-0.06 - -

3460 Vacuum Spectrometre is used to examine

and test the chemical components of the molten

iron before and after its nodularization.

Large metal graphic microscope is used to test the

nodularization state and organics of the products

M

i

c

r

o

s

t

r

u

c

t

u

r

e

7

Mechanical property test

Corrosion resistance to potable water

Mechanical Properties

Volume corroded (gr / cm

2

)

Kind of pipe

After 45 days After 90 days

Ductile iron pipe 0.0060 0.0090

Grey cast iron pipe 0.0060 0.0103

Seamless steel pipe 0.0170 0.0273

Sprial-weided steel

pipe

0.0294 0.0396

Ductile iron pipe

(Annealed)

Ductile iron pipe

(not Annealed)

Grey cast iron pipe Steel pipe

Tensile strength (N/

mm

2

)

>=420 150-260 >=400

DN60-1000>=10

Elogation (%)

Dn1100-2600>=7

3-5 Neglect >=18

Hardness (HB) <=230 <=210 Approx. 140

<=DN300 5.0

DN350-600 4.0

DN700-1000 3.2

DN1100-2000 2.5

Hydraulic test (MPa)

DN2100-2200 1.8

2.5-3.0

Air test (MPa) >=0.3

Ring test

8

The cement mortar lining machines.

Grinding Cement Lining

COATINGS AND LININGS

IN ACCORDANCE WITH ISO 2531 / BS 4472 / BS EN 545 / BS EN 598

STANDARD COATING AND LINING

Outside - Bitumen Coating

- Zinc Coating

- Epoxy

Inside - Bitumen Lining

- Cement Mortar Lining

- High Alumina Cement Lining

Bituminous Coating

9

PIPES WITH TYTON SOCKET JOINTS, K9 & K12

Mass of length L, including mass of socket Nominal

DN

D

E

e

Approx. mass

of pipe barrel 4.0 m 5.0 m 5.5 m 6.0 m 8.0 m

mm mm kg/m kg kg kg kg kg

80 98 6.0 12.2 52 64.5 70.5 76.5 -

100 118 6.1 15.1 64.5 80.0 87 95 -

150 170 6.3 22.8 98.5 121 131 144 -

200 222 6.4 30.6 133 163 177 194 -

250 274 6.8 40.2 175 215 234 255 -

300 326 7.2 50.8 222 273 297 323 -

350 378 7.7 63.2 277 340 368 403 -

400 429 8.1 75.5 331 407 441 482 -

450 480 8.6 89.9 389 479 524 569 -

500 532 9.0 104.3 460 564 610 669 -

600 635 9.9 137.1 608 745 806 882 -

700 738 10.8 173.9 775 949 1012 1123 -

800 842 11.7 215.2 963 1179 1247 1394 -

900 945 12.6 260.2 1171 1431 0 1694 2164

1000 1048 13.5 309.3 1399 1708 - 2017 2594

1100 1152 14.4 362.8 - - - - 3054

1200 1255 15.3 420.1 - - - - 3551

1400 1462 17.1 547.2 - - - - 4657

1600 1668 18.9 690.6 - - - - 5898

Remark: Non-standard length & size may be supplied by the manufacturer.

All dimension please refer to manufacturer drawing.

Bolted Gland Joints (Mechanical) & Flanged Joints are available upon request.

10

Tyton Joint Fitting

90

o

Bend 45

o

Bend 22

o

Bend

11

o

Bend 90

o

Socket Duckfoot Bend

Tee Branch Tee 45

o

Angle Branch

Socket Collar Concentric Tape

Remark: Non-standard length & size may be supplied by the manufacturer.

All dimension please refer to manufacturer drawing.

11

Flange Joint Fitting

90

o

Bend 45

o

Bend 22

o

Bend

11

o

Bend 90

o

Flanged Ductfoot Bend 90

o

Bend

Long Radius

Tee & Reducing Tee Invert Tee Radial Tee

Crosses 45

0

Angle Branches Y Pipe

Remark: Non-standard length & size may be supplied by the manufacturer.

All dimension please refer to manufacturer drawing.

12

Flange Blank Flange Tyton Socket Piece

Spigot Piece Spigot Pieces with Screwed-on

or Welded-on Flanges

90

o

Long Radius Bend Having

Cleaning Hole and Cover

Remark: Non-standard length & size may be supplied by the manufacturer.

All dimension please refer to manufacturer drawing.

13

Concentric Taper Eccentric Taper

Mechanical Flexible Joint Flange Spigot with Cast

Collars with Bolt Gland K12 on Puddle Flange

Bellmouth

Remark: Non-standard length & size may be supplied by the manufacturer.

All dimension please refer to manufacturer drawing.

Das könnte Ihnen auch gefallen

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryVon EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Knife Gate Valve - For Reference OnlyDokument16 SeitenKnife Gate Valve - For Reference Onlysj_scribdNoch keine Bewertungen

- Compipe BrochureDokument48 SeitenCompipe Brochureninju1Noch keine Bewertungen

- Flange Dim EN1092 1 BS4504Dokument13 SeitenFlange Dim EN1092 1 BS4504rcpretoriusNoch keine Bewertungen

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDokument8 SeitenSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNoch keine Bewertungen

- UPVC Pipes & Fittings Upload 11.03.2019Dokument20 SeitenUPVC Pipes & Fittings Upload 11.03.2019Rushan LakdimuthuNoch keine Bewertungen

- Fiberstrong Wavistrong: Flange GuideDokument1 SeiteFiberstrong Wavistrong: Flange Guidesiva8000Noch keine Bewertungen

- U PVCDokument12 SeitenU PVCGeorge SobhyNoch keine Bewertungen

- Draft MRR Isolation JointDokument9 SeitenDraft MRR Isolation JointIqbal Nurrasa BaktiNoch keine Bewertungen

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFDokument8 SeitenDimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFMohamad RifkiNoch keine Bewertungen

- Virgo Welded Valve BrochureDokument8 SeitenVirgo Welded Valve BrochureHerrera Jorge AgustínNoch keine Bewertungen

- GRP Technical SheetDokument41 SeitenGRP Technical SheetHassan Ali SadiqNoch keine Bewertungen

- Tender Specification - Potable WaterDokument12 SeitenTender Specification - Potable WaterSuhas NatuNoch keine Bewertungen

- Storage and HandlingDokument6 SeitenStorage and HandlingalagurmNoch keine Bewertungen

- Hobas FTBDokument78 SeitenHobas FTBdarkroomzc100% (1)

- Bonstrand #2412 Keylock System PDFDokument28 SeitenBonstrand #2412 Keylock System PDFKamatchi NathanNoch keine Bewertungen

- HOBAS Pressure Pipes SystemsDokument40 SeitenHOBAS Pressure Pipes Systemsu_florinNoch keine Bewertungen

- GS P&D Archsd 2012Dokument127 SeitenGS P&D Archsd 2012Andy Lee100% (1)

- Plastic Pipe StandardDokument7 SeitenPlastic Pipe Standardしんちゃん ナカリンNoch keine Bewertungen

- ADS Corrugated Heavy Duty Pipe Data SheetDokument4 SeitenADS Corrugated Heavy Duty Pipe Data Sheetiask5275Noch keine Bewertungen

- FRP Duct ThicknessDokument33 SeitenFRP Duct ThicknessAdrian RogersNoch keine Bewertungen

- HP Lok: 2010 EditionDokument38 SeitenHP Lok: 2010 Editiondeema saleemNoch keine Bewertungen

- Econ Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800Dokument1 SeiteEcon Gate Valve Cast Iron Bronze Trim ANSI Class 125 Fig. 1800ChristianGuerreroNoch keine Bewertungen

- MS Data Sheet TanqueDokument2 SeitenMS Data Sheet TanqueLION_FIRENoch keine Bewertungen

- Saddle Build-Up Lamination & Nozzle Fixation Method Statement (5222)Dokument13 SeitenSaddle Build-Up Lamination & Nozzle Fixation Method Statement (5222)ABAID ULLAHNoch keine Bewertungen

- En Standard SpecificationDokument33 SeitenEn Standard SpecificationSimbu ArasanNoch keine Bewertungen

- GRP - GRE - GRV Pipes and FittingDokument11 SeitenGRP - GRE - GRV Pipes and FittingPankajNoch keine Bewertungen

- Sample2 DrawingDokument1 SeiteSample2 DrawingganeshNoch keine Bewertungen

- Y Strainer CatalogDokument21 SeitenY Strainer CatalogIrfan FahmiNoch keine Bewertungen

- Technical Manual - 2000 USG Horizontal Lined Acid TankDokument20 SeitenTechnical Manual - 2000 USG Horizontal Lined Acid TankGade JyNoch keine Bewertungen

- CPVC Manual PDFDokument92 SeitenCPVC Manual PDFarsssyNoch keine Bewertungen

- Polypropylene: Section GuideDokument55 SeitenPolypropylene: Section GuideKarthik RajNoch keine Bewertungen

- Water SoftenersDokument11 SeitenWater Softenersadel rihanaNoch keine Bewertungen

- KL UHP Catalog 2011-02 PDFDokument30 SeitenKL UHP Catalog 2011-02 PDFaconibet9040Noch keine Bewertungen

- DGS-2010-001 Design BasisDokument19 SeitenDGS-2010-001 Design BasisJose ManjooranNoch keine Bewertungen

- Hermle Brochure Overview en PDFDokument78 SeitenHermle Brochure Overview en PDFNguyen GiangNoch keine Bewertungen

- Minimum Pipe Spacing ChartDokument8 SeitenMinimum Pipe Spacing ChartOrlando Porras MoraNoch keine Bewertungen

- V8 Import Spreadsheet Rev 11Dokument5.363 SeitenV8 Import Spreadsheet Rev 11Raymond de WeeverNoch keine Bewertungen

- 175 018000 PDFDokument2 Seiten175 018000 PDFAbu Anas M.SalaheldinNoch keine Bewertungen

- Asme Sa-836 Specification For Forgings, Titaniumstabilized Carbon Steel, For Glass-Lined Piping and Pressure Vessel ServiceDokument5 SeitenAsme Sa-836 Specification For Forgings, Titaniumstabilized Carbon Steel, For Glass-Lined Piping and Pressure Vessel Servicelucecita1902Noch keine Bewertungen

- Pipes and Bends Data SheetDokument2 SeitenPipes and Bends Data SheetManali PatilNoch keine Bewertungen

- Pressure VesselsDokument14 SeitenPressure VesselsChevronelleNoch keine Bewertungen

- S o P-PipingDokument17 SeitenS o P-PipingPrakash TiwariNoch keine Bewertungen

- Pipeline Acronyms and Classifications GuidelineDokument12 SeitenPipeline Acronyms and Classifications GuidelinelsaishankarNoch keine Bewertungen

- Is 16205 24 PMDokument6 SeitenIs 16205 24 PMR.HarishNoch keine Bewertungen

- BS 5480-2 (1982) Design and Performance RequirementsDokument24 SeitenBS 5480-2 (1982) Design and Performance RequirementsGregory Simmon100% (1)

- AlMunifPipes GRP-Pipes PDFDokument36 SeitenAlMunifPipes GRP-Pipes PDFbalot100% (1)

- E1 Technical Data Sheet - ShortDokument2 SeitenE1 Technical Data Sheet - ShortOmaiyio M. SaginiNoch keine Bewertungen

- HDPE FittingsApril2012Dokument110 SeitenHDPE FittingsApril2012Carlos GutierrezNoch keine Bewertungen

- Cement-Mortar Lined & Coated Steel PipeDokument5 SeitenCement-Mortar Lined & Coated Steel Pipenay denNoch keine Bewertungen

- BOQ-ValvesDokument4 SeitenBOQ-ValvesGourav SharmaNoch keine Bewertungen

- Equipment List Inquire 1Dokument1 SeiteEquipment List Inquire 1Agung Eko PurnomoNoch keine Bewertungen

- Ami Product Guide CatalogDokument50 SeitenAmi Product Guide CatalogAnonymous Iev5ggSRNoch keine Bewertungen

- HDPE Pipe and Fittings PDFDokument9 SeitenHDPE Pipe and Fittings PDFCris BandaNoch keine Bewertungen

- u-PVC InchDokument46 Seitenu-PVC Inchegemen7404612Noch keine Bewertungen

- Tubular Products From Special MetalsDokument26 SeitenTubular Products From Special Metalskaveh-bahiraeeNoch keine Bewertungen

- Aplication Pipe and Tube - Nippon SteelDokument29 SeitenAplication Pipe and Tube - Nippon Steelmatheus david100% (1)

- EIG Product Catalogue PLASTICSDokument40 SeitenEIG Product Catalogue PLASTICSrodinooNoch keine Bewertungen

- Seamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00Dokument8 SeitenSeamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00refeiNoch keine Bewertungen

- NuFlo Liquid Turbine FlowmetersDokument6 SeitenNuFlo Liquid Turbine FlowmetersphostyNoch keine Bewertungen

- Leica Manual M3 Quick ReferenceDokument8 SeitenLeica Manual M3 Quick ReferenceDFNoch keine Bewertungen

- MP+Technical+Data enDokument2 SeitenMP+Technical+Data enRodrigo Alvarez EspejelNoch keine Bewertungen

- The NEW Darkroom Handbook PDFDokument201 SeitenThe NEW Darkroom Handbook PDFrundeluxe50% (2)

- Darkroom ChemicalsDokument3 SeitenDarkroom ChemicalsDFNoch keine Bewertungen

- Leica Manual M6 JDokument51 SeitenLeica Manual M6 JDFNoch keine Bewertungen

- MP+Technical+Data enDokument2 SeitenMP+Technical+Data enRodrigo Alvarez EspejelNoch keine Bewertungen

- Kodak Gold 100 and 200 FilmsDokument6 SeitenKodak Gold 100 and 200 FilmsDF100% (1)

- Kobishi BellDokument2 SeitenKobishi BellDFNoch keine Bewertungen

- SRI CO2 Fire ExtinguisherDokument1 SeiteSRI CO2 Fire ExtinguisherDFNoch keine Bewertungen

- Datenblatt M+ (Typ+240) eDokument3 SeitenDatenblatt M+ (Typ+240) eDFNoch keine Bewertungen

- 2020年鼠年運程Dokument409 Seiten2020年鼠年運程DFNoch keine Bewertungen

- COP 101 Version 12 Document (Text) June 2012Dokument45 SeitenCOP 101 Version 12 Document (Text) June 2012DFNoch keine Bewertungen

- Wheelock StrobeDokument4 SeitenWheelock StrobeDFNoch keine Bewertungen

- Datenblatt M+Typ+262 eDokument2 SeitenDatenblatt M+Typ+262 eDFNoch keine Bewertungen

- Fujicolour Superia 200 Data SheetDokument4 SeitenFujicolour Superia 200 Data SheetDF100% (1)

- Fujicolour X-TRa 400 Colour Negative Films Data SheelDokument6 SeitenFujicolour X-TRa 400 Colour Negative Films Data SheelDFNoch keine Bewertungen

- Fujicolour Superia 200 Data SheetDokument4 SeitenFujicolour Superia 200 Data SheetDF100% (1)

- Fuicolour Superia 800 Data SheetDokument4 SeitenFuicolour Superia 800 Data SheetDFNoch keine Bewertungen

- Kodak Gold 100 and 200 FilmsDokument6 SeitenKodak Gold 100 and 200 FilmsDF100% (1)

- Datenblatt M+Monochrom+ (Typ+246) eDokument2 SeitenDatenblatt M+Monochrom+ (Typ+246) eDFNoch keine Bewertungen

- General Low Voltage Cable Supply Connection GuidelineDokument2 SeitenGeneral Low Voltage Cable Supply Connection GuidelineDFNoch keine Bewertungen

- GuideToSupplyMetering 270810 FinalDokument21 SeitenGuideToSupplyMetering 270810 FinalZafira FirzanahNoch keine Bewertungen

- COP 101 Version 12 DrawingsDokument89 SeitenCOP 101 Version 12 DrawingsBen CheungNoch keine Bewertungen

- Fuicolour Superia 800 Data SheetDokument4 SeitenFuicolour Superia 800 Data SheetDFNoch keine Bewertungen

- Fujicolour X-TRa 400 Colour Negative Films Data SheelDokument6 SeitenFujicolour X-TRa 400 Colour Negative Films Data SheelDFNoch keine Bewertungen

- Hong Kong Waterworks Standard Requirements For Plumbing Installation in BuildingsDokument45 SeitenHong Kong Waterworks Standard Requirements For Plumbing Installation in BuildingsAndy LeeNoch keine Bewertungen

- Handbook On Plumbing Installation For Buildings PDFDokument106 SeitenHandbook On Plumbing Installation For Buildings PDFCad NoviceNoch keine Bewertungen

- A Guide To Factory Canteen (2012)Dokument23 SeitenA Guide To Factory Canteen (2012)DFNoch keine Bewertungen

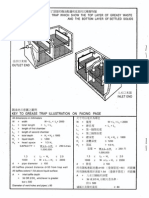

- Guide WPC GT C IllustrationDokument1 SeiteGuide WPC GT C IllustrationDFNoch keine Bewertungen

- Guide WPC GT C KeyDokument1 SeiteGuide WPC GT C KeyDFNoch keine Bewertungen

- Dynagen 2014 SpecSheets ES52 PDFDokument2 SeitenDynagen 2014 SpecSheets ES52 PDFBrianHaze100% (1)

- Marine BoilerDokument30 SeitenMarine BoilerCarloNoch keine Bewertungen

- SN398 2008-04 eDokument4 SeitenSN398 2008-04 ewasim_akp9885Noch keine Bewertungen

- IGC Doc 24-08-EDokument19 SeitenIGC Doc 24-08-Elutfirashid87Noch keine Bewertungen

- Delta School of Trades Welding Handbook by Norman J. AshleyDokument164 SeitenDelta School of Trades Welding Handbook by Norman J. Ashleyamin_corporationNoch keine Bewertungen

- List of Approved OLR Antimicrobials For PoultryDokument33 SeitenList of Approved OLR Antimicrobials For PoultryVo Long ThuanNoch keine Bewertungen

- Integrated Waste Management PDFDokument7 SeitenIntegrated Waste Management PDFTechsrijan DriveNoch keine Bewertungen

- Contractor Job Safety PlanDokument15 SeitenContractor Job Safety PlanAnonymous ocCa18RNoch keine Bewertungen

- All Sites DPR 02-06-2017Dokument16 SeitenAll Sites DPR 02-06-2017San SvsNoch keine Bewertungen

- Uop Polybed Psa For Gas Extraction Purification DatasheetDokument2 SeitenUop Polybed Psa For Gas Extraction Purification DatasheetRaji RauofNoch keine Bewertungen

- Tranportation All ExperimentDokument55 SeitenTranportation All ExperimentMaiwand KhanNoch keine Bewertungen

- Description and Instructions For Water Leakage DetectorDokument3 SeitenDescription and Instructions For Water Leakage Detectorsaurabhjerps231221Noch keine Bewertungen

- Windsor Steampac WT Boiler Brochure 2019Dokument2 SeitenWindsor Steampac WT Boiler Brochure 2019AnthonyNoch keine Bewertungen

- Draka 2Dokument260 SeitenDraka 2Sakinah Cik KinoNoch keine Bewertungen

- Beneficiation of AvocadoDokument10 SeitenBeneficiation of AvocadoJUANNoch keine Bewertungen

- Hybrid Geosynthetic Paving Mat For Highway ApplicationsDokument4 SeitenHybrid Geosynthetic Paving Mat For Highway ApplicationsmithileshNoch keine Bewertungen

- Paper Material Balanceand Energy Balance Analysisfor SyngasDokument7 SeitenPaper Material Balanceand Energy Balance Analysisfor SyngasXtylish RajpootNoch keine Bewertungen

- Chapter 1 Technology and DevelopmentDokument46 SeitenChapter 1 Technology and DevelopmentKeep ThrowNoch keine Bewertungen

- Multipower Cha K 726-P÷36012-P CLB 41.7Dokument40 SeitenMultipower Cha K 726-P÷36012-P CLB 41.7Xavi Tendre100% (1)

- Spot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesDokument9 SeitenSpot Weld Growth On 304L Austenitic Stainless Steel For Equal and Unequal ThicknessesAmin MojiriNoch keine Bewertungen

- E SN752Dokument3 SeitenE SN752hasan_676489616Noch keine Bewertungen

- Untitled DocumentDokument3 SeitenUntitled DocumentRoxan MoraNoch keine Bewertungen

- Pressure and Temperature Chart of Ammonia - I NH Sub 3 Sub IDokument4 SeitenPressure and Temperature Chart of Ammonia - I NH Sub 3 Sub Inishant361Noch keine Bewertungen

- Paschen's LawDokument6 SeitenPaschen's LawKhan YousafzaiNoch keine Bewertungen

- GUC 50 SpecsDokument2 SeitenGUC 50 SpecsAnonymous 07llXWiiFHNoch keine Bewertungen

- Permissible Crack Width ExplanationDokument4 SeitenPermissible Crack Width ExplanationAntony John VianyNoch keine Bewertungen

- CH312 Experiment 3 - Soil Chemistry ReportDokument5 SeitenCH312 Experiment 3 - Soil Chemistry ReportNarelle Iauma100% (1)

- ExerciseDokument4 SeitenExerciseariefnur19Noch keine Bewertungen

- Plug Valves: P4T and P6T SeriesDokument8 SeitenPlug Valves: P4T and P6T SeriesKahl YeongNoch keine Bewertungen

- Lathe Accessories: Work Holding Tool HoldingDokument33 SeitenLathe Accessories: Work Holding Tool HoldingSuhasNoch keine Bewertungen