Beruflich Dokumente

Kultur Dokumente

Engleski TTF Skripta 1 Semestar

Hochgeladen von

Andrea Vekarić0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

176 Ansichten6 SeitenSkripta, ovo stavljam samo da mogu pročitati nešto

Originaltitel

Engleski TTF skripta 1 semestar

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenSkripta, ovo stavljam samo da mogu pročitati nešto

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

176 Ansichten6 SeitenEngleski TTF Skripta 1 Semestar

Hochgeladen von

Andrea VekarićSkripta, ovo stavljam samo da mogu pročitati nešto

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

I.

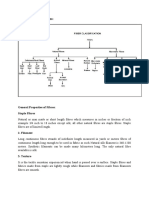

TEXTILE RAW MATERIALS

Fibres are the mess of threads, used to make clothes. Textile raw materials can be devided into two

main groups, natural and man-made fibres.

Natural fibres:

All the natural fibres used in industry are organic by origin, with the exception of asbestos, the only

inorganic natural fibre to be used in the textile industry.

Organic natural fibres can be either plant (cellulose) or animal (protein).

Among plant fibres the most widely used are seed fibres (cotton and kapok).

Bast fibres are flax and hemp. They are also called long vegetable fibres.

The main member of the hard fibre is raffia. Hard fibres are coarse fibres from the leaves of some

plants. Fruit fibres are also coarse fibres used for restricted purposes. The example is coconut.

Animal or protein fibres are wool or other animal hair and silk.

Organic man-made fibres:

They can be also organic or inorganic.

Organic man-made fibres can be manufactured from natural or synthetic polymers.

Natural polymers used in manufacturing man-made fibres can be of:

1. plant origin (viscose, acetate)

2. made from latex

3. proteins

4. can be animal origin

Synthetic polymers are organic by nature and can roughly be devided into the groups:

1. Polyester fibres

2. Polyamide fibres

3. Acrylic fibres

4. Elastane fibres

II. FIBRE PROPERTIES

Key properties:

1. Length

2. Fineness

3. Breaking strength

4. Elasticity

5. Resistance to the impact of various forces

6. Density

7. Hygroscopicity

8. Thermal, electric and chemical properties

9. Resistance to the various biological influences

Most important properties:

1. Fibre fineness

2. Maximum breaking strength (dry and wet)

3. Elongation

4. Hydrophilicity

5. Dyeability

6. Resistance to wear and fatigue (especially for technical textiles)

7. Resistance to high temperature

8. Light fastness

9. Resistance to weathering

10. Resistance to various chemicals

11. Fibre density

12. Creasing behaviour

13. Pilling behaviour

14. Durability

15. Lustre

Degradation is a negative change in fibre properties, where fibre quality is reduced due to chemical

or some other outer influence.

Fibres can be degraded in:

1. processing

2. finishing or use

3. throughthe activity of acids, alkalis, oxidants or other chemicals

4. high temperature

5. UV light,

6. micro-organismsor insects

Fibre properties inherent to fibres are curlyness, dullness and hydrophilicity.

Fibres can be straight or curly. Wool and other protein fibres are inherently curly, while cotton is

twisted. Man-made fibres are generally straight , although curliness in them can be achieved in the

process of texturing. Curly fibres are easier to spin, the yarn made from them is bulkier and the

fabrics warmer.

The lustre or dullness of the fabric surface depends generaly upon the surface structure of the fibres

used.

Hydrophilicity is the ability of a fibre to absorb and transport moisture.

Some fibre properties are inherent to particular fibres, while some are artificially obtained through

various processes, whether in fibre manugacture, in spinning or in finishing fabrics or garments.

Fibres can be analysed quantitatively and qualitatively.

Quantitative methods include flammability tests, swelling ability tests, microscopy, microchemical

reactions, defininf meltingpoint, defining variousphysical properties.

Qualitative methods can be microscopic or microchemical and are used to define the content of a

fibreblend, as well as the raw material content of textiles.

III. COTTON

Cotton fibre is a seed cellulose fibre, obtained from a wide range of some 39 different sorts of the

Gossypium plant.

Only four of them are used in the produstion of usable fibres:

1. Gossypium barbadense

2. Gossypium hirsutum

3. Gossypium herbaceum

4. Gossypium arboreum

Gossypium hirsutum sort counts for more than 90% of the global production of global fibres. It is

resistant to detrimental influences and yields crops of medium quality. The biggest producers of

cotton are USA and China. American cottons are mostly used because they are longer, stronger and

of higher quality than Upland cotton. Others are i some countries of the former Soviet Union, India,

Iran, Pakistan, Syria, Turkey, Argentina, Brazil, Columbia, Paraguay, Peru, Egypt, Mexico, the Sudan,

Zimbabwe, Greece, Spain and Australia.

The cotton plant needs at least 200 warm and sunny days a year, with abundant moisture, and is

most often grown in the valley of big rivers, where irrigation is cheep (the Nile, the Mississippi). The

plant grows between 1 and 2 meters tall. It has about 20 white flowers. When the petals drop off, a

boll of walnut size remains, containing seeds and fibres growing from them . When it is ripe, it opens

up to the size of a billiard ball, revealing 20-40 seeds, with up to 20.000 fibres per boll.The prime

advantageof cotton is that its fibre is almost immediately ready for processing. Ginning is the process

of separating fibres from seed and impurities. That is the only preparatory process. Longer fibres are

first separated and pressed in bales. Than they are transported to spinning mills.

Content of cotton fibre: It contains from 88% to 96% cellulose-

Description: Cotton fibre is a very fine and even, unicellular fibre with a pronounced twist as a result

of fibre drying after its stops growing. They are 10-65 mm long and they belong to the group of the

fine fibres.

Colour: The fibres are light yellowish and are not especially lustrous.

Resistance: Cotton is not resistant to acid, but it is moth-resistant.

Strength: Strength is medium, the elasticity is low, so thats why its characteristic is to crease. Cotton

is highly versatile. Because of such great supply in the market, it is relatively cheap. Its properties

make it the best raw material to be used directly on human skin.

Purpose: Great number of purposes and cant be compered to any other fibres.

Types of cotton fabrics: denim and corduroy

Blends: Cotton is used in various blends with man-made fibres, in order to improve its properties. It is

still the most widely used textile fibre (constituting 43% of all the fibres used).

Weakness: elasticity and strength.

IV. WOOL

Wool is a natural protein (animal) fibre, obtained from various breeds od sheep, goats and some

other animals.

History: People started using wool in prehistoric times, when sheep were first tamed in what is today

northern Iraq in the ninth millennium BC, and in some other parts of the Middle East two thousand

years later. Sheep were bred for wool by the Sumerians , and the export of wool from Babylon was

regulated by Hamurabi. Wool was used in ancient Egypt, Greece and Rome, as well sa in Europe in

the Middle Ages. In 1788. the first 29 merino sheep were transported from Spain to Australia and

from them more than 200 million sheep were bred in two centuries. Australia supplies more than

half of the worlds wool today.

Shearing: Wool is a hair covering of sheep, growing as fleece. Once a year, and twice in extremely

warm climates, sheeps are sheared, by hand or power clippers. As the fibres from various parts of

the body of an individual sheepare not of the same quality, wool is separated and sorted.

Wool obtained by shearing is also called fleece wool or virgin wool.

Lambs wool is the wool obtained from a sheep younger than a year, from the first or second

shearing.

The machine for scouring wool is called a leviathan. Plant impurities present in wool are removed by

carding and combing, and also by carbonising, a process where wool is exposed to diluted sulphuric

acid to carbonise plant remains and keep the fibres undamaged.

Apart from shearing wool can be obtained by pulling. Wool thus obtained is called dead wool.

Wool is sorted on the basis of the following:

1. Age and gender of the sheep

2. Fibre fineness

3. Manner and degree of scouring

4. Manner of obtaining

5. Part of the fleece

6. Plant impurities

7. Usability

8. Errors

9. Sales

Sensitivity: Structurally, wool is quite a heterogeneous and complex material, highly sensitive to

chemicals, water and heat.

Surface: Wool fibres have a scaly surface. The cellular part is situated below the scales, while some

coarser fibres can have a medulla, too.

Wool fibres are 5 to 35 cm long, with coarser breeds exceeding 20 cm.

Curliness: Curliness also depends upon the breed. Merino wool is curly to a high degree, while coarse

wools have fewer curls. Wool fabrics are warm due to fibre curliness, since the curls retain air as an

excelent insulator.

Colour: Wool fibres are yellowish to white in colour, but some wools are also black or brown. Of all

the fibres wool has the lowest strength, and the strength is further reduced in wet state. However,

since wool yarns are generally rather thick, wool is not considered a weak material.

Resisrance: Wool fabrics are crease-resistant, but are prone to permanent deformation under

repeated strain and longer wear. Wool is highly sensitive to alkalisand much more resistantto acids. It

is also resistant to organic solvents and can be dry-cleaned.

Felting: Wool is also prone to felting- unrecoverable length-wise and width-wise shrinkage with fabric

thickening. Felting is characteristic of all types of hairs in washing. Wool is damaged at temperatures

above 50C.

Wool is used in the manufacture of warm clothes, but is also processed into various woven and

knitten fabrics, and non-woven textiles. Carded woollen yarns are manufactured from coarser wools

and are processed into bulky, hairy and soft fabrics for coats and costumes, thick pullovers, blankets,

carpets and rugs. Combed yarn is manufactured from finer and curly fibres; yarns are usually

compact and smooth and constitute thin and strong fabrics used for suits and similar articles of

clothing.

Das könnte Ihnen auch gefallen

- Ponasanje Obicaji I Odeca Kroz Srednji VekDokument418 SeitenPonasanje Obicaji I Odeca Kroz Srednji Vekkalganov100% (1)

- KATALOG Street Art 2.0Dokument118 SeitenKATALOG Street Art 2.0torosross6062Noch keine Bewertungen

- History SummaryDokument4 SeitenHistory Summaryapi-378408622Noch keine Bewertungen

- Estetika PredsoktratovacaDokument31 SeitenEstetika PredsoktratovacaUmetnik ProleterNoch keine Bewertungen

- A.M. CassandreDokument2 SeitenA.M. CassandreDejan BogdanovicNoch keine Bewertungen

- Forma I Stil 1 DeoDokument37 SeitenForma I Stil 1 DeoAnonymous yzfLyNGBINoch keine Bewertungen

- Poster FullDokument5 SeitenPoster FullDareen SaeedNoch keine Bewertungen

- History of SareeDokument10 SeitenHistory of SareeJaya Radha100% (2)

- Prostor - Haludovo Uvala Scott - MrduljasDokument14 SeitenProstor - Haludovo Uvala Scott - MrduljasmmrduljasNoch keine Bewertungen

- Louise Bourgeois PDFDokument3 SeitenLouise Bourgeois PDFAnelise VallsNoch keine Bewertungen

- Newsletter Archives: The Saree - The Very Essence of Indian WomanhoodDokument18 SeitenNewsletter Archives: The Saree - The Very Essence of Indian WomanhoodGarima ChauhanNoch keine Bewertungen

- Fashion Design Course OutlineDokument2 SeitenFashion Design Course OutlineNaomi BoesonoNoch keine Bewertungen

- Adnan Busuladzic-Umjetnost Antickih Mozaika Na Tlu BiHDokument120 SeitenAdnan Busuladzic-Umjetnost Antickih Mozaika Na Tlu BiHkerembechNoch keine Bewertungen

- Frida Kahlo: The Self PainterDokument37 SeitenFrida Kahlo: The Self PainterRuth RosarioNoch keine Bewertungen

- Aa - 01 OnlineDokument66 SeitenAa - 01 OnlineModelArtStudioNoch keine Bewertungen

- Prehistoric Clothing: (C) 2013 Cengage Learning. All Rights ReservedDokument3 SeitenPrehistoric Clothing: (C) 2013 Cengage Learning. All Rights Reservedarpit yadav100% (1)

- Jean Paul Gaultier ResearchDokument5 SeitenJean Paul Gaultier ResearchchaztheheroNoch keine Bewertungen

- Protective Clothing DesignDokument33 SeitenProtective Clothing Designzinabu abrhaNoch keine Bewertungen

- Francis Upritchard BookletDokument4 SeitenFrancis Upritchard Bookletapi-280302545Noch keine Bewertungen

- Istorija Umetnosti, Sveska 1Dokument95 SeitenIstorija Umetnosti, Sveska 1Vida Alisa Vitezovic100% (1)

- Katalog 0408Dokument60 SeitenKatalog 0408Zoran MoskovicNoch keine Bewertungen

- Perslang Exercise Bangames-1Dokument1 SeitePerslang Exercise Bangames-1Milly FinNoch keine Bewertungen

- 1960s Fashion HistoryDokument3 Seiten1960s Fashion HistoryPratyush BaruahNoch keine Bewertungen

- Classification of FibresDokument12 SeitenClassification of FibresARYAN RATHORENoch keine Bewertungen

- Fibres, Sutures andDokument82 SeitenFibres, Sutures andSara Rafique100% (2)

- Properties Natural FibresDokument46 SeitenProperties Natural FibresanishaNoch keine Bewertungen

- Fabric Studies - 2nd SetDokument32 SeitenFabric Studies - 2nd SetP. Lakshmanakanth100% (3)

- Textile Fibers: Prof. Aravin Prince PeriyasamyDokument46 SeitenTextile Fibers: Prof. Aravin Prince PeriyasamyAreda BatuNoch keine Bewertungen

- Fabric Powerpoint 19Dokument55 SeitenFabric Powerpoint 19Japhet GatchoNoch keine Bewertungen

- Textile Fibres Classification PPT 1Dokument43 SeitenTextile Fibres Classification PPT 1tutu1990100% (4)

- TextileDokument67 SeitenTextileBunty NagapNoch keine Bewertungen

- Cellulosic FibresDokument52 SeitenCellulosic Fibresnitishkohli100% (1)

- Cta Properties PDFDokument20 SeitenCta Properties PDFAlen Jose ThomasNoch keine Bewertungen

- Wool 1Dokument44 SeitenWool 1VNoch keine Bewertungen

- Fiber, Yarn, Fabrics 3Dokument18 SeitenFiber, Yarn, Fabrics 3Mahadi HabibNoch keine Bewertungen

- Textile FibresDokument44 SeitenTextile FibresMadhu MathiNoch keine Bewertungen

- Textile Industry - 01 LectureDokument40 SeitenTextile Industry - 01 Lectureisabelism100% (1)

- Relations Between Fiber Structure and PropertiesDokument7 SeitenRelations Between Fiber Structure and PropertiesChikam BuraNoch keine Bewertungen

- FIBRE (Power Point)Dokument54 SeitenFIBRE (Power Point)MonirHossainNoch keine Bewertungen

- Fiber CraftDokument37 SeitenFiber CraftTagaBukidDotNet100% (1)

- Textile Raw Materials-IIDokument2 SeitenTextile Raw Materials-IIMOJAHID HASAN Fall 19100% (1)

- Tex. Pipeline, Fibre PartDokument87 SeitenTex. Pipeline, Fibre PartRohanNoch keine Bewertungen

- Wool FibreDokument2 SeitenWool FibreSourav Behera100% (1)

- Wrinkles Silk: Characteristics of Organdy FabricDokument6 SeitenWrinkles Silk: Characteristics of Organdy FabricShivendu BhadauriaNoch keine Bewertungen

- Natural FibreDokument11 SeitenNatural FibreArj VirkNoch keine Bewertungen

- FIBERDokument9 SeitenFIBERnaivaanNoch keine Bewertungen

- Types of Fibers Written ReportDokument7 SeitenTypes of Fibers Written ReportMikee Betinol DomalaonNoch keine Bewertungen

- Importance of Fibers in Textiles: Kavitha RajanDokument44 SeitenImportance of Fibers in Textiles: Kavitha RajankavineshpraneetaNoch keine Bewertungen

- Prepared By: Aryan Shandilya Roll - No.03 Subject: Chemistry Submitted To: Umesh PandeyDokument16 SeitenPrepared By: Aryan Shandilya Roll - No.03 Subject: Chemistry Submitted To: Umesh PandeyTHE TALKIESNoch keine Bewertungen

- Training Report On Textile Wet ProcessingDokument38 SeitenTraining Report On Textile Wet ProcessingMunazza SohailNoch keine Bewertungen

- Introduction To TextilesDokument13 SeitenIntroduction To TextilesJashwa Paul ChhettriNoch keine Bewertungen

- Fabric Science Assignment 1 On "Hemp" & "Bamboo" Cohesiveness PropertyDokument10 SeitenFabric Science Assignment 1 On "Hemp" & "Bamboo" Cohesiveness PropertyaadishNoch keine Bewertungen

- CGTPaper IIDokument130 SeitenCGTPaper IIMd. Humayun KabirNoch keine Bewertungen

- "Triple Gold Medalist": by M.E. Textile EnggDokument46 Seiten"Triple Gold Medalist": by M.E. Textile EnggFouzia MirzaNoch keine Bewertungen

- Wool and Worsted YarnDokument10 SeitenWool and Worsted Yarnraghavbindal100% (1)

- Textile: Types, Properties, Production, Uses and CareDokument25 SeitenTextile: Types, Properties, Production, Uses and CareChikanma OkoisorNoch keine Bewertungen

- Fiber Textile Fashion IndustriesDokument33 SeitenFiber Textile Fashion IndustriesRishi KumarNoch keine Bewertungen

- 79 1 ET V1 S1 - Unit - 1 PDFDokument14 Seiten79 1 ET V1 S1 - Unit - 1 PDFvandana upadhyayNoch keine Bewertungen

- Textile Basics NotesDokument33 SeitenTextile Basics Notesparthraj89100% (3)

- Even More Forest Hexes - Draft 1Dokument15 SeitenEven More Forest Hexes - Draft 1Sandro BKPNoch keine Bewertungen

- Agriculture Unit 7Dokument66 SeitenAgriculture Unit 7ShumailaMumtaz100% (1)

- Goat FarmingDokument57 SeitenGoat Farmingbadal23238100% (3)

- English Grade 8Dokument36 SeitenEnglish Grade 8dawit.a.ejiguNoch keine Bewertungen

- Jibachha's Handook of Animal HusbandryDokument40 SeitenJibachha's Handook of Animal HusbandryJibachha ShahNoch keine Bewertungen

- Udan Ubia: The Sudan Archaeological Research SocietyDokument12 SeitenUdan Ubia: The Sudan Archaeological Research SocietyJac StrijbosNoch keine Bewertungen

- Capstone ResearchDokument15 SeitenCapstone Researchapi-591689189Noch keine Bewertungen

- Addis Ababa Abattoirs Enterprise EthiopiDokument243 SeitenAddis Ababa Abattoirs Enterprise EthiopiGebrewahid W WeldemichaelNoch keine Bewertungen

- Clark's Production TechniquesDokument35 SeitenClark's Production TechniquesDia Clarkson EwiNoch keine Bewertungen

- Agri and Animal Husbandry Schemes - Karnataka: ObjectivesDokument10 SeitenAgri and Animal Husbandry Schemes - Karnataka: ObjectivesHallikara SanghaNoch keine Bewertungen

- كلمات الاستماع في ٢٠٢٢ هام للغاية لدراسة الايلتسDokument15 Seitenكلمات الاستماع في ٢٠٢٢ هام للغاية لدراسة الايلتسElsayed Ibrahim Abdelhamid ElsayedNoch keine Bewertungen

- Wolves and SheepsDokument6 SeitenWolves and SheepsJulian Andres Gutierrez LondoñoNoch keine Bewertungen

- SAG - Organic Agriculture Production NC II (New)Dokument5 SeitenSAG - Organic Agriculture Production NC II (New)Neil Ian Seth BacaniNoch keine Bewertungen

- Technical Bulletin - ESGPIPDokument18 SeitenTechnical Bulletin - ESGPIPkatyNoch keine Bewertungen

- IMIDOCARPDokument3 SeitenIMIDOCARPAna Paola ZFNoch keine Bewertungen

- Siklus MonieziaDokument18 SeitenSiklus MonieziaAdinda RahmaNoch keine Bewertungen

- Livestock Industry Video IcevonlineDokument2 SeitenLivestock Industry Video IcevonlineMarleneDouglas0% (2)

- Class 7 Science Notes Chapter 3 Fibre To FabricDokument7 SeitenClass 7 Science Notes Chapter 3 Fibre To FabricImran UL HAQNoch keine Bewertungen

- 1973 Uerpmann Animal Bone Finds and Economic Archaeology, A Critical Study of Osteoarchaeological MethodDokument17 Seiten1973 Uerpmann Animal Bone Finds and Economic Archaeology, A Critical Study of Osteoarchaeological MethodBernadette FelicianoNoch keine Bewertungen

- SS1 Animal HusbandryDokument11 SeitenSS1 Animal HusbandryAdeoye OyebisiNoch keine Bewertungen

- Second Quarterly Assessment1Dokument20 SeitenSecond Quarterly Assessment1John Elmar GutierrezNoch keine Bewertungen

- Sheep YardsDokument60 SeitenSheep YardsRia Heriawati100% (1)

- Book Response - The Way of The ShepherdDokument5 SeitenBook Response - The Way of The ShepherdmedkardNoch keine Bewertungen

- Washtenaw County 4-H Youth Show Livestock ResultsDokument43 SeitenWashtenaw County 4-H Youth Show Livestock ResultsMichelle RogersNoch keine Bewertungen

- Storytelling CompetitionDokument10 SeitenStorytelling CompetitionYvonne Phan CKNoch keine Bewertungen

- A Review of Poisonous Plants That Cause Reproductive Failure and Malformations in The Ruminants of BrazilDokument10 SeitenA Review of Poisonous Plants That Cause Reproductive Failure and Malformations in The Ruminants of BrazilDwi FrauNoch keine Bewertungen

- Turkey and The Armenian Atrocities. The Armenians, and The Events That Have Led Up To The Terrible Massacres That Have Occurred in Armenia, With A Full Account (1896)Dokument592 SeitenTurkey and The Armenian Atrocities. The Armenians, and The Events That Have Led Up To The Terrible Massacres That Have Occurred in Armenia, With A Full Account (1896)mykkNoch keine Bewertungen

- Nutrient Requirement OF SheepDokument27 SeitenNutrient Requirement OF SheepcchatrumaNoch keine Bewertungen

- ResearchReport No16 PDFDokument94 SeitenResearchReport No16 PDFsalmanNoch keine Bewertungen

- Management Education Programs: Lamb and Wool Management: Sheep Management WheelDokument3 SeitenManagement Education Programs: Lamb and Wool Management: Sheep Management WheeleddieNoch keine Bewertungen

- The Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewVon EverandThe Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewBewertung: 4.5 von 5 Sternen4.5/5 (26)

- Wear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedVon EverandWear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedBewertung: 5 von 5 Sternen5/5 (1)

- Basic Black: 26 Edgy Essentials for the Modern WardrobeVon EverandBasic Black: 26 Edgy Essentials for the Modern WardrobeBewertung: 4 von 5 Sternen4/5 (10)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsVon EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsBewertung: 4 von 5 Sternen4/5 (5)

- Metric Pattern Cutting for Women's WearVon EverandMetric Pattern Cutting for Women's WearBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Bulletproof Seduction: How to Be the Man That Women Really WantVon EverandBulletproof Seduction: How to Be the Man That Women Really WantBewertung: 4.5 von 5 Sternen4.5/5 (170)

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (138)

- Japanese Knitting Stitch Bible: 260 Exquisite Patterns by Hitomi ShidaVon EverandJapanese Knitting Stitch Bible: 260 Exquisite Patterns by Hitomi ShidaBewertung: 4.5 von 5 Sternen4.5/5 (35)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresVon EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresBewertung: 1 von 5 Sternen1/5 (2)

- Make Your Mind Up: My Guide to Finding Your Own Style, Life, and Motavation!Von EverandMake Your Mind Up: My Guide to Finding Your Own Style, Life, and Motavation!Bewertung: 3.5 von 5 Sternen3.5/5 (391)

- A Lapidary of Sacred Stones: Their Magical and Medicinal Powers Based on the Earliest SourcesVon EverandA Lapidary of Sacred Stones: Their Magical and Medicinal Powers Based on the Earliest SourcesBewertung: 4.5 von 5 Sternen4.5/5 (2)

- 250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaVon Everand250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaBewertung: 5 von 5 Sternen5/5 (7)

- The Magic of Crystals and Gems: Unlocking the Supernatural Power of Stones (Magical Crystals, Positive Energy, Mysticism)Von EverandThe Magic of Crystals and Gems: Unlocking the Supernatural Power of Stones (Magical Crystals, Positive Energy, Mysticism)Bewertung: 4 von 5 Sternen4/5 (7)

- Vintage Knit Hats: 21 Patterns for Timeless FashionsVon EverandVintage Knit Hats: 21 Patterns for Timeless FashionsBewertung: 4 von 5 Sternen4/5 (4)

- DIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!Von EverandDIY Updos, Knots, & Twists: Easy, Step-by-Step Styling Instructions for 35 Hairstyles—from Inverted Fishtails to Polished Ponytails!Bewertung: 3.5 von 5 Sternen3.5/5 (7)

- Polish Your Poise with Madame Chic: Lessons in Everyday EleganceVon EverandPolish Your Poise with Madame Chic: Lessons in Everyday EleganceBewertung: 4 von 5 Sternen4/5 (80)

- Modern Ladies' Tailoring: A basic guide to pattern draftingVon EverandModern Ladies' Tailoring: A basic guide to pattern draftingBewertung: 5 von 5 Sternen5/5 (13)

- No More Codependency, Healthy Detachment Strategies To Break The Patterns, Discover How To Stop Struggling With Codependent Relationships, Obsessive Jealousy And Narcissistic AbuseVon EverandNo More Codependency, Healthy Detachment Strategies To Break The Patterns, Discover How To Stop Struggling With Codependent Relationships, Obsessive Jealousy And Narcissistic AbuseBewertung: 4.5 von 5 Sternen4.5/5 (3)

- How To Make Jewelry With Beads: An Easy & Complete Step By Step GuideVon EverandHow To Make Jewelry With Beads: An Easy & Complete Step By Step GuideBewertung: 3 von 5 Sternen3/5 (12)

- Wear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedVon EverandWear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedBewertung: 4 von 5 Sternen4/5 (1)

- Creative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtVon EverandCreative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtNoch keine Bewertungen

- The Beginner's Guide to Kumihimo: Techniques, Patterns and Projects to Learn How to BraidVon EverandThe Beginner's Guide to Kumihimo: Techniques, Patterns and Projects to Learn How to BraidBewertung: 4.5 von 5 Sternen4.5/5 (3)

- 50 Fat Quarter Makes: Fifty Sewing Projects Made Using Fat QuartersVon Everand50 Fat Quarter Makes: Fifty Sewing Projects Made Using Fat QuartersAme VersoBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Japanese Wonder Knitting: Timeless Stitches for Beautiful Hats, Bags, Blankets and MoreVon EverandJapanese Wonder Knitting: Timeless Stitches for Beautiful Hats, Bags, Blankets and MoreBewertung: 4 von 5 Sternen4/5 (4)

- The Ultimate Book of Outfit Formulas: A Stylish Solution to What Should I Wear?Von EverandThe Ultimate Book of Outfit Formulas: A Stylish Solution to What Should I Wear?Bewertung: 5 von 5 Sternen5/5 (23)