Beruflich Dokumente

Kultur Dokumente

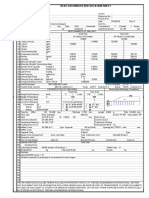

Yale & Sentry 2010 Closure Catalog - R&M

Hochgeladen von

Alfredo OrellanaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Yale & Sentry 2010 Closure Catalog - R&M

Hochgeladen von

Alfredo OrellanaCopyright:

Verfügbare Formate

Yale

and

SENTRY

Closures

Closures Catalog-FINAL.qxd 12/8/09 9:40 AM Page 1

2

Yale

and SENTRY

Closures | Table of Contents

Yale

and SENTRY

Closures

Yale

Quick Opening Closures

Yale Figure 500

, 500R

and 515

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Design Features and Safety Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Closure Design Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Materials and Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

How to Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Class Designations and Pressures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Yale Figure 500 and 500R Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . .8

Yale Figure 515 Flanged Closure Dimensional Data . . . . . . . . . . . . . . . . . .9

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Yale

Lugless Closures

Yale Figure 500

SafeGuard

Lugless . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

SENTRY

Closures

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Main Door Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Closures Catalog-FINAL.qxd 12/8/09 9:40 AM Page 2

3

Yale

Quick Opening Closures | Figure 500

, 500R

and 515

www.rmenergy.com

Yale

Figure 500

The Original

Threaded Closure

Over 60 years of reliable field service has

made Yale the leader in the industry. With

the original Figure 500

closure, Yale was

first to develop the inherent safety and

operating ease of a threaded closure.

The Figure 500 closure design combines

simplicity and reliability through the use

of a rugged, modified ACME thread to

fasten the cap to the hub. The pressure

seal is achieved by an O-ring set in the

face of the hub. Figure 500 closures are

manufactured in sizes 2"14".

Yale

Figure 500R

Closures

The Figure 500R

was designed

for larger diameter closure appli-

cations. Figure 500R closures are

machined with a bevel seat. The

bevel seat on the hub provides

the operator an accurate stabbing

section and reduces the risk for

thread and seal damage. All

Figure 500R closures also have

a minimum of 3" thread length

for greater safety and mechanical

sealing integrity. The Figure 500R

design is available in sizes 16" or

larger. Closure horizontal hinges

swing left or right for sizes 16"

and above.

Yale

Figure 515

Closures

The Figure 515

flanged closure offers a

bolted flange-to-flange configuration.

A rugged ACME thread fastens the cap

to the hub, making the Figure 515 the

safest in the industry. The pressure seal

is achieved by an O-ring set in the

face of the hub. Figure 515 closures

are available in diameter from 2"72"

and ANSI class 150 through 2500.

For fast, easy and economical accessibility to pipelines and other

vessel applications, think first of the broad family of Yale closures.

Yale closures feature a quick-opening threaded design. The Yale product

line includes a series of high pressure Figure 500

, 500R

and 515

threaded closures.

Closures Catalog-FINAL.qxd 12/8/09 9:40 AM Page 3

Yale

Quick Opening Closures | Design Features and Safety Protection

Yale

and SENTRY

Closures

Field Weldable Hubs

The closure hub is field weldable using welding instructions furnished with

each closure order. When attaching the closure hub to high-strength, thin-wall

pipe, the O.D. of the hub weld bevel can be increased to compensate for the

different Specified Minimum Yield Strengths (SMYS) as recommended in ASME

B16.5, B31.4 and other pipeline codes. Thus, the standard closure hub of SA 350

LF2-CL1 forged steel can be jointed to pipe having a SMYS of up to 1.5 times

the SMYS of SA 350 LF2-CL1. Materials to match higher strength pipe are avail-

able on request.

Double Safety Protection

The most important feature of the Yale

closures is safety. Preventing serious

injuries, or even deaths, is of primary concern to R&M Energy Systems. Pressure

Alert Valves (PAV

), standard on 6" and larger closures, provide warning of

internal pressure. Furthermore, the threaded design makes Yale closures among

the safest in the industry. For example, if pressure was trapped behind the cap

of the closure, it would be extremely difficult to unscrew the cap because of the

thread friction. However, if the cap was rotated less than 1/4 turn, the pressure

energized O-ring would relax and the trapped pressure would bleed around

the threads. At this point, there would still be over 90% of thread engagement

holding the cap onto the hub.

Pressure Alert Valve (PAV

)

A Pressure Alert Valve (PAV

) is furnished as standard equipment on all 6" and

larger closures (may be purchased as an option on smaller sizes). The PAV is

installed on the closure hub. A chain attaches the PAV stem to the closure cap

(see photo bottom left). Before the cap can be rotated, the valve stem must be

removed from the PAV body. This action is designed to warn the operator of

any residual pressure in the vessel before the closure cap is loosened. The PAV

is NOT designed to function as a bleed down or blowdown valve.

A Yale

Figure 500R

Closure installed on pig launcher

Pressure Alert Valve

The threaded design makes Yale closures

among the safest in the industry

4

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 4

Yale

Quick Opening Closures | Closure Design Options

www.rmenergy.com

5

Closure Design Options

To accommodate most applications Yale

closures are available for HORIZONTAL,

VERTICAL or ANGLE installations.

Horizontal closures are equipped with side arm hinges or jib arm hinges

depending on closure size and pressure rating.

Side arm hinges are hinged on the left side (facing the closure) unless ordered

otherwise.

Jib arm hinges will permit the cap to swing to either side after opening,

thus providing greater installation and operational flexibility.

Six inch and larger closure caps for vertical installations are suspended from a

davit hinge by a threaded center pin having the same thread pitch as the closure.

Angled closure hinges are custom designed to match the specified incline

or decline angle.

All closure hinges are adjusted at the factory to support the entire weight of the

closure cap. This prevents the cap from resting on the threads of the mating hub

and allows even the heaviest of caps to be easily rotated off and on the threaded

hub. If field adjustment is necessary, the horizontal jib and the 26" and larger

vertical davit have adjustment in two planes permitting fast, positive positioning

of the cap relative to the hub. Twenty-four inch and smaller vertical davits have

adjustments in the vertical plane only.

Twelve inch and smaller closures can be ordered with any of the following

options or combinations:

Cap and hub only

Cap and hub with chain and swivel

Cap and hub with Figure 500 bleeder plug

Cap and hub with PAV

Cap and hub with hinge (excluding 2")

Closure caps can be center drilled and tapped for no hinge closures,

or drilled and tapped off center for hinged closures.

Cap pins on vertically hinged closures can be drilled and tapped as

follows: Sizes 8" to 14" drilled

1

/4" thru and tapped

3

/8" NPT; sizes 16"

and larger, drilled

1

/2" thru and tapped

1

/2" NPT. Larger NPT couplings

available upon request.

NOTE: From pipeline horizontal centerline,

incline angles up, decline angles down.

Angled Closure

(Inclined shown, declined available)

Horizontal Closure

(Side arm hinge shown)

Vertical Closure

No Hinge Closure

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 5

Yale

Quick Opening Closures | Materials and Testing

Yale

and SENTRY

Closures

Materials

Standard materials used in closures are made to ASTM specifications and are

types permitted under ASME Section VIII, Division 1, Boiler and Pressure Vessel

Code. Closure hubs and most 14" and smaller caps use SA 350 LF2-CL1. The

standard material for 16" and larger caps is SA 516 Grade 70 normalized.

Standard material for flanges for Figure 515

closures is SA105N. Materials for

special applications, including hinges for offshore service, can be furnished

upon request.

O-Ring Material

Pressure, temperature and chemical environments need to be considered

when selecting O-ring material.

The standard O-ring material for Yale

closures is Nitrile (NBR) which has both

excellent resistance to the effects of most hydrocarbons and very good flexibility

at low temperature. The maximum operating temperature is 250 F.

FKM (Viton) O-rings are recommended for higher temperature applications

to 400 F.

Ethylene Propylene (EP) Rubber compounds are available for glycol and

steam service up to 300 F.

Other elastomers are available for specific service conditions.

Code Compliance

Yale

closures are designed and proof tested in accordance with the require-

ments of ASME Section VIII, Division 1 Boiler and Pressure Vessel Code. The

table on page 7 lists suggested allowable working pressures based on ANSI

B16.5 class designations.

It is important to provide R&M Energy Systems with system design pressure,

line size, operating temperature, and application code to ensure the most

economical closure selection.

ASME Code Stamped Closures

Yale

closures can be code

stamped and U-2A Partial Data

Reports furnished. Code stamping

verifies shop inspection of the

closure and materials by an ASME

Authorized Inspector.

Manufacturers Statement of

Code Compliance

A manufacturers statement of

code compliance can be furnished

affirming that the closure is manu-

factured in accordance with the

requirements of an applicable

code including ASME, API 6-H, ANSI,

DOT and customer specifications.

6

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 6

Yale

Quick Opening Closures | How to Order and Class Designations

www.rmenergy.com

7

How to Order

Yale

Closures

To assure proper handling of your

order, the following information

must be provided:

1. Maximum design pressure or

ANSI rating and minimum and

maximum design temperature.

2. Design factor.

3. Maximum field test pressure.

4. I.D., wall thickness, nominal pipe

diameter and grade of material

of the matching pipe.

5. Type of hinge as determined by

position of the installation:

(a) Horizontal Horizontal

hingesSizes 3"-14" are

hinged on the left side

(facing the closure) unless

ordered otherwise. Larger

sizes are hinged in the

center and will swing to

either side.

(b) Vertical Vertical hinge.

(c) AngleAngle hinge

(specify inclined or declined

and degree of angle) refer

to photo on page 5.

(d) Flangedfor bolt up

applications (provide

desired material).

6. Mating flange type and rating.

7. Service to determine proper O-

ring material. Use only factory

replacement O-rings.

8. Specific codes or special material

requirements applicable to the

closure design.

Class Designations and Pressures

ANSI Working

Closure Pressure

Hydrostatic

-50 to 400 F

Test Pressure

Series PSI bar kPa PSI bar kPa

150 285 19.6 1960 450 30 3000

300 740 51.1 5110 1125 77 7700

400 990 68.3 6828 1500 103 10300

600 1480 102.1 10210 2225 154 15400

900 2220 153.2 15320 3350 230 23000

1500 3705 255.3 25530 5575 383 38300

2500 6170 425.5 42550 9275 639 63900

Yale

Figure 500

with PAV

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 7

Yale

Quick Opening Closures | Figure 500

and 500R

Dimensional Data

Yale

and SENTRY

Closures

O RING

A

BORE

T

V SWING RADIUS

U

C

B

A

B

C

F

O RING

BORE

H SWING

RADIUS

D

H SWING RADIUS

E

G

A

F

B

C

BORE

D

Sizes 44" and larger available upon request.

Note 1: All Dimensions Nominal and for reference only. Dimension drawings can be provided upon request at time of order.

N/A - not applicable

Horizontal 3" - 14" Horizontal 16" and Larger Vertical

Horizontal Vertical

Closure

A B C

G

H

T

V

Size &

Cap Hub Cap/Hub D E F Swing U Swing

Series

O.D. Length Makeup

Min.

Radius

Height

Radius

(Note 1)

2 150/900 4

3

/8 2

5

/8 3

1

/4 NO HINGE

3 150/900 5

1

/2 2

5

/8 3

1

/4 6 N/A 7 N/A 8

3

/4 7 7 8

3

/4

4 150/900 6

3

/4 3

1

/2 5 7 N/A 8 N/A 9

1

/4 7 8 9

1

/4

6 150/600 9

3

/4 4

1

/2 5

3

/4 9 N/A 10

1

/2 N/A 13 11 8 13

8 150/600 11

1

/4 5 6

3

/4 9

1

/2 N/A 11 N/A 15 12 8

1

/2 14

1

/4

8 900 12

1

/4 5

1

/2 7

3

/4 13

1

/2 N/A 13

1

/2 N/A 16 14

1

/4 9 15

1

/4

10 150/600 13

7

/8 5

1

/2 8 14

3

/4 N/A 13

1

/2 N/A 18 14

1

/4 11

1

/2 18

1

/2

10 900 15

3

/8 5

1

/2 10

1

/2 15

1

/2 N/A 13

1

/4 N/A 18 14 12

3

/4 20

12 150/600 15

3

/8 5

1

/2 8 15

1

/2 N/A 13

1

/2 N/A 20 14

1

/4 12

1

/4 20

12 900 16

3

/4 5

1

/2 11

1

/4 15

1

/2 N/A 13

1

/4 N/A 20 13

1

/2 12

1

/2 21

14 150/600 18 5

1

/2 8 17

1

/4 N/A 13

1

/2 N/A 22 14

1

/4 13 22

14 900 18

3

/4 8

1

/2 14

1

/4 24 20 24

3

/4 22 32 24 18

3

/4 28

16 150/600 19

7

/8 9

1

/4 14

1

/2 24

3

/4 20

3

/8 25

3

/4 2

1

/4 33 25 20 30

16 900 20

7

/8 10 15

3

/4 24

3

/4 20

3

/8 26

1

/4 3 33 26

1

/4 20 30

1

/2

18 150/600 22

1

/8 9

1

/4 15

1

/4 25

3

/4 21

3

/8 26

1

/4 2

1

/4 33 25

3

/4 21 32

1

/4

18 900 23

1

/8 10 16 25

3

/4 21

3

/8 26

3

/4 3 33 27 21 32

3

/4

20 150/600 24

3

/8 11 16

3

/4 27

1

/2 27

5

/8 27

1

/2 3

1

/4 47 27

1

/2 22 34

1

/4

20 900 25

1

/2 13 19

1

/2 29

1

/2 27

5

/8 29

1

/2 4

1

/4 47 28

3

/4 23 35

1

/8

22 150/600 26

7

/8 11 17

3

/4 28

1

/2 28

7

/8 28

1

/2 4

1

/4 47 28

1

/4 23

1

/4 36

3

/4

22 900 28

1

/4 13 19

1

/4 29

1

/4 28

7

/8 30 3

1

/4 47 29

1

/2 23

1

/4 37

1

/2

24 150/600 29 11 19 35

3

/4 30

3

/8 29

1

/4 3

1

/4 48 29

1

/2 25

1

/4 39

24 900 30

5

/8 13 20

1

/2 35

3

/4 30

3

/8 33

1

/2 3

1

/4 48 30 25

1

/4 40

26 150/600 31

1

/4 11 18

1

/2 35

3

/4 31

3

/8 32

1

/2 3

1

/4 48 34

1

/2 27

3

/4 43

1

/2

26 900 32

7

/8 13 21

1

/4 39

3

/4 29

1

/4 34

1

/4 4

1

/4 48

28 150/600 33

1

/2 11 19 40

3

/4 30

1

/4 33

1

/4 3

1

/4 48 34

1

/2 28

3

/4 45

3

/4

28 900 35

1

/8 13 21

3

/4 40

3

/4 30

1

/4 34

1

/4 4

1

/4 48

30 150/600 35

7

/8 12 20

1

/2 41

3

/4 31

1

/4 33

3

/4 3

1

/4 48 36

1

/4 29 47

30 900 37

1

/2 16 22

1

/4 50

1

/4 33

1

/4 35

1

/4 5 59

32 150/600 38

1

/8 12 21 42

3

/4 32

3

/4 34 3

1

/4 48 36

1

/2 30 49

1

/4

32 900 39

7

/8 16 26

1

/4 51

1

/4 34

1

/4 38

1

/4 5 59

34 150/600 40

1

/4 12 21

1

/2 43

3

/4 33

3

/4 34

1

/2 3

1

/4 48 36

3

/4 31 51

1

/4

34 900 42

3

/8 16 27 51

1

/4 34

1

/4 39 5 59

36 150/300 40

3

/8 13 22

1

/4 53

1

/4 36

1

/4 36 4 59 38

1

/2 36 56

1

/4

36 400/600 42

3

/8 15 25

1

/4 53

1

/4 36

1

/4 38

1

/4 5 59 40

1

/2 36 57

1

/4

36 900 44

1

/2 16 27

1

/4 53

1

/4 36

1

/4 40

1

/4 5 59 52

1

/4 37

3

/4 59

3

/4

38 150/300 42

3

/4 14 23

3

/4 54

1

/2 37

1

/2 37 4 60

38 400/600 44

7

/8 15 25

3

/4 55

1

/2 38

1

/4 38

3

/4 5 59

38 900 47 17 28

3

/4 54

1

/2 37

1

/2 43

1

/4 5 59

40 150/300 44

7

/8 13 23

1

/2 55

1

/4 39

1

/2 37

1

/2 5 59

40 400/600 47 15 26

1

/4 55

1

/2 38

1

/4 39 5 59 41

1

/4 38 61

1

/2

42 150/300 46

7

/8 13 23

3

/4 56

1

/2 39

1

/4 37

3

/4 4 60

42 400/600 49

1

/4 15 26

3

/4 56

1

/2 39

1

/4 39

1

/2 5 60 41

3

/4 39 63

3

/4

Yale

Figure 500

and 500R

Dimensions

8

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 8

Yale

Quick Opening Closures | Figure 515

Flanged Closure Dimensional Data

www.rmenergy.com

Yale

Figure 515

Dimensions

9

CC

Size ANSI AA BB

Vert Horz

2" 150 6.000 0.750 5.750 5.750

300 6.500 0.875 6.000 6.000

600 6.500 1.000 6.125 6.125

900 8.500 1.500 7.250 7.250

3" 150 7.500 0.938 9.750 9.750

300 8.250 1.125 10.125 10.125

600 8.250 1.250 10.250 10.250

900 9.500 1.500 11.000 11.000

4" 150 9.000 0.938 10.000 11.000

300 10.000 1.250 10.375 11.375

600 10.750 1.500 11.000 12.000

900 11.500 1.750 11.500 12.500

6" 150 11.000 1.000 14.500 14.000

300 12.500 1.438 14.875 14.375

600 14.000 1.875 15.625 15.125

8" 150 13.500 1.125 16.000 15.000

300 15.000 1.625 16.375 15.375

600 16.500 2.188 17.250 16.250

900 18.500 2.500 20.625 19.875

10" 150 16.000 1.188 18.250 17.500

300 17.500 1.875 18.875 18.125

600 20.000 2.500 20.250 19.500

900 21.500 2.750 21.250 20.500

12" 150 19.000 1.250 18.750 18.000

300 20.500 2.000 19.375 18.625

600 22.000 2.625 20.375 19.625

900 24.000 3.125 21.375 21.125

14" 150 21.000 1.375 19.250 18.500

300 23.000 2.125 19.875 19.125

600 23.750 2.750 20.750 20.000

900 25.250 3.375 32.375 33.125

16" 150 23.500 1.438 30.000 30.750

300 25.500 2.250 30.750 31.500

600 27.000 3.000 32.000 32.750

900 27.750 3.500 34.750 34.750

18" 150 25.000 1.563 31.125 31.750

300 28.000 2.375 32.000 32.500

600 29.250 3.250 33.000 33.500

900 31.000 4.000 36.000 35.750

20" 150 27.500 1.688 33.188 33.188

300 30.500 2.500 33.875 33.875

600 32.000 3.500 35.000 35.000

900 33.750 4.250 38.500 39.250

24" 150 32.000 1.880 35.500 35.250

300 36.000 2.750 36.125 35.875

600 37.000 4.000 37.500 37.250

900 41.000 5.500 41.500 45.000

CC

Size ANSI AA BB

Vert Horz

26" 150 34.250 2.690 39.250 37.250

300 38.250 3.125 41.750 39.750

600 40.000 4.250 43.250 41.250

900 42.750 5.500 45.500

28" 150 36.500 2.810 39.440 38.190

300 40.750 3.380 42.250 41.000

600 42.250 4.380 43.750 42.500

900 46.000 5.620 46.000

30" 150 38.750 2.125 41.375 38.875

300 43.000 3.625 44.500 42.000

600 44.500 4.500 46.000 43.500

900 48.500 5.875 47.500

32" 150 41.750 3.190 42.190 39.690

300 45.250 3.880 45.250 42.750

600 47.000 4.620 46.750 44.250

900 51.750 6.250 51.250

34" 150 43.750 3.250 42.630 40.380

300 47.500 4.000 45.870 43.620

600 49.000 4.750 47.370 45.120

900 55.000 6.500 52.750

CC

Size ANSI AA BB

Vert Horz

36" 150 46.000 2.375 43.875 41.375

300 50.000 4.125 48.000 45.500

400 50.000 4.500 50.375 48.125

600 51.750 4.875 51.625 49.375

900 57.500 6.750 66.500 54.500

38" 150 48.750 3.440 43.190

300 46.000 4.250 44.120

400 47.500 4.880 46.870

600 50.000 6.000 48.750

900 57.500 7.500 57.130

40" 150 50.750 3.560 43.940

300 48.750 4.500 45.120

400 50.000 5.120 49.750 47.500

600 52.500 6.250 51.630 49.380

42" 150 53.000 3.810 44.500

300 50.750 4.690 45.630

400 52.000 5.250 50.560 48.310

600 55.250 6.620 52.750 50.500

Size not available.

Vertical

Horizontal 3" - 14"

Horizontal 16" and Larger

Note 1: All Dimensions Nominal (inches). Dimension drawings available upon request at time of order.

Note 2: For sizes of 24" and less, the flanges are in accordance with ASME B16.5, Pipe Flanges and Flanged Fittings,

NPS

1

2 Through NPS 24.

Note 3: For sizes of 26" and larger, the flanges are in accordance with ASME B16.47, Large Diameter Steel Flanges,

NPS 26 Through NPS 60.

This specification gives dimensions for type A and type B flange. Dimensions shown here are in accordance

with type A, which is larger.

With both sizes available, please state which type is desired. Dimension drawings can be produced accordingly.

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 9

Conversion: Closure to Figure 505

Pipeline Union

Twelve inch and smaller ANSI Series 150600 closures can be converted to Yale

Figure 505 unions. This is a convenient method to extend the pipeline without

welding.

Pressure Alert Valve (PAV

)

An additional safety featurea PAV

is furnished as standard equipment on

all 6" and larger closures and may be purchased as an option on smaller sizes.

Before the cap can be rotated, the seating screw must be removed from the

PAV body. This action will warn the operator of any residual pressure in the

vessel before the closure cap is loosened. The PAV is NOT designed to release

internal pressure.

Closure Actuator Tool

For easy operation, 16" and larger closures are furnished with a Closure

Actuator Tool (CAT). The CAT tool is designed to assist in both opening and

closing the closure.

Thread Inspection Gauge/Training

Corroded, severely worn or damaged threads can be a safety hazard. Thread

gauges and seminars are available for training field personnel in proper main-

tenance and thread inspection procedures.

Yale

Lug Wrench

Closure caps, 4" 14", are formed with the characteristic Yale lugs. A specially

designed detached wrench slips over the lugs for quick closure closing and

opening.

Yale

Quick Opening Closures | Accessories

Yale

and SENTRY

Closures

Yale

Detached Lug Wrench

(shown on closure in opening position)

Pipeline Union

Closure Caps

Pressure Alert Valve

Closure Actuator Tool

(shown in closing position)

Thread Inspection Gauge

10

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 10

Yale

SafeGuard

Lugless Closure | Figure 500

www.rmenergy.com

Yale

Figure 500

SafeGuard

Lugless Closure

The lugless feature of the SafeGuard closure prevents in-field safety risks associated

with hammering on the closure cap lugs as well as the potential for damage to

the closure that could hinder its sealing capability and shorten the service life

of the closure. The Yale SafeGuard closure can be easily operated with a standard

24" or 36" pipe wrench.

The unique, lugless feature of the Yale SafeGuard closure provides significant

benefits to end users that include an overall low total cost of ownership.

Specific benefits include:

Safety for the operators

Secure sealing without leakage

Quick and easy operation that saves time and effort on the part of

the operators

Long service life to optimize the return on your investment

Designed for simplicity and reliability, the Yale

SafeGuard

Lugless

Closure is part of the extensive line of Yale Figure 500 closures. It provides

secure sealing and easy operation utilizing the field-proven threaded

closure cap with O-ring pressure seal design, with the additional safety

aspect of the lugless design for effective pipeline and vessel accessibility.

11

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 11

12

Yale

SafeGuard

Lugless Closure | Features, Benefits and Dimensions

Yale

and SENTRY

Closures

Horizontal

Vertical

Horizontal Vertical

Closure

A B C

G

H

T

V

Size &

Cap Hub Cap/Hub D E F Swing U Swing

Series

O.D. Length Makeup

Min.

Radius

Height

Radius

2 150/900 4

3

/8 2

5

/8 4

3

/8 NO HINGE

3 150/900 5

1

/2 2

5

/8 3

3

/4 6 N/A 7

1

/2 N/A 9

1

/4 7

1

/2 7 9

7

/8

4 150/900 6

3

/4 3

1

/2 6

1

/8 7 N/A 9

1

/8 N/A 10

3

/8 8

1

/8 8 11

3

/8

6 150/600 9

3

/4 4

1

/2 7

1

/4 9 N/A 12 N/A 14

1

/2 12

1

/2 8 13

1

/8

8 150/600 11

1

/4 5 8

1

/2 9

1

/2 N/A 12

3

/4 N/A 16

3

/4 13

3

/4 8

1

/2 14

1

/4

10 150/600 13

7

/8 5

1

/2 9

7

/8 14

3

/4 N/A 15

3

/8 N/A 19

7

/8 16

1

/8 11

1

/2 18

5

/8

Dimensions

Features and Benefits of the SafeGuard Lugless Closure

The lugless design eliminates risk of hammering on closure cap for added

safety and prevention of damage to the closure

Rugged, ACME-threaded design with secure O-ring pressure seal ensures

positive sealing

Available in sizes from 2" through 10" for application versatility

A variety of O-ring materials such as Nitrile, Viton, Ethylene Propylene

compounds and others are available to meet a broad range of pressure,

temperature and chemical requirements for effective sealing in the most

critical applications

All standard materials used in the manufacture of Yale closures are to ASTM

specifications as permitted under ASME Section VIII, Division 1, Boiler and

Pressure Vessel Code to ensure performance and safety

The closure hub is field weldable for easy and secure installation

The Yale closure is among the safest in the industry due to its threaded

design that makes it extremely difficult to unscrew the cap of a pressurized

pipeline or vessel

A Pressure Alert Valve (standard on 6" and larger closures and optional on all

others) ensures that all residual pressure in the pipeline or vessel is eliminated

before the pressure cap is loosened to ensure operator safety

Ideal for applications such as pipelines, pressure vessels, pig traps, filter and

filtration systems and manway access along with many others

Yale Figure 500 SafeGuard Lugless Closures provide productivity, durability

and safety for the most critical installations.

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 12

13

SENTRY

Closure | Design

www.rmenergy.com

General Design

The SENTRY concept relies on a simple locking ring that slides within a groove

machined into the outer flange or hub. When expanded to the closed position,

the locking ring securely locks the door into position.

This design methodology is well proven within the oil and gas industry and

provides distinct advantages of integral safety and avoids the reliance on

external clamps with combined screw thread expanders.

Heavy-duty components are used to actuate the locking ring and are designed

to withstand the rigors of long term operation. Components are designed

and arranged to ensure secure retention of all hinge hardware and simplified

handling by fabricators.

SENTRY closures are available with the ASME U stamp Cloverleaf and can be

supplied in compliance with most international design codes.

Closure Operation

The SENTRY closure operating cycle consists of removing the Pressure Alert

Valve/Safety Segment assembly and then rotation of the actuator lever

through 180. This simple operation contracts the locking ring sufficiently to

clear the outer hub, allowing the door to be pulled open. Closing is simply a

reversal of this operation.

Closure Sealing

A key feature of the SENTRY closure is the pressure energized lip seal. Located

within the face of the door (horizontal) or the hub (vertical) for protection, the

seal is available in several materials to meet the demands of todays pipeline

industry. The increased contact of the sealing surface reduces stress loads and

extends the closure operating life. Designed to provide extended service life,

the SENTRY seal is a one-piece design consisting of an integral elastomeric seal

and a coiled spring anti-extrusion device.

Closure Safety

Safety is paramount in todays industry and the SENTRY closure not only provides

speed of operation but also the benefit of integral safety features that prevent

unsafe operation. With the locking ring in the locked, closed position, internal

pressure creates a seating force that physically traps the locking element between

the door and outer hub, making it impossible for the door to open. This design

characteristic is further enhanced by the integral Pressure Alert Valve (PAV

) that

threads into a pressure sensing port. A small removable segment of the locking

ring is attached to the PAV forming a double safety feature and preventing

accidental opening. Operation of the PAV provides positive indication as to

the pressurized state of the pressure vessel.

A key feature of the SENTRY closure is

the pressure energized lip seal

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 13

SENTRY

Closure | Configurations and Product Overview

Yale

and SENTRY

Closures

Configurations

The SENTRY closure is available in both:

Horizontal

For horizontal applications, the SENTRY closure is supplied with a heavy duty,

double pivot hinge arrangement that fully supports the weight of the closure

door, minimizes the swing radius and insures repetitive operation. Note: Hori-

zontal are hinged on the left side (facing the closure) unless ordered differently.

Vertical

For vertical operation, the SENTRY closure can be supplied in several designs

to suit the requirements of the customer and to suit their site needs.

Vertical closures can be supplied with lifting eyes only to permit removal with

client supplied equipment. Options for davit arms using simple screw jack,

chain hoist or hydraulic are available. The heavy duty davit arm is designed to

fully support the weight of the door and provide long term reliable operation

A low height davit arm is also available on request.

For larger diameter closures, where the weight of the door becomes a restraining

factor, the door is supplied with three lifting eyes only for use with overhead

lifting equipment.

Product Overview

Size Range 10" to 72" nominal diameter (other sizes available

upon request)

Design Pressures Full vacuum to 3705 PSIG working pressure

Ratings ANSI 150#, 300#, 600#, 900# and 1500#

Design Specifications ASME Section VIII Division 1 U stamp

ANSI B31.3, B31.4 & B31.8

Other international codes available on request

Configurations Available Horizontal

Vertical

Materials of Construction Carbon steel (SA105, A694 F48)

Low temp carbon steel (SA350 LF2 Cl 1)

High yield carbon steel (A694 F56, A694 F60)

Stainless steel

Duplex stainless steel

Clad / weld overlay alloys

Specialty alloys

Sealing Elastomeric pressure energized lip seal with encap-

sulated stainless steel anti-extrusion back up ring.

Elastomeric seal available in: Nitrile, Viton and HNBR.

Optional Accessories Protective weather covers

Non-venting Pressure Alert Valve

Key interlock systems

Position indicators

Tamper proof / lock out security device

Horizontal

Vertical

14

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 14

SENTRY

Closure | Main Door Seal

www.rmenergy.com

15

Door Open

Door Closed

Pressurized

Door Open

Seal shown in neutral condition

while the door is open.

Door Closed

The closing action of the door

compresses the lip of the seal

to create the initial pressure

boundary. The seal makes

contact both within the door

groove and across the length

of the lip upper surface. It is

capable of withstanding both

vacuum and positive internal

pressures.

Pressurized

The benefit of the SENTRY

closure design is that when

pressure is introduced, it

bears against the internal

U cup surface of the seal.

The pressure on the inside

of the seal insures constant

contact between the seal

lip and the seal surface.

Closed Hub

(Horizontal Closure Shown)

Internal Pressure

Door

Main Door Seal

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 15

2009 by R&M Energy Systems.

Yale and SENTRY are registered trademarks of R&M Energy Systems.

Viton is a registered trademark of DuPont Performance Elastomers.

Figure 500, Figure 500R, Figure 505, Figure 515, PAV and SafeGuard are trademarks of R&M Energy Systems. Printed in U.S.A.

R&MEnergy Systems is part of the Fluid Management Group of Robbins & Myers, Inc. C-3101-1209

Web Site: www.rmenergy.com

E-Mail: info@rmenergy.com

R&M Energy Systems Australia

7B Newfield Road

Para Hills West, SA, Australia 5096

61-8-8260-4000

61-8-8260-4333

Fax: 61-8-8260-4777

R&M Energy Systems de Argentina SA

Debenedetti 1372La Lucila

Vicente LopezProvincia de Buenos Aires

CP 1636Argentina

0 54 11-4313-6358

Fax: 0054 11-5235-5482

R&M Energy Systems

10906 R.M. 2920

Tomball, Texas, U.S.A. 77375

(800) 654-5603

(281) 351-2222

Fax: (281) 351-6557

R&M Energy Systems Canada

3703 - 98th Street

Edmonton, Alberta, Canada T6E 5N2

(877) 465-9500

(780) 465-9500

Fax: (780) 465-9535

Closures Catalog-FINAL.qxd 12/8/09 9:41 AM Page 16

Das könnte Ihnen auch gefallen

- Working Drawing Check ListDokument12 SeitenWorking Drawing Check Listfeelingbloppy83% (6)

- Pressure Vessel Design Calculations - by Abdel Halim Galala PDFDokument127 SeitenPressure Vessel Design Calculations - by Abdel Halim Galala PDFsizmaru100% (1)

- The Game Mechanics d20 Modern Slave Drivers AdvDokument26 SeitenThe Game Mechanics d20 Modern Slave Drivers Advsandur7760% (1)

- AWS - Design Handbook For Calculating Fillet Weld Sizes 1997 PDFDokument27 SeitenAWS - Design Handbook For Calculating Fillet Weld Sizes 1997 PDFMustafaSaylav100% (1)

- FVC Catalog - UnlockedDokument80 SeitenFVC Catalog - UnlockedhumbubbleNoch keine Bewertungen

- Grand Prix Engg.: Tag No. 90-EH-02Dokument6 SeitenGrand Prix Engg.: Tag No. 90-EH-02Abhay UpadhyayNoch keine Bewertungen

- Plate RectangularDokument8 SeitenPlate RectangularRUBEN BARTOLOME GARCIANoch keine Bewertungen

- Fallas en CojinetesDokument2 SeitenFallas en CojinetesAlfredo OrellanaNoch keine Bewertungen

- Fallas en CojinetesDokument2 SeitenFallas en CojinetesAlfredo OrellanaNoch keine Bewertungen

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDokument4 SeitenUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNoch keine Bewertungen

- Sample FLG CalcDokument6 SeitenSample FLG CalcameyyammaiNoch keine Bewertungen

- CSWIP 3.2 Course Material 2016Dokument418 SeitenCSWIP 3.2 Course Material 2016skychurch97% (29)

- Xcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseDokument2 SeitenXcalcs: Circular Flat Flanges Without Hubs: 2.7:+looseayushNoch keine Bewertungen

- Weld Neck Flange Design - As Per Denis MorisDokument2 SeitenWeld Neck Flange Design - As Per Denis Morissouren1975Noch keine Bewertungen

- ContentDokument23 SeitenContentajay katrojNoch keine Bewertungen

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDokument17 Seiten181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542Noch keine Bewertungen

- Astm E140Dokument25 SeitenAstm E140Qonni FanskasNoch keine Bewertungen

- Boilers and Condensers YuanDokument77 SeitenBoilers and Condensers YuanDaniel SetyadiNoch keine Bewertungen

- Experimental Analysis of Heat Transfer Enhancement in Shell and Helical Tube Heat ExchangersDokument9 SeitenExperimental Analysis of Heat Transfer Enhancement in Shell and Helical Tube Heat ExchangersKartikAgrawalNoch keine Bewertungen

- Quick Open ClosureDokument12 SeitenQuick Open ClosurecliffrajjoelNoch keine Bewertungen

- YaleDokument211 SeitenYaleAnonymous aGwpVFNoch keine Bewertungen

- Main parts and nozzles used in equipment manufacturingDokument17 SeitenMain parts and nozzles used in equipment manufacturingDeepikaNoch keine Bewertungen

- Main Pivot Pin Diameter CalculationDokument2 SeitenMain Pivot Pin Diameter Calculationjdutia83100% (1)

- Fire Safety Checklist On Building Plans FinalDokument2 SeitenFire Safety Checklist On Building Plans FinalRozel Laigo Reyes100% (4)

- Pest and Vermin Control Procedures SummaryDokument30 SeitenPest and Vermin Control Procedures SummaryOm KarnNoch keine Bewertungen

- Narrow Face Flange - Slip On Hub TypeDokument17 SeitenNarrow Face Flange - Slip On Hub TypeEng-CalculationsNoch keine Bewertungen

- X Steam Tables (English Units)Dokument8 SeitenX Steam Tables (English Units)Troy ThennisNoch keine Bewertungen

- LF 1Dokument1 SeiteLF 1opulitheNoch keine Bewertungen

- Heat Transfer Correlations for Internal FlowsDokument18 SeitenHeat Transfer Correlations for Internal FlowsarssNoch keine Bewertungen

- Output Summary: SI UnitsDokument42 SeitenOutput Summary: SI UnitsAkhil JoseNoch keine Bewertungen

- SSPC TU3 Overcoating Existing Coating Systems Applied To Steel Substrates PDFDokument11 SeitenSSPC TU3 Overcoating Existing Coating Systems Applied To Steel Substrates PDFAlfredo OrellanaNoch keine Bewertungen

- Section 7Dokument64 SeitenSection 7WlopezaNoch keine Bewertungen

- Cause and Effect Table PDFDokument3 SeitenCause and Effect Table PDFKamal DeshapriyaNoch keine Bewertungen

- Flat HeadsDokument11 SeitenFlat HeadsToniNoch keine Bewertungen

- Internal Pipe Distributor Design ProcedureDokument5 SeitenInternal Pipe Distributor Design Proceduresenthil kumarNoch keine Bewertungen

- Steam HXDokument1 SeiteSteam HXrajachemNoch keine Bewertungen

- Manhole. API 650-2021Dokument3 SeitenManhole. API 650-2021jose luisNoch keine Bewertungen

- Pipe Thickness & RF Pad Calculations As Per Asme b313Dokument3 SeitenPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNoch keine Bewertungen

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDokument20 SeitenExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsLeonardo Ramirez GuzmanNoch keine Bewertungen

- Stair Case PressurisationDokument5 SeitenStair Case Pressurisationsardarmkhan100% (1)

- Buffer Vessel Data SheetDokument4 SeitenBuffer Vessel Data SheetUmair A. KhanNoch keine Bewertungen

- Burner specification document summaryDokument6 SeitenBurner specification document summaryHafiz Muhammad AbubakarNoch keine Bewertungen

- ETHANOL (6.0D X 8.825 H), Rev. 0Dokument26 SeitenETHANOL (6.0D X 8.825 H), Rev. 0Sangramkeshari BejaNoch keine Bewertungen

- UHX STudyDokument12 SeitenUHX STudyAKSHAY BHATKARNoch keine Bewertungen

- Aircraft Hangar Superstructure Selection - Identifying Selection CriteriaDokument2 SeitenAircraft Hangar Superstructure Selection - Identifying Selection Criteriacbler100% (1)

- Pressure Vessel Calculation ReportDokument82 SeitenPressure Vessel Calculation ReporteeghbaliNoch keine Bewertungen

- Ellipsoidal Flange to Circular Conversion DimensionsDokument3 SeitenEllipsoidal Flange to Circular Conversion Dimensionsnaveenkumar_madasettNoch keine Bewertungen

- Tailing LugDokument2 SeitenTailing Lugjagannadha varmaNoch keine Bewertungen

- Painting DFT Rules-SSPC-PA-2Dokument16 SeitenPainting DFT Rules-SSPC-PA-2Michael AlbuquerqueNoch keine Bewertungen

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsDokument9 SeitenPressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie MartinezNoch keine Bewertungen

- Ligament Efficiency and Thickness of The Support PlateDokument10 SeitenLigament Efficiency and Thickness of The Support PlatePankajDhobleNoch keine Bewertungen

- Standard Hook-Up Wires & Cables For ElectronicsDokument124 SeitenStandard Hook-Up Wires & Cables For ElectronicsdlstoneNoch keine Bewertungen

- Analysis of a rectangular pressure vesselDokument7 SeitenAnalysis of a rectangular pressure vesselPressure VesselNoch keine Bewertungen

- 01-Datos y Planos de Motor PDFDokument13 Seiten01-Datos y Planos de Motor PDFAlfredo Orellana100% (1)

- Design of Weir Plate: X Q X B 2 / T 2Dokument3 SeitenDesign of Weir Plate: X Q X B 2 / T 2Husin SaputraNoch keine Bewertungen

- Eqn Reference ASME BPVC r1sDokument5 SeitenEqn Reference ASME BPVC r1sagarcia654127Noch keine Bewertungen

- KIRK KWM Mist EliminatorsDokument3 SeitenKIRK KWM Mist EliminatorsperrychemNoch keine Bewertungen

- Coupling UW16.2 KL Ver 1.1Dokument4 SeitenCoupling UW16.2 KL Ver 1.1gopaltryNoch keine Bewertungen

- Sample Vessel Design (Sec - VIII Div.1)Dokument34 SeitenSample Vessel Design (Sec - VIII Div.1)Chano HanokNoch keine Bewertungen

- PB TW10 GBDokument6 SeitenPB TW10 GBfebri_bontangNoch keine Bewertungen

- Pressure Vessel Cone Design ToolDokument1 SeitePressure Vessel Cone Design ToolPramod KumarNoch keine Bewertungen

- Elliptical Head Design ToolDokument1 SeiteElliptical Head Design ToolssierroNoch keine Bewertungen

- Design and Finite Element Assessment of Mounded Bullet PDFDokument14 SeitenDesign and Finite Element Assessment of Mounded Bullet PDFc0g100% (1)

- PDS Air CompressorDokument1 SeitePDS Air Compressordhavalesh1Noch keine Bewertungen

- Horizontal Bandlock2 Manual PDFDokument23 SeitenHorizontal Bandlock2 Manual PDFGigena100% (1)

- 300 - F&D Head Design Tool Ver E4.01Dokument1 Seite300 - F&D Head Design Tool Ver E4.01Mo ZeroNoch keine Bewertungen

- Design of JointsDokument41 SeitenDesign of JointsVivek LevinNoch keine Bewertungen

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDokument1 SeiteL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77Noch keine Bewertungen

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDokument127 SeitenPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresNoch keine Bewertungen

- Girth Flange Load Calculation Using by FEA TechniquesDokument12 SeitenGirth Flange Load Calculation Using by FEA TechniqueskingstonNoch keine Bewertungen

- PSV Reaction Force CalculationDokument2 SeitenPSV Reaction Force CalculationSuthanNoch keine Bewertungen

- Development of a Cone: Dimensions, Calculations & WeightDokument1 SeiteDevelopment of a Cone: Dimensions, Calculations & WeightnileshNoch keine Bewertungen

- Yale and Sentry Closures: Closures Catalog-FINAL - QXD 12/8/09 9:40 AM Page 1Dokument16 SeitenYale and Sentry Closures: Closures Catalog-FINAL - QXD 12/8/09 9:40 AM Page 1Daryl DelimanNoch keine Bewertungen

- kfp3 Ball ValvesDokument20 Seitenkfp3 Ball ValvesKristy DavisNoch keine Bewertungen

- CURC 01bDokument8 SeitenCURC 01bmontsegranNoch keine Bewertungen

- Certificate Pipe SCH40Dokument1 SeiteCertificate Pipe SCH40Alfredo Orellana0% (1)

- INSPECTION CERTIFICATE FOR MIG WIREDokument1 SeiteINSPECTION CERTIFICATE FOR MIG WIREAlfredo OrellanaNoch keine Bewertungen

- CERTIFICADODokument1 SeiteCERTIFICADOAlfredo OrellanaNoch keine Bewertungen

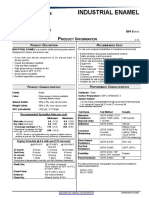

- DATA SHEET Industrial Enamel BlancoDokument4 SeitenDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNoch keine Bewertungen

- Catalogo Durma PDFDokument17 SeitenCatalogo Durma PDFAlfredo Orellana100% (1)

- Buttweld Fittings Accesorios SoldadosDokument5 SeitenButtweld Fittings Accesorios SoldadosJuan CadenaNoch keine Bewertungen

- 1010 PDFDokument1 Seite1010 PDFJonkadri HamzaNoch keine Bewertungen

- Pig Valve Orientation Diagram PDFDokument1 SeitePig Valve Orientation Diagram PDFAlfredo OrellanaNoch keine Bewertungen

- Ambato Psv-13 High Performance Series Rev1-40cDokument8 SeitenAmbato Psv-13 High Performance Series Rev1-40cAlfredo OrellanaNoch keine Bewertungen

- EA C MEC 001 Model PDFDokument1 SeiteEA C MEC 001 Model PDFAlfredo OrellanaNoch keine Bewertungen

- Manifold RiobambaDokument1 SeiteManifold RiobambaAlfredo OrellanaNoch keine Bewertungen

- Pig Valve Orientation Diagram PDFDokument1 SeitePig Valve Orientation Diagram PDFAlfredo OrellanaNoch keine Bewertungen

- ABS. 39600-44600 - H12.TRC - OTDR Report 1550 NM: Job InfoDokument2 SeitenABS. 39600-44600 - H12.TRC - OTDR Report 1550 NM: Job InfoAlfredo OrellanaNoch keine Bewertungen

- 03-Manual de MotorDokument28 Seiten03-Manual de MotorAlfredo OrellanaNoch keine Bewertungen

- 11058-09-0905!01!001 - Pressure Drop Calculation-Ambato SkidDokument10 Seiten11058-09-0905!01!001 - Pressure Drop Calculation-Ambato SkidAlfredo OrellanaNoch keine Bewertungen

- Termatech TT stove product guideDokument10 SeitenTermatech TT stove product guideJoe RowingNoch keine Bewertungen

- Regular safety inspections ensure safe operationDokument32 SeitenRegular safety inspections ensure safe operationRasheed AhmadNoch keine Bewertungen

- Construction Drawing EssentialsDokument27 SeitenConstruction Drawing EssentialsKyle LicopNoch keine Bewertungen

- 10 IWT Parts Model Specific PDFDokument63 Seiten10 IWT Parts Model Specific PDFJurgita SkruibieneNoch keine Bewertungen

- Baridhara Offer Letter - Option 1.Dokument6 SeitenBaridhara Offer Letter - Option 1.AB Rakib AhmedNoch keine Bewertungen

- FMVSS 220Dokument40 SeitenFMVSS 220Marlon MontenegroNoch keine Bewertungen

- Diamond NewDokument36 SeitenDiamond NewFocus WindowsNoch keine Bewertungen

- Damp-proofing methods to prevent moisture damageDokument68 SeitenDamp-proofing methods to prevent moisture damageMARUFNoch keine Bewertungen

- Mastering Chief Architect X5 atDokument28 SeitenMastering Chief Architect X5 atob37Noch keine Bewertungen

- Automazioni EngDokument68 SeitenAutomazioni EngMohammed AbdulnaserNoch keine Bewertungen

- BLD 212 Lecture 3BDokument8 SeitenBLD 212 Lecture 3BUmar Bello NuhuNoch keine Bewertungen

- ECO Bus 2.0 Automatic Folding DoorDokument22 SeitenECO Bus 2.0 Automatic Folding Doorsamuel_ventura4Noch keine Bewertungen

- PorterCable CatalogDokument56 SeitenPorterCable CatalogAlejandro Antonio Alvarez BalveroNoch keine Bewertungen

- Hardwarematerials PricelistDokument215 SeitenHardwarematerials PricelistRaychel MalonNoch keine Bewertungen

- Kenmore Microwave Repair Manual Model 721.66339Dokument39 SeitenKenmore Microwave Repair Manual Model 721.66339jkwandmanNoch keine Bewertungen

- 1.15.1 FINAL - Legrand SJ Brochure 8-210421Dokument30 Seiten1.15.1 FINAL - Legrand SJ Brochure 8-210421ShaifulBellamyNoch keine Bewertungen

- TECHNICAL SPECIFICATIONS HF 455-575-730-900: Professional Laundry EquipmentDokument6 SeitenTECHNICAL SPECIFICATIONS HF 455-575-730-900: Professional Laundry EquipmentNguyễn Đức BìnhNoch keine Bewertungen

- Clean Room DetailDokument40 SeitenClean Room DetailAjay SastryNoch keine Bewertungen

- Factory Hardware Production LinesDokument49 SeitenFactory Hardware Production LinesriskiriskNoch keine Bewertungen

- DCVG PDFDokument215 SeitenDCVG PDFSultana KhanumNoch keine Bewertungen

- Dishwasher Installation Instructions: Import Ant!Dokument14 SeitenDishwasher Installation Instructions: Import Ant!Dmitriy SemakovNoch keine Bewertungen

- Power Products Power Solution For Your Better TomorrowDokument24 SeitenPower Products Power Solution For Your Better TomorrowRath AsypadenNoch keine Bewertungen