Beruflich Dokumente

Kultur Dokumente

International Journal of Adhesion & Adhesives: H. Lei, G. Du, Z. Wu, X. Xi, Z. Dong

Hochgeladen von

Irmaa YunitasariOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

International Journal of Adhesion & Adhesives: H. Lei, G. Du, Z. Wu, X. Xi, Z. Dong

Hochgeladen von

Irmaa YunitasariCopyright:

Verfügbare Formate

Cross-linked soy-based wood adhesives for plywood

H. Lei

n

, G. Du, Z. Wu, X. Xi, Z. Dong

Materials and Engineering College, Southwest Forestry University, Kunming 650224, Yunnan, PR China

a r t i c l e i n f o

Article history:

Accepted 22 January 2014

Available online 6 February 2014

Keywords:

Soy adhesive

Cross-linker

Water resistance

Plywood

a b s t r a c t

To improve the water resistance of soy-based adhesive for wood panels, three kinds of cross-linkers,

namely, epoxy resin (EPR), melamineformaldehyde (MF) and their mixture EPRMF were used in this

paper. The results indicated that all the three cross-linkers improved the water resistance of soy-based

adhesive and the hybrid cross-linker EPRMF, was the best. With press temperature 160 1C and press

time 8 min, type II and even type I plywood could be prepared when 6.4%EPR6.4%MF is used as cross-

linker of soy-based adhesive. FT-IR indicated that the great improvement of water resistance of soy-based

adhesive modied with EPR and MF might be caused by the reaction between epoxy and OH, and that

between MF and NH.

& 2014 Elsevier Ltd. All rights reserved.

1. Introduction

Formaldehyde-based adhesives, such as ureaformaldehyde (UF),

melamineformaldehyde (MF), phenolformaldehyde (PF), are widely

used for the preparation of wood panels. But formaldehyde emission

caused by these resin adhesives has confused wood industry and has

been a topic of concern for many years. Some standards or require-

ments were given to dene the acceptable formaldehyde emission

levels. The newest requirement on formaldehyde emission comes

from California Air Resources Board (CARB) formaldehyde emissions

regulation of U.S. It was passed in 2008 and got effective in 2009.

Today, the mounting interest in formaldehyde emission is still driving

major changes in wood panel industry as well as the resin industry

that supplies the wood panel industry. In response to the need on

environment-friendly adhesives, great attention has been given to

adhesives from natural materials, such as starch [1,2], soy-based

adhesives [35], and so on, although most of these adhesives have

almost been pushed out of market in wood panel industry during the

past 30 years.

Soy-based adhesive was once a major adhesive for preparation of

plywood. But it has been replaced by synthetic resins since the 1960s.

Till the 1990s, it returned to the study area as a wood adhesive. It is

reported that one of the soy-based formaldehyde-free adhesives has

been used for production of interior plywood panels since 2004 [6].

However, the application of soy-based adhesives is rather limited.

Now, most of the efforts on soy-based adhesive are given to the

improvement of its bad water resistance. To resolve this problem,

some methods could be employed to modify the soy adhesive, such

as hydrolysis, chemical denaturation, cross-linking, enzyme modi-

cation, and so on.

Cross-linking modication is a comparatively acceptable

method for the modication of soy-based adhesive. Cross-linkers

can be either mixed with soy adhesive directly before its applica-

tion or added during the preparation of soy adhesive. For the latter

method, acrylates [7,8], maleic anhydride [9], etc. are used and in

most cases graft polymerization will occur. Commonly, some

complex preparation procedures are involved in this method.

Therefore, it is much easier in handling to mix cross-linkers

directly with soy adhesive. An effective cross-linker is the key for

this method. Since there are many reactive groups in soy proteins,

such as OH, SH, COOH, and NH

2

, many chemicals could be

used for the cross-linking of soy adhesive. Epoxy [6], aldehyde and

its deratives [10] have already been proved effective cross-linkers

for soy-based adhesive. With different cross-linkers, the mechan-

ism for the improvement of performance of soy adhesive is

different. Epoxy groups are thought to react with all of the

aforementioned functional groups in soy proteins [11]. Huang J

et al. proposed the possible curing mechanisms of the

soypolyepoxide adhesives [12]. For cross-linker aldehyde and

its derivatives, such as ureaformaldehyde, hydroxymethyl phe-

nol, the main reaction group, comes from NH

2

in soy protein.

Besides choosing a suitable cross-linker, its addition amount is

very important for the application of soy adhesive. Because of the

usage of some expensive cross-linkers, such as epoxy, the cost of

soy-based adhesive is greatly dependent on the addition amount

of cross-linker. Wood composites bonded with soy protein isolate

and Kymene are reported to show shear strengths comparable to

or higher than those of composites bonded with phenolformal-

dehyde [13]. As a wet-strength agent for paper, Kymene is an

aqueous solution of cationic polyamidoamineepichlorohydrin

Contents lists available at ScienceDirect

journal homepage: www.elsevier.com/locate/ijadhadh

International Journal of Adhesion & Adhesives

http://dx.doi.org/10.1016/j.ijadhadh.2014.01.026

0143-7496 & 2014 Elsevier Ltd. All rights reserved.

n

Corresponding author.

E-mail address: honeyray2006@hotmail.com (H. Lei).

International Journal of Adhesion & Adhesives 50 (2014) 199203

(PAE). However, because of the high dry weight ratio SPI/Kymene

1.33:1, cross-linker Kymene is the most expensive component of the

soy-based adhesive. A new curing agent was developed by the same

research group from epichlorohydrin and ammonium hydroxide to

decrease the cost of soy-based adhesive. But there was still about 14%

on dry soy our weight of this curing agent needed for the

preparation of soy-based adhesive and interior plywood [6]. When

melamineureaformaldehyde (MUF) resin is added to soy-adhesive

as a cross-linker, the addition amount of solid MUF is about 40% on

solid soy our or even higher [14,15]. For phenolformaldehyde, the

weight ratio of phenolformaldehyde to soy adhesive was 30:70 in

public reports [16]. In this formulation phenolformaldehyde had a

solid content of 55% and soy solution of 42%.

In this paper, the effects of different cross-linkers on the water

resistance of soy-based adhesive were studied. In order to transfer

all of the possible hydrophilic groups of soy protein to hydro-

phobic ones, a hybrid cross-linker was used for the modication of

soy-based adhesive. The objectives of this work were as follows:

(1) to optimize the proportion of components of hybrid cross-

linker; (2) to decrease the addition amount of cross-linker; and

(3) to prepare plywood with good water resistance.

2. Materials and methods

2.1. Materials

Defatted soy our (53.4% protein content) was obtained from

Yuxin Soybean Protein Co., Ltd, China. Poplar veneer with a

thickness of 1.5 mm and moisture content of 810% was purchased

for the preparation of plywood. Epoxy resin (EPR) was a commer-

cial product with the name of E-44, whose epoxide number was

0.410.47 and softening point was 1220 1C. All other chemicals

mentioned in this work were all of reagent grade.

2.2. Preparation of soy-based adhesive

Soy-based adhesive was prepared according to a method already

reported [17]. A three-neck round-bottom ask equipped with a

mechanical stirrer, a thermometer and a condenser was charged with

water (187 g), sodium dodecyl benzene sulfonate (0.8 g), CaO( 1.9 g)

and NaOH (3.7 g) to 70 1C. Soy our (80 g) was then charged to the

rapidly stirring solution. The mixture was heated to 90 1C over

15 min, with rapid agitation, and held between 88 1C and 92 1C for

3 h. The mixture was cooled to 35 1C in an ice bath. The solid content

of the resulting soy-based adhesive was 3071%.

2.3. Preparation of melamineformaldehyde (MF) resin

Formaldehyde 37% (150 g), melamine (80 g) and water (107 g)

were charged into a three-neck ask equipped with a mechanical

stirrer, thermometer and condenser and then the pH was adjusted

to 9.0 with NaOH 30%. The mixture was heated to 85 1C during

2030 min, and held the temperature for another 30 min. The

mixture was cooled to room temperature and kept at pH 9.0 and

room temperature.

2.4. Preparation of plywood samples bonded with soy-based

adhesive

The soy-based adhesive was mixed well with different cross-

linkers just before the preparation of three-layer plywood of

dimensions 300 mm220 mm4 mm. The double sides glue

loading was 360 g/m

2

. Before sending into the press, the veneers

with adhesives were allowed to rest at room temperature for

15 min and were then assembled. The plywood was pressed under

pressure of 2 MPa at 160 1C for 8 min. Other press times and press

temperatures were also used in this paper.

2.5. Test of dry and wet shear strength of plywood samples

After conditioning in the laboratory for 1 day, the plywood panel

was then cut into shear specimens with dimension of 100 mm

25 mm to determine its shear strength and water resistance. Each

specimen has a bonded area of 25 mm25 mm. Both dry and wet

shear strength of plywood specimens were tested on a WDS-50KN

mechanical testing machine. For wet shear strength, the specimens

were soaked in (6373) 1C water or in boiling water for determined

time. The mean result of 810 specimens was considered as the nal

shear strength. The testing method was referred to Chinese national

standard GB/T 9846.3-2004. In this standard, for type II plywood, the

specimens were soaked in (6373)1C water for 3 h. For type I plywood,

the specimens should pass waterdrywater cycle. That is to say, the

specimens were rstly soaked in boiling water for 4 h, then dried in

(6373) 1C for 20 h, and lastly re-applied in boiling water for another

4 h. For both type II and type I plywood, before the measuring by the

testing machine, the specimens were taken out of water and left at

room temperature for 10 min.

2.6. FT-IR analysis

The oven was preheated to 160 1C. Liquid soy adhesives with or

without cross-linkers were put in the oven to a constant weight.

The cured soy adhesives were ground into ne powder. 1 g KBr

and 0.001 g soy adhesive samples were mixed well for the

preparation of KBr pills. The FT-IR spectra were obtained on a

Varian 1000 infrared spectrophotometer.

3. Results and discussion

3.1. Effect of cross-linker on performance of soy adhesive-based

plywood

Table 1 shows the performance of plywood specimens with soy

based-adhesive with or without different amounts of cross-linkers.

The cross-linkers used in this work included EPR, MF and their

mixture. The dry shear strength for all of the soy-based plywood

specimens was good enough to satisfy the requirement of relative

Chinese national standard (GB/T 9846.3-2004, Z0.70 MPa). But

considering that wood failure for almost all of the specimens is

100%, which meant the measured dry strengths were mainly

determined by the strength of wood, it was difcult to see the effects

of cross-linker on the dry shear strength of plywood. However, the

water resistance of plywood specimens showed big differences with

or without cross-linkers. Soy adhesive without cross-linking had no

water resistance at all, which was indicated by the 100% delamination

of specimens when soaked in 63 1C water for 3 h. All of the three

cross-linkers in this work improved the water resistance of soy-based

adhesive more or less. When cross-linked with different amounts of

EPR, although the wet strength of plywood at 60 1C for 3 h could be

measured, it was not enough to meet the requirement of relative

standard. More than 50% of the specimens cross-linked by EPR failed

the soak test in 63 1C water for 3 h and 100% of the specimens

delaminated when the test condition became more severe as in

boiling water cycles. With the increase of the addition amount of EPR,

the percentage of number of specimens that failed in the soak test to

the total number of specimens decreased from 50% to 20%, which

indicated the improvement of the water resistance of soy-based

adhesive, although their water resistance was not enough to meet the

relative standard. Epoxy was assumed to improve the water resis-

tance of soy adhesive because of the reaction between epoxy groups

H. Lei et al. / International Journal of Adhesion & Adhesives 50 (2014) 199203 200

with high reactivity at the opposite ends of resin molecule and

reactive groups in soy protein. In this work, just epoxy was used as

itself without excess solvent or even curing agent being added. It is

wellknown that a curing agent is necessary for the curing of epoxy.

The most commonly used curing agent for epoxy is amine. Here, soy

protein could be regarded as the curing agent of epoxy. Once there is

some curing reaction between epoxy and protein, the water resistance

and mechanical performances of the nal soy-based system would be

improved with the increase of its molecular weight. Although EPR

could react with a wide variety of functional groups in soy protein,

high addition amount of EPR could not be used as an ideal cross-linker

for three reasons. (1) EPR is not soluble in water. Simple mixing of soy

our and an epoxy resin in water cannot generate a homogeneous

mixture. High addition amount EPR tended to aggregate in the

presence of water and got a poor cross-linking with soy. This was

the reason why the soy adhesive could not resist the boiling water

cycle test. (2) EPR will increase the viscosity of soy-based adhesive a

lot with a high addition amount, which will greatly affect the

application of the adhesive. (3) EPR is too expensive. It was unac-

ceptable to the industry when addition amount of EPR was higher

than 10% of the solid soy. Once the addition amount of EPR was higher

than 10%, the cost of EPR would be almost 30% of the soy powder.

MF is a widely-used adhesive with good water resistance in wood

industry. Soy adhesive cross-linked with water-soluble MF shows

better water resistance than that with the same amount of EPR, as

seen from Table 1. All of the specimens with MF passed the soak test

at 63 1C for 3 h. No specimen delaminated and the wet strength for

all the specimens was higher than the standard requirement

0.70 MPa. This meant that interior type II plywood could be prepared

with soy adhesive cross-linked with as low as 6% of MF on solid soy

adhesive. But when the test conditions were changed to those of

boiling water cycle, although most of the specimens did not

delaminate, the wet shear strength decreased greatly. Even when

the addition amount of MF increased to 14% of solid soy, the wet

shear strength could not satisfy the relative standard. This meant that

only with MF, the hydrophilic groups in soy adhesive of this paper

could not be totally hidden or reacted with hydrophobic groups. For

wet shear strength in 63 1C water and in boiling water, the effects of

addition amount of MF on wet strength were not clear.

To make use of the high reactivity of EPR and the water

solubility of MF, a hybrid cross-linker EPRMF was used in this

work. As seen from Table 1, the hybrid cross-linker MFEPR

indeed showed the best water resistance. With 10% EPRMF, even

type I plywood could be prepared.

3.2. Effect of hybrid cross-linker EPRMF on the performance

of soy adhesive -based plywood

Hybrid cross-linker EPRMF was proved to be the best cross-

linker for soy-based adhesive as seen from Table 1. To optimize the

proportion of components of hybrid cross-linker and decrease the

addition amount of soy adhesive for plywood, in the hybrid cross-

linker, different amounts of EPR and MF were used for preparation

of plywood (Table 2). As in Table 1, when using hybrid EPRMF as

a cross-linker of soy adhesive, all of the dry shear strength of

plywood specimens cross-linked with different amounts of

EPRMF satised the requirements of the relative standard. In

the soak test, either in 63 1C water for 3 h or in boiling water cycle,

no specimen delaminated. It indicated that soy-based adhesive

cross-linked with EPRMF had good water resistance even with a

very low addition amount of cross-linker, that is, 3.2% EPR and

2.6% MF on solid soy adhesive. In laboratory condition, during the

preparation of plywood, lower addition amount of cross-linker

than 3.2% EPR or 2.6% MF was difcult to handle because of the

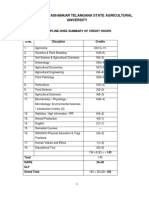

Table 1

Effect of different kinds of cross-linker on the performance of soy adhesive-based plywood.

Cross-linker Addition amount

of cross-linker (%)

Dry shear

strength(MPa)

63 1C 100 1C

Wet shear

strength (MPa)

Number of specimens failed

in the soak test/total specimens (%)

Wet shear

strength (MPa)

Number of specimens failed

in the soak test/total specimens (%)

Without cross-linker 0 1.02 100

EPR 6 0.85 0.41 50 100

8 0.80 0.38 50 100

10 0.86 0.39 30 100

12 0.77 0.48 20 100

14 0.85 0.46 20 100

MF 6 0.80 1.03 0 0.47 40

8 1.06 0.80 0 0.51 30

10 0.88 0.94 0 0.51 20

12 0.86 0.92 0 0.52 10

14 1.32 0.94 0 0.52 20

EPRMF 10(55)

n

1.05 0.91 0 0.85 100

n

The weight ratio of solid EPR to MF on the solid weight of soy adhesive was 1:1.

Table 2

Effect of addition amount of cross-linker EPRMF on the performance of soy adhesive-based plywood.

Cross-linker Dry shear

strength (MPa)

63 1C 100 1C

Wet shear

strength (MPa)

Number of specimens failed

in the soak test/total specimens (%)

Wet shear

strength (MPa)

Number of specimens failed

in the soak test/total specimens (%)

3.2%EPR2.6%MF 0.96 0.49 0 0.45 0

3.2%EPR3.9%MF 1.02 0.44 0 0.49 0

3.2%EPR5.1%MF 1.01 0.73 0 0.65 0

3.2%EPR6.4%MF 1.21 0.72 0 0.65 0

6.4%EPR6.4%MF 0.95 1.08 0 0.81 0

6.4%EPR7.7%MF 0.93 0.76 0 0.93 0

H. Lei et al. / International Journal of Adhesion & Adhesives 50 (2014) 199203 201

small amount. When the addition amount of EPR was xed to 3.2%

on solid soy adhesive, with the increase of the addition amount of

MF, the wet shear strength of plywood increased. However, at least

5.1% MF should be used together with 3.2% EPR to get the modied

soy-based adhesive for the preparation of type II plywood. For

type I plywood, the minimum addition amount of cross-linker of

soy based-adhesive was 6.4% MF with 6.4% EPR in Table 2.

Considering the results of Table 1, the total amount of hybrid

cross-linker MFEPR should be 1012.8% for preparation of type I

plywood. The increase of wet shear strength caused by the

increase of addition amount of EPR could also be seen in Table 2.

3.3. Effect of press procedure on the performance of soy-based

adhesive with hybrid cross-linker EPRMF

Soy adhesives with 6.4%EPR6.4%MF were used for the pre-

paration of plywood in the laboratory. Effects of press temperature

and press time on the performance of plywood with soy-based

adhesive are shown in Table 3. The results show that even with

press temperature 120 1C, type II plywood could be obtained. With

press temperature 140 1C, the water resistance of plywood was

good enough to meet the requirement of type I plywood and did

not show much difference with those when higher temperatures

160 1C and 180 1C were used.

26 min at 160 1C was too short to cure soy adhesive with

EPRMF, which indicated by the poor water resistance shown in

Table 3. With 46 min, the dry shear strength of plywood was

good. This meant that 46 min was enough for curing of soy

adhesive but not enough for its cross-linking. Hot-press time as

long as 8 min may be a problem for the commercialization of the

cross-linked soy adhesive.

3.4. FT-IR analysis of soy adhesive modied with cross-linkers

The FTIR spectra of cured soy-based adhesive, soy6.4% EPR,

soy6.4%MF and soy6.4% EPR6.4%MF are given in Fig. 1. For soy

adhesive without cross-linkers, the broad band observed in the range

of 35003000 cm

1

was assigned to the free and bound OH and N

H groups. The absorption bands of amide, the characteristic group of

protein, were observed at 1654, 1539, and 1238 cm

1

, which were

assigned to CQO stretching, NH bending, CN stretching and NH

bending vibration, respectively. The COO and CNH

2

absorptions

were seen at 1390 and 1058 cm

1

, respectively. The main difference

between spectra of soy adhesive with or without EPR came from the

absorptions at 1249 and 833 cm

1

, which were assigned to COC

stretching. There were three possibilities for the COC stretching:

(1) epoxy ether; (2) phenolOC; and (3) the resulting ether from the

reaction between epoxy and OH of soy protein [18]. The former two

groups came from EPR itself. The reaction between EPR and OH of

soy protein might be the main reason for the improvement of water

resistance of soy-based adhesives caused by epoxy. However, the

possible reaction between EPR and NH

2

, SH, COOH groups of soy

is not clearly observed in Fig. 1. In soy adhesive cross-linked with MF,

the absorption at 1238 cm

1

got weaker than that in pure soy

adhesive, which might be a result of the reaction between methylol

group of MF resin and NH groups of soy adhesive [11]. The increase

of the absorption at 1539 cm

1

was caused by CQN ring vibration

of melamine. Bending vibration of triazine ring was found at

829 cm

1

.The spectra of soy cross-linked with EPR and MF were

almost the multiplicity of soy adhesive cross-linked by EPR or MF

alone. Although a thorough mechanism on the soy-based mixing

system is still needed, the fact that epoxy and MF could react with

different groups in soy protein might be the main reason for the good

water resistance of soy-based adhesive with hybrid cross-linker. On

one hand, the mixing of epoxy and MF transferred the hydrophilic

groups of soy protein to hydrophobic ones as much as possible.

On the other hand, the epoxy was used as less as possible to avoid

aggregation and the large increase of viscosity.

4. Conclusions

To develop a soy-based adhesive with good water resistance

and acceptable cost, it was modied with cross-linkers, namely,

EPR, MF and their mixture EPRMF in this paper. All the three

Table 3

Effect of press procedure on the performance of soy adhesive-based plywood.

Press variable Dry shear

strength (MPa)

63 1C 100 1C

Wet shear

strength (MPa)

Number of specimens failed

in the soak test/total specimens (%)

Wet shear

strength (MPa)

Number of specimens failed

in the soak test/total specimens (%)

Press temperature (1C)

120 1.12 0.84 0 0.61 0

140 0.94 1.03 0 0.83 0

160 0.95 1.08 0 0.81 0

180 0.85 1.12 0 0.76 0

Press time (min)

2 0.45 100 100

4 0.83 100 100

6 0.89 100 100

8 0.95 1.08 0 0.81 0

4000 3500 3000 2500 2000 1500 1000 500

Wave numbers/cm

-1

Fig. 1. FT-IR of the soy adhesive with or without cross-linker: (a) soy adhesive;

(b) soy6.4%EPR; (c) soy6.4%MF; and (d) soy6.4%EPR6.4%MF.

H. Lei et al. / International Journal of Adhesion & Adhesives 50 (2014) 199203 202

cross-linkers improved the water resistance of soy-based adhesive

more or less. The soy-based adhesive cross-linked with hybrid

cross-linker EPRMF showed the best water resistance. With

press temperature 160 1C and press time 8 min, type II and even

type I plywood could be prepared when 6.4%EPR6.4%MF was

used as the cross-linker of soy-based adhesive. FT-IR indicated that

the great improvement of water resistance of soy-based adhesive

modied with EPR and MF might be caused by the reaction

between epoxy and OH, and that between MF and NH.

Acknowledgments

This research was supported by the National Natural Science

Foundation of China (31170530) and New Century Excellent

Talents of Ministry of Education of China (NCET-10-0972).

References

[1] Wang Z, Li Z, Gu Z, Hong Y, Cheng L. Preparation, characterization and

properties of starch-based wood adhesive. Carbohyd Polym 2012;88

(2):699706.

[2] Tondi G, Wieland S, Wimmer T, Schnabel T, Petutschnigg A. Starchsugar

synergy in wood adhesion science: basic studies and particle board produc-

tion. Eur J Wood Wood Prod 2012;70(13):2718.

[3] Lin Q, Chen N, Bian L, Fan M. Development and mechanism characterization of

high performance soy-based bio-adhesives. Int J Adhes Adhes 2012;34:116.

[4] Nordqvist P, Khabbaz F, Malmstrom E. Comparing bond strength and water

resistance of alkali-modied soy protein isolate and wheat gluten adhesives.

Int J Adhes Adhes 2010;30:729.

[5] Huang J, Li K. A new soy our-based adhesive for making interior type II

plywood. J Am Oil Chem Soc 2008;85:6370.

[6] Jang Y, Huang J, Li K. A new formaldehyde-free wood adhesive from renewable

materials. Int J Adhes Adhes 2011;31:7549.

[7] Gao Q, Shi S, Li J, Liang K. Soybean meal-based wood adhesives enhanced by

modied polyacrylic acid solution. Bioresources 2012;7(1):94656.

[8] Steinmetz L, Krinski T. Modied protein adhesive binder and process for

producing. US patent 4687826. 1987.

[9] Liu Y, Li K. Development and characterization of adhesives from soy protein

for bonding wood. Int J Adhes Adhes 2007;27:5967.

[10] Lambuth AL. Protein adhesives for wood. In: Pizzi A, Mittal KL, editors.

Advanced wood adhesive technology. New York: Marcdel Dekker Inc.;

199425981.

[11] May CA. Epoxy resinschemistry and technology. New York: Marcel Dekker;

1988.

[12] Huang J, Li C, Li K. A new soy ourpolyepoxide adhesive system for making

interior plywood. Holzforschung 2012;66:42731.

[13] Li K, Peshkova S, Geng X. Investigation of soy proteinKymene adhesive

systems for wood composites. J Am Oil Chem Soc 2004;81(5):48791.

[14] Fan D, Qin T, Chu F. A soy our-based adhesive reinforced by low addition of

MUF resin. J Adhes Sci Technol 2011;25(13):32333.

[15] Gao Q, Shi SQ, Zhang S, Li J, Wang X, Ding W, et al. Soybean meal-based

adhesive Enhanced by MUF resin. J Appl Polym Sci 2012;125:367681.

[16] Yang I, Kuo M, Myers D. Bond quality of soy-based phenolic adhesives in

southern pine plywood. J Am Oil Chem Soc 2006;83(3):2317.

[17] Wu Z, Lei H, Du G. Disruption of soy-based adhesive treated by Ca(OH)

2

and

NaOH. J Adhes Sci Technol 2013;3:17.

[18] Rogers J, Geng X, Li K. Soy-based adhesives with 1,3-dichloro-2-propanol as a

curing agent. Wood Fiber Sci 2004;36(2):18694.

H. Lei et al. / International Journal of Adhesion & Adhesives 50 (2014) 199203 203

Das könnte Ihnen auch gefallen

- Jurnal Teguh 3Dokument14 SeitenJurnal Teguh 3Teguh Hidayat PanjaitanNoch keine Bewertungen

- Research Article: Synthesis and Thermal Degradation Studies of Melamine Formaldehyde ResinsDokument7 SeitenResearch Article: Synthesis and Thermal Degradation Studies of Melamine Formaldehyde Resinstahera aqeelNoch keine Bewertungen

- Jurnal Urea Formaldehyde 1Dokument9 SeitenJurnal Urea Formaldehyde 1Afriyanti RosmadianaNoch keine Bewertungen

- 1 s2.0 S0141813023040321 MainDokument10 Seiten1 s2.0 S0141813023040321 Mainsaeed.uopNoch keine Bewertungen

- The Effect ofDokument13 SeitenThe Effect ofvyNoch keine Bewertungen

- Synthesis and Characterization of A Bio-Aldehyde-based Lignin Adhesive With Desirable Water ResistanceDokument12 SeitenSynthesis and Characterization of A Bio-Aldehyde-based Lignin Adhesive With Desirable Water Resistancesaeed.uopNoch keine Bewertungen

- Enhancing The Performance of Starch-Based Wood Adhesive by Silane Coupling Agent (KH570)Dokument8 SeitenEnhancing The Performance of Starch-Based Wood Adhesive by Silane Coupling Agent (KH570)Son NguyenNoch keine Bewertungen

- Epoxy ResinDokument17 SeitenEpoxy Resinamin peyvandNoch keine Bewertungen

- Biobased Epoxy Resin From Canola OilDokument9 SeitenBiobased Epoxy Resin From Canola Oilmartina.cirronis96Noch keine Bewertungen

- Development and Application of Green Composites: Using Coffee Ground and Bamboo FlourDokument8 SeitenDevelopment and Application of Green Composites: Using Coffee Ground and Bamboo FlourTeresa MataNoch keine Bewertungen

- Adhesion Properties of Eco Friendly PVAc Emulsion Adhesive Using Nonphthalate PlasticizerDokument16 SeitenAdhesion Properties of Eco Friendly PVAc Emulsion Adhesive Using Nonphthalate PlasticizerThịnh HuỳnhNoch keine Bewertungen

- Effects of Stearic Acid Coating On Zeolite in PE CompositesDokument12 SeitenEffects of Stearic Acid Coating On Zeolite in PE CompositesendexceoNoch keine Bewertungen

- 1 s2.0 S0141813023031501 MainDokument11 Seiten1 s2.0 S0141813023031501 Mainsaeed.uopNoch keine Bewertungen

- Effects of Parameter Changes On The Structure and Properties of Low-Density Polyethylene FoamDokument9 SeitenEffects of Parameter Changes On The Structure and Properties of Low-Density Polyethylene FoamZunaida ZakariaNoch keine Bewertungen

- Polymers: Natural Tannins As New Cross-Linking Materials For Soy-Based AdhesivesDokument15 SeitenPolymers: Natural Tannins As New Cross-Linking Materials For Soy-Based AdhesivesnameNoch keine Bewertungen

- Potential of Carbohydrates For Exterior-Type Adhesives: A.W. Christiansen R.H. GillespieDokument9 SeitenPotential of Carbohydrates For Exterior-Type Adhesives: A.W. Christiansen R.H. GillespieDébora NobregaNoch keine Bewertungen

- Organic Acrylate Binder Synthesis ThrougDokument7 SeitenOrganic Acrylate Binder Synthesis ThrougAmr Abdelmegid abdelsalam husseinNoch keine Bewertungen

- New Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricDokument24 SeitenNew Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricSSNoch keine Bewertungen

- Syntheis of Aqueous Polymer Iso Cyan Ate For Plywood AdhesiveDokument9 SeitenSyntheis of Aqueous Polymer Iso Cyan Ate For Plywood AdhesiveeuishermiatiNoch keine Bewertungen

- The Effect of Carboxymethyl Cellulose Addition OnDokument14 SeitenThe Effect of Carboxymethyl Cellulose Addition OnvyNoch keine Bewertungen

- Composites From Rice Straw and High Density Polyethylene - Thermal and Mechanical PropertiesDokument8 SeitenComposites From Rice Straw and High Density Polyethylene - Thermal and Mechanical PropertiesTI Journals PublishingNoch keine Bewertungen

- Marlen Valverde MME 2011Dokument11 SeitenMarlen Valverde MME 2011Satyam BhuyanNoch keine Bewertungen

- Biodegradability of Cassava StarchHigh Density PolDokument9 SeitenBiodegradability of Cassava StarchHigh Density PolemeliaNoch keine Bewertungen

- Đánh giá hiệu suất kết dính của hỗn hợp protein đậu nành, lúa miến và hạt cảiDokument9 SeitenĐánh giá hiệu suất kết dính của hỗn hợp protein đậu nành, lúa miến và hạt cảiLuan Tran ThanhNoch keine Bewertungen

- 6moyDokument11 Seiten6moyiaydn1810Noch keine Bewertungen

- Pineapple Peel Fiber Biocomposite CharacDokument6 SeitenPineapple Peel Fiber Biocomposite CharacpazziuaganmarkNoch keine Bewertungen

- Multi Component IsothermsDokument9 SeitenMulti Component IsothermsTDSNoch keine Bewertungen

- Mechanical and Thermal Properties of Epoxy Tamarind Shell Composite - PUBLISHEDDokument7 SeitenMechanical and Thermal Properties of Epoxy Tamarind Shell Composite - PUBLISHEDku1zarinaNoch keine Bewertungen

- Processing and Characterization of Thermoplastic Starch/Polypropylene BlendsDokument7 SeitenProcessing and Characterization of Thermoplastic Starch/Polypropylene BlendsInternational Journal of Scientific Research in Science, Engineering and Technology ( IJSRSET )Noch keine Bewertungen

- CHEMIMECHANICAL PULPING OF COTTON STALKS SoakingDokument19 SeitenCHEMIMECHANICAL PULPING OF COTTON STALKS SoakingBlue BlazeNoch keine Bewertungen

- Mechanical and Thermal Properties of Hybrid Blends of LLDPEStarchPVA, 2013Dokument5 SeitenMechanical and Thermal Properties of Hybrid Blends of LLDPEStarchPVA, 2013Akidah YusakNoch keine Bewertungen

- Properties of Rice Husk/Epoxy Composites Under Different Interfacial TreatmentsDokument9 SeitenProperties of Rice Husk/Epoxy Composites Under Different Interfacial TreatmentsSyed Ahmad Ali ShahNoch keine Bewertungen

- Highly Flexible Glycol-Urea-Formaldehyde ResinsDokument10 SeitenHighly Flexible Glycol-Urea-Formaldehyde ResinsRatu TiaraNoch keine Bewertungen

- Ecotoxicology and Environmental Safety: R. Sathish Kumar, G. Arthanareeswaran, Diby Paul, Ji Hyang KweonDokument6 SeitenEcotoxicology and Environmental Safety: R. Sathish Kumar, G. Arthanareeswaran, Diby Paul, Ji Hyang KweonLintang Noor FitriaNoch keine Bewertungen

- Chalk Resistant Epoxy ResinDokument9 SeitenChalk Resistant Epoxy Resinuocmogiandi_aNoch keine Bewertungen

- Preparation of Dimer Acid Based Polyamide Film by Solution Casting Method and Its Properties OptimizationDokument12 SeitenPreparation of Dimer Acid Based Polyamide Film by Solution Casting Method and Its Properties OptimizationMuhammad AdeelNoch keine Bewertungen

- For Review Only: Poly (Arylene Ether) - Polysiloxane Multiblock CopolymersDokument8 SeitenFor Review Only: Poly (Arylene Ether) - Polysiloxane Multiblock CopolymersRajesh ChowdhuryNoch keine Bewertungen

- 2005 Huh Enhanced Swelling Kinetics of Poly (Ethylene Glycol) - Grafted SuperDokument13 Seiten2005 Huh Enhanced Swelling Kinetics of Poly (Ethylene Glycol) - Grafted SuperErwin Tallu SangrapuNoch keine Bewertungen

- Industrial Crops & Products: Research PaperDokument11 SeitenIndustrial Crops & Products: Research PaperbelkhamasNoch keine Bewertungen

- Hybrid Biocomposites Based On Used Coffee Grounds and Epoxy ResinDokument12 SeitenHybrid Biocomposites Based On Used Coffee Grounds and Epoxy ResinEliz NguyenNoch keine Bewertungen

- 1 s2.0 S0141813023027848 MainDokument11 Seiten1 s2.0 S0141813023027848 Mainsaeed.uopNoch keine Bewertungen

- Polymer JournalDokument6 SeitenPolymer Journalabilio_j_vieiraNoch keine Bewertungen

- Influence of Residual Lignin Content On Physical and Mechanical Properties of Kraft Pulp / PP CompositesDokument9 SeitenInfluence of Residual Lignin Content On Physical and Mechanical Properties of Kraft Pulp / PP CompositesArmando BeltránNoch keine Bewertungen

- The Preparation and Characterization of ChitosanDokument9 SeitenThe Preparation and Characterization of ChitosanEndarto YudoNoch keine Bewertungen

- Industrial Crops and Products: Chun Chang, Yusheng Qin, Xiaolan Luo, Yebo LiDokument7 SeitenIndustrial Crops and Products: Chun Chang, Yusheng Qin, Xiaolan Luo, Yebo LiMohamed HalemNoch keine Bewertungen

- Mittal Et Al 2020 Synthesis of Polyvinyl Alcohol Modified Starch Based Biodegradable Nanocomposite Films ReinforcedDokument12 SeitenMittal Et Al 2020 Synthesis of Polyvinyl Alcohol Modified Starch Based Biodegradable Nanocomposite Films ReinforcedFauzan Ramadhan PratamaNoch keine Bewertungen

- 8 Final Stydy On Ferric Chloride CoagulationDokument10 Seiten8 Final Stydy On Ferric Chloride CoagulationMervatNoch keine Bewertungen

- 1 s2.0 S0141813023056118 MainDokument9 Seiten1 s2.0 S0141813023056118 Mainsaeed.uopNoch keine Bewertungen

- UntitledDokument11 SeitenUntitledMohamed HalemNoch keine Bewertungen

- Fernandes2017 PDFDokument26 SeitenFernandes2017 PDFsamuelben87Noch keine Bewertungen

- Factos Affecting The Properties of Nitrocellulose Emulsion A Comparative StudyDokument23 SeitenFactos Affecting The Properties of Nitrocellulose Emulsion A Comparative Studyshikaru7114Noch keine Bewertungen

- Materials and Design: V. Fombuena, L. Bernardi, O. Fenollar, T. Boronat, R. BalartDokument7 SeitenMaterials and Design: V. Fombuena, L. Bernardi, O. Fenollar, T. Boronat, R. Balarteid elsayedNoch keine Bewertungen

- Preparation and Characterization of High-Flux Polysulfone Hollow Fibre Gas Separation MembranesDokument10 SeitenPreparation and Characterization of High-Flux Polysulfone Hollow Fibre Gas Separation MembranesRacheal ShaktiNoch keine Bewertungen

- Hamz Eh 2019Dokument13 SeitenHamz Eh 2019reza jordanaNoch keine Bewertungen

- Composites: Part A: M.J.A. Van Den Oever, B. Beck, J. MüssigDokument8 SeitenComposites: Part A: M.J.A. Van Den Oever, B. Beck, J. MüssigJoyce TonniNoch keine Bewertungen

- Processing Induced Segregation in PLA/TPS Blends: Factors and ConsequencesDokument12 SeitenProcessing Induced Segregation in PLA/TPS Blends: Factors and ConsequencesRoshni PattanayakNoch keine Bewertungen

- Canola OilDokument9 SeitenCanola OilAnonymous JMuM0E5YONoch keine Bewertungen

- My JournalDokument7 SeitenMy Journalyusuf abdulazizNoch keine Bewertungen

- New Approach For Developing Epoxy-Amine Adductcurative With Modified Epoxy ResinsDokument13 SeitenNew Approach For Developing Epoxy-Amine Adductcurative With Modified Epoxy Resinsvipin1222Noch keine Bewertungen

- June 9, 2015 Central Wisconsin ShopperDokument24 SeitenJune 9, 2015 Central Wisconsin ShoppercwmediaNoch keine Bewertungen

- Assignment (1) - Nat ResDokument1 SeiteAssignment (1) - Nat ResRex Del ValleNoch keine Bewertungen

- Paper DictionaryDokument114 SeitenPaper DictionarySamadhanMachineTools100% (2)

- Chloroleucon É A Denominação Cientifica Que Engloba Toda Uma EspécieDokument2 SeitenChloroleucon É A Denominação Cientifica Que Engloba Toda Uma EspécieRosangela Matter KamlaNoch keine Bewertungen

- 2 TractorDokument93 Seiten2 TractorMaría Luisa AcuñaNoch keine Bewertungen

- PotteryDokument14 SeitenPotterymetstephNoch keine Bewertungen

- A Review of Recent Application of Near Infrared SPDokument9 SeitenA Review of Recent Application of Near Infrared SPNega1986Noch keine Bewertungen

- Schinus MolleDokument5 SeitenSchinus MolleFlower Rouss AQNoch keine Bewertungen

- Enviromental Report Group 6Dokument26 SeitenEnviromental Report Group 6Divagaran A/L GunasekaranNoch keine Bewertungen

- TCT Circular Saw Blades PCD Circular Saw Blades Band Saw Blades 2014Dokument58 SeitenTCT Circular Saw Blades PCD Circular Saw Blades Band Saw Blades 2014rizkyNoch keine Bewertungen

- Manish PHD Thesis PDF CD PDFDokument158 SeitenManish PHD Thesis PDF CD PDFNitin Vinay KhareNoch keine Bewertungen

- Section 11Dokument6 SeitenSection 11dak comeiNoch keine Bewertungen

- Bamboo in Southeast AsiaDokument98 SeitenBamboo in Southeast AsiavelkadirNoch keine Bewertungen

- 250 + WoodWorking Projects Part 1Dokument868 Seiten250 + WoodWorking Projects Part 1asociatia_psitek100% (2)

- Steelwork GlossaryDokument24 SeitenSteelwork Glossaryshailesh9jan100% (3)

- Research Project DescriptionDokument5 SeitenResearch Project DescriptionMeghan BarrettNoch keine Bewertungen

- Chikmagalur - Macro Site AnalysisDokument20 SeitenChikmagalur - Macro Site Analysisadarsh vaitlaNoch keine Bewertungen

- Delicious Deciduous ForestsDokument12 SeitenDelicious Deciduous ForestsdcsquaredNoch keine Bewertungen

- Contemporary ArtsDokument3 SeitenContemporary ArtsjarealNoch keine Bewertungen

- Farm ToolsDokument1 SeiteFarm ToolsShane Favia Lasconia-Maceren100% (5)

- Making A Perone HiveDokument20 SeitenMaking A Perone Hivetemp19930100% (3)

- Biodiversity in The HimalayasDokument13 SeitenBiodiversity in The HimalayasauroraNoch keine Bewertungen

- Indonesia Forests 2018 BookDokument196 SeitenIndonesia Forests 2018 Bookdaru.wre.ftubNoch keine Bewertungen

- 3 1 Plants and How They GrowDokument14 Seiten3 1 Plants and How They Growapi-173544316100% (1)

- BScHAg PDFDokument209 SeitenBScHAg PDFGanpat Lal Sharma100% (1)

- Filehost - The Art of Woodworking - Handbook of JoineryDokument147 SeitenFilehost - The Art of Woodworking - Handbook of JoineryAlbinuta1100% (26)

- Taiga BiomeDokument1 SeiteTaiga BiomeANNEROSE JIMENEZNoch keine Bewertungen

- Northpac Forest Letter Logs 2019-08-16Dokument3 SeitenNorthpac Forest Letter Logs 2019-08-16Tom FletcherNoch keine Bewertungen

- OTO Press Release 2023 Pop UpDokument1 SeiteOTO Press Release 2023 Pop UpNBC MontanaNoch keine Bewertungen

- Juan N His CarabaoDokument8 SeitenJuan N His CarabaoGrace Martinez TorresNoch keine Bewertungen