Beruflich Dokumente

Kultur Dokumente

Guidelines For Corrosion Prevention: Lesson 1: Forms of Stainless Steel Corrosion

Hochgeladen von

German ToledoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Guidelines For Corrosion Prevention: Lesson 1: Forms of Stainless Steel Corrosion

Hochgeladen von

German ToledoCopyright:

Verfügbare Formate

N iDI E-LEAR N IN G S Y S TEM N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

N iDI, 2 0 0 2

P ower ed by C AS TI Technology

G U ID E L IN E S F O R C O R R O S IO N P R E V E N T IO N

LES S ON 1 : F OR M S OF S TAIN LES S S TEEL C OR R OS ION

Thank you for us ing t he N ickel Development Ins t it ut e E-Lear ning S ys t em. U s e of t his s ys t em is s ubject t o t er ms and condit ions ,

acces s ible by clic king her e. B y cont inuing pas t t his page, you expr es s ly agr ee t o be bound by t hos e t er ms and condit ions .

V IE W IN S T R U C T IO N S

S TA R T L E S S O N

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 1

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

Forms of Stainless Steel Corrosion

If stainless steel is selected, installed, and maintained correctly, it does not suffer corrosion. However, if

the environment exceeds the corrosion resistance of a particular stainless steel in a specific location,

some corrosion may occur. Only certain types of corrosion may affect stainless steels.

Ex

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 2

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

TARNISHING

Tarnishing is a fairly uniform discolouration of a metals surface. With exterior stainless steel applications,

there may be a slight yellow tarnishing of the surface and some loss of brightness, especially if fine

particles of dirt are incorporated into the surface deposit. Some improvement may be obtained from

washing but the overall effect on appearance is small and may not be apparent when viewed from a

distance.

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 3

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

PITTING

If a stainless steel corrodes, pitting is the most likely form of corrosion. If the environment overwhelms

the capability of the stainless steel, the protective, passive film is disrupted and cannot heal itself. This is

shown schematically in Figure 1a. (See Atmospheric Corrosion Section.) Pitting starts as tiny points of

attack and is usually black or dark brown in colour. In the most severe cases, the number and depth of

the pits can increase to give an extensively corroded appearance. If the attack is mild, the pits may not

detract from the general appearance but the area below them may be stained as rust leaches out.

Selecting an appropriate stainless steel and cleaning regularly to remove surface deposits reduce the

potential of pitting damage.

Figure 1a Pitting corrosion

Solution

Passive film

Stainless steel

Ex

Figure 1c

Ex

Figure 1b

Figure 1a

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 4

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

CREVICE CORROSION

Crevice corrosion is similar to pitting but occurs over a larger area when deposits or other materials

block the oxygen access needed to maintain the passive film. Corrosion can occur if chloride-containing

rainwater or condensation is present in a tight crevice and conditions are created which exceed the

corrosion resistance of a particular stainless steel. It is more likely with lower-alloyed stainless steels,

particularly where the crevice gap is very small (a tight washer) and the path to free oxygen is long (a

large diameter washer). Correct design reduces the potential for crevice corrosion. In areas exposed to

water, designers should minimize crevices, seal them, or consider a more corrosion-resistant, higher-

alloyed grade. See Figure 2a.

Figure 2a Crevice corrosion

Solution

Passive film

Stainless steel

Metal or non-metal

Ex

Figure 2b

Figure 2a

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 5

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

GALVANIC CORROSION

Galvanic or "bimetallic" corrosion can occur when two metals of differing electrochemical potential are

electrically coupled in a conducting liquid, usually called an electrolyte. Several factors determine

galvanic corrosion potential: the electrochemical potential difference, the presence of moisture to

connect the metals on a regular basis, and the relative surface area ratio of the metals. If no moisture is

present or an inert, electrically insulating material prevents electrical contact, galvanic corrosion cannot

occur.

Figure 3 illustrates galvanic corrosion.

Figure 3 Galvanic corrosion

Less noble metal

Solution

Stainless steel

Current

Figure 3

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 6

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

Figure 4a shows examples of when galvanic

corrosion can and cannot occur. Figure 4b

illustrates electrochemical cell components

while Figures 4c and 4d illustrate anode and

cathode processes respectively. Figure 5

shows the galvanic series in seawater. The

metals are arranged in order from the least

noble (least corrosion-resistant) to the most

noble (most corrosion-resistant). Environment

affects a metals potential. Some metals are

shown twice along with the terms "active" or

"passive". In extremely severe corrosion

environments like strong acids, a stainless

steel may not be able to maintain its protective

passive film and may begin to corrode actively.

This might occur in an industrial equipment

application. These conditions are not present

in architectural applications and stainless

steels can be considered to be in the passive

state.

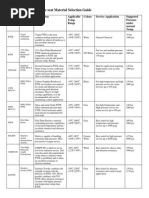

Figure 5 Galvanic series in seawater at 77F (25C)

Least noble = anodic = most susceptible to corrosion

Magnesium and its alloys

Zinc

Galvanized steel or galvanized wrought iron

Aluminum alloys 3004, 3003, 1100, in this order

Cadmium

Low carbon steel

Wrought iron

Cast iron

Nickel cast irons

Stainless steel, Type 410 (active)

50-50 lead-tin solder

Stainless steel, Type 304 (active)

Stainless steel, Type 316 (active)

Lead

Tin

Muntz metal, C28000

Alloy 200 (active)

Alloy 600 (active)

Yellow brass, C27000

Aluminum bronzes, C61400

Red brass, C23000

Commercially pure copper, C11000

Silicon bronze, C65500

Alloy 200 (passive)

Alloy 600 (passive)

Alloy 400

Stainless steel, Type 410 (passive)

Stainless steel, Type 304 (passive)

Stainless steel, Type 316 (passive)

Alloy 825

Alloy 625

Alloy C

Silver

Titanium

Gold

Most noble = cathodic = most corrosion-resistant

Figure 4a

Figure 4b

Figure 4c

Figure 4d

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 7

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

Galvanic corrosion may be a concern if there is a significant difference in electrochemical potential and

the metals are not electrically isolated from one another. If two metals are close together in the galvanic

series (e.g., two stainless steels or copper and stainless steel), the potential for galvanic corrosion is low

in all but the most aggressive environments.

The relative surface area of the two metals is important. When the surface area of the more corrosion-

resistant metal is large relative to the less corrosion-resistant metal, an unfavourable ratio exists and

there is an increase in the corrosion rate of the less corrosion-resistant metal. For example, coupling a

small piece of carbon steel to a large piece of stainless steel could cause rapid corrosion of the carbon

steel. If the ratio is reversed and the less corrosion-resistant material has a large surface area, the

corrosion rate of the less corrosion-resistant metal is only slightly increased.

Ex

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 8

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

Dissimilar metal combinations should be avoided in areas where moisture is likely to accumulate and

remain for long periods. In well-drained exterior applications, dissimilar metals can be used together if a

favourable surface ratio exists, but they should be electrically insulated from one another.

Neoprene washers, roofing felt, paint, and other inert materials or coatings are effective barriers. When

painted carbon steel and stainless steel are welded together in an exterior application, the welded joint

should be painted. Hidden and exposed stainless steel fasteners with neoprene or other inert washers

are used regularly in aluminum, zinc, and painted galvanized steel roof applications. The inert washer

separates the metals in case water is frequently present or infiltrates under the head of the fastener.

Tip

Ex

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 9

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

EMBEDDED OR TRANSFERRED IRON

Iron or carbon steel can become transferred to or embedded in the surface of stainless steel and other

architectural metals and begin to rust within a few hours or days. This can give the incorrect impression

that the material underneath is rusting. However, in severe cases, the rusting steel may actually cause

the stainless steel under it to corrode because the protective passive film cannot re-form.

The source of iron can be steel tools, abrasive polishing or blasting media or fabrication areas previously

used on carbon or low-alloy steels, use of carbon steel wool or carbon steel brushes during cleaning,

and accidental scratching. Ideally, the fabrication area should be dedicated to stainless steel. If that is not

possible, the area should be cleaned prior to stainless steel fabrication to remove residual iron particles.

To prevent accidental contamination, the stainless steel surface should be protected with protective

paper or strippable plastic films during fabrication, handling, storage and transport.

Ex

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 10

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

The purchaser can specify that stainless steel products pass one of several non-destructive tests for

detection of embedded iron such as ASTM A 967. A particularly simple and straightforward test is to

thoroughly wet the surface with clean water and wait for 24 hours to see if rust appears. Additional

information about preventing, detecting and removing embedded iron and steel can be found in the

Nickel Development Institute publication, Fabrication and post-fabrication cleanup of stainless steels, No.

10 004.

Ex

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

Las t P age N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 11

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

EROSION-CORROSION

Erosion-corrosion is accelerated metal loss caused by a flowing corrosive liquid which contains abrasive

particles such as sand or debris. It can be a problem with aluminum, copper and other susceptible

materials in applications like piping and roof drainage systems. Resistance to erosion-corrosion is not

related to hardness or strength, but flow velocity, high turbulence, or changes in flow direction can have a

significant impact on performance in susceptible metals. Stainless steels are virtually immune to erosion-

corrosion because they form thin, tightly adherent, protective passive films. High flow velocities are

beneficial to stainless steel corrosion performance because they help keep the stainless steel surface

clean.

Q

?

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of P age

N iDI, 2 0 0 2

S elf Tes t N ext P age F ir s t P age P r evious P age

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 12 12

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N

CHLORIDE STRESS CORROSION CRACKING, (SCC)

Chloride stress corrosion cracking (SCC) may occur in Types 304 and 316 exposed to chlorides and

tensile residual stress at temperatures above about 150F (65C). These conditions are unlikely in most

architectural applications.

SCC has occurred at lower temperatures in unusually severe indoor environments, such as swimming

pool suspended ceilings. The Nickel Development Institute publication No. 12 010, Stainless steel in

swimming pool buildings, provides additional information about appropriate grades for this application.

The potential for SCC in an aggressive marine environment was evaluated in a five-year study of 300-

series stainless steels in three metallurgical conditions: annealed (the normal as-delivered mill

condition), as welded, and cold-worked. The site for these tests, Kure Beach, North Carolina, U.S.A.,

experiences hot summers. The underside of the panels reached temperatures of about 120F (50C) and

the exposed side 140F (60C). None of the samples experienced stress corrosion cracking.

Ex

E nd of L es s on

C lic k on t he S elf Tes t B ut t on below

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

N ext Ques t ion P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 1

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

Choose the most accurate statement:

A. Stainless steel never tarnishes or corrodes in an architectural application

B. If the proper grade of stainless steel is selected, it will never tarnish or corrode

C. If corrosion is seen on stainless, it is likely the material was made "cheaply"

D. Stainless will maintain its proper appearance if the proper grade is chosen, and it is

installed and maintained appropriately

E. Always use the same grade of stainless for all parts of a building

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

N ext Ques t ion P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 2

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

Choose one of the following that best completes the sentence "Pitting is possible if the

stainless steel is exposed to..."

A. chlorides

B. acids

C. carbon monoxide

D. other metals

E. heat

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

N ext Ques t ion P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 3

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

Which one of the following will not cause pitting on stainless steel (Choose one):

A. Urine

B. Road salt

C. Marine environment

D. Laundry bleach

E. Soap

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

N ext Ques t ion P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 4

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

Crevice corrosion can occur underneath what kinds of crevices? (Choose one):

A. Metal to metal crevices

B. Glass or plastic to metal crevices

C. Crevices that are sometimes wet

D. Crevices that are always wet

E. All the above

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

N ext Ques t ion P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 5

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

If I use 2 different metals that are in contact with each other, one will always get

galvanic corrosion.

A. True

B. False

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

N ext Ques t ion P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 6

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

Choose one of the following that best completes the sentence "If galvanized (zinc coated steel)

fasteners are used to hold stainless steel panels in an external application,..."

A. that is bad because zinc is more active that than stainless steel, and the area ratio

effect is bad

B. that is not so bad because the area ratio is good even if zinc is more active than stainless

C. that is OK because stainless is more active than zinc, and the area ratio effect is good

D. that is not so bad because the iron in the fastener will protect the zinc coating

E. that cannot be so bad because other architects do it regularly

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

N ext Ques t ion P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 7

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

I should design to ensure that components in the lower alloyed 304 and the higher alloyed 316

stainless never come in contact to avoid to prevent galvanic corrosion between these two metals.

A. True

B. False

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

N ext Ques t ion P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 8

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

Some components in 304 stainless steel are now "rusting" even before they have been installed.

The most likely reason for this is (choose one):

A. The wrong grade was specified

B. Cheap imported 304 stainless steel

C. The stainless was contaminated with iron during fabrication or shipping or handling

D. The passive oxide layer didn't form

E. The wrong grade was delivered

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

N ext Ques t ion P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 9

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

Choose one of the following that best completes the sentence "Stainless steels are very resistant

to flowing liquids even if they contain some abrasive particles because..."

A. stainless steels are form a thin, tightly adherent passive oxide layer that protects the metal

B. stainless steels are hard

C. stainless steels are soft

D. stainless steel contains hard wear-resistant particles

E. the statement is false

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

of Ques t ion

N iDI, 2 0 0 2

Evaluat e S elf Tes t P r evious Ques t ion

GU IDELIN ES F OR C OR R OS ION P R EVEN TION 10 10

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t

Indoor swimming pool environments create special conditions where stainless steels may be

used but must be carefully selected.

A. True

B. False

N iDI E-LEAR N IN G S Y S TEM

NiDI

Nickel

Development

Institute

N iDI, 2 0 0 2

R eview S elf Tes t R et ur n t o Les s on

You have completed the Self Test.

You may review answers and explanations to the Self Test questions

by clicking on the Review Self Test button below.

GU IDELIN ES F OR C OR R OS ION P R EVEN TION

L E S S O N 1 : F O R M S O F S TA IN L E S S S T E E L C O R R O S IO N - S elf Tes t E valuat ion

Self Test Score

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Sheet Metal BasicsDokument16 SeitenSheet Metal BasicsvittlevishnuNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Valve Seat Material Selection GuideDokument1 SeiteValve Seat Material Selection Guidemurtuza5Noch keine Bewertungen

- Pulley Systems - RopebookDokument4 SeitenPulley Systems - RopebookGerman ToledoNoch keine Bewertungen

- Supplier APQP Training SupplementDokument78 SeitenSupplier APQP Training SupplementjcperezNoch keine Bewertungen

- Instrumentation TextbookDokument166 SeitenInstrumentation TextbookGerman ToledoNoch keine Bewertungen

- Material Selection For CNG TubeDokument13 SeitenMaterial Selection For CNG Tubearyoblitar100% (1)

- Rebound Hammer TestDokument12 SeitenRebound Hammer Testmahmood hunar100% (4)

- 03 49 00 Glass Fiber Reinforced Concrete PanelsDokument15 Seiten03 49 00 Glass Fiber Reinforced Concrete PanelsSourav BasakNoch keine Bewertungen

- DrillingDokument52 SeitenDrillingMd AamerNoch keine Bewertungen

- Water Reducing - Retarding AdmixturesDokument17 SeitenWater Reducing - Retarding AdmixturesAbdullah PathanNoch keine Bewertungen

- The Agri Handbook 2013-14Dokument676 SeitenThe Agri Handbook 2013-14Craig Macaskill92% (13)

- Cold Metal Transfer: A Revolution in Mechanised Root Pass Pipeline WeldingDokument3 SeitenCold Metal Transfer: A Revolution in Mechanised Root Pass Pipeline Weldingargentino_ar01Noch keine Bewertungen

- Offshore Design Section Functional Specification For Level TransmitterDokument10 SeitenOffshore Design Section Functional Specification For Level TransmitterGerman ToledoNoch keine Bewertungen

- Clean Programa Ly PDFDokument48 SeitenClean Programa Ly PDFLilianaGómezNoch keine Bewertungen

- Tca 14 0063 13divDokument77 SeitenTca 14 0063 13divGerman ToledoNoch keine Bewertungen

- DMAddins SampleData enDokument2.224 SeitenDMAddins SampleData enGerman ToledoNoch keine Bewertungen

- Cross Reference GV3Dokument2 SeitenCross Reference GV3German ToledoNoch keine Bewertungen

- Pulley Systems Printed Handout - HeilmanDokument46 SeitenPulley Systems Printed Handout - HeilmanGerman ToledoNoch keine Bewertungen

- Miniature Circuit Breaker Multi 9 (C60), 10A, 1-Pole, 240 Vac, 60 VDC, HACR RatedDokument1 SeiteMiniature Circuit Breaker Multi 9 (C60), 10A, 1-Pole, 240 Vac, 60 VDC, HACR RatedGerman ToledoNoch keine Bewertungen

- Tca 14 0063 13divDokument77 SeitenTca 14 0063 13divGerman ToledoNoch keine Bewertungen

- Sensor Catalog Chapt1 2-3-122012 enDokument96 SeitenSensor Catalog Chapt1 2-3-122012 enGerman Toledo100% (1)

- K S RF M 805 T: Otron Mart Odel RansmitterDokument16 SeitenK S RF M 805 T: Otron Mart Odel RansmitterGerman ToledoNoch keine Bewertungen

- Instrument Loop DiagramDokument121 SeitenInstrument Loop Diagramroutine1976Noch keine Bewertungen

- Quiz Feedback - CourseraDokument5 SeitenQuiz Feedback - CourseraGerman Toledo100% (1)

- Quiz Feedback - CourseraDokument9 SeitenQuiz Feedback - CourseraGerman ToledoNoch keine Bewertungen

- Stress Calculation For Aluminium PlateDokument8 SeitenStress Calculation For Aluminium PlateJacques Ontal100% (1)

- K KL2 0 C0069 BDokument15 SeitenK KL2 0 C0069 BRaduIonNoch keine Bewertungen

- Is-2121-I-1981Dokument19 SeitenIs-2121-I-1981Rohan MudshingikarNoch keine Bewertungen

- FINAL Report Recreational Boating Formatted REVISED 241115Dokument146 SeitenFINAL Report Recreational Boating Formatted REVISED 241115Panagiotis KarathymiosNoch keine Bewertungen

- Esmat CVDokument8 SeitenEsmat CVعصمت ضيف اللهNoch keine Bewertungen

- SCM-Module-5-Resource Planning - MRP 1 & IIDokument24 SeitenSCM-Module-5-Resource Planning - MRP 1 & IIMuhammed Husain MusaniNoch keine Bewertungen

- Bata - India's Favorite Footwear BrandDokument4 SeitenBata - India's Favorite Footwear BrandArpit AgarwalNoch keine Bewertungen

- Market Access - 1 - TariffsDokument50 SeitenMarket Access - 1 - TariffsNguyen Tuan AnhNoch keine Bewertungen

- E Waste ManagementDokument20 SeitenE Waste ManagementSandeep YadavNoch keine Bewertungen

- Especificaciones - Técnicas de RevitDokument393 SeitenEspecificaciones - Técnicas de RevitzuenboNoch keine Bewertungen

- Duqm Refinery Project EPC Package OneDokument22 SeitenDuqm Refinery Project EPC Package OnePrashant KumarNoch keine Bewertungen

- Observing Chemical Changes: Purpose: MaterialDokument2 SeitenObserving Chemical Changes: Purpose: Materialctremblaylcsd150Noch keine Bewertungen

- Group 2 Michigan Manufacturing CorporationDokument22 SeitenGroup 2 Michigan Manufacturing CorporationtheplacementcircleNoch keine Bewertungen

- Method Statement: Nitoflor FC130Dokument4 SeitenMethod Statement: Nitoflor FC130Karen MiradNoch keine Bewertungen

- Engineering Director R&D Products in United States Resume Micha EizenDokument2 SeitenEngineering Director R&D Products in United States Resume Micha EizenMichaEizenNoch keine Bewertungen

- K60-Product Data Sheet PDFDokument2 SeitenK60-Product Data Sheet PDFdakidofdaboomNoch keine Bewertungen

- Course: MIS & ERPDokument13 SeitenCourse: MIS & ERPpeacetrainpkNoch keine Bewertungen

- CWI SCWI Renewal PKG v1Dokument2 SeitenCWI SCWI Renewal PKG v1jayaarnavNoch keine Bewertungen

- From 2004: China Report: Chemical Product TrendsDokument16 SeitenFrom 2004: China Report: Chemical Product TrendstotpityiNoch keine Bewertungen

- Company Profile: Bramco (Oman) LLCDokument4 SeitenCompany Profile: Bramco (Oman) LLCSwarna RkNoch keine Bewertungen