Beruflich Dokumente

Kultur Dokumente

Artifact 4 Parts Small Engines Powerpoint

Hochgeladen von

api-240922530Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Artifact 4 Parts Small Engines Powerpoint

Hochgeladen von

api-240922530Copyright:

Verfügbare Formate

SMALL ENGINES

http://auto.howstuffworks.com/engine.htm

Internal Combustion

A cannon uses the basic

principles of internal

combustion engines. If

you take a small amount

of high energy fuel (like

gasoline) in a small,

enclosed space and

ignite it, an incredible

amount of energy is

released in the form of

expanding gas.

WHAT USES SMALL

ENGINES?

lawn mowers, tillers, cultivators,

trimmers, edgers, snowblowers, chain

saws, pumps, generators, air

compressors, and other useful home

tools

outboard boats, snowmobiles,

motorcycles, all-terrain vehicles,

ultralight aircraft

Types of Small Engine

2 stroke

http://www.carbibles.com/videos/twostrokeanimatio

n.mp4

4 stroke

http://www.carbibles.com/videos/fourstrokeanimatio

n.mp4

Strokes

Stroke-refers to the movement of the

piston in the engine

http://www.carbibles.com/fuel_engine_

bible.html

http://www.animatedengines.com

/otto.shtml

2 stroke strokes

Compression

Combustion

4 stroke strokes

Intake

Compression

Power

Exhaust

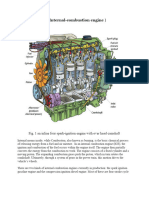

4 STROKE

The four-stroke cycle

The four stroke

combustion cycle

consists of:

1. Intake

2. Compression

3. Combustion

4. Exhaust

INTAKE Stroke

The Piston is going

down so the

volume of the

cylinder is

getting larger

The Intake valve is

open.

Fuel is mixed with

the air, and the

Cylinder is filled

with the mixture of

air and fuel.

Compression Stroke

The Piston is

going up so the

volume of the

cylinder is getting

smaller.

Both valves are

closed. Air/fuel

mixture is trapped

in the cylinder.

Pressure is

increasing.

Power Stroke

The Piston is going down.

Volume of the cylinder is

increasing.

Both valves closed. Spark

plug fires, causing

compressed air/fuel mixture

to burn.

The flame front travels

across the combustion

chamber.

The burning fuel creates

tremendous pressure which

forces the piston down.

turning the crankshaft and

producing power.

This is not an explosion, but

a smooth, controlled burn.

Exhaust Stroke

The Piston is going

up, so the volume

of the cylinder is

getting smaller.

The Piston pushes

the burned exhaust

gasses out past the

open exhaust

valve, and out

through the

exhaust system

and into the

atmosphere.

2 STROKE

The two stroke cycle

The two stroke engine ignites every

revolution of the crankshaft. These

engines overlap operations to reduce

parts while maintaining power.

Intake

The fuel/air

mixture is first

drawn into the

crankcase by the

vacuum created

during the upward

stroke of the

piston.

Intake

The fuel mixture is

then compressed

in the crankcase

during the

remainder of the

stroke.

Transfer/Exhaust

Toward the end of the

stroke, the piston

exposes the intake

port, allowing the

compressed fuel/air

mixture in the

crankcase to escape

around the piston into

the main cylinder.

This expels the

exhaust gasses out

the exhaust port,

usually located on the

opposite side of the

cylinder.

Compression

The piston then

rises and

compresses the

fuel mixture.

Power

At the top of the

stroke the spark

plug ignites the fuel

mixture.

The burning fuel

expands, driving

the piston

downward, to

complete the cycle.

Advantages

Disadvantages

Simpler

Power boost

Lighter weight

Cost Less

Can work in any position

don't live as long as four-

stroke engines

Two-stroke engines

require a mix of oil in with

the gas

do not use fuel efficiently

Produce more pollution.

Engine Systems

Compression system

Fuel system

Ignition system

Cooling system

Lubrication system

ACTIVITY! Break yourselves into groups of 2

Each group is responsible for 1 system in the

engine. You need to either make a descriptive

poster or power point describing your engine

system. YOUR group will be RESPONSIBLE

for TEACHING other groups about your

SYSTEM.

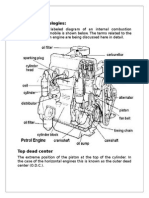

PARTS OF ENGINE

5 Main components of engine

Fuel

Ignition

Combustion

Cooling

Lubrication

Parts of an engine

Cylinder- where the piston moves up

and down. Most lawnmowers are 1

cylinder while automobiles are 4,6,8,

and 10.

Spark plug- supplies spark for the

fuel/air mixture.

Valves- let air in and exhaust out.

Note: both valves are closed during

the compression stroke.

Parts of an engine

Piston- cylindrical piece of metal that moves

up and down the cylinder.

Piston rings- rings provide a sliding seal

between the piston and cylinder.

Rings serve two purposes:

prevent fuel/air from leaking into the sump

prevent oil from entering the combustion

chamber

Parts of an engine

Combustion chamber- area where

combustion and compression takes place.

Connecting rod- connects the piston to the

crankshaft.

Crankshaft- the crankshaft turns the up and

down motion of the piston into circular

motion

Sump- (oil pan) contains and collects oil for

lubrication

Parts of an engine

FUEL and EXHAUST

Gasoline: Gasoline is a combustible liquid that burns

relatively slowly. However, when sprayed as a mist and mixed

with air, it is quite explosive. All it needs is a spark. Two-

stroke engines require that oil be mixed with the gasoline to

lubricate internal parts. Four-stroke engines use a fuel-air

mixture.

Fuel Tank: The fuel tank stores fuel in preparation for mixing

by the carburetor and use by the engine. Some fuel tanks are

pressurized with air to help deliver fuel to the carburetor.

Other tanks are non-pressurized and depend on a fuel pump

to deliver fuel to the carburetor.

Fuel Line: Fuel is moved from the tank to the pump and/or

carburetor through a fuel line. Pressurized fuel systems often

have a squeeze bulb in the fuel line for building pressure.

FUEL and EXHAUST

Filter: A carburetor jet has a small opening

that can easily become clogged. A fuel filter

traps dirt and sediment from the gas before it

is delivered to the carburetor.

Pump: A fuel pump produces a vacuum that

pulls the fuel from an unpressurized tank,

then delivers it to the carburetor.

Carburetor: The carburetor has one job: to

mix the correct proportion of gasoline and air

for the engine. Too much gasoline in the

mixture makes it rich; too little gas makes it

lean.

FUEL and EXHAUST

Throttle: The throttle controls the amount of fuel-air mixture that

enters the engine from the carburetor. The throttle thus controls the

speed of the engine.

Primer: A primer injects a small amount of gasoline into the

carburetor throat to make the initial fuel-air mixture rich. A primer is

used to help start a cold engine.

Choke: Some engines control the richness of the fuel-air mixture at

startup by controlling the air rather than the fuel. A choke reduces

the amount of air in the fuel-air mixture.

Governor: A governor is a device that automatically opens the

engine's throttle when more power is needed and closes it when the

load is light.

Muffler: Small gas engines, especially two-stroke engines, are noisy

when they operate. A muffler reduces the sound of the exhaust

gases by passing them through baffles.

INGITION SYSTEM TYPES

Magneto-Powered Ignition System: A magneto uses

magnetism to supply electricity in ignitions where there is no

battery. The magneto is turned by the crankshaft, which

rotates when the manual recoil starter is pulled. The three

types of magneto ignition systems are mechanical-breaker,

capacitor-discharge, and transistor-controlled.

Battery-Powered Ignition System: If your small engine

includes a battery for starting, the ignition coil will also use it

to supply spark to the spark plugs. A battery stores electrical

energy until needed. Battery ignition systems also use

mechanical-breaker, capacitor-discharge, and transistor-

controlled ignitions.

Mechanical-Breaker Ignitions: High-voltage electricity must

be sent to the spark plug at the appropriate time. In

mechanical-breaker ignitions, this job is performed through

the contact points and a condenser.

IGNITION

Coil: An ignition coil is simply two coils of wire wrapped

around an iron core.

Spark Plug: A spark plug is an insulated electrode that

is screwed into the top of the engine cylinder. High-

voltage timed electricity from the magneto travels by

wire to the spark plug. The base of the plug has an air

gap of about 0.030 inch (30 thousandths of an inch),

which the current must jump.

Wires: The primary wire from the coil to the breaker

point and secondary wire from the coil to the spark

plug(s) deliver electricity to the ignition components.

COMBUSTION

Cylinder Block: The largest single part in a small gas

engine is the cylinder block. It is a piece of metal in

which the cylinder hole is bored or placed.

Cylinder Head: The cylinder head is the top, or ceiling,

of the cylinder and is attached to the block with bolts.

Depending on the type of engine, the head may or may

not include valves.

Piston: A piston is the movable floor in the combustion

chamber. Its upward movement compresses the fuel-air

mixture. After combustion, its downward movement

rotates the crankshaft.

COMBUSTION

Crankshaft: An engine's crankshaft is a metal shaft with an

offset section onto which the connecting rod is attached.

Rotation of the crankshaft moves the piston up in the cylinder.

Movement of the piston down in the cylinder then rotates the

crankshaft.

Connecting Rod: Between the piston and the crankshaft is a

connecting rod. At the larger end of the connecting rod is a

bearing that allows rotation around the moving crankshaft.

The small end is attached to the piston pin.

Valves: Valves simply open and close passages. A reed

valve in a two-stroke engine is activated by changes in air

pressure.

Flywheel: At the end of the crankshaft is a circular weighted

wheel called a flywheel. The flywheel delivers the engine's

power to devices (wheels, blades, etc.) and helps keep the

crankshaft turning smoothly.

COOLING and

LUBRICATION

Air-Cooling Fins: For simplicity, most smaller gas engines

are cooled by air. Metal fins around the outside of the

combustion chamber help dissipate the internal heat.

Bearings: A bearing is a replaceable part that takes the brunt

of the friction. A friction bearing relies on lubricants to

minimize friction. A non-friction bearing uses hard steel rollers

or balls to prevent wear, though it too requires some

lubrication.

Lubricants: Lubricants such as oil and grease reduce

surface friction by coating parts with a film. Lubricants in two-

stroke engines are applied to surfaces by mixing oil with fuel.

Filters: Friction happens. Moving parts wear, even with the

best lubricants. The resulting metal as well as carbon from

the combustion process must be cleaned from the oil to

ensure long lubrication. Some small engines use oil filters to

remove contaminants from the circulating oil.

Flywheel Key

Holds the flywheel on

Flywheel Shroud

Protects flywheel

Engine Shroud

Covers engine for protection

Starter Rod

connects ignition and throttle kind of.

Gasoline

Combustible liquid burns relatively

slow.

Oil

Lubricants such as oil and grease

reduce surface friction by coating

parts with a film. Lubricants in two-

stroke engines are applied to surfaces

by mixing oil with fuel.

Water

Keeps engine cool

Fins

Cools engine

Crankshaft

Crankshaft: An engine's crankshaft is

a metal shaft with an offset section

onto which the connecting rod is

attached. Rotation of the crankshaft

moves the piston up in the cylinder.

Movement of the piston down in the

cylinder then rotates the crankshaft.

Head gasket

Seals engine to prevent fluid leaking

Head Bolt

Holds the head to engine block

Spark Plug

Creates spark

Armature

Converts the current

Spark plug wire

Connects spark plug

Carburetor

Carburetor: mix the correct proportion

of gasoline and air for the engine

Air Cleaner

Clean dirt and particles out of air to

keep engine running properly

Gas Tank

Hold gas

Throttle

controls the amount of fuel-air mixture

that enters the engine from the

carburetor. The throttle thus controls

the speed of the engine.

Horsepower

http://www.youtube.com/watch?v=eh7

uFumf-

vc&feature=results_main&playnext=1

&list=PL3EE86E23668789E1

Das könnte Ihnen auch gefallen

- Asi Unit 3Dokument21 SeitenAsi Unit 3Raja RamNoch keine Bewertungen

- Diesel and Petrol Engines ReportDokument8 SeitenDiesel and Petrol Engines ReportJonathan MalamulaNoch keine Bewertungen

- Theory of Engine OperationDokument19 SeitenTheory of Engine OperationGabriel Dela Cruz LagmanNoch keine Bewertungen

- Internal Combustion EnginesDokument32 SeitenInternal Combustion Enginespramodkb_cusatNoch keine Bewertungen

- 发动机专业英语 (柴油机和汽油机)Dokument30 Seiten发动机专业英语 (柴油机和汽油机)周庆卓Noch keine Bewertungen

- Vehicle EngineDokument31 SeitenVehicle EnginenoahNoch keine Bewertungen

- Greater Noida Institute of Technology: 2-Stroke Petrol EngineDokument13 SeitenGreater Noida Institute of Technology: 2-Stroke Petrol EngineEr Raghvendra SinghNoch keine Bewertungen

- Systems and Components of AutomobileDokument34 SeitenSystems and Components of AutomobileSuperUserNoch keine Bewertungen

- Petrol Engine (Nehru Garden, JalandharDokument7 SeitenPetrol Engine (Nehru Garden, Jalandharapi-3731257Noch keine Bewertungen

- Document CepDokument7 SeitenDocument CepShanzay DaudNoch keine Bewertungen

- Lab Report 12Dokument8 SeitenLab Report 12mamoona noreenNoch keine Bewertungen

- AGR 318 Lec 3 - Engine Cons & CompDokument42 SeitenAGR 318 Lec 3 - Engine Cons & CompHaikal SapurataNoch keine Bewertungen

- 4 Stroke Petrol EngineDokument9 Seiten4 Stroke Petrol EngineZahid MughalNoch keine Bewertungen

- 2Dokument13 Seiten2msaqibraza93Noch keine Bewertungen

- ICE (Internal Combustion Engine)Dokument22 SeitenICE (Internal Combustion Engine)johnlloydsantossssNoch keine Bewertungen

- Gasoline EngineDokument6 SeitenGasoline EngineJonan TutaanNoch keine Bewertungen

- Practical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineDokument9 SeitenPractical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineMuhammad Arslan AfzalNoch keine Bewertungen

- Introduction To Internal Combustion Engines.: Fundamentals of Engineering Thermodynamics ME 1052Dokument7 SeitenIntroduction To Internal Combustion Engines.: Fundamentals of Engineering Thermodynamics ME 1052Supun AmarasingheNoch keine Bewertungen

- Applied Physics WORDDokument19 SeitenApplied Physics WORDMojtaba AhmadiNoch keine Bewertungen

- Piston Engine - Weight BasedDokument7 SeitenPiston Engine - Weight BasedVEERAMANINoch keine Bewertungen

- Experiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineDokument6 SeitenExperiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineHafeez AliNoch keine Bewertungen

- Thermodynamics Lab ReportDokument49 SeitenThermodynamics Lab Reportjawad60% (5)

- Multi FuelDokument21 SeitenMulti FuelManas Ranjan SahooNoch keine Bewertungen

- Auto Material EngineDokument36 SeitenAuto Material EngineHardik ShahNoch keine Bewertungen

- Component Parts of Internal Combustion EnginesDokument26 SeitenComponent Parts of Internal Combustion EnginesPeter AshrafNoch keine Bewertungen

- IC EnginesDokument8 SeitenIC EnginesNo MINoch keine Bewertungen

- I.C EnginesDokument58 SeitenI.C EnginesvndeshmukhNoch keine Bewertungen

- Applications: and TheirDokument88 SeitenApplications: and TheiralexNoch keine Bewertungen

- Internal Combustion Engines: ApplicationsDokument88 SeitenInternal Combustion Engines: ApplicationscarlosNoch keine Bewertungen

- Lecture 2 - Internal CombussionDokument80 SeitenLecture 2 - Internal Combussionchoongwenkang100% (1)

- 4 STROKE PETROL ENGINE ArsalDokument5 Seiten4 STROKE PETROL ENGINE ArsalMuhammad Arslan AfzalNoch keine Bewertungen

- Me 56Dokument9 SeitenMe 56RhizhailNoch keine Bewertungen

- Parts of An Automobile EngineDokument16 SeitenParts of An Automobile EngineEric James CatanguiNoch keine Bewertungen

- Diesel Automotive Engines: Energy and Power Technology TextbookDokument32 SeitenDiesel Automotive Engines: Energy and Power Technology TextbookSrinivas EedaraNoch keine Bewertungen

- Compression EngineDokument15 SeitenCompression EngineAlina RajputNoch keine Bewertungen

- Lab ReportDokument7 SeitenLab Reportshah_gen89Noch keine Bewertungen

- What Is The Difference Between A Two Stroke and Four Stroke EngineDokument7 SeitenWhat Is The Difference Between A Two Stroke and Four Stroke EngineAllen NopreNoch keine Bewertungen

- Engine Part IDokument39 SeitenEngine Part Iaashish koiralaNoch keine Bewertungen

- Thermal Engineering 1: Lecture NotesDokument17 SeitenThermal Engineering 1: Lecture NotesAndy LoNoch keine Bewertungen

- Ic Engines: Four Stroke Cycle Diesel EnginesDokument11 SeitenIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meNoch keine Bewertungen

- Chapter 1 Introduction: 1.1 Ic EngineDokument54 SeitenChapter 1 Introduction: 1.1 Ic Engineavanish SinghNoch keine Bewertungen

- LP-2 Factors Influencing Power DoneDokument5 SeitenLP-2 Factors Influencing Power DoneKashif UsmanNoch keine Bewertungen

- Study of Working Mechanisms of Important Components of Automobile EngineDokument5 SeitenStudy of Working Mechanisms of Important Components of Automobile EngineNiranjana KarandikarNoch keine Bewertungen

- The Device and Principle of Operation of A TwoDokument6 SeitenThe Device and Principle of Operation of A TwoЭлиза ЛатыповаNoch keine Bewertungen

- First Semester:-Course Title: Applied Thermodynamics TopicDokument8 SeitenFirst Semester:-Course Title: Applied Thermodynamics TopicHafeez AliNoch keine Bewertungen

- Two Stroke NXT Generation EngineDokument10 SeitenTwo Stroke NXT Generation EnginesaswatmahantyNoch keine Bewertungen

- Internal Combustion Engine ManualDokument7 SeitenInternal Combustion Engine Manualali sultan1Noch keine Bewertungen

- Car EngineDokument9 SeitenCar Engineayesha amjadNoch keine Bewertungen

- Presentation On Petrol Engine: Presented By-Mridul Mudai Sec-B4004 Roll No-B64Dokument12 SeitenPresentation On Petrol Engine: Presented By-Mridul Mudai Sec-B4004 Roll No-B64mridulmudai1991Noch keine Bewertungen

- 2 and 4 Stroke EngineDokument5 Seiten2 and 4 Stroke EnginehammadNoch keine Bewertungen

- Assignment-1: Types of EngineDokument14 SeitenAssignment-1: Types of EngineRaj SinghNoch keine Bewertungen

- Internal Combustion EngineDokument14 SeitenInternal Combustion EngineSamridhiNoch keine Bewertungen

- Unit 1 B Ic EnginesDokument47 SeitenUnit 1 B Ic Enginesoliyad teferiNoch keine Bewertungen

- Internal Combustion EngineDokument136 SeitenInternal Combustion Enginepreethu02Noch keine Bewertungen

- Diesel Power PlantDokument47 SeitenDiesel Power PlantRajput Divyapratap Singh Chauhan0% (1)

- Chapter 1 Automotive Basics: 1.1 Principal ComponentsDokument42 SeitenChapter 1 Automotive Basics: 1.1 Principal ComponentsJames JiangNoch keine Bewertungen

- Engine and TransmissionDokument26 SeitenEngine and TransmissionWFilmy STARNoch keine Bewertungen

- Vroom! How Does A Car Engine Work for KidsVon EverandVroom! How Does A Car Engine Work for KidsBewertung: 5 von 5 Sternen5/5 (1)

- Comparison of Diesel and Petrol EnginesVon EverandComparison of Diesel and Petrol EnginesBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Resume FinalDokument2 SeitenResume Finalapi-240922530Noch keine Bewertungen

- PksdsummaryDokument1 SeitePksdsummaryapi-240922530Noch keine Bewertungen

- PWSTDLDokument4 SeitenPWSTDLapi-240922530Noch keine Bewertungen

- Dairy Lactation Lesson Plan Standard 6Dokument1 SeiteDairy Lactation Lesson Plan Standard 6api-240922530Noch keine Bewertungen

- Tutortm LettterDokument1 SeiteTutortm Lettterapi-240922530Noch keine Bewertungen

- Standard 7 ReflectionDokument2 SeitenStandard 7 Reflectionapi-240922530Noch keine Bewertungen

- Lecture 3: Bode Plots: Prof. NiknejadDokument26 SeitenLecture 3: Bode Plots: Prof. Niknejadselaroth168Noch keine Bewertungen

- Mooring OperationsDokument5 SeitenMooring OperationsHerickson BerriosNoch keine Bewertungen

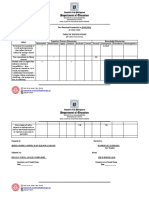

- TOS 1st QuarterDokument6 SeitenTOS 1st QuarterQuerisa Ingrid MortelNoch keine Bewertungen

- Student Ought To Possess To Produce Clean-Up and In-Between DrawingsDokument2 SeitenStudent Ought To Possess To Produce Clean-Up and In-Between Drawingscristian friasNoch keine Bewertungen

- 10 TazmahalDokument12 Seiten10 TazmahalSifat E Noor SahibaNoch keine Bewertungen

- Plastics Library 2016 enDokument32 SeitenPlastics Library 2016 enjoantanamal tanamaNoch keine Bewertungen

- Ricoh Aficio SP C420DN PARTS CATALOGDokument82 SeitenRicoh Aficio SP C420DN PARTS CATALOGYury Kobzar100% (2)

- LeaP Math G7 Week 8 Q3Dokument10 SeitenLeaP Math G7 Week 8 Q3Reymart PalaganasNoch keine Bewertungen

- Scriptcase MacrosDokument6 SeitenScriptcase MacrosMeliana WangNoch keine Bewertungen

- EvoFox Katana-X Mechanical Gaming Keyboard With Outemu Blue Switches Vivid Rainbow Lighting With 13 Preset Effects DedicatedDokument1 SeiteEvoFox Katana-X Mechanical Gaming Keyboard With Outemu Blue Switches Vivid Rainbow Lighting With 13 Preset Effects Dedicatedsaqibdar7051236186Noch keine Bewertungen

- Odt Article - Djo - Virtual Population Analysis Improves Orthopedic Implant Design 1 PDFDokument3 SeitenOdt Article - Djo - Virtual Population Analysis Improves Orthopedic Implant Design 1 PDFDragana RajicNoch keine Bewertungen

- American J Political Sci - 2023 - Eggers - Placebo Tests For Causal InferenceDokument16 SeitenAmerican J Political Sci - 2023 - Eggers - Placebo Tests For Causal Inferencemarta bernardiNoch keine Bewertungen

- Authority To TravelDokument39 SeitenAuthority To TraveljoraldNoch keine Bewertungen

- Network Tools and Protocols Lab 2: Introduction To Iperf3Dokument17 SeitenNetwork Tools and Protocols Lab 2: Introduction To Iperf3Fabio MenesesNoch keine Bewertungen

- Radiology PearlsDokument2 SeitenRadiology PearlsSalman Rashid100% (2)

- Nonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical PlaneDokument10 SeitenNonlinear Robust Control of High-Speed Supercavitating Vehicle in The Vertical Planesamsaptak ghoshNoch keine Bewertungen

- AAR Safety Fact SheetDokument2 SeitenAAR Safety Fact Sheetrogelio mezaNoch keine Bewertungen

- Prepared by M Suresh Kumar, Chief Manager Faculty, SBILD HYDERABADDokument29 SeitenPrepared by M Suresh Kumar, Chief Manager Faculty, SBILD HYDERABADBino JosephNoch keine Bewertungen

- Jesoc5 1 PDFDokument15 SeitenJesoc5 1 PDFfaisal3096Noch keine Bewertungen

- Reducing Motor Vehicle Crashes in B.C.Dokument260 SeitenReducing Motor Vehicle Crashes in B.C.Jeff NagelNoch keine Bewertungen

- Lab5.ipynb - ColaboratoryDokument8 SeitenLab5.ipynb - ColaboratoryMin YNoch keine Bewertungen

- Catalogo Repetidor EnergyAxisDokument2 SeitenCatalogo Repetidor EnergyAxisolguita22Noch keine Bewertungen

- The Eclectic (OLI) Paradigm of International Production - Past, Present and FutureDokument19 SeitenThe Eclectic (OLI) Paradigm of International Production - Past, Present and FutureJomit C PNoch keine Bewertungen

- Monorail Hoist SystemDokument17 SeitenMonorail Hoist SystemypatelsNoch keine Bewertungen

- Pulsating Heat Pipe ReportDokument65 SeitenPulsating Heat Pipe ReportIdul Azharul HoqueNoch keine Bewertungen

- AS Film Production Lesson.Dokument13 SeitenAS Film Production Lesson.MsCowanNoch keine Bewertungen

- Small Scale IndustriesDokument6 SeitenSmall Scale IndustriesMangesh KadamNoch keine Bewertungen

- Nickel 200 201 PDFDokument20 SeitenNickel 200 201 PDFwdavid81Noch keine Bewertungen

- Writing Capstone Research Project For Senior High School A Modified Guide ManualDokument9 SeitenWriting Capstone Research Project For Senior High School A Modified Guide ManualIOER International Multidisciplinary Research Journal ( IIMRJ)Noch keine Bewertungen

- Case Study-BPPVDokument97 SeitenCase Study-BPPVArbie Jacinto83% (6)