Beruflich Dokumente

Kultur Dokumente

B014 M01 en 02

Hochgeladen von

Sanjeev Viswambharan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

25 Ansichten14 SeitenExtraction of asphalt mixture

Originaltitel

B014.M01.EN.02

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenExtraction of asphalt mixture

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

25 Ansichten14 SeitenB014 M01 en 02

Hochgeladen von

Sanjeev ViswambharanExtraction of asphalt mixture

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 14

I NSTRUCTI ON MANUAL

CONTINUOUS FLOW FILTER-LESS CENTRIFUGE EXTRACTOR

MANUAL CODE

B014

Do not attempt to operate this equipment before reading

and comprehending the manual in all its parts

USERS: MACHI NE MANUFACTURERS | DRAUGHTSMEN | OPERATORS | MAINTENANCE WORKERS | ANY OTHERS

REV. DESCRIZIONE REDATTO/GESTITO APPROVATO COD. IDENT. PAGINE DATA EMIS.

02 Manuale Istruzioni Ufficio Tecnico Resp. Tecnico B014.M01.EN.02 14 01/2007

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 2/14 01/2007

GENERAL INDEX

Chapter 1 GENERAL INFORMATION

1.1 GENERAL FEATURES

1.2 IDENTIFICATION

1.3 APPLICATIONS

1.4 STRUCTURE AND OPERATING OF THE MACHINE

Chapter 2 SAFETY INFORMATION

2.1 GENERAL SAFETY STANDARDS

2.2 SAFETY SYSTEMS

2.3 DANGEROUS PARTS AND RESIDUAL RISKS

2.4 NOISE

Chapter 3 INSTALLATION

3.1 LIFTING

3.2 UNPACKING

3.3 INSTALLATION

3.4 ELECTRIC CONNECTIONS

Chapter 4 MACHINE FEATURES

4.1 DIMENSIONS AND MASS OF THE APPLIANCE

Chapter 5 OPERATOR INTERFACE

5.1 CONTROLS AND MESSAGES

Chapter 6 USE

6.1 WARNINGS

6.2 SWITCHING ON OF THE APPLIANCE

6.3 TOOLING UP

6.4 SPECIMENS POSITIONING

6.5 TEST STARTING

6.6 EMERGENCY STOP

6.7 RESTARTING AFTER AN EMERGENCY STOP

6.8 SWITCHING OFF

6.9 FIRST TRIAL SWITCHING ON

6.10 EXAMPLE OF OPERATING

Chapter 7 MAINTENANCE

7.1 ROUTINE MAINTENANCE

7.2 SPECIAL MAINTENANCE

7.3 PERIODICAL INSPECTIONS AND OPERATIONS

Chapter 8 DIAGNOSIS

8.1 DIAGNOSIS

Chapter 9 SCRAPPING

9.1 SETTING ASIDE

9.2 SCRAPPING

ENCLOSURES

A GENERAL VIEW OF THE APPLIANCE

ELECTRICAL DIAGRAMS

S VIEW OF THE ELECTRIC DIAGRAM

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 3/14 01/2007

3

Chapter 1 GENERAL INFORMATION

1.1 GENERAL FEATURES

This manual id addressed to the carrier, the installer, the user, the maintenance operator, the scrapping

operator.

Please read it carefully because it informs you about the operating of the machine in safety conditions.

This manual has to be considered a part of the product and concerns only the machine it is delivered with.

Keep the manual in order during the whole life of the appliance to consult it for any needs.

In case of sale, the manual and its enclosures should be given together with the machine.

The manufacturer assumes no liability for any damages caused by a misuse of the machine.

The manufacturer has the right to modify this technical literature as well as the machines this refers to

without any previous notice.

Messages meaning:

ATTENTION It shows the procedures that can damage seriously the machine if they are not

followed carefully.

DANGER It shows the procedures that can be dangerous to the operator if they are not

followed carefully.

1.2 IDENTIFICATION

MANUFACTURER IDENTIFICATION: See the cover page

MACHINE IDENTIFICATION: See the plate on the machine where the complete

identification data and the electrical features are to be found.

1.3 APPLICATIONS

The centrifuge extractor has been designed to separate the filler from the bitumen or other mixtures having

sediments in suspension (cement, soil and clay) using the method of continuous flow centrifuge extraction.

This appliance is made for the aim, which it has been conceived for.

Any other uses are not allowed.

ATTENTION The appliance is made to work only with non-flammable and non-explosion solvents.

The use of the appliance with materials and solvents that are flammable and/or explosion

type is a source of danger and risk of fire or explosion.

The machine can be used only and exclusively with non-flammable and non-explosion

solvents.

The manufacturer assumes no liability for any damages to people and things due to a

lack of observance of these instructions.

ATTENTION The instructions given in this operating manual are only made for the right use of the

appliance.

To carry out the test in the right way, the user must refer to the specific standards in

force for the test itself.

1.4 STRUCTURE AND OPERATING OF THE MACHINE

The continuous flow centrifuge extractor is made by a metal frame (A1 and A2) holding the container of the

rotating group (A9) and its propeller (A14). The feeding of the centrifuge extractor is made through a funnel

(A4) in cast aluminium; the drain is made through a collector (A5) and its drain pipe (A7).

The appliance is delivered complete with an aluminium beaker and two sieves having a mesh opening of

0,149 and 0.074 mm. As you can see from the description this centrifuge extractor is a continuous flow

extractor; this means that quite a big quantity of solution can be centrifuged in order to have a maximum of

100 g filler kept into the test tube.

The solution that has to be centrifuged and having solid parts to be separated in suspension (filler) is

transferred into the beaker of the centrifuge extractor when this is already rotating through the funnel (A4).

Thanks to the centrifuge force given by the beaker rotation at 11500 revolutions per minute, the solution

staying on the bottom of the beaker (A6) goes up along the walls and is expelled outside against the collector

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 4/14 01/2007

4

walls (A5). The collector has an inclined base and drains the liquid through the pipe (A7); the liquid is

collected in a tray.

During this operation the parts is suspension will adhere to the inside walls of the beaker and we shall have

only the liquid coming out. The suspension particles that are eventually taken by the liquid are kept by the

inside upper edge of the beaker.

The centrifuge operation is finished when no more liquid is coming out from the drainpipe.

Chapter 2 SAFETY INFORMATION

2.1 GENERAL SAFETY STANDARDS

The use, lifting, installation, maintenance and scrapping of the machine are allowed only to

qualified staff. Qualified staffs are composed by people who are authorised by the safety responsible to

do any activities due to their experience and acknowledgement of the operating of the machine and of the

standards, rules and actions.

The user must be carefully taught about the operating of the machine to avoid any misuse of it and about

the safety devices, which the machine could be eventually equipped with. The safety devices will have to

be kept always assembled and to be daily checked.

The manufacturers offer training and assume no liability for any damages due to a misuse of the machine

by an unskilled staff.

The manufacturer recommends following carefully the instructions and procedures of the operating

manual and the safety standards concerning the safety devices and the general rules of the work

environment.

Verify the accordance of the machine to the standards in force in the State where the machine has to be

installed.

The operating manual must be carefully read by the safety responsible, by the operators and maintenance

engineers. It must always be kept near the machine in order to be able to read it any times it will be

necessary.

Any tampering or modifications of the machine (electric, mechanical etc.) that are not allowed by a written

agreement of the manufacturer must be considered as not permitted and the manufacturer will not accept

to be charged for any damages.

The removal or the tampering of the safety devices will be an infringement to the EEC Safety Standards.

The manufacturer assumes no liability for any damages.

The machine has to be installed in places safe from fire and explosions.

We do recommend using only original spare parts and accessories; on the contrary the manufacturer

assumes no liability.

Be careful that any dangerous situations wont happen during the working; stop immediately the machine

in the event that it will not work properly and ask the manufacturer or the Authorised Service Staff of the

dealer at once.

The manufacturer assumes no liability for any damages caused to people, things and animals in case the

general safety standards or if the instructions of this manual are not followed.

2.2 SAFETY SYSTEMS

MEANING: Safety devices are all the safety measures using specific technical equipment (guards, cages

etc.) to protect the operator from any danger that couldnt be avoided when the appliance was planned.

DANGER The removal of the safety devices or any tampering of the machine could cause risks

to the operator or to any other people.

The manufacturer assumes no liability for any damages to people, things or animals due to the tampering of

the safety devices.

ACTIVE SAFETY DEVICES

All those devices avoiding or reducing the risks for the operators are active safety devices. These devices

require an active and aware intervention to be operated.

The switchboard has a main switch that can also be used as an emergency switch.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 5/14 01/2007

5

2.3 DANGEROUS PARTS AND RESIDUAL RISK

The dangerous place is the space inside and around the machine where the operator could be wounded or

damaged.

During some procedures the operator could face some risks of danger.

The risks can be eliminated following carefully the procedures written in this manual and using suitable safety

devices.

ATTENTION In case the Manufacturer does not do the machine installation, employ only skilled

operators particularly trained for the lifting of heavy machinery.

GENERAL INFO.

Before starting the standard use of the equipment, ensure that all the components are in good

working conditions check there are no defective or damaged parts. If necessary repair or replace

any damaged part.

Pay attention to the risk of electric shocks both for direct or indirect contact, due to unforeseen failure to

the electric system.

Do not subject the equipment to violent shocks.

Do not expose the equipment to fire, extreme temperature or weld splatters.

Avoid corrosive substances to come in touch with the equipment.

Never wash the appliance using water sprays.

DURING THE USE

In order to grant the max. safety levels for the operator, it is recommended not to touch any moving

components during the test execution and always use the proper safety means.

During the test execution always pay attention to the possibility of hands, fingers or body squeezing,

cutting or trapping caused by the moving parts of the container.

Do not wear large clothes, ties, watches, rings or others, which could entangle into the moving

parts of the appliance.

Never remove the funnel (A4) during the working of the centrifuge extractor.

LIFTING

During the lifting take care that the machine is conveniently held and secured and that it cannot slide.

Do not stand in a direct line with the application of force. Do not allow people entrance under loads that

are no conveniently supported by mechanical means.

RISK OR DANGER FORESEEN SAFETY MEASURE

FINGER OR HANDS SQUEEZE REINFORCED GLOVES

ABRASIONS CUTTINGS REINFORCED GLOVES

DAMAGES TO THE EYES CAUSED BY MATERIAL EJECTIONS GLASSES

The manufacturer assumes no liability for any damages to people and things due to a lack of observance of

the instructions and the use of the safety devices. (See laws against the accidents in force)

2.4 NOISE

The indicated levels of noise are not necessarily safety levels for the operator.

The exposure levels of the operator are obviously related to the emission levels of the appliance, but other

factors influence the exposure levels as the time of exposure, the environment, and other appliances installed

near to the appliance etc.

The exposure levels permit to value the damages that could be caused by the noise.

Acoustical pressure level equivalent Laeq at 1 mt. distance 62 dB(A)

Acoustical power emitted by the appliance LWA 67 dB(A)

Standard above data are referred EN ISO 3746

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 6/14 01/2007

6

DANGER

The continuous use of the machine together with other noisy appliances could cause

a high level of exposure to the noise.

If the daily exposure of the operator is equal or higher than 85 dB(A), Safety Devices

as headphone are suggested to be worn.

If the daily exposure is equal or higher than 90 dB(A), the use of the Safety Device is

compulsory.

For further information consult the standards of the country where the machine has

been installed.

Chapter 3 INSTALLATION

DANGER Consult DANGEROUS PARTS AND RESIDUAL RISKS before proceeding

3.1 LIFTING

The operating instructions must be respected during the moving of the appliance and particularly in the

following phases:

The lifting and the storing

The first installation

The further installations

The machine is usually packed in a wooden case or in a carton that allow the easy moving of the same.

The machine must be moved by a forklift truck suitable for the weight indicated on the plate on the machine.

The moving of cases with lifting devices must be made with all cautions required and following the indications

given on the packing. Never use chains to lift the cases.

ATTENTION The moving of cases with lifting devices must be made with all cautions required and

following the indications given on the packing. Never use chains to lift the cases. Pay

attention to avoid impacts and turnovers

ATTENTION Protect the machine from the atmospheric agents. Water and humidity could oxidise

it, damaging it seriously.

3.2 UNPACKING

After removing the package, check that any parts of the machine are not damaged. In case of doubt, DO

NOT USE THE MACHINE and ask the manufacturer.

DANGER The materials used for the package (plastic, polystyrene, screws, nails, wood etc.)

have to be kept far from children. They must be thrown away in a proper collection

centre.

ATTENTION Pay attention to avoid impacts and turnovers.

ATTENTION Before throwing away the package, pay attention that any accessory, manuals,

documents, spare parts are not inside.

3.3 INSTALLATION

The machine has to be placed in an environment suitable for the aim it has been conceived for (laboratory

protected by any atmospheric agents). Skilled operator must do the installation.

ALLOWED TEMPERATURE from + 5C to + 40C

ALLOWED HUMIDITY from 30% to 95%

O.S.L. MAXIMUM HEIGHT 1000 m

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 7/14 01/2007

7

GENERAL RECOMMENDATIONS

The machine must be installed so that it is free from each side in order to be able to carry out easily the

maintenance operations

No authorised people and no dangerous objects must be near the machine.

The machine must be placed on a desk in order to be able to work at a proper height for the user.

The machine must be placed in a place properly aired in order not to accumulate any noxious gas.

3.4 ELECTRIC CONNECTIONS

DANGER Skilled operators must arrange the electric connections.

DANGER Before connecting, see the attached electric diagram and the plate on the machine

for the information about the voltage, the frequency, etc.

DANGER Connect the ground by the terminal PE (yellow-green) before making any other

connections.

DANGER Apply a knife switch at the top of the connecting cable of the machine to the power

system.

The knife switch must be combined with a safety device against the overload with a

differential switch (safety switch).

The technical features of the safety device must be in accordance with the standards

in force in the country where the machine has been installed and following the

machine features.

ELECTRIC TOLERANCES:

Real voltage 10 % of the nominal one

Frequency: 1 % of the nominal one in a continuous way

2 % of the nominal one for a short period

The harmonic distortion of the sum from the second to the fifth harmonics not more than 10% of the total

voltage as a real value between the conductors. A further distortion of 2% is accepted for the sum from

the sixth to the thirtieth harmonics of the real total value between the conductors.

With reference to the tension unbalance of the three-phase voltage, the inverted sequence component

and the zero sequence component must not be more than 2% of the direct sequence component of the

voltage

The voltage pulses must not last more than 1,5 ms with an up/down time between 500 ms e 500 s and a

peak value not higher than 200% of the real value of the nominal tension.

The electric feeding must not be interrupted or zeroed for more than 3 ms. Between two interruptions it

must not take more than 1 s.

The interruptions must not overcome 20% of the tension peak for more than one cycle. Between two

interruptions it must not take more than 1 s.

Chapter 4 MACHINE FEATURES

4.1 DIMENSIONS AND MASS OF THE APPLIANCE

B014

LENGTH 350 mm

WIDTH 600 mm

HEIGHT 720 mm

WEIGHT 60 kg

REVOLUTION SPEED 11000 rev. per min.

CENTRIFUGING STRENGTH 4700 G

EXTRACTION CAPACITY 550 ml/min.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 8/14 01/2007

8

Chapter 5 OPERATOR INTERFACE

5.1 CONTROLS AND MESSAGES

A1 FRAME

The frame holds the container of rotating system and the motor.

A2 PROTECTION CASE

Together with the frame it is the main structure of the centrifuge extractor.

A3 BEARINGS

The bearings hold the rotating basket.

A4 FUNNEL

The funnel is placed over the receiver with special release locks.

Once the solution that has to be centrifuged has gone through the sieves, it is hold inside the funnel.

The solution stays into the funnel up to the moment when the tap is opened. This allows the test to be

started.

A5 COLLECTOR

It allows collecting the liquid coming out from the aluminium beaker thanks to the centrifuge energy.

The collector has the bottom inclined in order to allow the liquid coming out from the drainpipe.

A6 ALUMINIUM BEAKER

It allows collecting the solution that has solid parts in suspension to be separated and allows its centrifuging.

A7 DRAIN PIPE

It allows the liquid coming out from the collector.

A8 ANTI-VIBRATION FEET

They allow the appliance being stable on the surface it is installed.

A9 CONTAINER OF THE ROTATING SYSTEM

It contains the shaft of the rotating basket.

A10 ROTATING BASKET

It contains the aluminium beaker.

A11 TAP

The opening of the tap allows the solvent coming out from the tunnel to the beaker of the centrifuge extractor.

A12 FLAT BELT

It allows transmitting the movement from the electric motor to the basket multiplying the revolutions.

A13 MOTOR BLOCKING STIRRUP

They are installed in order to block the motor in its position after having put in tension the belt.

A14 ELECTRIC MOTOR

It allows the rotation of the basket.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 9/14 01/2007

9

Chapter 6 USE

DANGER Consult DANGEROUS PARTS AND RESIDUAL RISKS before proceeding.

6.1 WARNINGS

Before starting the normal use of the equipment it is recommended to verify that it is in good working

conditions with no defective or damaged parts.

If necessary proceed with the required maintenance operations

6.2 SWITCHING ON OF THE APPLIANCE

Turn the main switch on I.

6.3 TOOLING UP

Here under we describe some standard procedures allowing even to an operator without a wide experience

to tool up properly the appliance.

POSITIONING OF THE BEAKER

Remove the loading funnel by opening the release locks, introduce the beaker inside the rotating basket by

centring it properly in order not to have any blocking; to make this operation easy put some grease on the

outside surface of the beaker.

POSITIONING OF THE LOADING FUNNEL

Place the tunnel over the collector and block it using the release locks.

POSITIONING OF THE SIEVES

Place the sieves over the loading funnel and block them using the release locks.

ATTENTION Place the appliance on a flat surface properly levelled.

ATTENTION Before arranging any tooling up of the appliance pay attention and check that the

main switch is on position 0.

ATTENTION Before proceeding with the normal use of the appliance check that all the parts are

properly tooled up and are suitable for the test that has to be effected.

6.4 SPECIMENS POSITIONING

The positioning of the material that must be tested can be made in many different ways that are depending

from the kind of test that must be arranged. To arrange a right specimen preparation and positioning we

kindly ask to check the standards referring to the test that must be made.

ATTENTION The continuous flow centrifuge allows centrifuging quite a big quantity of solution up

to a maximum value of 100 grams of filler retained by the specimen. The only

operation is the weighing of the solution before starting the test.

6.5 TEST STARTING

Put the main switch on I and wait some seconds so that the appliance reaches the normal rotating speed.

6.6 EMERGENCY STOP

In case of emergency the test execution can be stopped immediately by positioning the main switch on

position 0.

ATTENTION Its always worth reminding that the test interruption could give wrong results of the

centrifuge test.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 10/14 01/2007

10

6.7 RESTARTING AFTER AN EMERGENCY STOP

DANGER Before starting the appliance again, find and eliminate the problem, which caused the

need for an emergency stop.

To start again the appliance just turn the main switch on position I, this will start again the normal working of

the centrifuge extractor.

6.8 SWITCHING OFF

Once the cycle of tests is finished follow the instructions given here below to turn off the appliance:

1. Turn off the appliance by turning the main switch on position 0 and wait for some seconds in order

to have the machine completely stopped.

2. Lift the load funnel (A4) remove the beaker (A6) up, paying attention not to misshape its upper part.

6.9 FIRST TRIAL SWITCHING ON

Before beginning the standard use of this machine, check its perfect working conditions by performing at

least a complete trial cycle according to the instructions given up to this point.

In case of problems during this test cycle, see Chapter DIAGNOSIS .

If neither the instructions given in this manual are not able to solve the problem, please contact our After Sale

Service.

6.10 EXAMPLE OF OPERATING

DANGER Proceed as per following example of operating only after having entirely read and

understood all the indications given in this manual.

Here under we describe some standard procedures allowing even to an operator without a wide experience

to complete a correct centrifuging operation:

1. Tool up the centrifuge extractor properly in all its parts as explained in the charter TOOLING UP of

this manual.

2. Ensure that the beaker (A6) is properly introduced in the rotating basket (A10).

3. Close the tap (A11) and poor the solution to be centrifuged over the sieves of the load funnel (A4).

4. Turn the main switch on I and wait for some seconds in order to have the appliance turning at the

normal working revolution speed.

5. Open slowly the tap (A11) in order to let the solution drop into the beaker (A6).

DANGER

The correct opening of the stopcock, have to be studied considerino

the kind of solvent used and the quality of bitumen mixture contained;

this matter is really important, because just in case you over-fill the

container, this will overflow, get dirty and damage all internal

mechanism of the machine.

We suggest to make some practical trials before using the machine, in order

to know in advance the correct opening of the stopcock.

1. Collect in a tray the liquid that has been centrifuged and that has come out from the drain pipe (A7).

2. Let the centrifuge extractor work for some more minutes after the test is finished in order to let

evaporate the traces of solution that may be inside the beaker. To obtain a drain filler without having

to introduce the beaker in a drying oven leave the appliance working for some minutes.

3. Once the centrifuge operation is finished turn the handle of the switch on 0 and wait for some

seconds in order to have the machine completely stopped.

4. Lift the load funnel (A4) and remove the beaker (A6) paying attention not to misshape its upper part.

5. Remove the filler from the beaker (A6) by means of a flexible spatula or with something similar

paying attention not to damage the internal walls and the internal border that is on the upper part of

the beaker.

6. Once the filler has been totally removed wash the loading and collecting accessories using clean

solvent.

For other tests pls. follow above procedure.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 11/14 01/2007

11

Chapter 7 MAINTENANCE

DANGER Consult "DANGEROUS PARTS AND RESIDUAL RISKS before proceeding.

DANGER All the maintenance operations must be carried out with the machine turned off and

unplugged from the knife switch.

DANGER Skilled operators instructed about the purposes the machine is made for must carry

any kind of maintenance operations concerning the components of the machine and

of the electric components, even those that may seem very simple.

DANGER Only original spare parts are allowed. The Manufacturer assumes no liability in the

event that non original parts are used.

7.1 ROUTINE MAINTENANCE

In order to maintain good working of the machine for a long time, clean periodically all the parts and oil the

parts that are not painted.

After each test, check that all the parts of the appliance are not damaged. In case something is damaged get

in touch with the After Sales Service.

Ensure that all procedures described in the Chapter PERIODICAL INSPECTIONS and PERIODICAL

OPERATIONS are correctly and punctually executed. This care will help preventing failures and dysfunctions.

7.2 SPECIAL MAINTENANCE

In case of special maintenance operations (repairs, replacement of parts and any other operation not

described in this manual) ask directly to the manufacturer.

7.3 PERIODICAL INSPECTIONS AND OPERATIONS

Ensure that all procedures described in this Chapter are correctly and punctually executed. This care will help

preventing failures and dysfunctions.

OPERATION CONTROL OF THE BELT

PROCEDURE Check periodically the proper tension of the belt (A12) acting on

the screws closing the motor blocking stirrups (A13) and moving

left the motor slide until you reach the proper tension that

corresponds to about 10 kg, made in the centre of the

conducting side. In case the resetting of the proper tension must

be made too frequently, replace the belt.

FREQUENCY EVERY SIC MONTHS OF USE

OPERATION CLEANING OF THE BEAKER

PROCEDURE The beaker must be cleaned from any rest of filler.

FREQUENCY AFTER EVERY TEST

OPERATION REPLACEMENT OF THE GASKETS OF THE COVER AND OF

THE BEAKER SIT

PROCEDURE Remove the used gasket using a fine screwdriver, clean its seat

and install a new gasket.

The gaskets must be made in VITON.

FREQUENCY ONLY WHEN THE GASKETS ARE USED AND START

HAVING SOME CRACKS.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 12/14 01/2007

12

Chapter 8 DIAGNOSIS

8.1 DIAGNOSIS

Some easy to solve and simple problem, which can happen during the working of the appliance, are

introduced in this chapter.

ATTENTION All maintenance, checking, control and repairing operations of each part of the

machine or of the electric system, must be carried out by skilled operators instructed

about the functions and working procedures of the appliance.

PROBLEM POSSIBLE CAUSE CURE

No supply Check that the plug is properly plugged to

the main.

After the activation of the Main switch, the

centrifuge doesnt start

Damage to the

motor

Contact the After Sale Service

Damage to the

electric installation

Contact the After Sale Service

When the shaft is moving the bearings

are noisy

Bearings worn out Contact the After Sale Service for the

proper replacement of the bearings.

ATTENTION Contact the After Sale Service for any other problem not listed in the above table or

in case the problem continues after the operator intervention following the modes

given in the above table.

Chapter 9 SCRAPPING

9.1 SETTING ASIDE

In case of setting aside for a long time it is necessary to disconnect the electric feeding.

Execute all the maintenance operations.

Lubricate with some oil the parts not painted of the appliance. Its recommended to cover the machine

against the dust.

9.2 SCRAPPING

When the machine is not used anymore, it is recommended:

Disconnect the feeding cable.

Cover/destroy all the parts which may be dangerous as cutting, projecting or sharpened ones.

Disassemble the machine and scrap it as per the actual laws.

Recycling notice for the disposal of electrical and electronical devices

This symbol, placed on the device or on the package and/or on the documentation, suggest that

the device shouldnt be dispose together with other home garbage at the end of its life cycle.

To avoid further environment, or health-care damages, caused by the unsuitable disposal of

garbage, we kindly recommend the user to separate this device from other different types of

garbages and to recycle it in a responsible way to avoid the arguable reuse of material

resources. Indeed users must take care at the disposal of the equipment that have to be discarded, taking

them away to the next recycling site for the appropriate recycling treatment for electrical and electronical

devices. Gathering and Recycling deplete devices allow the preservation of natural resources and grant for

them the adequate treatment respecting health and environment.

For further information about your local recycling site please contact your local city hall or city waste treatment

department. The developer, as producer of electrical and electronical devices, will provide to finance the

recycling and treatment services for deplete devices that will come back through these recycling site

accordingly the local statement.

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 13/14 01/2007

13

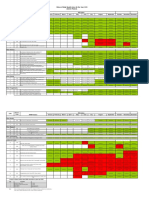

Enclosure A GENERAL VIEW OF THE APPLIANCE

Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

02 Manuale Istruzioni Ufficio Tecnico Ufficio Tecnico B014.M01.EN.02 14/14 01/2007

14

DIAGRAM VIEW OF THE ELECTRIC DIAGRAM

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Saudi Arabia Releases 9 New Environmental Laws - EHS JournalDokument7 SeitenSaudi Arabia Releases 9 New Environmental Laws - EHS JournalhrenamNoch keine Bewertungen

- Solid Waste Management Plan and Status of The Municipality of Rosario CaviteDokument14 SeitenSolid Waste Management Plan and Status of The Municipality of Rosario CaviteLauren RefugioNoch keine Bewertungen

- Asphalt Facts To RememberDokument12 SeitenAsphalt Facts To RememberSanjeev ViswambharanNoch keine Bewertungen

- Sedimentary Rocks in The United Arab EmiDokument92 SeitenSedimentary Rocks in The United Arab EmiSanjeev ViswambharanNoch keine Bewertungen

- Bitumen ProductionDokument5 SeitenBitumen ProductionSanjeev ViswambharanNoch keine Bewertungen

- Part 6 - Asphalt TestingDokument36 SeitenPart 6 - Asphalt TestingSanjeev ViswambharanNoch keine Bewertungen

- Bleeding Road Pavement PDFDokument108 SeitenBleeding Road Pavement PDFmustafurade1Noch keine Bewertungen

- Centrifuge Extractor B011: Do Not Try To Operate The Appliance Before Reading and Learning This Manual in All Its PartsDokument18 SeitenCentrifuge Extractor B011: Do Not Try To Operate The Appliance Before Reading and Learning This Manual in All Its PartsSanjeev ViswambharanNoch keine Bewertungen

- Asphalt Mix Design - Superpave FundamentalsDokument27 SeitenAsphalt Mix Design - Superpave FundamentalsJohn Tejada IIINoch keine Bewertungen

- MS For Sub BaseDokument7 SeitenMS For Sub BaseSanjeev Viswambharan100% (1)

- PH Values of Water Completely ExplainedDokument2 SeitenPH Values of Water Completely ExplainedSanjeev Viswambharan100% (1)

- 650 554Dokument17 Seiten650 554Hamad AhmadNoch keine Bewertungen

- Heavy Combination VehiclesDokument18 SeitenHeavy Combination VehiclesSanjeev ViswambharanNoch keine Bewertungen

- Ohsas 18001Dokument12 SeitenOhsas 18001Sanjeev ViswambharanNoch keine Bewertungen

- Question and AnswerDokument5 SeitenQuestion and AnswerSanjeev ViswambharanNoch keine Bewertungen

- Volume 3 - Sec 4Dokument90 SeitenVolume 3 - Sec 4Sanjeev ViswambharanNoch keine Bewertungen

- English - FISPQ - Mobilith SHC 1000 SpecialDokument11 SeitenEnglish - FISPQ - Mobilith SHC 1000 SpecialMagnoNoch keine Bewertungen

- Recyclability Index For Automobiles - Toxicity IndexDokument90 SeitenRecyclability Index For Automobiles - Toxicity IndexFranke Yogesh FNoch keine Bewertungen

- Green ManufacturingDokument21 SeitenGreen Manufacturingpankaj kumar100% (1)

- List of Sanitary FixturesDokument8 SeitenList of Sanitary Fixturesnaam9Noch keine Bewertungen

- Reducing Plastic Waste in A Microbiology LaboratoryDokument16 SeitenReducing Plastic Waste in A Microbiology LaboratorybrodyNoch keine Bewertungen

- Bio Medical Waste ManagementDokument22 SeitenBio Medical Waste ManagementdranukapoorNoch keine Bewertungen

- SL1000 Getting Started Guide (Issue1.0) For GEDokument46 SeitenSL1000 Getting Started Guide (Issue1.0) For GETeyob RayosNoch keine Bewertungen

- Sulabh Public Toilets & Bath Complexes: Sulabh International Social Service OrganisationDokument32 SeitenSulabh Public Toilets & Bath Complexes: Sulabh International Social Service OrganisationSanjt BhoiNoch keine Bewertungen

- Computer and Electronic Equipment RecyclingDokument4 SeitenComputer and Electronic Equipment RecyclingMellaniNoch keine Bewertungen

- Waste Water Report Field Visit 3Dokument11 SeitenWaste Water Report Field Visit 3Brian LeeNoch keine Bewertungen

- AMCON INC. Global Installation Record Sweage PDFDokument9 SeitenAMCON INC. Global Installation Record Sweage PDFJulio TovarNoch keine Bewertungen

- Controlled DemolitionDokument3 SeitenControlled DemolitionJim FrancoNoch keine Bewertungen

- Safety Data Sheet Clean & SmoothDokument7 SeitenSafety Data Sheet Clean & SmoothSarah Jane BroñolaNoch keine Bewertungen

- 03 Bgpms DCF 2016Dokument36 Seiten03 Bgpms DCF 2016Mary Angelie Ferreras MapiliNoch keine Bewertungen

- Water Quality Index (WQI) For The Year, 2019 PDFDokument2 SeitenWater Quality Index (WQI) For The Year, 2019 PDFCreate IInnocateNoch keine Bewertungen

- B SC EVS PDFDokument35 SeitenB SC EVS PDFAfroz alamNoch keine Bewertungen

- HSE-MS-PR-03 - Waste Management Procedure - Rev 01Dokument17 SeitenHSE-MS-PR-03 - Waste Management Procedure - Rev 01Mohammad Mokhtarul HaqueNoch keine Bewertungen

- Landfill Privatization ReportDokument17 SeitenLandfill Privatization ReportDavid LombardoNoch keine Bewertungen

- Adrianus Van Haandel (Author) Book List - IsBNDokument2 SeitenAdrianus Van Haandel (Author) Book List - IsBNksbbs100% (1)

- Literature Review of Worms in Waste Management: Volume 1Dokument52 SeitenLiterature Review of Worms in Waste Management: Volume 1Pennsylvania Association for Sustainable Agriculture100% (5)

- Sip N8503280VDokument4 SeitenSip N8503280VparathasiNoch keine Bewertungen

- Implementation Review: Submission DetailsDokument5 SeitenImplementation Review: Submission DetailsLedya FobesNoch keine Bewertungen

- 12 Design - For - EnvironmentDokument32 Seiten12 Design - For - EnvironmentAriq AshshiddiqNoch keine Bewertungen

- Correlation Between Sludge Volume Index (SVI) and Mixed Liquor Suspended Solids (MLSS)Dokument2 SeitenCorrelation Between Sludge Volume Index (SVI) and Mixed Liquor Suspended Solids (MLSS)Antony ThanosNoch keine Bewertungen

- Roduction Anagement: Unit 9 - Waste ManagementDokument28 SeitenRoduction Anagement: Unit 9 - Waste Managementlamao123Noch keine Bewertungen

- Ord - 2006-041 Waste DisposalDokument4 SeitenOrd - 2006-041 Waste DisposalGenevie Manlabao DaguiNoch keine Bewertungen

- PT - Science 5 - Q1Dokument5 SeitenPT - Science 5 - Q1AlfaNoch keine Bewertungen

- Silvo - Ficha Tecnica 1447813238Dokument11 SeitenSilvo - Ficha Tecnica 1447813238Papaleguas gamesNoch keine Bewertungen