Beruflich Dokumente

Kultur Dokumente

NCAC G41S W-Beam Height Report Final 120407

Hochgeladen von

aktc0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

100 Ansichten32 SeitenNCAC G41S W-beam Height Report Final 120407

Originaltitel

NCAC G41S W-beam Height Report Final 120407

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenNCAC G41S W-beam Height Report Final 120407

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

100 Ansichten32 SeitenNCAC G41S W-Beam Height Report Final 120407

Hochgeladen von

aktcNCAC G41S W-beam Height Report Final 120407

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 32

EVALUATION OF RAIL HEIGHT EFFECTS ON THE

SAFETY PERFORMANCE OF W-BEAM BARRIERS

by

Dhafer Marzougui

Pradeep Mohan

and

Steve Kan

NCAC 2007-R-003

Sponsored by

Federal Highway Administration

U.S. Department of Transportation

Contract No. DTFH61-02-X-00076

NOVEMBER 2007

DISCLAIMER

The contents of this report reflect the views of the authors who are solely responsible for the facts and

accuracy of the data, and the opinions, findings and conclusions presented herein. The contents do not

necessarily reflect the official views or policies of the George Washington University, FHWA/NHTSA

National Crash Analysis Center, or Federal Highway Administration. This report does not constitute a

standard, specification, or regulation. In addition, the above listed agencies assume no liability for its

contents or use thereof. The names of specific products or manufacturers listed herein do not imply

endorsement of those products or manufacturers.

KEYWORDS

W-Beam Guardrail, Roadside Hardware, Finite Element Analysis, Crash Simulation, Model Validation,

Crash Testing, Highway Safety

ACKNOWLEDGEMENTS

This study was sponsored by The Federal Highway Administration.

Technical Report Documentation Page

1. Report No.

2. Government Accession No.

3. Recipient's Catalog No.

5. Report Date

Draft - J uly 2006

Final - November 2007

4. Title and Subtitle

EVALUATION OF RAIL HEIGHT EFFECTS ON THE

SAFETY PERFORMANCE OF W-BEAM BARRIERS

6. Performing Organization Code

7. Author(s)

Dhafer Marzougui, Pradeep Mohan, and Steve Kan

8. Performing Organization Report No.

NCAC 2007-R-004

10. Work Unit No. (TRAIS)

9. Performing Organization Name and Address

FHWA/NHTSA National Crash Analysis Center

The George Washington University

Ashburn, VA 20147

11. Contract or Grant No.

DTFH61-02-X-00076

13. Type of Report and Period Covered

Summary Report

12. Sponsoring Agency Name and Address

Office of Safety and Traffic Operation R&D

Federal Highway Administration

U.S. Department of Transportation

6300 Georgetown Pike

McLean, VA 22101-2296

14. Sponsoring Agency Code

15. Supplementary Notes

Agreement Officers Technical Representative (AOTR) Kenneth Opiela

16. Abstract

The objective of this study is to investigate the effect of rail height on the safety performance of

G4(1S) w-beam guardrail systems. The study involved three steps. In the first step, a detailed finite

element model of the G4(1S) w-beam guardrail system was adapted from a model previously

developed. The model incorporated the details of the rail, connections, the post, the blockout, and the

soil in which the post was embedded. To validate the model of the w-beam guardrail system, a model

of the test setup of a w-beam system subjected to a full-scale crash test, was created. Simulation runs

were made using this model to identify any deficiencies in the coding and to generate data for

comparison to the full-scale crash test data generated by others. The results of the simulation and the

full-scale tests for a crash event involving a standard height w-beam guardrail hit by a Chevy C2500

pick-up truck (2000kg) at 100 k/hr and 25 degrees were similar indicating that the model provided an

accurate representation of the crash event.

In the second step of the study, the validated model served as the basis for four additional models

of the G4(1S) guardrail to reflect varying rail heights. In two of the four models, the rails were raised

40 and 75 mm (1.5 and 3 inches). In the other two models, the rails were lowered 40 and 75 mm.

Simulations with these four new models were carried out and compared to the initial simulation for a

standard height guardrail to evaluate the effect of rail height on safety performance. The simulation

results indicated that the effectiveness of the barrier to redirect a vehicle is compromised when the rail

height is lower than recommended, particularly for larger vehicles like the pick-up truck.

The third step of the study consisted of performing full-scale crash tests with the guardrail at

standard height and 60 mm (2.5 inches) lower for a similar crash event. The data from the crash tests

validated the simulation results.

17. Key Word

W-Beam Guardrail, Roadside Hardware, Finite

Element Models, Crash Simulation, Model

Validation, Safety, Crash Testing

18. Distribution Statement

Copyrighted. Not to be copied or reprinted without

consent from sponsor

19. Security Classif. (of this report)

Unclassified

20. Security Classif. (of this page)

Unclassified

21. No. of Pages

50

22. Price

Form DOT F 1700.7 (8-72) Reproduction of completed page authorized

ii

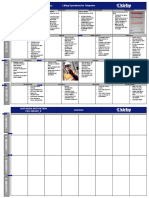

Table of contents

TABLE OF CONTENTS ................................................................................................ 3

LIST OF FIGURES ........................................................................................................ 4

LIST OF TABLES ......................................................................................................... 5

1.0.....INTRODUCTION ............................................................................................... 6

2.0.....BACKGROUND ................................................................................................. 7

3.0.....COMPUTER MODEL DEVELOPMENT ......................................................... 8

4.0 ....MODEL VALIDATION .................................................................................... 12

5.0 ....RAIL HEIGHT EFFECT EVALUATION ....................................................... 16

6.0 ....FULL-SCALE CRASH TESTS.......................................................................... 21

7.0 ....CONCLUSIONS ............................................................................................... 28

8.0 ....REFERENCES .................................................................................................. 29

APPENDIX A: TEST 04002 SUMMARY .................................................................. 30

APPENDIX B: TEST 04003 SUMMARY .................................................................. 40

3

LIST OF FIGURES

Figure 1: Typical W-Beam Guard Rail System ......................................................................... 6

Figure 2: W-Beam Guard Rail Finite Element Model ................................................................ 8

Figure 3: Finite Element Model of Steel Post with Wooden Blockout ...................................... 9

Figure 4: Finite Element Model of W-Beam Rail ....................................................................... 9

Figure 5: W-beam Connected to Wooden Blockout ................................................................. 10

Figure 6: Finite Element Model of W-beams Connected to Post and Blockouts...................... 10

Figure 7: Soil Model with Post and Wooden Blockout ............................................................ 11

Figure 8: Complete G41S Guardrail System Model with Vehicle ........................................... 12

Figure 9: Full-Scale Crash Test/Simulation Comparisons ....................................................... 13

Figure 10: Full-Scale Crash Test/Simulation Comparisons ..................................................... 14

Figure 11: Dynamic and Permanent Test Article Deflections .................................................. 14

Figure 12: Simulation Results from the 475 mm Rail Height Case ......................................... 17

Figure 13: Simulation Results from the 510 mm Rail Height Case ......................................... 18

Figure 14: Simulation Results from the 550 mm Rail Height Case ......................................... 19

Figure 15: Simulation Results from the 590 mm Rail Height Case ......................................... 20

Figure 16: Full-scale Results from Test 04002- Isometric View .............................................. 22

Figure 17: Full-scale Results from Test 04002- Close Side View ............................................ 23

Figure 18: Full-scale Results from Test 04002- Far Side View ............................................... 24

Figure 19: Full-scale Results from Test 04003- Isometric View .............................................. 25

Figure 20: Full-scale Results from Test 04003- Close Side View ............................................ 26

Figure 21: Full-scale Results from Test 04003- Far Side View .............................................. 27

4

LIST OF TABLES

Table 1: FE Model Information ................................................................................................ 12

Table 2: Dynamic and Permanent Test Article Deflections ..................................................... 14

Table 3: Occupant Impact Velocity from Full-Scale Crash Test and Simulation .................... 15

Table 4: Occupant Ridedown Acceleration from Full-Scale Crash Test and Simulation ........ 15

Table 5: Simulation Results Summary. ................................................................................... 16

Table 6: Crash Test Results Summary ..................................................................................... 21

5

1.0. Introduction

W-beam guardrails are the most common types of longitudinal roadside barriers used on

the roadways in the United States. They have played an important role in improving the safety

of highway systems when used to redirect vehicles away from roadside hazards such as bridge

abutments, light poles, ditches, trees, mounds, or other fixed objects found on the roadside.

Figure 1 shows the features of a typical w-beam guardrail barrier with steel posts and routed

wood blockouts (typically referred to as the G4(1S) barrier). In this study, the safety

performance of this barrier system is evaluated relative to the effect of variations in the rail

height on its adequacy in redirecting the striking vehicle. Variations in rail height can occur as a

result of shoddy installation, settlement, and/or successive overlays of the pavement. Rail height

has become a more critical issue as larger vehicles, such as sport utility vehicles (SUVs) and

pick-up trucks, have become a predominant element of the vehicle fleet.

Figure 1: Typical W-Beam Guard Rail System.

In this analysis, the dynamic explicit finite element code LS-DYNA [1,2] is used to

simulate the crash performance of a modified G4(1S) w-beam guardrail. A detailed finite

element model of the guardrail was developed and simulations of a vehicle impacting the barrier

with varied rail heights were performed. Upon completing the finite element analysis, two full-

scale crash tests were performed at The Federal Highway Administration (FHWA) Federal

Outdoor Impact Laboratory (FOIL) to validate the simulation results.

6

2.0. BACKGROUND

During the early 1960s a wide variety of guardrail systems were developed and installed

on highways in the US. W-beam systems came into widespread use since standard steel sheet

could be rolled into the W-shape to form a rigid beam that could catch the bumpers of typical

vehicles. As guardrail systems evolved, variations in posts, rail connections, blockouts, and

other elements changed. Consequently, there are many variations of w-beam guardrail that have

met crashworthiness standards and have been deployed on U.S. highways. The Roadside Design

Guide (RDG) designates the G4(1S) as a strong-post guardrail system. It incorporates a 12

guage steel w-beam rail, mounted on W150 x 14 (W6x9) steel posts spaced at 1.905 m (6 ft 3 in)

with a wood or steel blockout. The blockout was an element that was added to reduce the

potential for an impacting vehicle to snag on the posts during impacts. While either steel or

wood blockouts can be used, the barrier has only been certified to Test Level 2 (TL2) with steel

blockouts, but has achieved TL 3 with routed wood blockouts. The barrier is noted to have a

maximum dynamic deflection of about 1 m (3 ft).

A series of full-scale crash tests have been conducted on w-beam guardrail systems at

different testing agencies including the Texas Transportation Institute and the Midwest Roadside

Safety Facility to examine the performance of the G4(1S) and G4(2W) guardrail systems in

accordance with NCHRP Report 350 guidelines [3,4,5,6]. These guardrails were tested with

different types of posts and blockouts. The full-scale crash tests (test with 2000P vehicle at 100

km/h impact speed and 25 degrees impact angle) showed that w-beam guardrails with steel

blockouts do not meet Test Level 3 criteria of NCHRP Report 350. A similar full-scale crash

test on a design with steel posts and wood blockouts at Test Level 3 did meet the NCHRP criteria.

The data from one of the crash tests, which was conducted on a G4(1S) system, was used in this

study to validate the model and analyze the influence of the w-beam guardrail height on its safety

performance.

The effect of the rail height relative the vehicle is critical and became more critical in

recent years for three reasons. The first relates to changes in the nature of vehicles (i.e. fleet)

operating on U.S. highways. The use of larger vehicles such Sport Utility Vehicles (SUVs)

and pick-up trucks has been on the rise in the US since the late 1980s and they now account

from more than half of the vehicles in the fleet. These vehicles have higher bumpers and centers

of gravity. These features make them more susceptible to overriding or vaulting over standard

barriers. Most w-beam barriers, were originally designed for standard-sized sedans, and thus

could be less effective in redirecting SUVs and pickup trucks. The second reason is related to

road resurfacing practices. There has been increased use of resurfacing as a pavement

management strategy, often without milling to lower the pavement before the addition of a new

layer of material. The effect is a relative lowering of the height of the barrier. When agencies

are faced with limited funds, they often do not make adjustments to the heights of barriers along

resurfaced road sections. The third reason relates to the basic installation tolerances currently

considered acceptable for barrier height. The tolerances for the height are specified as 75mm

(3in). The standard rail height, 550mm (21.6 in) from ground level to center of the rail, is

specified but little testing has been undertaken to determine the degree of effect on safety

performance for rail height variations within the tolerance limits.

7

3.0. COMPUTER Model Development

Crash simulation analysis requires computer descriptions of the object hit and the striking

object. In this effort a previously developed model of the w-beam guardrail system was adapted

to be the object struck. An NCAC-generated model of a Chevy C2500 pick-up truck was used to

represent the striking object. The features of these models are described below.

3.1. Guardrail Model

The guardrail system used in this study is based on the modified G4(1S) design. The

rails in this system are made up of standard 12-gauge w-beams with lengths of 3.807 m (12.5ft).

The rails are supported using W150x12.6 (W6x9) steel posts. These posts are 1830 mm (72in)

length and embedded 1100 mm (43.3in) into the ground. Routed wood blockouts are placed

between the posts and the w-beam rails and have dimensions of 150 mm x 200 mm x 360 mm (6

in x 8 in x 14 in). The system level model of the G4(1S) guardrail system is modeled to have a

total length of 53.3m (175 ft) and it is anchored at both ends using a standard Breakaway Cable

Terminal (BCT). The system consists of 29 posts and 14 w-beam sections.

The NCACV created a finite element model of the w-beam guardrail system in a previous

effort and adapted it for use in this study. Its key features were carefully examined to ensure that

the model could be effectively used to represent rail height variations. First, explicit geometry of

all components of the guardrail system were incorporated in the model (Figure 2). This included

the w-beams, posts, blockouts, and bolts. This is important to ensure the correct mass, inertia,

and stiffness of the different parts is reflected in the model. The soil was also explicitly modeled

using solid elements. The shape of the post was incorporated in the soil mesh to simulate the

post/soil interactions. The geometry of the bolts was found to affect system behavior so they

were explicitly incorporated in the model.

Figure 2: W-Beam Guard Rail Finite Element Model

8

The LS-DYNA finite element analysis program was used in this study [1,2]. It uses an

explicit Lagrangian numerical method to solve three dimensional, dynamic, nonlinear, large

displacement problems. While the softwares initial focus was in military related studies, in the

past 20 years, LS-DYNA has gained new ground in automotive analysis such as crashworthiness

and occupant safety. More recently, the code has been successfully used in analyzing other types

of structures including roadside hardware.

Modeling of Steel and Soil Elements

Appropriate material and cross-sectional properties were assigned to all components of

the guardrail system. Two main LS-DYNA material types were used in the w-beam guardrail

model. The metal components, such as the posts and w-beams, were represented as

piecewise_linear_plasticity material in LS-DYNA. This material model has been extensively

utilized to represent structural metals, such as steel and aluminum, and it has been fully validated

and optimized. The material behavior is isotropic, elasto-plastic with strain rate effects and

failure. The properties used for these materials were extracted from the literature as well as data

from coupon tests that were performed on similar steels. The soil_and_foam model in LS

DYNA was used to representing the soil. The properties used for this model were back-

calculated from previously conducted tests. These tests consisted of a Bogie vehicle impacting

wood and steel posts that are embedded in similar soil to that used the full-scale crash test.

Simulations with the same test setups were performed and the material properties were varied

until acceptable comparisons were achieved between the tests and simulations.

Modeling of w-beam, post and blockouts

A detailed finite element model of the steel post with wooden blockout is shown in

Figure 3 and the finite element model of the w-beam is shown in Figure 4. For computational

purposes, six rails located at the middle of the entire guardrail system were modeled using fine

mesh while the remaining rails were modeled using coarser mesh. All post and rails were

modeled using quadrilateral shell elements. The shell element used in this analysis is based on

the Belytschko-Lin-Tsay shell formulation [7]. The material formulation used for the rail and

post is the isotropic piecewise linear elastic-plastic model.

Figure 3: Finite Element Model of Figure 4: Finite Element Model of

Steel Post with Wooden Blockout W-Beam Rail

9

Wooden blockouts were modeled using eight node reduced integration hexahedral solid

elements. These elements capture the behavior of the model at much lower cost because they

consume much less computer time and memory.

Bolt Modeling:

Eight small bolts were used to connect the w-beams together and a long bolt used to

connect the rails to the wooden blockout and post as shown in Figures 5 and 6. For the small

bolts and nuts, a rigid material formulation was selected. This assumption was made to reduce

the computation time, since small elements are needed to capture the geometry of the bolts.

These elements would control the time step and lead to larger computation time. By assuming

the rigid material model for the bolts, their element size is no longer critical since rigid elements

do not control the time step. A spring is placed between the bolt head and the nut to represent

the stiffness of the bolt. The properties of these springs are determined from the material

properties, cross-sectional area, and length of the bolt.

The long bolts have significant effect on the behavior of the G4(1S) system and have to

be modeled in detail. To accurately and efficiently represent these bolts, special modeling

technique was utilized. In this technique, the bolt is modeled with beam elements to capture its

tensile, bending, and shear behavior. By using beam elements, the time step is not controlled by

the cross-sectional geometry of the bolt. Hence, a larger simulation time step and smaller

computation time is needed to reach a solution. Elasto-plastic material model with failure was

assigned to the beam elements to simulate the nonlinear and failure behavior of the bolt. The

geometry of the bolt is represented by shell elements with null material properties. The null

shell elements have no effect on the stiffness of the bolts and their size does not affect the

simulation time step. They are used to represent the bolt geometry only for contact purposes.

Nodes from shell elements are tied to the beam element nodes to transfer the contact forces. This

method was found to be very accurate and efficient and has been successfully used in several

previous studies [8, 9, 10, 11].

Figure 5: W-beam Connected Figure 6: Finite Element Model of W-beams

to Wooden Blockout Connected to Post and Blockouts

10

Soil and Soil/Post model

The soil was modeled as a cylindrical block 2.7m (9 ft) in diameter and 2.02m (6.5 ft) in

length as shown in Figure 7. These dimensions were chosen such that the behavior of the soil

and post/soil interaction is accurately captured with reasonable computation time. The outer

boundaries of the soil model were constrained using the non-reflection boundary constraint

option. This option is often used in modeling infinite domain and prevents the stress wave from

reflecting at the fixed boundary. The soil block is modeled using eight node hexahedral solid

elements. The shape of the post was incorporated into the soil mesh with appropriate flange and

web thickness in order to avoid penetration between post and soil and to have full representation

of the post/ soil interaction. Automatic single surface sliding interface is defined between the

outer faces of the post and inner faces of the soil block to simulate the contact between the post

and the soil and friction between the post and the soil was also included. The material

constitutive model used for the soil is the soil and crushable foam model.

Figure 7: Soil Model with Post and Wooden Blockout.

3.2. Vehicle Model

The NCAC used a model of the Chevy C2500 pick-up truck as the striking object

(bullet). This FE model was developed by reverse engineering and it has been widely used

in crash simulations byt the NCAC and others. Version 9 of this model was used, It had

approximately 108,000 elements.

11

4.0. MODEL VALIDATION

Once the G4(1S) guardrail model was completed, it was combined with the vehicle

model for the Chevy C2500 pick-up truck to simulate the setup for test 3-11 (i.e., 2000P, 100

km/hr (62 mph), 25 degrees test) as recommended in NCHRP Report 350. Figure 8 depicts the

model representation of G4(1S) guardrail system with the C2500 pickup truck (i.e., the typical

2000p vehicle used for testing roadside barriers). The vehicle weight is approximately 2000 kg

(4400 lb). The vehicle orientation and initial speed were set in the model as recommended in

Report 350, 25 degrees and 100 km/hr (62 mph). Details of the model size and setup are shown

in Table 1.

Parts 198

Nodes 106,268

Elements 108,133

Impact Speed 100 km/hr

Impact Angle 25 Degree

Simulation Time 0.5 s

LS-DYNA Version LS960

Computer Platform SGI Origin 2000

Vehicle Model C2500R V9

Computation Time 48 hr

Table 1: FE Model Information.

Figure 8: Complete G4(1S) Guardrail

System Model with Vehicle.

A full-scale crash test, which was performed at the Texas Transportation Institute, was

selected for model validation. The setup for this test was replicated in the G4(1S) and vehicle

simulation model. The model was then exercised to check its validity. Several simulations were

performed to identify and correct deficiencies in the model. This process continued until

reasonable correlations were obtained between the full-scale test and simulations. Figure 9

shows comparisons between the test and simulation. The roll and yaw angles comparisons are

shown in Figure 10. Overall the simulations results compared well with the full-scale crash test.

The dynamic and permanent test article deflections reported by TTI were compared to the

simulation results. The deflections are shown in Table 2. The dynamic deflection is higher in

the simulation than in the test while the permanent deformation is slightly lower. This difference

could be attributed to soil variation between the model and the test. This difference did not

affect the overall behavior of the vehicle which is the focus of this study. Rail permanent

deformation from the test and simulations are shown in Figure 11.

12

Figure 9: Full-Scale Crash Test/Simulation Comparisons

13

Roll, and Yaw Angle Comparisons

-5

0

5

10

15

20

25

30

35

40

0 0.05 0.1 0.15 0.2 0.2

Test - Roll

Simulation - Roll

Simulation Yaw

Test- Yaw

5 0.3 0.35 0.4 0.45 0.5

Tim

A

n

g

l

e

(

D

e

g

)

e (s)

Figure 10: Full-Scale Crash Test/Simulation Comparisons

Figure 11: Dynamic and Permanent Test Article Deflections.

Table 2: Dynamic and Permanent Test Article Deflections (m).

Crash test Simulation

Dynamic deflection (m) 1 1.237

Permanent deflection (m) 0.7 0.637

14

The occupant impact velocity (feet per second) in the X and in the Y directions for the

full-scale test. These results are listed in Table 3 with the results of the simulation and the limits

evaluated in the NCHRP Report 350. The results show good agreement between the test and

simulation.

Table 3: Occupant Impact Velocity from Full-Scale Crash Test and Simulation (m/s).

Crash test Simulation Preferred limit Maximum limit

x-direction 7.1 5.27 9 12

y-direction 4.4 4.51 9 12

The occupant ridedown acceleration (feet per second per second) in the X and in the Y

directions was also compared. These results are listed in Table 4 with the values from the

simulation and the limits evaluated in the NCHRP Report 350 criteria. The values of the

simulation are also very close to the values of the full scale crash test for the occupant ridedown

acceleration.

Table 4: Occupant Ridedown Acceleration from Full-Scale Crash Test and Simulation.(g)

Crash

test

Simulation Preferred limit Maximum limit

x-direction 7.9 7.44 15 20

y-direction 8.4 10.32 15 20

Thus, the researchers concluded that the crash simulations using these models provided a

sound representation of the ral crash event.

15

5.0. RAIL HEIGHT EFFECT EVALUATION

Upon completing the validations, four additional simulations were run in which rail heights

were varied. The rail heights in these simulations, measured from ground level to the center of

the W-Beam rail were 475, 510, 550, 590, and 625 mm (rounded to 18.5, 20, 21.5, 23, and 24.5

in). [The top of rail would be 75 mm or 3 inches higher.] The standard rail height (550 mm) data

was modeled in the first phase and validated with a full-scale crash test. The results showed that

it would meet all NCHRP Report 350 recommendations. The data from simulations at the other

rail heights were compared to that for the standard height.

This analysis focused on not only evaluating whether the barrier would meet the NCHRP 350

performance recommendations, but also effectiveness in reducing the potential for the vehicle to

underride or override the w-beam guardrail and its capacity to remain upright during and after

collision. These are typically the critical factors considered in evaluating guardrail systems.

Occupant impact velocity and ridedown accelerations were less critical and were below the

recommended limits.

Four w-beam guardrail models were created that were identical except for a different height

of the rail. The results from the simulations using these various models are shown in Figures 12

to 15 (results for the 625 mm height were similar to that for the 590 mm case so they are not

included). The results showed that in the standard height case and the two increased height cases,

the vehicle was redirected and the barrier would likely meet all report 350 recommendations.

For the two cases with reduced rail height, the vehicle over-rode the barrier and consequently did

not meet on the report 350 criterion. The results indicate that reducing the height by as little as

40 mm (1.5 in) could hinder the ability of the barrier to redirect pickup trucks and large SUVs.

Summary results from these simulations are listed in Table 5.

Table 5: Simulation Results Summary.

Height to Center of

the Rail (mm/inches)

475 mm

18.5 in

510 mm

20.0 in

550 mm

21.5 in

590 mm

23 .0 in

625 mm

24.5 in

Occupant Impact

Velocity (m/s)

-4.68 -6.12 -7.44 -8.28 -8.47

Occupant Ridedown

Acceleration (g)

-3.98 -3.59 -5.27 -8.69 -13.92

Maximum Barrier

Deformation (m)

.228 .511 0.637 .560 .455

Maximum Roll

Angle (deg 0.5 sec

duration

10.82 17.78 8.40 8.37 7.83

Maximum Yaw

Angle (deg) 0.5 sec

duration

8.22 20.71 35.32 37.71 36.82

16

Figure 12: Simulation Results from the 475 mm Rail Height Case

17

Figure 13: Simulation Results from the 510 mm Rail Height Case

18

Figure 14: Simulation Results from the 550 mm Rail Height Case

19

Figure 15: Simulation Results from the 590 mm Rail Height Case

20

6.0. FULL-SCALE CRASH TESTS

To validate the simulation results, two full-scale crash tests were performed (Tests 04002

and 04003). Both tests were performed at The Federal Highway Administration (FHWA)

Federal Outdoor Impact Laboratory (FOIL). The tests consisted of 2000P vehicle (Chevrolet

C2500 pickup) impacting the w-beam guardrail at 100 km/hr impact speed and 25 degree impact

angle. Both tests were identical except for the rail height. In the first test, the rail height relative

to the vehicle was similar to the standard rail height simulation. In the second test, the rail was

lowered by 60 mm (2.5 in). The effective rail heights for the two tests, from ground level to

center of the rail, were 550 mm (21.5 in) for test 04002 and 490 mm (19 in) for test 04003.

When measured from ground to the top of the rail, these heights would be equivalent to 700 mm

(27.5 in) for test 04002 and 650 mm (25 in) for test 04003.

The results from the first test are shown in Figure 16-18. The results from the second test

are shown in Figures 19-21. Additional information about these two tests is shown in

Appendixes A and B respectively.

The results from the first test showed the barrier redirecting the pickup truck vehicle

when the rail is set at the standard height. In the second test, the vehicle overrode the barrier and

rolled over upon impact with ground surface behind the barrier. These results confirmed the

finite element simulation results. Summary results from the two full-scale crash tests are listed in

Table 6.

Table 6: Crash Test Results Summary

FOIL Test 04002

FOIL Test 04003

Rail Height to Center & Top (mm/inches)

Center 550/21.5

Top 700/27.5

Center 490/19.0

Top 650/25.0

Evaluation Criteria

Occupant Impact Velocity (m/s) 1 sec

Duration

-7.11 -7.52

Occupant Ride Down Acceleration (g) 1 sec

Duration

-9.16 -10.05

Maximum Roll Angle (deg) 1 sec Duration 13.5 23.4

Maximum Yaw Angle (deg) 1 sec Duration 40.1 42.8

21

Figure 16: Full-scale Results from Test 04002 - Isometric View

22

Figure 17: Full-scale Results from Test 04002- Close Side View

23

Figure 18: Full-scale Results from Test 04002 - Far Side View

24

Figure 19: Full-scale Results from Test 04003- Isometric View

25

Figure 20: Full-scale Results from Test 04003- Close Side View

26

Figure 21: Full-scale Results from Test 04003 - Far Side View

27

7.0. CONCLUSIONS

Computer crash simulations were performed to evaluate the effect of guardrail height on the

safety performance of G4(1S) w-beam barrier systems. A finite element model of the w-beam

guardrail system was adapted from one developed in a previous research effort. It had been

validated against full-scale crash tests performed by the Texas Transportation Institute. Next, the

model of the G4(1S) guardrail system was modified to investigate five different rail heights: a

standard height, two lower heights (-1.5 and -3.0 inches), and two higher heights (1.5 and 3.0

inches). Simulations results showed that when the w-beam guardrail is lower than the standard

height, there is a high risk of vehicle overriding or vaulting the guardrail and/or rolling over. A

higher guardrail position, on the other hand, would redirect the vehicle and meet all the NCHRP

Report 350 criteria.

Two full-scale crash tests were conducted to validate the simulation results. The first test

showed the barrier redirects the vehicle when the rail is set at the standard height. The second

test showed that lowering the height by 60mm (2.5) caused the vehicle to override the barrier.

This result is consistent with the simulation results.

The simulation results indicate that reducing the height by as little as 40 mm (1.5 in) could

hinder the ability of the barrier to redirect pickup trucks and large SUVs. Considering the fact

that bumper height could also vary among the test vehicles, reducing the tolerance on the rail

height and setting the minimum height to be equal to the standard height, 550 mm (21.5 in) to

center of the rail or 700 mm (27.5 in) to the top of the rail would lead to better barrier

performance when impacted by pickup trucks and large SUVs.

28

8.0. REFERENCES

1. Hallquist, J . O., LS-DYNA Users Manual, Livermore Software Technology Corporation,

April 2003.

2. Hallquist, J . O., LS-DYNA Theory Manual, Livermore Software Technology Corporation,

May 1998.

3. Belytschko, T., Lin, J ., and Tsay, C.S., Explicit algorithms for non-linear dynamics of

shells, Computer Methods in Applied Mechanics and Engineering, 1984, 42, pp. 225-251.

4. Ross, H. E., Sicking, D., and Zimmer, R. A., Recommended Procedures for the Safety

Performance Evaluation of Highway Features, NCHRP Report 350, Transportation

Research Board, Washington D.C., 1993.

5. Buth, C.E., Menges, W.L., Ivey, D.L., and Williams, W.F., W-Beam Guardrail

Proceedings of the 78th Annual Meeting Transportation Research Board, Paper No. 990871,

Washington D.C., J anuary 1999.

6. Polivka, K.A., Sicking, D.L., Rohde, J .R., Faller, R.K., and Holloway, J .C., Crash Testing

of Michigans Type B (W-Beam) Guardrail System, Midwest Roadside Safety Facility,

Report No. TRP-03-90-99, November 1999.

7. Polivka, K.A., Sicking, D.L., Rohde, J .R., Faller, R.K., and Holloway, J .C., Crash Testing

of Michigans Type B (W-Beam) Guardrail System Phase II, Midwest Roadside Safety

Facility, Report No. TRP-03-104-00, October 2000.

8. Marzougui, D., Eskandarian A., Meczkowski, L., Analysis and Evaluation of a Redesigned

3x3 Slipbase Sign Support System Using Finite Element Simulations, International, J ournal

of Crashworthiness, Vol. 4, No. 1., 1999.

9. Eskandarian, A., Marzougui, D., and Bedewi, N., Impact Finite Element Analysis of Slip-

Base Sign Support Mechanism, ASCE J ournal of Transportation Engineering, Vol. 126, No.

2, March 2000.

10. Marzougui, D., Bahouth, G., Eskandarian, A., Meczkowski, L., and Taylor, H., Evaluation

of Portable Concrete Barriers Using Finite Element Simulation, In Transportation Research

Record 1720, J ournal of the Transportation Research Board, Washington DC, 2000.

11. Marzougui, D., Meczkowski, L., Taylor, H. and Bedewi, N., Sign support height analysis

using finite element simulation, International J ournal of Crashworthiness , Vol. 6, No. 1, pp.

33-41, 2001.

29

30

Das könnte Ihnen auch gefallen

- 03 Prediction of Design Wind SpeedsDokument24 Seiten03 Prediction of Design Wind Speedsmdkml2Noch keine Bewertungen

- Wu-Performance of LS-DYNA Concrete Constitutive ModelsDokument14 SeitenWu-Performance of LS-DYNA Concrete Constitutive ModelsaktcNoch keine Bewertungen

- BS5950!1!2000 Steel Code Check Theory EnuDokument30 SeitenBS5950!1!2000 Steel Code Check Theory Enupopaciprian27Noch keine Bewertungen

- DN-14 BlastDokument32 SeitenDN-14 BlastParthiban ArivazhaganNoch keine Bewertungen

- EN1993 Practice Paper-Buckling Analysis of Steel BridgesDokument16 SeitenEN1993 Practice Paper-Buckling Analysis of Steel BridgesaktcNoch keine Bewertungen

- VSL Catalog PTDokument44 SeitenVSL Catalog PTVu Phi Long100% (1)

- Linzell - Computational Simulation of Blast Effects On Structural ComponentsDokument46 SeitenLinzell - Computational Simulation of Blast Effects On Structural ComponentsaktcNoch keine Bewertungen

- Strand7 - Buckling Analysis - Linear Vs NonlinearDokument5 SeitenStrand7 - Buckling Analysis - Linear Vs Nonlinearaktc100% (1)

- LUSAS Linear and Nonlinear Buckling AnalysisDokument3 SeitenLUSAS Linear and Nonlinear Buckling Analysisaktc100% (1)

- Transformers 20th Anniversary Optimus Prime InstructionDokument5 SeitenTransformers 20th Anniversary Optimus Prime InstructionaktcNoch keine Bewertungen

- CHONG Alecs KT - PHD ThesisDokument369 SeitenCHONG Alecs KT - PHD ThesisaktcNoch keine Bewertungen

- LS-DYNA Concrete MaterialDokument3 SeitenLS-DYNA Concrete MaterialaktcNoch keine Bewertungen

- Strand7 - Buckling Analysis - Linear Vs NonlinearDokument5 SeitenStrand7 - Buckling Analysis - Linear Vs Nonlinearaktc100% (1)

- Mackenzie - Footbridge Pedestrian Vibration LimitsDokument10 SeitenMackenzie - Footbridge Pedestrian Vibration LimitsaktcNoch keine Bewertungen

- Geobrugg-Flexible Ring Net Barriers For Debris Flow Protection-The Economic SolutionDokument16 SeitenGeobrugg-Flexible Ring Net Barriers For Debris Flow Protection-The Economic SolutionaktcNoch keine Bewertungen

- ThisDokument357 SeitenThisaktcNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- February 2020 OTP - AirportsDokument44 SeitenFebruary 2020 OTP - AirportsvindaNoch keine Bewertungen

- Ford Service Calculator EstimateDokument1 SeiteFord Service Calculator EstimateShreyas TamhanNoch keine Bewertungen

- T5 Model IdentificationDokument6 SeitenT5 Model Identificationapi-26140644Noch keine Bewertungen

- Volume 1 PDFDokument91 SeitenVolume 1 PDFArindam NandyNoch keine Bewertungen

- RACQ 2018 Unroadworthy Roads SurveyDokument7 SeitenRACQ 2018 Unroadworthy Roads SurveyCheryl GoodenoughNoch keine Bewertungen

- DM HB0002 13 EngDokument28 SeitenDM HB0002 13 EngYakuAtokNoch keine Bewertungen

- EHS-SWI-019 - 0 Lifting Operations For Teleporter - DraftDokument2 SeitenEHS-SWI-019 - 0 Lifting Operations For Teleporter - DraftChris BonningtonNoch keine Bewertungen

- Incoterms For Beginners 1Dokument4 SeitenIncoterms For Beginners 1Timur OrlovNoch keine Bewertungen

- Final Handout - BasicDokument232 SeitenFinal Handout - BasicPhoenixofficialNoch keine Bewertungen

- Glass ReferenceDokument26 SeitenGlass ReferenceArbey GonzalezNoch keine Bewertungen

- TFL - Traffic Modelling Guidelines PDFDokument184 SeitenTFL - Traffic Modelling Guidelines PDFThiago Tavares100% (1)

- RPM CalculatorDokument2 SeitenRPM CalculatorPablo DpNoch keine Bewertungen

- Incla DP20001 6158Dokument22 SeitenIncla DP20001 6158Joey KlenderNoch keine Bewertungen

- Cover Sheet: Transportation Research Part F: Traffic Psychology and BehaviourDokument22 SeitenCover Sheet: Transportation Research Part F: Traffic Psychology and Behaviourscribd_fcostaNoch keine Bewertungen

- Oejd Fir NotamDokument8 SeitenOejd Fir NotamAbdulazi AlnahdiNoch keine Bewertungen

- Owner'S Manual: Read This Manual Carefully Before Operating This VehicleDokument84 SeitenOwner'S Manual: Read This Manual Carefully Before Operating This VehicleAminullah MuhammadNoch keine Bewertungen

- 1990 Volkswagen VW Vanagon - Transporter Instruction Manual - Owners Handbook ... (PDFDrive)Dokument165 Seiten1990 Volkswagen VW Vanagon - Transporter Instruction Manual - Owners Handbook ... (PDFDrive)mouad firesNoch keine Bewertungen

- Automotive Questionnaire 12Dokument3 SeitenAutomotive Questionnaire 12Sagar AhujaNoch keine Bewertungen

- Supra PPT NewDokument14 SeitenSupra PPT NewPraveen RathodNoch keine Bewertungen

- Authorise Letter ThailandDokument1 SeiteAuthorise Letter ThailandDon Manaff100% (3)

- Production Planning and Control (PP&C)Dokument29 SeitenProduction Planning and Control (PP&C)stajaNoch keine Bewertungen

- Lista Exedy IndiaDokument8 SeitenLista Exedy IndiagaelNoch keine Bewertungen

- IRSE News 258 (September 2019)Dokument40 SeitenIRSE News 258 (September 2019)Rohit Kumar0% (1)

- Evergreen Park Arrests Dec. 23, 2016 To Dec. 29, 2016Dokument8 SeitenEvergreen Park Arrests Dec. 23, 2016 To Dec. 29, 2016Lorraine SwansonNoch keine Bewertungen

- What Transportation Problems Are There in Your CityDokument2 SeitenWhat Transportation Problems Are There in Your CitybruhhNoch keine Bewertungen

- 2014 Ram 2500Dokument7 Seiten2014 Ram 2500sigNoch keine Bewertungen

- MANUAL DE UTILIZARE PiaGGiomp3 300Dokument128 SeitenMANUAL DE UTILIZARE PiaGGiomp3 300tatichiefNoch keine Bewertungen

- Brunel The Practical ProphetDokument6 SeitenBrunel The Practical ProphetTactics HerosNoch keine Bewertungen

- WSO ChecklistDokument1 SeiteWSO ChecklistgdudgshsNoch keine Bewertungen

- CESM1114AMEDokument5 SeitenCESM1114AMEjivinaNoch keine Bewertungen