Beruflich Dokumente

Kultur Dokumente

DS482

Hochgeladen von

mariomatoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DS482

Hochgeladen von

mariomatoCopyright:

Verfügbare Formate

Magnesium Elektron UK,

P.O. Box 23, Rake Lane, Swinton, Manchester, M27 8DD, England.

Tel: 0161 911 1000 Fax: 0161 911 1010

Web: www.magnesium-elektron.com VAT No: GB 668 2142 26

A Division of MAGNESIUM ELEKTRON LIMITED. Registered in England No. 3141950.

Registered Office: The Victoria, 150-182 Harbour City, Salford Quays, Salford, M50 3SP

A Luxfer Group Company

Elektron AZ31B

Sheet, Plate & Coil

Datasheet : 482

AZ31B is a wrought magnesium base

alloy with good room-temperature

strength and ductility combined with

corrosion resistance and weldability.

Increased strength is obtained by

strain hardening with a subsequent

partial anneal (H24 and H26

tempers).

APPLICATIONS

Sheet and plate in AZ31B find

application in medium strength

service at temperatures below

150C. Diverse uses including

aircraft fuselage, concrete tools,

cell phone/camera/notebook

computer cases, speaker cones and

textile machinery can all benefit from

light weight AZ31B.

AZ31B is non-magnetic and has

high electrical and thermal

conductivity filling the requirements

for RFI and EMI shielding in the

electronics and computer industries.

Superplastic forming of AZ31B

sheet at elevated temperatures

allows production of a wide variety

of intricate parts for automotive uses.

Monocoque construction utilizing

formed sheet can be adapted to

many commercial applications.

SPECIFICATIONS

UNS No. M11311

AMS 4375

AMS 4376

AMS 4377

AMS 4382

ASTM B90

CHEMICAL COMPOSITION

Aluminum 2.5-3.5%

Zinc 0.7-1.3%

Manganese 0.20-1.0%

Magnesium Balance

PHYSICAL PROPERTIES

Specific gravity 1.78

Coefficient of

thermal expansion 26.8x10

-6

K

-1

Specific heat 1040 Jkg

-1

K

-1

Thermal conductivity 76.9 Wm

-1

K

-1

Electrical resistivity 92 nm

Modulus of elasticity 45x10

9

Pa

Poissons ratio 0.35

Melting range 566-632C

HEAT TREATMENT

No thermal treatment is available

for increasing the strength of this

alloy after fabrication.

DESIGN DATA

Specification minimum tensile

properties.

AZ31B-O 0.5-1.5mm

0.2% Proof Stress 125MPa

Tensile Strength 220MPa

Elongation in 5.65A 10%

AZ31B-O 1.5-6.3mm

0.2% Proof Stress 105MPa

Tensile Strength 220MPa

Elongation in 5.65A 10%

AZ31B-O 6.3-75mm

0.2% Proof Stress 105MPa

Tensile Strength 220MPa

Elongation in 5.65A 8%

AZ31B-H24 0.5-6.3mm

0.2% Proof Stress 200MPa

Tensile Strength 270MPa

Elongation in 5.65A 5%

AZ31B-H24 6.3-9.5mm

0.2% Proof Stress 180MPa

Tensile Strength 260MPa

Elongation in 5.65A 7%

AZ31B-H24 9.5-12.7mm

0.2% Proof Stress 165MPa

Tensile Strength 255MPa

Elongation in 5.65A 7%

AZ31B-H24 12.7-25mm

0.2% Proof Stress 150MPa

Tensile Strength 245MPa

Elongation in 5.65A 7%

AZ31B-H24 25-50mm

0.2% Proof Stress 135MPa

Tensile Strength 235MPa

Elongation in 5.65A 7%

AZ31B-H24 50-75mm

0.2% Proof Stress 125MPa

Tensile Strength 235MPa

Elongation in 5.65A 7%

AZ31B-H26 6.3-12.7mm

0.2% Proof Stress 180MPa

Tensile Strength 260MPa

Elongation in 5.65A 5%

AZ31B-H26 12.7-25mm

0.2% Proof Stress 160MPa

Tensile Strength 255MPa

Elongation in 5.65A 5%

AZ31B-H26 25-50mm

0.2% Proof Stress 145MPa

Tensile Strength 240MPa

Elongation in 5.65A 5%

OTHER PROPERTIES

TYPICAL HARDNESS

O temper 67 Rockwell E

H24 temper 83 Rockwell E

WELDABILITY

Excellent weldability with gasshielded

arc using AZ61A

(preferred) or AZ92A filler rod; post

weld stress relief is required to prevent

stress corrosion cracking. Resistance

welding is excellent.

MACHINING

AZ31B, like all magnesium alloy sheet

and plate, machines faster than any

other metal. Providing the geometry of

the part allows, the limiting factor is the

power and speed of the machine

rather than the quality of the tool

material. The power required per cubic

centimeter of metal removed varies

from 9 to 14 watts per minute

depending on machining operation.

DENT RESISTANCE

Weight for weight, AZ31B-H24 has

proven to be superior to competitive

materials in its resistance to

denting at moderate energy levels.

Dent Resistance of 1mm Gauge Sheet

Dent depth in mm from 25mm spherical radius indentor on 350mm span

Impact Impact Impact

Energy Energy Energy

0.34 J 0.62 J 1.25 J

AZ31B-H24 0.66 1.42 2.34

6061-T6 0.94 1.52 2.46

3003-H14 2.24 3.23 4.90

5052-H34 1.55 2.41 3.35

2024-T6 0.99 1.52 2.29

SAE 1010 1.09 1.70 2.67

Mild Steel

SURFACE TREATMENT

All the normal chromating, anodizing,

plating, and finishing treatments are

readily applicable. AZ31B also

responds well to plasma electrolytic

oxidation finishing.

CORROSION RESISTANCE

Continuous exposure for 2.5 years

Marine Atmosphere

AZ31B-H24 0.008 mgcm

-2

d

-1

Mild steel 0.323 mgcm

-2

d

-1

Industrial Atmosphere

AZ31B-H24 0.013 mgcm

-2

d

-1

Mild steel 0.055 mgcm

-2

d

-1

Rural Atmosphere

AZ31B-H24 0.006 mgcm

-2

d

-1

Mild steel 0.032 mgcm

-2

d

-1

Elektron AZ31B Sheet, Plate & Coil

All Information is given in good faith but without warranty. Freedom from patent rights must not be assumed. Health and Safety information is available for all

Magnesium Elektron products. MAGNESIUM ELEKTRON, THE 'e' LOGO, MEL, ELEKTRON and ZIRMAX are registered trademarks of Magnesium Elektron Limited.

05/06

Elektron AZ31B Sheet, Plate & Coil

AMBIENT TEMPERATURE MECHANICAL

PROPERTIES FOR T5 TEMPER

TYPICAL TENSILE PROPERTIES 0.5-6mm

0.2% Proof stress 220 MPa

Tensile strength 290 MPa

Elongation in 5.65A 13%

TYPICAL TENSILE PROPERTIES 6-10mm

0.2% Proof stress 200 MPa

Tensile strength 275 MPa

Elongation in 5.65A 15%

TYPICAL TENSILE PROPERTIES 10-25mm

0.2% Proof stress 175 MPa

Tensile strength 265MPa

Elongation in 5.65A 16%

TYPICAL TENSILE PROPERTIES 25-75mm

0.2% Proof stress 150 MPa

Tensile strength 255 MPa

Elongation in 5.65A 13%

TYPICAL COMPRESSIVE PROPERTIES

0.2% Proof stress 0.5-6mm 180 MPa

0.2% Proof stress 6-10mm 160 MPa

0.2% Proof stress 10-25mm 120 MPa

0.2% Proof stress 25-50mm 95 MPa

0.2% Proof stress 50-75mm 85 MPa

TYPICAL SHEAR PROPERTIES

Ultimate stress 0.5-6mm 200 MPa

Ultimate stress 6-10mm 195 MPa

Ultimate stress 10-75mm 180 MPa

FRACTURE TOUGHNESS

K

IC

28 MPam

FATIGUE PROPERTIES

FIG. 1 Cantilever bending fatigue test

160

140

120

100

80

180

MAXIMUM

STRESS

(MPa)

CYCLES OF STRESS

104 105 106 107 108

300

200

100

0 0

10

20

30

40

50

60

70

80

90

100

110

120

130

STRESS

(MPa)

TEMPERATURE (C)

E

L

O

N

G

A

T

I

O

N

(

%

)

0 100 200 300

Elongation

0.2% Proof Stress

Tensile Strength

ELEVATED TEMPERATURE MECHANICAL

PROPERTIES FOR H24 TEMPER

TYPICAL TENSILE PROPERTIES

FIG. 2 Effect of temperature on tensile properties

CREEP PROPERTIES

FIG. 3 Stress/time relationship for specified creep at 100C

FIG. 4 Stress/time relationship for specified creep at 150C

STRESS

(MPa)

120

100

80

60

40

0

20

140

TIME (HOURS)

10 1 100 500

1.0%

0.5%

0.2%

0.1%

STRESS

(MPa)

120

100

80

60

40

0

20

140

TIME (HOURS)

10 1 100 500

0.5%

0.2%

0.1%

Das könnte Ihnen auch gefallen

- Duplex Stainless Steel WeldingDokument25 SeitenDuplex Stainless Steel WeldingcfcshakerNoch keine Bewertungen

- URB25Dokument4 SeitenURB25malika_00Noch keine Bewertungen

- Duplex Stainless Steel WeldingDokument25 SeitenDuplex Stainless Steel Weldingkdsenipah6667Noch keine Bewertungen

- Pinnacle Alloys E8018-B6 Code and Specification DataDokument2 SeitenPinnacle Alloys E8018-B6 Code and Specification DataMurad AlmoudiNoch keine Bewertungen

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDokument7 Seiten22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeNguyen Anh TuanNoch keine Bewertungen

- Tubular Products From Special MetalsDokument26 SeitenTubular Products From Special Metalskaveh-bahiraeeNoch keine Bewertungen

- Esab DublexDokument8 SeitenEsab DublexSuphi YükselNoch keine Bewertungen

- Duplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dokument6 SeitenDuplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dell_RevanNoch keine Bewertungen

- Boehler Mig DMO IGDokument1 SeiteBoehler Mig DMO IGदिनेश कुशवाहाNoch keine Bewertungen

- SAF Welding Cutting GuideDokument165 SeitenSAF Welding Cutting GuideSelvem0% (1)

- Welding PresentationDokument48 SeitenWelding Presentationedu_canete100% (2)

- Mechanical Engineering Design Presentation Bsme01183097Dokument30 SeitenMechanical Engineering Design Presentation Bsme01183097Waqar KhanNoch keine Bewertungen

- 316l Austenitic Stainless Steel BarDokument3 Seiten316l Austenitic Stainless Steel Barதமிழன் இராமசாமிNoch keine Bewertungen

- Welding Duplex Stainless SteelDokument44 SeitenWelding Duplex Stainless SteelTran Thanh HaoNoch keine Bewertungen

- Kavish DesaiDokument33 SeitenKavish DesaiKavish DesaiNoch keine Bewertungen

- Principal of DPTDokument5 SeitenPrincipal of DPTJhandu KumarNoch keine Bewertungen

- Grades of Stainless Steel - Grade 316: SX 316 / 316L Technical DataDokument3 SeitenGrades of Stainless Steel - Grade 316: SX 316 / 316L Technical Data03sri03Noch keine Bewertungen

- Data Sheet Aluminium 6061 t6 Group (H)Dokument7 SeitenData Sheet Aluminium 6061 t6 Group (H)احمد نعيمNoch keine Bewertungen

- Metrode Welding Duplex & Superduplex Stainless SteelsDokument18 SeitenMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- Alluminium SheetsDokument7 SeitenAlluminium SheetsVaibhav ShuklaNoch keine Bewertungen

- Metrode E2209 (B-60) ElectrodeDokument6 SeitenMetrode E2209 (B-60) ElectrodeClaudia MmsNoch keine Bewertungen

- Data SAF2205 04Dokument8 SeitenData SAF2205 04il_yoo_1Noch keine Bewertungen

- 253MA High Temperature Resistant TubesDokument2 Seiten253MA High Temperature Resistant TubesBerkan FidanNoch keine Bewertungen

- DH 1232NSDokument1 SeiteDH 1232NSGopiNathNoch keine Bewertungen

- 701 Armox Workshop RecommendationsDokument11 Seiten701 Armox Workshop RecommendationssudhavelNoch keine Bewertungen

- Alloy 625 Spec SheetDokument3 SeitenAlloy 625 Spec SheetLinnie McleodNoch keine Bewertungen

- CF10MC (1.4571)Dokument3 SeitenCF10MC (1.4571)Gilcimar Cavalcante GilcimarNoch keine Bewertungen

- 1.smaw All PDFDokument76 Seiten1.smaw All PDFkaviatchennaiNoch keine Bewertungen

- Raffmetal: UNI EN 1676 and 1706Dokument2 SeitenRaffmetal: UNI EN 1676 and 1706Anshuman RoyNoch keine Bewertungen

- Selectrode: High Deposition 316L Stainless Steel International ClassificationsDokument2 SeitenSelectrode: High Deposition 316L Stainless Steel International ClassificationsMohamed AdelNoch keine Bewertungen

- Mechanical Properties of Metric FastenersDokument2 SeitenMechanical Properties of Metric Fastenersghostghost123Noch keine Bewertungen

- Sandvik 2re10Dokument7 SeitenSandvik 2re10himan_chongiNoch keine Bewertungen

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Dokument2 SeitenAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNoch keine Bewertungen

- High-Reliability Lead-Free Solder Paste: Senju Metal Industry Co., Ltd. Senju Manufacturing (Europe) LTDDokument3 SeitenHigh-Reliability Lead-Free Solder Paste: Senju Metal Industry Co., Ltd. Senju Manufacturing (Europe) LTDzaizamNoch keine Bewertungen

- Electrode Booklet F Web 100Dokument1 SeiteElectrode Booklet F Web 100satnamNoch keine Bewertungen

- Elgacore DWA 55EDokument2 SeitenElgacore DWA 55Ecfyjdyu_684672809Noch keine Bewertungen

- Low Alloy13Dokument5 SeitenLow Alloy13Branko FerenčakNoch keine Bewertungen

- Metrode ER110S-G FillerDokument6 SeitenMetrode ER110S-G FillerBernie SimcsNoch keine Bewertungen

- Brass Material Property Data SheetDokument2 SeitenBrass Material Property Data SheetMuzammil Ali KhanNoch keine Bewertungen

- Hollow Bar Ovako 280Dokument3 SeitenHollow Bar Ovako 280fernandojNoch keine Bewertungen

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageDokument2 SeitenClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasNoch keine Bewertungen

- Kaiser Aluminum Shapes Soft Alloy PDFDokument18 SeitenKaiser Aluminum Shapes Soft Alloy PDFgerrzen64Noch keine Bewertungen

- E 2209 AcdcDokument2 SeitenE 2209 AcdcLuis Alejandro Gonzalez SantanaNoch keine Bewertungen

- InvarDokument5 SeitenInvardusan.papez9216Noch keine Bewertungen

- Zapp Precision Wire Inc Product CatalogueDokument49 SeitenZapp Precision Wire Inc Product CatalogueAyesha AleemNoch keine Bewertungen

- Dynaweld 12Dokument16 SeitenDynaweld 12Riverland Welding and Tool SuppliesNoch keine Bewertungen

- Aluminum 5052Dokument2 SeitenAluminum 5052Praveen ThomasNoch keine Bewertungen

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Dokument1 SeiteB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55Noch keine Bewertungen

- Userguide For SSDokument26 SeitenUserguide For SSehsan4uNoch keine Bewertungen

- Welding in Power SectorDokument50 SeitenWelding in Power SectoraadmaadmNoch keine Bewertungen

- LFBCW510L TN enDokument4 SeitenLFBCW510L TN endrgilleNoch keine Bewertungen

- Data Sheet A-10: Alloy TypeDokument3 SeitenData Sheet A-10: Alloy Typemohamed AdelNoch keine Bewertungen

- Technical Data Sheet: Stainless Steel: SuperausteniticDokument5 SeitenTechnical Data Sheet: Stainless Steel: SuperausteniticSue EpicNoch keine Bewertungen

- Sheet Metalwork Aluminium 5251Dokument2 SeitenSheet Metalwork Aluminium 5251Josko SpehNoch keine Bewertungen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesVon EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNoch keine Bewertungen

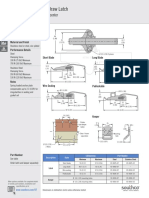

- V2 Draw Latch: Over-CenterDokument2 SeitenV2 Draw Latch: Over-CentermariomatoNoch keine Bewertungen

- Effective Modal Masses: 1 AbstractDokument4 SeitenEffective Modal Masses: 1 AbstractmariomatoNoch keine Bewertungen

- Aikido Shudokan Emag 2012Dokument61 SeitenAikido Shudokan Emag 2012mariomato100% (2)

- Some Recent Advances For Practical Finite Element AnalysisDokument11 SeitenSome Recent Advances For Practical Finite Element AnalysismariomatoNoch keine Bewertungen

- Unit 25 Essential Working Practices in Vehicle TechnologyDokument10 SeitenUnit 25 Essential Working Practices in Vehicle TechnologymariomatoNoch keine Bewertungen

- Fatigue Life Evaluation of Mechanical Components Using Vibration Fatigue Analysis TechniqueDokument7 SeitenFatigue Life Evaluation of Mechanical Components Using Vibration Fatigue Analysis TechniquemariomatoNoch keine Bewertungen

- Thermal Stress An A 00 MCM ADokument230 SeitenThermal Stress An A 00 MCM AmariomatoNoch keine Bewertungen

- Whirlpool Duet HTDokument96 SeitenWhirlpool Duet HTdanny85901100% (2)

- Estimate SR 14-15 02 KHANDEKARDokument5 SeitenEstimate SR 14-15 02 KHANDEKARAkshay SavvasheriNoch keine Bewertungen

- IEM PI A401 - ANNEXE - Design & Site ExperienceDokument5 SeitenIEM PI A401 - ANNEXE - Design & Site ExperienceapiplajengilaNoch keine Bewertungen

- Optimizing Technique-Grenade Explosion MethodDokument18 SeitenOptimizing Technique-Grenade Explosion MethodUday Wankar100% (1)

- Know PlywoodDokument3 SeitenKnow PlywoodNirvana NircisNoch keine Bewertungen

- Braun KF40 - CDokument17 SeitenBraun KF40 - CAgung UtoyoNoch keine Bewertungen

- Methods of Tube Expansion in Tube To TubDokument19 SeitenMethods of Tube Expansion in Tube To Tubkurcek100% (1)

- Bazele Matematice Ale Calculatoarelor - Florian Mircea BoianDokument132 SeitenBazele Matematice Ale Calculatoarelor - Florian Mircea BoiannimsocNoch keine Bewertungen

- Gathering Network RequirementsDokument30 SeitenGathering Network RequirementsAmin ZangetsuNoch keine Bewertungen

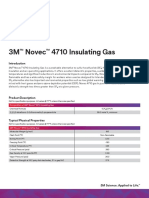

- SF6 Novec 4710Dokument4 SeitenSF6 Novec 4710Fidya Eka PrahestiNoch keine Bewertungen

- Woodworking Plans - Wheelbarrow PlanterDokument3 SeitenWoodworking Plans - Wheelbarrow PlanterMirel HotescuNoch keine Bewertungen

- Noise Optimization in Sensor Signal Conditioning Circuit Part IDokument37 SeitenNoise Optimization in Sensor Signal Conditioning Circuit Part Iyzhao148Noch keine Bewertungen

- Philips Aquatrio FC7070 - 01 Esploso ManualeDokument9 SeitenPhilips Aquatrio FC7070 - 01 Esploso ManualeRocco Mangione0% (1)

- Eje Delantero BMW F10Dokument94 SeitenEje Delantero BMW F10Daniel Muñoz SotomayorNoch keine Bewertungen

- Waqas Riaz: Total Years of Experience: 2 Years ObjectiveDokument2 SeitenWaqas Riaz: Total Years of Experience: 2 Years ObjectiveIrfanNoch keine Bewertungen

- Solar Module CellDokument4 SeitenSolar Module CellVinod BabhaleNoch keine Bewertungen

- Alloys DensityDokument4 SeitenAlloys DensityArnold Melissa CollettNoch keine Bewertungen

- Portal Info StubDokument11 SeitenPortal Info Stubzamanqomaru8Noch keine Bewertungen

- Steel Top Hats Battens Capacitytables Product Technical ManualDokument16 SeitenSteel Top Hats Battens Capacitytables Product Technical ManualbhukthaNoch keine Bewertungen

- Mech 3-Module 1Dokument41 SeitenMech 3-Module 1melkisidick angloanNoch keine Bewertungen

- Coastal DefenceDokument112 SeitenCoastal DefenceMorvin BudhanNoch keine Bewertungen

- RequirementsDokument18 SeitenRequirementsmpedraza-1Noch keine Bewertungen

- Standardization of Naoh 1Dokument3 SeitenStandardization of Naoh 1api-309208977Noch keine Bewertungen

- AI in RobotsDokument75 SeitenAI in RobotsIslam SehsahNoch keine Bewertungen

- WDU 2.5 enDokument14 SeitenWDU 2.5 enAhmadBintangNegoroNoch keine Bewertungen

- HighpuritysealsDokument6 SeitenHighpuritysealstuannhocutNoch keine Bewertungen

- 6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFDokument31 Seiten6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFOwen PerrinNoch keine Bewertungen

- Ude My For Business Course ListDokument51 SeitenUde My For Business Course ListShehroz BhuttaNoch keine Bewertungen

- 25252525Dokument38 Seiten25252525Ivan GonzalezNoch keine Bewertungen