Beruflich Dokumente

Kultur Dokumente

Design of Pile Caps - Mahila Samakya Buildings

Hochgeladen von

D.V.Srinivasa RaoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Pile Caps - Mahila Samakya Buildings

Hochgeladen von

D.V.Srinivasa RaoCopyright:

Verfügbare Formate

ANALAYSIS & DESIGN OF PILE CAPS

Mahilasamakhya Buildings

ANALAYSIS & DESIGN OF PILE CAPS

Mahilasamakhya Buildings

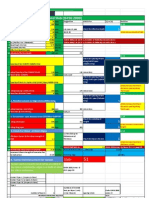

I) Design Parametres:-

Concrete mix : M20

Steel : Fe415

Cover to Reinforcement : 50mm

Unit weight of RCC = 25.0KN/cum

Unit weight of Brick masonry = 19.0KN/cum

Characteristic compressive strength of concrete = 20.00N/sqmm

Yield strength of steel = 415N/sqmm

Bredth of column = 0.30m

Depth of column = a = 0.38m

Dia of pile = 0.375m

Factored load on column = P = 777.35KN

II) Proportioning of pile cap:-

Factored load on the pile cap = 777.35KN

Add for self weight of pile cap = 77.74KN

Total load = P

u

= 855.09KN

As per Table 1 of IS:2911(Part III)-1980,safe load carrying capacity 375mm dia DUR piles in medium compact

sandy soils or clayey soils of medium consistency is = 360.00KN

As per clause 5.2.7.2 of IS:2911(Part III)-1980,the minimum spacing between the centre to centre of bored DUR

piles should not be less than 1.5D

u

.

Further as per clause 5.2.8.1,the load carrying capacity of each individual pile should be reduced by 10% due to

group action.

As per Table 1 of IS:2911(Part III)-1980,safe load carrying capacity 375mm dia DUR piles in medium compact

sandy soils or clayey soils of medium consistency is = 360.00KN

Providing two piles,the load carrying capacity of the pile cap will be 720.00KN

Reducing 10% per each pile due group action,the net safe load carrying 648.00KN

capacity

Hence,ultimate load carrying capacity of the pile cap = 972.00KN

Hence O.K

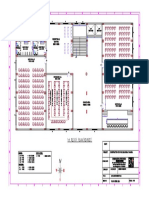

As per the above criteria,the proposed pile cap is as shown below:-

DESIGN OF PILE CAPS----PC1

2.13

0.70

0.15

piles

1.45

As such,the dimensions of the pile cap of as given below:-

The length of pile cap proposed = 2.13m

The width of pile cap proposed = 0.70m

Distance between c/c of piles = L = 1.45m

Shear span a

v

= 0.535m

III) Depth of pile cap:-

a)For bending action:-

The ultimate bending moment on the pile cap = M

u

= (P

u

/2)x[L/2-a/4] = 269.35KN-m

Adopting Limit state method of design M

u

= 0.138 f

ck

bd

2

The effective depth of footing required = d = [M

u

/(0.138f

ck

b)]

0.5

373.38mm

Over all depth required assuming 20mm dia bars = = 433.38mm

However assume 700mm overall depth,then the effective depth comes to 640.00mm

The actual depth of neutral axis = 88.66mm

Area of steel required = 1237.67sqmm

No.of 20mm dia bars required = 3.94Nos

Hence No.of 20mm dia bars to be provided within pile diametre = 5Nos

Then the area of reinforcement provided = 1570.00sqmm

Percentage of reinforcement provided = 0.35

b)Check for shear:-

The critical section of one way shear is at a distance of 'd' from the face of the column

Hence,the factored design shear force V

Fd

= 427.54KN

Nominal shear stress T

v

= 0.954N/sqmm <2.8 N/sqmm

(As per Table 20 of 1S 456)

2.13

0.70

0.15

piles

1.45

Hence,the section is safe from shear point of view

The percentage area of the tensile reinforcement provided = 0.350%

The design shear strength of concrete for the above steel percentage from

Table 19 of IS 456 is 0.408 N/sqmm

As per clause 40.5.1 of IS 456:2000,the shear strength can be increased by 2d/a

v

times for the sections located

at a distance closer than 2d from concentrated load or face of support,where a

v

is the shear span

2d/a

v

= 2.39

Hence,increased shear strength = 0.975 N/sqmm Hence V

uc

= 436.85KN

0.975 >0.954

Hence,no shear reinforcement is required.

c) Check for Truss action:-

The shear span to depth ratio = a

v

/d = 0.84 >0.60

Though,the truss action is not pre-dominant,the tensile reinforcement should be checked for horizontal tensile force ' H '

resulting from truss action,because a

v

/d ratio is not more than 2.

Hd=(P

u

/2)[L/2-a/4]

H = P

u

/8d[2L-a] = 420.86KN

Area of steel required to resist the above above tensile force A

st

= 1165.66sqmm

The tensile reinforcement provided is more than the above value.Hence O.K

d) Bursting steel:-

Generally 0.2 times tensile steel will be provided as bursting steel.

Hence,the bursting steel required = 314.00sqmm

Adopting 12mm rings,No.of rings required = 2.78

However,provide 4 Nos of 12mm dia rings as bursting steel.

As per Table 1 of IS:2911(Part III)-1980,safe load carrying capacity 375mm dia DUR piles in medium compact

As per clause 5.2.7.2 of IS:2911(Part III)-1980,the minimum spacing between the centre to centre of bored DUR

Further as per clause 5.2.8.1,the load carrying capacity of each individual pile should be reduced by 10% due to

As per Table 1 of IS:2911(Part III)-1980,safe load carrying capacity 375mm dia DUR piles in medium compact

> Total load

DESIGN OF PILE CAPS----PC1

2.13

0.70

0.15

piles

1.45

2.13

0.70

0.15

piles

1.45

As per clause 40.5.1 of IS 456:2000,the shear strength can be increased by 2d/a

v

times for the sections located

Though,the truss action is not pre-dominant,the tensile reinforcement should be checked for horizontal tensile force ' H '

Das könnte Ihnen auch gefallen

- Design of Two-Way Restrained Slab (IS456:2000)Dokument3 SeitenDesign of Two-Way Restrained Slab (IS456:2000)BasandharaAdhikariNoch keine Bewertungen

- RCC Rect Col-Dsn Kns 176Dokument7 SeitenRCC Rect Col-Dsn Kns 176nvnrevNoch keine Bewertungen

- Basement Wall DesignDokument2 SeitenBasement Wall DesignArindam RoyNoch keine Bewertungen

- Wcr= (h-x) 3 a ϵ 1+2 (a C) : Crack Width Calculation for ColumnDokument3 SeitenWcr= (h-x) 3 a ϵ 1+2 (a C) : Crack Width Calculation for ColumnAnil kumar RNoch keine Bewertungen

- EQ06 - Shear Wall and B.E. DesignDokument124 SeitenEQ06 - Shear Wall and B.E. DesignrahuljainNoch keine Bewertungen

- Analysis and Design of Pier CapDokument5 SeitenAnalysis and Design of Pier CapRoshan KejariwalNoch keine Bewertungen

- Design of Pile CapDokument3 SeitenDesign of Pile CapHaris Lee100% (2)

- Flat Slab 6 X 6 Ext PNLDokument5 SeitenFlat Slab 6 X 6 Ext PNLDarshan Shah100% (1)

- End Plate Moment ConnectionDokument3 SeitenEnd Plate Moment ConnectionIndustry Standard Structural DesignNoch keine Bewertungen

- Column Design - As Per BS CodeDokument16 SeitenColumn Design - As Per BS CodeYam BalaoingNoch keine Bewertungen

- Axial Circular Column DesignDokument5 SeitenAxial Circular Column Designkalpanaadhi100% (1)

- R.C.C Designs As Per Is 456-2000Dokument188 SeitenR.C.C Designs As Per Is 456-2000Umesh ChamaraNoch keine Bewertungen

- Eccentric-Footing 2Dokument5 SeitenEccentric-Footing 2Yash GoyalNoch keine Bewertungen

- Short Term Deflection Calculation (Subramanyam Example 12.4)Dokument9 SeitenShort Term Deflection Calculation (Subramanyam Example 12.4)Saugat ThapaNoch keine Bewertungen

- Retrofitting Columns 20JAN09Dokument4 SeitenRetrofitting Columns 20JAN094geniecivilNoch keine Bewertungen

- Elevated Rectangular Water Tank DesignDokument12 SeitenElevated Rectangular Water Tank DesignKhaled Ramadan0% (1)

- Pile Cap DesignDokument5 SeitenPile Cap DesignAddrien DanielNoch keine Bewertungen

- Design of RCC Footing As Per ACI 318 95 EdDokument2 SeitenDesign of RCC Footing As Per ACI 318 95 EdMaad Ahmed Al-MaroofNoch keine Bewertungen

- Detailed Longitudinal Section Through RCC Deep BeamDokument1 SeiteDetailed Longitudinal Section Through RCC Deep BeamShaikh ImranNoch keine Bewertungen

- Slab Design ExcelDokument5 SeitenSlab Design ExcelVinod RevankarNoch keine Bewertungen

- Isolated Footing For PedestalDokument3 SeitenIsolated Footing For Pedestalkushaljp8989Noch keine Bewertungen

- Cantilever SlabDokument16 SeitenCantilever SlabMukhlish AkhatarNoch keine Bewertungen

- Precast Dowel ConnectionDokument1 SeitePrecast Dowel ConnectionmathuNoch keine Bewertungen

- Pad Foundation With Two Columns ExampleDokument10 SeitenPad Foundation With Two Columns ExampleakankwasaNoch keine Bewertungen

- Rect. RCC Col. Design As Per IS 456 by K. N. ShethDokument10 SeitenRect. RCC Col. Design As Per IS 456 by K. N. ShethKanaiyalal N. ShethNoch keine Bewertungen

- A. For Column C: Design of Combined Footing (CF) : 1. Design DataDokument12 SeitenA. For Column C: Design of Combined Footing (CF) : 1. Design Datap_ignatiusNoch keine Bewertungen

- Steel Connection DesignDokument68 SeitenSteel Connection DesignPushkar KokaneNoch keine Bewertungen

- Project: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionDokument4 SeitenProject: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionEr Ravi VishwakarmaNoch keine Bewertungen

- Ductile Details To Seismic Forces - Is 13920Dokument4 SeitenDuctile Details To Seismic Forces - Is 13920MUTHUKKUMARAMNoch keine Bewertungen

- Design of UG Water Tank As Per Is CodeDokument3 SeitenDesign of UG Water Tank As Per Is Codeprabhu_civil20Noch keine Bewertungen

- Design of 75Kl Zinc Alume (Znal) Elevated Water Storage TankDokument26 SeitenDesign of 75Kl Zinc Alume (Znal) Elevated Water Storage TankSmit PatelNoch keine Bewertungen

- Isolated Footing DesignDokument14 SeitenIsolated Footing DesignDhandapany ArunNoch keine Bewertungen

- JassimDokument29 SeitenJassimZain Communication0% (1)

- Section Properties: Column Design As Per IS:456-2000 Column No. 3Dokument4 SeitenSection Properties: Column Design As Per IS:456-2000 Column No. 3Eknath TaleleNoch keine Bewertungen

- Design Z Section PurlinDokument9 SeitenDesign Z Section PurlinSudipta HuiNoch keine Bewertungen

- Crack Width Calculation For Rectangular RC BeamDokument1 SeiteCrack Width Calculation For Rectangular RC BeamRomyMohanNoch keine Bewertungen

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDokument56 SeitenSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNoch keine Bewertungen

- Design of Two Pile Cap DATADokument4 SeitenDesign of Two Pile Cap DATAhemanth funny100% (1)

- Design of Simply Supported One Way SlabDokument15 SeitenDesign of Simply Supported One Way SlabNikhil100% (2)

- Reinforced Concrete Rectangular Beam Design To AS3600-2009Dokument4 SeitenReinforced Concrete Rectangular Beam Design To AS3600-2009Rron de GuzmanNoch keine Bewertungen

- CompositeDokument11 SeitenCompositeluuvandong48xf396100% (1)

- Peb Design PPT ModelDokument37 SeitenPeb Design PPT ModelYELLAMANDA SANKATINoch keine Bewertungen

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Dokument14 SeitenGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsNoch keine Bewertungen

- PDF Wind Load Calculations As Per Is 875 Part 3xls CompressDokument85 SeitenPDF Wind Load Calculations As Per Is 875 Part 3xls CompressNews Side Effects.Noch keine Bewertungen

- Structural Calculation Report - BuildingDokument41 SeitenStructural Calculation Report - Buildingarafat.cuet99Noch keine Bewertungen

- Design Basis Report (DBR) : Proposed Steel Truss With Crane Essembly"Dokument18 SeitenDesign Basis Report (DBR) : Proposed Steel Truss With Crane Essembly"Architects AsiaNoch keine Bewertungen

- Loads: Short Column With Axial LoadingDokument5 SeitenLoads: Short Column With Axial LoadingMohd AftabNoch keine Bewertungen

- Design of Reinforced Concrete Shear WallDokument8 SeitenDesign of Reinforced Concrete Shear WallklynchelleNoch keine Bewertungen

- 1 10 PDFDokument10 Seiten1 10 PDFV.m. RajanNoch keine Bewertungen

- Design of T Beam Using SP16 Economic Depth and CheckDokument10 SeitenDesign of T Beam Using SP16 Economic Depth and CheckRiazahemad B JagadalNoch keine Bewertungen

- XyzDokument64 SeitenXyzP S HARSHITANoch keine Bewertungen

- Slab Design of Partially Fixed Circular SlabDokument4 SeitenSlab Design of Partially Fixed Circular SlabBithika DattaNoch keine Bewertungen

- Nib CalculationDokument1 SeiteNib CalculationKen LuuNoch keine Bewertungen

- Combined FootingDokument15 SeitenCombined FootingAbhishek GuptaNoch keine Bewertungen

- IAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanDokument29 SeitenIAT-IV Question Paper With Solution of 18CV72 Design of RC and Steel Structural Elements Feb-2022-Sreelakshmi GopalakrishnanSrikanth ReddyNoch keine Bewertungen

- Seismic Performance of Concrete-Shear-Wall Buildings in IndiaDokument16 SeitenSeismic Performance of Concrete-Shear-Wall Buildings in IndiaMohamed100% (1)

- Design of Model Anganwadi BuildingDokument19 SeitenDesign of Model Anganwadi BuildingD.V.Srinivasa Rao100% (2)

- 20 KL SWCPH PekhlonDokument10 Seiten20 KL SWCPH PekhlonrahulNoch keine Bewertungen

- Example of Design of A Deep Beam Using Strut Tie ModelDokument34 SeitenExample of Design of A Deep Beam Using Strut Tie Modeldaniel workuNoch keine Bewertungen

- Compression Members ProblemsDokument23 SeitenCompression Members ProblemsReyNoch keine Bewertungen

- Community Pathanaguluru PLANDokument1 SeiteCommunity Pathanaguluru PLAND.V.Srinivasa RaoNoch keine Bewertungen

- RCC Drain DesignDokument1 SeiteRCC Drain DesignD.V.Srinivasa RaoNoch keine Bewertungen

- Old Designs ApprovedDokument14 SeitenOld Designs ApprovedD.V.Srinivasa RaoNoch keine Bewertungen

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDokument1 SeiteYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterD.V.Srinivasa RaoNoch keine Bewertungen

- Plan of BuildingDokument1 SeitePlan of BuildingD.V.Srinivasa Rao100% (1)

- DPRC at Kanuru FF Plan - RevisedDokument1 SeiteDPRC at Kanuru FF Plan - RevisedD.V.Srinivasa RaoNoch keine Bewertungen

- VJA Meeting Hall Detailed EstimateDokument56 SeitenVJA Meeting Hall Detailed EstimateD.V.Srinivasa Rao100% (1)

- Working Women's HostelDokument21 SeitenWorking Women's HostelD.V.Srinivasa RaoNoch keine Bewertungen

- 21 Column ProformaDokument2 Seiten21 Column ProformaD.V.Srinivasa RaoNoch keine Bewertungen

- Design of Isolated Footing (Rf1 - 14&20) : Input DataDokument1 SeiteDesign of Isolated Footing (Rf1 - 14&20) : Input DataD.V.Srinivasa RaoNoch keine Bewertungen

- DPRC 1st Floor Plan RevisedDokument1 SeiteDPRC 1st Floor Plan RevisedD.V.Srinivasa RaoNoch keine Bewertungen

- Proposals For Improvements To Rubbish Roads: S.No Mandal Grampanchayat Name of The Road LengthDokument4 SeitenProposals For Improvements To Rubbish Roads: S.No Mandal Grampanchayat Name of The Road LengthD.V.Srinivasa RaoNoch keine Bewertungen

- Detailed Report RNBDokument8 SeitenDetailed Report RNBD.V.Srinivasa RaoNoch keine Bewertungen

- Design - Fish MarketDokument7 SeitenDesign - Fish MarketD.V.Srinivasa RaoNoch keine Bewertungen

- Government of Andhrapradesh Panchayat Raj Engineering DepartmentDokument2 SeitenGovernment of Andhrapradesh Panchayat Raj Engineering DepartmentD.V.Srinivasa RaoNoch keine Bewertungen

- Muslim's Shadikhana Community Hall Plan & Soil ReportDokument8 SeitenMuslim's Shadikhana Community Hall Plan & Soil ReportD.V.Srinivasa RaoNoch keine Bewertungen

- Kankipadu Mandal AMC RecordingDokument23 SeitenKankipadu Mandal AMC RecordingD.V.Srinivasa RaoNoch keine Bewertungen

- D.V.Srinivasa Rao: Csi Bridge 2014, Bentley Leap Bridge Enterprise, Staad BeavaDokument5 SeitenD.V.Srinivasa Rao: Csi Bridge 2014, Bentley Leap Bridge Enterprise, Staad BeavaD.V.Srinivasa RaoNoch keine Bewertungen

- Balive Bridge EstimateDokument77 SeitenBalive Bridge EstimateD.V.Srinivasa Rao100% (1)

- Design of Structure: Construction of M.M.S.Building at NarsapurDokument4 SeitenDesign of Structure: Construction of M.M.S.Building at NarsapurD.V.Srinivasa RaoNoch keine Bewertungen

- Kavity StadiumDokument21 SeitenKavity StadiumD.V.Srinivasa RaoNoch keine Bewertungen

- Design of Typical Community HallDokument52 SeitenDesign of Typical Community HallD.V.Srinivasa Rao0% (1)

- Design of Structure: Construction of F.C.O Lab Building at T.P.GudemDokument17 SeitenDesign of Structure: Construction of F.C.O Lab Building at T.P.GudemD.V.Srinivasa RaoNoch keine Bewertungen

- Community Hall-Model EstimateDokument16 SeitenCommunity Hall-Model EstimateD.V.Srinivasa RaoNoch keine Bewertungen

- Topic 1: Relevant Regulations in Hazardous Waste ManagementDokument5 SeitenTopic 1: Relevant Regulations in Hazardous Waste ManagementD.V.Srinivasa RaoNoch keine Bewertungen

- Donkuru Bridge Repairs Work Est.Dokument17 SeitenDonkuru Bridge Repairs Work Est.D.V.Srinivasa RaoNoch keine Bewertungen

- Repairs To The Approach Road To PR Sub Division at IchapuramDokument8 SeitenRepairs To The Approach Road To PR Sub Division at IchapuramD.V.Srinivasa RaoNoch keine Bewertungen

- Vatluru Auction EstimateDokument15 SeitenVatluru Auction EstimateD.V.Srinivasa RaoNoch keine Bewertungen

- EGK Road To SeethampetaDokument41 SeitenEGK Road To SeethampetaD.V.Srinivasa RaoNoch keine Bewertungen

- Proformas of Heavy RainsDokument6 SeitenProformas of Heavy RainsD.V.Srinivasa RaoNoch keine Bewertungen

- Calculations of Notch Stress FactorDokument1 SeiteCalculations of Notch Stress FactorricardoNoch keine Bewertungen

- 1996 Von Wolffersdorff 1996 Mechanics of Cohesive-Frictional Materials Hypoplastic ModelDokument21 Seiten1996 Von Wolffersdorff 1996 Mechanics of Cohesive-Frictional Materials Hypoplastic ModelxiangyugeotechNoch keine Bewertungen

- Wrinkling Limit in Tube Bending: Xi Wang Jian CaoDokument6 SeitenWrinkling Limit in Tube Bending: Xi Wang Jian CaoYavuz KeskinNoch keine Bewertungen

- Assignment 8 SolutionDokument8 SeitenAssignment 8 SolutionSrinivas ShareNoch keine Bewertungen

- Fracture Mechanics Project On Plastic Deformation Using AnsysDokument12 SeitenFracture Mechanics Project On Plastic Deformation Using AnsysVipul Agrawal100% (1)

- Chapter 8 Failure Analysis and PreventionDokument76 SeitenChapter 8 Failure Analysis and Preventionminh_bk0101100% (1)

- Geotech Scope of WorkDokument3 SeitenGeotech Scope of Worksamirbendre1100% (1)

- Ce 513 Plates and Shells 2-Equations Governing Bending of Beams & Rectangular PlatesDokument36 SeitenCe 513 Plates and Shells 2-Equations Governing Bending of Beams & Rectangular PlatesabdulqaderNoch keine Bewertungen

- 8.0 Definition of Soil ConsistencyDokument9 Seiten8.0 Definition of Soil ConsistencySugiarYusufNoch keine Bewertungen

- BarChip Flooring-Design-Guideline 2018 Email-1Dokument60 SeitenBarChip Flooring-Design-Guideline 2018 Email-1Diego LazoNoch keine Bewertungen

- Montalban Earth Dam: Permeability TestDokument20 SeitenMontalban Earth Dam: Permeability TestMon MargalloNoch keine Bewertungen

- Study On Analysis of Flexible Pavement Using Finite Element Based Software Tool IJERTV4IS090865Dokument5 SeitenStudy On Analysis of Flexible Pavement Using Finite Element Based Software Tool IJERTV4IS090865pravin surveNoch keine Bewertungen

- Example - Buckling Resistance of A Pinned Column With Intermediate RestraintsDokument5 SeitenExample - Buckling Resistance of A Pinned Column With Intermediate RestraintsAndreea NanNoch keine Bewertungen

- Lecture 3 - Drained and Undrained BehaviorDokument19 SeitenLecture 3 - Drained and Undrained BehaviorAmr Elshanawany100% (1)

- 3muri Brief Theory PDFDokument19 Seiten3muri Brief Theory PDFIvan AntonovNoch keine Bewertungen

- Modeling Effects On Forces in Shear Wall-Frame Structures: Adang SurahmanDokument9 SeitenModeling Effects On Forces in Shear Wall-Frame Structures: Adang SurahmanTrio HardiyantoNoch keine Bewertungen

- ColumnsDokument2 SeitenColumnsShiva Kumar Raju RajuNoch keine Bewertungen

- Lapping of Column BarsDokument15 SeitenLapping of Column Barssaistructure3500Noch keine Bewertungen

- Badal and Sinha (2020) - A Framework To Incorporate Probabilistic Performance in Force Based Seismic Design of RC Buildings As Per Indian StandardsDokument29 SeitenBadal and Sinha (2020) - A Framework To Incorporate Probabilistic Performance in Force Based Seismic Design of RC Buildings As Per Indian StandardsSuman BanerjeeNoch keine Bewertungen

- Slpope Stability and Soil Shearing CapcityDokument9 SeitenSlpope Stability and Soil Shearing CapcityMohammed Naeem MusorNoch keine Bewertungen

- ICTAD-DEV-14 - Fire Regulations (Not Available) PDFDokument17 SeitenICTAD-DEV-14 - Fire Regulations (Not Available) PDFAvk SanjeevanNoch keine Bewertungen

- Design of Inverted Strip Fdn. BeamDokument7 SeitenDesign of Inverted Strip Fdn. Beamakankwasa100% (4)

- Test ConfigurationsDokument4 SeitenTest ConfigurationsThiago DelgadoNoch keine Bewertungen

- SX002a-En-EU-Example - Buckling Resistance of A Pinned Column With Intermediate RestraintsDokument5 SeitenSX002a-En-EU-Example - Buckling Resistance of A Pinned Column With Intermediate RestraintsWNoch keine Bewertungen

- Structural ReviewerDokument23 SeitenStructural ReviewerrogggNoch keine Bewertungen

- Cam ClayDokument15 SeitenCam ClayRico BartolomeNoch keine Bewertungen

- Mat Foundation Design PDFDokument3 SeitenMat Foundation Design PDFCivil Construction And TutorNoch keine Bewertungen

- PreviewpdfDokument63 SeitenPreviewpdfmamoun hammadNoch keine Bewertungen

- 5729 8Dokument27 Seiten5729 8americo tomas guerrero cardenasNoch keine Bewertungen

- AssignmentDokument9 SeitenAssignmentAlam Mohammad Parvez Saifi100% (1)