Beruflich Dokumente

Kultur Dokumente

Sfim 14000 0402

Hochgeladen von

Ricky Ocktavi RizkyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sfim 14000 0402

Hochgeladen von

Ricky Ocktavi RizkyCopyright:

Verfügbare Formate

Siemens Energy & Automation, Inc.

Reduced Voltage Controllers

Wye-Delta, Part-Winding And Autotransformer

Installation, Operation And Maintenance Instructions

SFIM-14000-0402

April, 2002

Siemens Energy & Automation, Inc. 2

Hazardous voltage.

Will cause death or serious injury.

Always de-energize and ground the equip-

ment before maintenance. Read and

understand this manual before installing,

operating or maintaining the equipment.

Maintenance should be performed only

by qualified personnel. The use of unau-

thorized parts in the repair of the equip-

ment or tampering by unqualified person-

nel may result in dangerous conditions

which may cause death or serious injury,

or equipment or property damage. Follow

all safety instructions contained herein.

QUALIFIED PERSON

For the purposes of this manual and product

labels, a qualified person is one who is familiar

with the installation, construction, operation or

maintenance of the equipment and the haz-

ards involved. In addition this person has the

following qualifications:

(a) is trained and authorized to energize,

de-energize. clear, ground and tag cir-

cuits and equipment in accordance with

established safety practices.

(b) is trained in the proper care and use of

protective equipment such as rubber

gloves, hard hat, safety glasses or face

shields, flash clothing, etc., in accor-

dance with established safety practices.

(c) is trained in rendering first aid.

SIGNAL WORDS

The signal words Danger, Warning and

Caution used in this manual indicate the

degree of hazard that may be encountered by

the user. These words are defined as:

Danger - Indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

Warning - Indicates a potentially hazardous

situation which, if not avoided, could result in

death, serious injury or property damage.

Caution - Indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be

used to alert against unsafe practices.

IMPORTANT

These instructions do not purport to cover all details or variations in equipment, nor to provide for every possible contingency to

be met in connection with installation, operation or maintenance. Should further information be desired or should particular

problems arise which are not covered sufficiently for the purchasers purposes, the matter should be referred to the local

Siemens sales office. The contents of this instruction manual shall not become part of or modify any prior or existing agree-

ment, commitment or relationship. The sales contract contains the entire obligation of Siemens. The warranty contained in the

contract between the parties is the sole warranty of Siemens. Any statements contained herein do not create new warranties

or modify the existing warranty.

Siemens Energy & Automation, Inc. 3

Table of Contents

1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Handling And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Parts And Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4 Introduction To Reduced Voltage Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

5 Autotransformer Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 9

6 Wye Delta Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 12

7 Part Winding Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-14

8 Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9 Maintenance / Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 - 17

10 Maintenance / Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

11 Preventative Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Siemens Energy & Automation, Inc. 4

Hazardous voltage.

Will cause death or serious injury.

To avoid electrical shock or burn, turn off

main and control voltages before perform-

ing installation or maintenance.

1 General Information

This product contains hazardous voltages. Severe personal

injury, death or property damage can result if safety instructions

are not followed. Only qualified personnel should work on or

around this equipment after becoming thoroughly familiar with

all warnings, safety notices, and maintenance procedures con-

tained herein.

Turn off power supplying this equipment before any adjust-

ments, servicing, wiring, parts replacement, or before any act

requiring physical contact with electrical working components

of this equipment is performed.

The successful and safe operation of electrical equipment is

dependent upon proper handling, installation, operation and

maintenance, as well as upon proper design and manufacture.

Failure to follow these installation and maintenance instructions

may also lead to the failure and loss of control equipment, as

well as damage to other property.

Siemens Reduced Voltage Controllers are built in accordance

with applicable provisions of NEMA and ANSI Standards, and

the National Electrical Safety Code. These publications and this

instruction manual should be thoroughly read and understood

prior to beginning any work on this equipment.

Qualified Person

For the purpose of this manual and product labels, a qualified

person is one who is familiar with the installation, construction

and operation of the equipment, and the hazards involved. In

addition, he has the following qualifications:

(a) Is trained and authorized to energize, de-energize, clear,

ground and tag circuits and equipment in accordance with

established safety practices.

(b) Is trained in the proper care and use of protective equipment

such as rubber gloves, hard hat, safety glasses or face

shields, flash clothing, etc., in accordance with established

safety practices.

(c) Is trained in rendering first aid.

Danger

For the purpose of this manual and product labels, DANGER

indicates an imminently hazardous situation which, if not avoid-

ed, will result in death or serious injury.

Warning

For the purpose of this manual and product labels, WARNING

indicates a potentially hazardous situation which if not avoided,

could result in death, serious injury or property damage.

Caution

For the purpose of this manual and product labels, CAUTION

indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

2 Handling And Installation

General

Although no special mountings or foundations are normally

required, the controller should be mounted in a reasonably level

position and adequately secured to prevent shifting.

Carefully remove any temporary packing, bracing, or blocking

from each device. Operate each movable contact device manu-

ally to assure free movement. Remove all traces of foreign mat-

ter from all contact surfaces.

Check to see that there are no loose connections and that ade-

quate clearances are maintained for the installation.

All external wiring from the controller must be made in strict

accordance with the main connection diagram supplied with the

unit and the National Electrical Code.

If supplied, the entire current transformer secondary circuit

should be checked for continuity of connections, as an open cir-

cuit could cause extremely high secondary voltages to be gen-

erated.

Siemens field service technicians are available for installation

and start-up supervision if desired. The cost of this supervisory

service is usually offset by a considerable saving in installation

time. For details, contact your nearest Siemens Sales Office.

Handling And Lifting

Shipment from the factory is usually accomplished by lag bolt-

ing the controller to a wooden skid. These controllers can be

moved with a fork lift truck providing the load is balanced and

steadied to prevent tipping.

Lifting eyebolts or angles are supplied as standard on larger

units for use with crane or hoist. Spreader bars should be used

when lifting eyebolts are provided.

The skid and lifting means should not be removed before instal-

lation.

If these instructions are ignored and controller is energized with-

out arc chutes in place, the warranty on this equipment is auto-

matically voided. Severe damage to controller components or

possible injury to personnel may result if contactors and starters

are operated without arc chutes in place.

Inspection

The controller and all accessory devices are normally shipped in

a single package. As soon as it is received, carefully inspect for

shortage or damage. If accessory items are a part of the ship-

ment thoroughly check each for damage. Recheck entire ship-

ment against the shipping manifest. If any shortage or damage

is found, immediately notify the local freight agent handling the

shipment. Proper notation should be made by the agent on the

freight bill to prevent any controversy or delay when a claim is

made.

Storage

The controller should be stored in a dry location at a uniform

temperature to prevent condensation.

Controllers designed for indoor applications do not have suffi-

cient packaging for outdoor storage. Additional packaging for

protection from the outside elements and temporary heat to

prevent condensation should be installed.

Controllers designed for outdoor applications should have space

heaters installed with a temporary electrical hookup to prevent

condensation.

Siemens Energy & Automation, Inc. 5

Hazardous voltage.

Will cause death or serious injury.

To avoid electrical shock or burn, turn off

main and control voltages before perform-

ing installation or maintenance.

Do not apply power to the Controller until the Operation and Maintenance Start-Up sections have been studied.

3 Parts And Service

This product contains hazardous voltages. Severe personal

injury, death or property damage can result if safety instructions

are not followed. Only qualified personnel should work on or

around this equipment after becoming thoroughly familiar with

all warnings, safety notices, and maintenance procedures con-

tained herein.

Disconnect and lock-out incoming power and control voltage

sources before beginning work on this or any other electrical

equipment.

Check all control circuit terminals with a voltmeter to make cer-

tain that the equipment is totally de-energized. Use only

approved high voltage test equipment to check power termi-

nals. Do not attempt to measure high voltage with a volt-ohm

meter.

It is recommended that a safety ground be connected to the

power bus after the system has been de-energized, and prior to

working on the equipment. Follow the procedure outlined in the

pre-energization check section of this manual before power is

restored.

For the safety of maintenance personnel as well as others who

might be exposed to hazards associated with maintenance

activities, the safety related work practices of NFPA 70E, part 11,

should always be followed when working on electrical equip-

ment. Maintenance personnel should be trained in the safety

practices, procedures, and requirements that pertain to their

respective job assignments.

The customer must establish a periodic maintenance program

to ensure trouble-free and safe operation. The frequency of

inspection, periodic cleaning and preventive maintenance

schedule will depend upon the operating conditions. NFPA

Publication 70B Electrical Equipment Maintenance may be

used as a guide to establish such a program. A preventive main-

tenance program is not intended to cover reconditioning or

major repair, but should be designed to reveal, if possible the

need for such actions in time to prevent malfunctions during

operation.

The items shown on the preventive maintenance checklist on

page 19 should be included in the preventive maintenance

program.

Parts And Service

When ordering parts, always give description and catalog

number of part desired and the following information for the

controller.

Catalog Number

Siemens Sales Order Number

Item Number

Customer Identification Number

The above information can be found on the inside of the starter

door. If possible, use the part number shown on each compo-

nent when requesting repair parts information from your

Siemens Sales Office or distributor.

To insure that Siemens quality standards are maintained, be

sure that genuine Siemens renewal parts are used when refur-

bishing the controller. Using non-Siemens replacement parts

may affect product warranty.

In case of major breakdown, contact the Siemens Sales Office

nearest you. Experienced field service personnel are available.

Siemens Energy & Automation, Inc. 6

Hazardous voltage.

Will cause death or serious injury.

To avoid electrical shock or burn, turn off

main and control voltages before perform-

ing installation or maintenance.

4 Introduction To Reduced Voltage

Controllers

Reduced voltage controllers are used to reduce the magnitude

of line current drawn at starting or to reduce the starting torque

of the motor applied to the drive load or both. Several types of

reduced voltage controllers are available and each exhibits dif-

ferent torque-current characteristics. When choosing a reduced

voltage controller, the individual application should be studied

carefully so that the best controller is selected.

A typical induction motor (Design B Code F thru K) has a start-

ing current of approximately 5 to 9 times rated motor current if

connected across the line at 100% voltage.

The starting torque produced by an induction motor is approxi-

mately proportional to the square of the stator current. For

example, a motor drawing 50% normal starting current pro-

duces approximately 25% rated torque. All reduced voltage

controllers operate in some way to reduce the current drawn by

the motor (and hence reduce the torque) on starting.

Some reduced voltage controllers lower the starting current and

torque by means of an autotransformer. Another common

means used for reduced voltage starting is connecting or recon-

necting the leads of multi-lead motors in various combinations.

This is typical of part winding and wye-delta starters.

Depending on the type of controller used, the motor will pro-

duce a different amount of torque on starting for a given value

of current drawn from the line. Some controllers provide for

adjustment of the starting current and torque by changing taps

on autotransformers while in others, such as part-winding and

wye-delta controllers, the starting values are fixed by the motor

design. On starters having a multi-tap arrangement, changing to

a higher tap setting (higher starting voltage) will reduce acceler-

ating time and increase starting torque. Lower tap settings will

cause the accelerating period to be longer and will reduce the

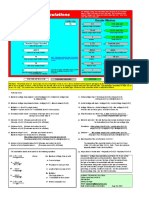

torque produced during this period. Table 1 is a summary of

the characteristics of the different types of reduced voltage

controllers.

Siemens Energy & Automation, Inc. 7

Reduced Voltage Starting

Characteristics Autotransformer Part-Winding Wye(Star) - Delta

50% 65% 80% 2 Step

Tap Tap Tap

Starting current drawn from line as %

of that which would be drawn upon 25% 42% 64% 65%

33%

full voltage starting.

Starting current drawn by the motor 50% 65% 80% 65%

58%

Starting torque developed as % of 25% 42% 64%

that which would be developed on Increasing slightly 40%

33%

full voltage starting. with speed.

Smoothness of acceleration First in order Third in order Second in order

of smoothness of smoothness of smoothness

Allowable accelerating times 15 seconds at 200HP max 5 seconds max 5 - 60 seconds

(typical) or 30 seconds on > 200 HP Limited by Limited by

based on NEMA medium motor design

motor design

Starting current and torque Adjustable within

and adjustments limits of various taps

Fixed

Closed transition

Approximate values only. Exact values may be obtained from motor manufacturer

Full voltage start usually draws between 500% and 900% of full-load current

Open or closed transition

Starting mode time for part winding

Percent of the motor phase winding current

50% tap not standard for 50HP and smaller

Table 1 - General comparison for various methods of Reduced Voltage motor starting

5 Autotransformer Controllers

Reduced Voltage Autotransformer - Size 1 To 7

Refer to the typical schematic diagram for NEMA Size 1 to 7

controllers shown in Figure 1.

If 3-wire control is used, connect the momentary start pushbut-

ton between terminals 2 and 3; stop pushbutton between 1 and

2. If 2-wire control is used, jumper terminals 2 and 3 and con-

nect the remote control contact between terminals 1 and 2.

Sequence Of Operations

The (TR) and (MR) coils are energized by pressing the Start but-

ton. As (TR) is energized the timing sequence begins. When

relay (MR) is energized, the normally open contacts of (MR)

close energizing contactor coil (1S). As soon as (1S) contactor

is energized the (2S) contactor coil is energized. Voltage is now

being

applied through (2S), the autotransformer, and the (1S) contac-

tor to the motor stator windings.

The motor accelerates on reduced line voltage determined by

the percentage tap used on the autotransformer. After a preset

time the timing relay (TR) times out and energizes the (CR1)

relay. As (CR1) is energized the (1S) coil is de-energized which

in turn energizes the (R) contactor. When the (R) contactor is

energized the (2S) contactor is de-energized. This leaves only

the (R) contactor energized which puts the motor on full line

voltage.

Siemens Energy & Automation, Inc. 8

OPTIONAL

DISCONNECT

or CIRCUIT

BREAKER

CONNECT

VOLTAGE

AS SPECIFIED

PER NAMEPLATE

FOR MOTOR

HP SEE

CONTROLLER

NAMEPLATE

FOR STARTER

SIZES 1-4, ICT-3CT

ARE NOT USED

2CT

1CT

3CT

J

U

M

P

E

R

OL

OL

OL

OL

OL

OL

(A1)

(A1)

(A2)

(A2) (95) (96)

OL

(A1) (A2)

(A1) (A2)

(A1) (A2)

Legend: (Components supplied as required)

R - Run Starter

1S - No. 1 Start Contactor

2S - No. 2 Start Contactor

CR1 - Time Delayed Relay

CR2 - Relay

TR - Starting Timer

TAS - Auto Transformer Over

Temperature Switch

MR - Master Control Relay

- Customer Connection Point

# - Device Termination Point

Figure 1

5LT

4LT

1LT

ETM

CONNECTIONS FOR OPTIONAL DEVICES

OPTIONAL DEVICES ARE FURNISHED PER

CONTRACT DOCUMENTS

Notes:

A. Class 36-branch circuit protection, fused disconnect or circuit breaker must be provided by installer since circuit

breaker or fusible disconnect is not factory installed.

B. Unwired auxiliary interlocks supplied in control relay (CR2) as specified by customer.

C. Unwired auxiliary interlocks are not shown on diagram for the R starter.

D. For protection of internal control circuit conductors in accordance with the N.E.C., use fuse kit 49MAFB4.

E. Remove jumper if thermal protective switch is provided.

F. 1, 2, 3CT may be located on line side of contactor depending on circuit design.

G. For separate source control connect separate source between TB points 12 and X2.

Siemens Energy & Automation, Inc. 9

Autotransformer Duty Cycle

The autotransformers used in standard controllers conform to

NEMA standards for medium duty and are suitable for general

motor starting service.

The starting duty cycle rating based on a 65% tap, with tap cur-

rent 300% of motor full-load current and a power factor of 50%

or less as follows:

Total of 15 cycles

Total of 3 cycles

If it is suspected or found that the acceleration period is longer

than 15 seconds for 200hp and smaller motors or 30 seconds for

larger motors, consult factory and motor manufacturer.

Transition Timer Setting

The timing cycle of the transition timer relay (TR) should be set

to obtain transfer after motor has accelerated to its maximum

speed on reduced voltage. For proper setting of this timer, refer

to the start-up section of this instruction book.

Starting voltage tap settings should be selected so that the

motor will start turning and accelerate smoothly to full speed in

the allowable starting time.

Motor Horsepower

Duty Cycle

To 200

Above 200 to

3000 inclusive

On 15 sec. 30 sec.

Off 3 min., 45 sec. 30 sec.

Repeat 14 times

2 times

Rest 2 hours 1 hour

Repeat As above As above

Under normal operating conditions

the transfer time should not exceed

the duty cycle of the autotransformer.

Allow cooling between trials if above duty

cycle timer setting is used.

Table 2

Siemens Energy & Automation, Inc. 10

6 Wye Delta Controllers

Reduced Voltage Wye-Delta Open And Closed

Transition

These controllers are applicable only to motors wound for wye-

delta starting and with all six leads brought out into the motor

junction box. Motors should be suitable for starting with wind-

ings in wye connection and normal running with windings in

delta connection. Such motors would normally be marked with

locked rotor KVA Code A.

Open Transition

Refer to the typical schematic diagram shown in Figure 2.

If 3-wire control is used, connect the momentary start pushbut-

ton between terminals 2 and 3; stop pushbutton between 1 and

2. If 2-wire control is used, jumper terminals 2 and 3 and con-

nect a remote control contact between terminals 1 and 2.

Sequence Of Operation - Open Transition Wye Delta

(Sizes 1 - 7)

Pressing the start button energizes the (CR1) relay, (TR) timer,

and (MR) relay. As soon as (CR1) and (MR) are energized the

normally open contacts close energizing the (S) contactor. With

(S) contactor energized the (1M) contactor energizes. The (S)

and (1M) contactors remain energized while timer (TR) times

out. When the timing sequence ends (CR1) is de-energized

which opens the (CR1) contact, de-energizing the (S) contactors.

As soon as the (S) contactors is de-energized the (2M) contac-

tor is energized which connects the circuit to the motor in Delta.

Pressing stop, or overload relay trip, will de-energize all contac-

tors and remove the motor from the line.

The wye-delta starter overload relays are connected in the motor

phase circuits in series with the (1M) contactor. Therefore, the

overload relay current is 58% of the motor line current.

See page 15 for setting instructions.

Siemens Energy & Automation, Inc. 11

CONNECT

VOLTAGE

AS SPECIFIED

PER NAMEPLATE

OPTIONAL

DISCONNECT

OR

CIRCUIT BREAKER

(A1) (A2)

(A1) (A2)

(A1) (A2)

(A1)

(A1)

(95) (96)

(A2)

H3 H2

(A2)

Figure 2

Legend

- Customer Connection Point

1M - First Main Contactor

2M - Second Main Contactor

S - Shorting Contactor

MR - Master Control Relay

CR1 - Time Delayed Relay

CR2 - Relay

TR - Timer

OL - Main Starter O/L Relay

(#) - Device Termination Point

Notes:

A. Class 36-branch circuit protection, fused disconnect or circuit breaker

must be provided by installer since circuit breaker or fusible disconnect is

not factory installed.

B. For protection of internal control circuit conductors in accordance with the

N.E.C., use fuse kit 49MAFB4.

C. Set TR for transition time required.

D. For separate control voltage connect source to terminals 1 and X2.

E. 2CT may be located on line side of contactor depending on circuit design.

F. Unwired auxiliary interlocks are not shown on diagram for the 1M starter.

1LT

ETM

4LT

5LT

CONNECTIONS FOR OPTIONAL DEVICES

OPTIONAL DEVICES ARE FURNISHED PER

CONTRACT DOCUMENTS

Siemens Energy & Automation, Inc. 12

OPTIONAL

DISCONNECT

OR

CIRCUIT BREAKER

(A1) (A2)

(A1) (A2)

(A1) (A2)

(A1) (A2)

H3 H2 CONNECT

VOLTAGE

AS SPECIFIED

PER NAMEPLATE

(A1) (A2)

(A1) (A2)

Closed Transition - Wye Delta

Refer to the typical schematic diagram shown in Figure 3.

If 3-wire control is used, connect the momentary start pushbut-

ton between terminals 2 and 3; stop pushbutton between 1 and

2. If 2-wire control is used, jumper terminals 2 and 3 and con-

nect a remote control contact between 1 and 2.

Closed transition wye-delta controllers contain all the compo-

nents used in open-transition plus a 3-pole transition contactor

(1A) a set of resistors (RES) to maintain continuity of the motor

connection to the line during transition.

As in open-transition starting, pressing the start button energizes

the (MR) relay, and (TR) timer. Relay (CR1) is energized as soon

a power is applied to the control circuit. As soon as (MR) relay is

energized (S) contactor is energized and in turn (1M) contactor is

energized. At the point of transition the timed contact (TR)

opens, de-energizing relay (CR1). When (CR1) is de-energized

contactor (1A) is energized which in turn de-energizes the (S) con-

tactor. With (1A) contactor energized the transition resistors are

connected in wye (parallel) with the motor windings. A normally

closed auxiliary contact of (S) closes and energizes contactor

(2M). As soon as (2M) is energized a normally closed auxiliary

contact opens removing power from contactors (1A) and (S).

With (2M) energized the resistors are bypassed forming the final

delta connection of the motor to the line.

Note: Transition Timer Setting

The timing cycle of the transition timing relay (TR) should be

set to obtain transfer after the motor has accelerated to its

maximum speed on reduced voltage. For proper setting of

this timer, refer to the start-up section of this instruction book.

Figure 3

Notes:

A. Class 36-branch circuit protection, fused dis-

connect or circuit breaker must be provided

by installer since circuit breaker or fusible dis-

connect is not factory installed.

B. For protection of internal control circuit con-

ductors in accordance with the N.E.C., use

fuse kit 49MAFB4.

C. Set TR for transition time required.

D. For separate control voltage connect source

to terminals 1 and X2.

E. 2CT may be located on line side of contactor

depending on circuit design.

F. Unwired auxiliary interlocks are not shown on

diagram for the 1M starter.

ETM

1LT

4LT

5LT

CONNECTIONS FOR OPTIONAL DEVICES

OPTIONAL DEVICES ARE FURNISHED PER

CONTRACT DOCUMENTS

Legend

- Customer Connection Point

1M - First Main Contactor

2M - Second Main Contactor

S - Shorting Contactor

1A - Resistor Contactor

MR - Master Control Relay

CR1 - Time Delayed Relay

CR2 - Relay

TR - Timer

OL - Main Starter OL Relay

(#) - Device Termination Point

Siemens Energy & Automation, Inc. 13

7 Part Winding Controllers

Reduced Voltage Part-Winding

Part-winding controllers are applicable only to induction motors

having stator windings divided into two or more equal parts with

the terminals of each part available for external connection.

Since every two-winding motor is not necessarily suitable for

part-winding starting, the applicability to a particular motor

should be checked with the motor manufacturer.

Refer to the typical schematic diagram shown Figure 4. Upon

starting, contactor (1M) closes, connecting one winding, or one

half of the motor to the incoming line. The current drawn is

approximately 65% of that which would be drawn if the whole

motor were connected to the incoming line. (Actual current

drawn is a function of motor design).

Correspondingly, less than half of the motor starting torque is pro-

duced. After a short time delay of approximately 1-5 seconds, con-

tactor (2M) closes, thus connecting the full motor to the incoming

line. Part winding controllers are inherently closed transition.

Part-winding controllers are generally of the increment type in

that the motor may not begin to accelerate on the first step. The

current drawn from the incoming line of a part-winding motor at

the first step is typically 65% of the full winding locked rotor cur-

rent. When the transition to the second step occurs the current

will rise to a value equal to or slightly less than the full--winding

locked rotor current, depending on whether or not the motor has

started to rotate. However, the maximum value is reached in

two increments separated by a short time interval which is suf-

ficient to meet some power company requirements.

During the running condition, each contactor is carrying one-half

of the motor full load current. See page 15 for the overload relay

setting instructions.

Siemens Energy & Automation, Inc. 14

At starting however, one of the contactors must carry approxi-

mately 65% of the full-winding locked rotor current. Since

NEMA horsepower ratings are based on full load and locked

rotor current, the horsepower rating for a given NEMA size

starter is somewhat less than twice the individual contactor rat-

ing (typically 1.5 - 1.75 x contactor horsepower rating depending

on contactor size). NEMA horsepower ratings for part-windings

starters are based on single-winding locked rotor currents cor-

responding to 65% of the full-winding values.

Note: Transition Timer Setting

The transition timing relay (TR) is normally set at 1 second;

refer to the start-up section of this instruction book.

Sequence Of Operation - 1 To 7 Part Winding

Pressing the start button energizes the relay (MR) and timer

(TR). As (MR) is energized the normally open contacts close

which energizes contactor (1M). After a short timing sequence

the normally open contact of (TR) closes energizing relay (CR1).

As soon as (CR1) coming in the normally open contact of this

relay closes energizing the (2M) contactor.

(A1) (A2)

(A1) (A2)

(A1)

FOR STARTER

SIZES 1-4, 1CT-6CT

ARE NOT USED

CIRCUIT

BREAKER

(1CB)

OR

DISCONNECT

(1DISC)

OPTIONAL

(A2)

(A1)

H3 H1

X1 X2

H4 H2

(A2)

Figure 4

Legend

1M - No. 1 Starter

2M - No. 2 Starter

CR1 - Relay

CR2 - Relay

TR - Starting Timer

MR - Master Control Relay

- Customer Connection

(#) - Device Termination Point

1LT

4LT

5LT

CONNECTIONS FOR OPTIONAL DEVICES

OPTIONAL DEVICES ARE FURNISHED PER

CONTRACT DOCUMENTS

Notes:

A. Class 36-branch circuit protection, fused disconnect or circuit breaker must be provided by installer since circuit

breaker or fusible disconnect is not factory installed.

B. For protection of internal control circuit conductors in accordance with the N.E.C., use fuse kit 49MAFB4.

C. Set TR for transition time required.

D. 2CT and 5CT may be located on line side of contactor depending on circuit design.

E. For separate source control connect separate source between TB points 1 and X2.

F. Unwired auxiliary interlocks are not shown on diagram for the 1M starter.

Siemens Energy & Automation, Inc. 15

8 Protective Devices

Overload Protection

Protection from motor overload during the starting and running

period is provided by the overload relay (OL). It provides pro-

tection against overloads and momentary surges but does not

protect against short circuit fault currents. For protection

against the latter, high interrupting capacity fuses or circuits

breakers should be installed ahead of the controller, per N.E.C.

requirements.

Overload protection consists of three-pole overload relay(s). The

3 phase overload relay provides outstanding motor protection

including single phase protection and an adjustable setting with-

out changing of heaters.

The adjustment dial should be set from actual motor full load

current in accordance with the overload relay adjustment

instructions using the overload factors of 58% for wye-delta or

50% for part winding.

For size 5 through 7 starters, three separately mounted current

transformers are provided and the overload relay is indirectly

powered from these CT secondaries. Set the overload relay dial

setting to the FLA of the motor for solid state overload.

Self-powered solid-state overload relays generate their own run-

ning power and do not need a separate source of 120V to power

the circuit board. The overload also provides phase loss protec-

tion for the motor by tripping within three seconds when there

is a complete loss of one phase of the three phase motor branch

circuit. Each overload has a current adjustment range with the

adjustment dial reading out in motor full load amps (FLA). In

addition to the markings on the dial, there are audible clicks

which allow for extremely fine tuning. Note that while thermal

overloads require a heater selection based on a relatively wide

range, these overloads have many clicks covering the same

ampere range.

For overload relays other than solid state overloads, divide the

motor full load amps by the current transformer ratio. For exam-

ple, the ratio of a 300/5 ct is 60/1. Divide the FLA by 60 to get

the current value that the overload will actually see.

Note: The overload relay is a NEMA Class 10, 20 design and will

trip within 10 to 20 seconds at a current of 600% of dial setting.

See overload relay instructions for motor service factor require-

ments before setting the overload relays.

Mechanical Sequence Interlock

A mechanical sequence interlock is provided on all autotrans-

formers and wye-delta controllers to prevent the simultaneous

closing of both starting and running contactors.

Optional Protective Devices

Power monitor relays, ground fault relays, over-under current

relays, etc., may require adjustments prior to start-up. Refer to

the instruction sheets provided with each device for proper set-

ting/resetting.

9 Maintenance / Start-Up

Controller Start-Up

Complete the installation section of this instruction book prior to

beginning the start-up procedures below.

Starting Limitations

With full-voltage starting, a squirrel-cage motor can at the

instant of energization draw from four to thirteen times normal

running current, depending on the design characteristics of the

motor. Many public utilities place current surge limitations on

electrical equipment connected to their system networks.

These system limitations, which are based on network stability

and capacity, can take the form of:

1. A maximum allowable horsepower that can be started direct-

ly across the line; above this horsepower, a limit in percent

of full-load current may be set for reduced-voltage starting.

2. A maximum rate of change of line current or a maximum

ampere increase per starting step may be specified.

3. A maximum amperage per motor or per horsepower may

be set.

In all questionable applications, the user should check with the

local utility for line limitations. Checking these limitations often

helps to determine the best method of reduced-voltage starting

for a specific application.

Also, the user should analyze his own distribution system to

determine the effects of current and voltage fluctuations from

starting of a large motor. Light flicker, malfunction of voltage

sensitive equipment, and actuation of protective devices on

other equipment, which might throw the system out of service,

are considerations.

Installation site feeder, branch circuit length, conductor size,

types and starting voltage drop may also be an application limi-

tation. Minimum equipment operating voltage must be main-

tained for motor(s) and controllers.

Motor starter type selections and the installation adjustments of

reduced voltage types affect starting inrush currents and result-

ing voltage drop.

In some applications, full-voltage starting torques might damage

belt or gear drives, couplings, or the driven loads.

The above considerations can dictate the use of reduced-volt-

age controllers. The term reduced-voltage controllers is

applied to all controllers other than those of the across-the-line

type. Thus the term includes part-winding controllers, even

though full voltage is actually applied to half of the motor termi-

nals. As developed above, the real purpose of reduced-voltage

controllers is to reduce the current applied to or the torque

developed by a motor upon starting.

An important fact to keep in mind when applying reduced-volt-

age starters is that when the voltage applied to motor terminals

is reduced, the current drawn by the motor and the torque

developed by the motor are also reduced. The torque of an

induction motor is proportional to the square of the rotor current

and therefore, approximately proportional to the square of the

stator current.

Regardless of whether reduced current or reduced torque is

more important in a given application, the two cannot be sepa-

rated. One follows the other.

The utility supply must be capable of maintaining the line volt-

age during both the reduced voltage starting period and while

the controller is in the run status. The minimum supply trans-

former KVA size should be at least 2 times the motor horse-

power. Incoming motor feeder or motor branch circuit conduc-

tors must be properly sized per applicable NEC and local code

requirements. Power feed should have a disconnect means and

be protected against overcurrent, ground and short circuit faults

per NEC.

The line voltage must not drop below the operating coil voltage

range of the controllers contactors and control circuit devices.

Contactors and control circuit devices operating at line voltage

must not be allowed to drop below 85% of the coils rated volt-

age. Supply line voltage for contactors and control power trans-

formers must not drop below 90% of the transformer primary

rated voltage. Voltage drops below these limits may cause con-

tactor chatter and could result in contactor burnout and damage

to the controller. Another source for possible contactor chatter

is a faulty remote input control signal(s). The line voltage should

also not exceed the upper coil voltage limit of 110% of the coils

rated voltage.

Perform the following steps to start wye-delta and autotrans-

former controllers:

1. Disconnect and lockout all source voltages applied to the

controller.

2. Continuity check controller load circuit for shorts to ground

and between phases.

3. Check motor leads for correct connections per motor and

controller diagrams.

Note: For wye-delta starters requiring motor rotation reversal,

interchange two lines at the input to the controller.

4. When applicable, set the circuit breaker instantaneous trip

dial(s) in accordance with the instructions provided on the

breaker trip setting label located on the controller door. The

initial setting should start at 700% of full load amperes and

may be increased per label instructions.

5. Calculate and set the overload dial setting per the instruc-

tions contained in the overload relay label located on the

controller door next to the overload relay reset button. For

autotransformer starters, refer to overload instruction sheet.

6. If motor acceleration time has been provided, set the tran-

sition timer (TR) to two (2) times this value. This value can

be used as a starting point. Do not exceed 30 seconds for

autotransformer controllers and 60 seconds for wye-delta

controllers.

Siemens Energy & Automation, Inc. 16

Multiple Voltage Sources

Can cause death or serious injury

or property damage.

Turn off and lock out all power to this

equipment before servicing.

7. Ensure all personnel are clear of the motor and its associat-

ed machinery.

8. Ensure the controller power disconnect device is in the Off

position. Apply feeder power to the controller disconnect

and measure the incoming line voltages, note the reading.

Verify that the control power transformer (CPT) voltage con-

nections and the coil voltage rating for the contactors and

control circuit devices are of the correct voltage per the

schematic diagram.

Note: The motor should be started under minimal loading

conditions. Ensure dampers are closed and unloading

valves are open, etc.

9. Connect a voltmeter to the load side of the disconnect

device. This will allow monitoring of the line voltage for any

drop during start. This value must not fall below the voltage

limits described previously.

10. Connect a clamp on ammeter to a motor lead or use a

tachometer to monitor motor speed. This will allow detec-

tion of the motor speed.

11. Apply power to the controller by turning on the controller

disconnect device.

12. Apply the start signal to the controller while observing the

line voltage and the ammeter (or tachometer). Check motor

for correct rotation. Record the time from start until the

motor current falls off rapidly. If this occurs, the transition

timer (TR) is set too short. Stop the motor and set the (TR)

timer to a longer time. Restart the motor and note the time

until the motor reaches full speed. If the transition timer is

set too long, reset the timer (TR) to a value 20% longer than

the time required to reach full motor speed. Continue this

procedure until the desired results are obtained. The line

voltage must not drop below the 85% as mentioned previ-

ously. If this occurs, the utilities must be consulted to

increase power sources.

Note: For autotransformer controllers, the required time to

reach operating speed can be reduced by changing the auto-

transformer taps to a higher percentage of the line voltage.

The capability of the utility to maintain the voltage at the

higher tap setting must be evaluated.

13. Upon completion of proper start-up, record the time setting,

remove test equipment and secure door.

Perform the following steps to start part-winding controller:

1. Disconnect and lockout all source voltages applied to the

controller.

2. Continuity check controller load circuit for shorts to ground

and between phases.

3. Check motor leads for correct connections per motor and

controller diagrams.

4. When applicable, set the circuit breaker instantaneous trip

dial(s) in accordance with the instructions provided on the

breaker trip setting label located on the controller door. The

initial setting should start at 700% of full load amperes and

may be increased per label instructions.

5. Calculate and set the overload dial setting per the instruc-

tions contained in the overload relay label located on the

controller door next to the overload relay reset button or

refer to overload instruction sheet.

6. Set the time (TR) to 1 second.

Note: Part-winding starters divide the starting inrush current

into two increments. Part-winding motors do not normally

reach full speed in the starting mode. Timer settings greater

than 2 to 3 seconds may result in overload relay tripping on

start-up.

7. Ensure all personnel are clear of the motor and its associat-

ed machinery.

8. Ensure the controller power disconnect device is in the Off

position. Apply feeder power to the controller disconnect

and measure the incoming line voltage, note the reading.

Verify that the control power transformer (CPT) voltage con-

nections and the coil voltage rating for the contactors and

control circuit devices are of the correct voltage per the

schematic diagram.

Note: The motor should be started under minimal loading

conditions. Ensure dampers are closed and unloading

valves are open, etc.

9. Connect a voltmeter to the load side of the disconnect

device. This will allow monitoring of the line voltage for any

drop during start. This value must not fall below the voltage

limits described previously.

10. Apply power to the controller by turning on the controller dis-

connect device.

11. Apply the start signal to the controller while observing the

line voltage. Check motor for correct rotation. The line volt-

age must not fall below 85% as mentioned previously. If

this occurs, the utilities must be consulted to increase the

power source.

12. Upon completion of proper start-up, remove the test equip-

ment and secure door.

Siemens Energy & Automation, Inc. 17

Hazardous voltage.

Will cause death or serious injury.

To avoid electrical shock or burn, turn off

main and control voltages before perform-

ing installation or maintenance.

Hazardous voltage.

Can cause death or serious injury.

To avoid electrical shock or burn, turn off

main and control voltages before perform-

ing installation or maintenance.

Siemens Energy & Automation, Inc. 18

10 Maintenance/Troubleshooting

Whenever assistance is desired from Siemens personnel,

please contact the nearest Siemens Sales Office. All informa-

tion required under the Maintenance, Parts and Service, sec-

tion of this instruction must be given.

Listed below are possible trouble areas with possible causes.

Control Fuses Opened

Check for shorted wires (frayed or bare wires shorted to

ground or together) or shorted coils

Check for jammed or binding contactor/relay contact carriers

Motor Fails To Accelerate

Check for low voltage or single phasing

Check for proper operating sequence of starter

Check for motor loading that is too high

Check motor leads for proper connections

Starter Fails To Operate

Check protective devices and settings. Some devices must

be reset manually, and also may require time delay.

Check for proper operation/wiring of local remote pilot

devices

Check for loose or open control wiring

Check for open coils

Check for presence of proper line and control voltages

Noisy Or Chattering Magnets

Check for low voltage

Check for dirty contactor magnet face

Check for worn parts

Check device signal controlling the coil for chatter.

Welded Contacts

Check for abnormal currents or short circuits

Check for repeated jogging or inching

Check for weak contact springs

Check for low voltage during starting

Check for momentary power interruptions

Check for chattering of local/remote control signals

Overload/Breaker Tripping, Main Fuses Opening

Check for short circuits and loose power connections

Check for single phasing or phase unbalance

Check starting current, running current, and motor acceler-

ating time against overload settings

Check for high ambient temperature within enclosure

Check for proper fuse type/sizing and circuit breaker trip unit

selection and adjustment

Abnormal Heat

Check for loose connections/proper terminations and wire

size

Check for excessive recycling of starter

Check for abnormal currents and low voltage

Resistor Failure

Check for proper sequence and timing

Check for proper mechanical and electrical interlock opera-

tion

Check for excessive recycling of starter

Check for loose power and control connections

Hazardous voltage.

Will cause death or serious injury.

To avoid electrical shock or burn, turn off

main and control voltages before perform-

ing installation or maintenance.

Siemens Energy & Automation, Inc. 19

11 Maintenance Preventative Checklist

Failure to properly maintain the equipment can result in

severe personal injury and product failure. The instructions

contained herein should be carefully reviewed, understood

and followed. The following maintenance procedures must be

performed regularly:

This checklist does not represent an exhaustive survey of main-

tenance steps necessary to insure safe operation of the equip-

ment. Particular applications may require further procedures.

Should further information be desired or should particular prob-

lems arise which are not covered sufficiently for the purchasers

purposes, the matter should be referred to the local Siemens

Sales Office.

Check Item Operation

Dust Clean

Rust and corrosion Clean - report if excessive

Connections Tighten electrical connections, look for discoloration of

any copper current carrying parts.

Nuts and bolts Check mechanical connections.

Fuse clips, bolt connection clamps Check for spring clip pressure, tightness of clamps.

Fuse ferrules If copper, polish; check for loose ferrules and proper

fuse size.

Coils Check for any signs of overheating or mechanical injury.

Magnets Clean faces, check for mechanical binding.

Overload relays Check settings in accordance with overload instructions.

Arc chutes Check for breaks and excessive burning. Make sure arc

chutes are set firmly in place.

Relays Clean and check for mechanical binding and sticking

Check contacts.

Resistors Check for signs of overheating. If equipped with

sliders, tighten.

Contacts Check for wear. Replace if excessive. Do not file or dress.

Dangerous voltages are present in the equipment which can

cause severe personal injury and product failure. Always de-

energize and ground the equipment before maintenance.

Maintenance should be performed only by qualified personnel.

The use of unauthorized parts in the repair of the equipment or

tampering by unqualified personnel will result in dangerous con-

ditions which can cause severe personal injury or equipment

damage. Follow all safety instructions contained herein.

Hazardous voltage.

Will cause death or serious injury.

To avoid electrical shock or burn, turn off

main and control voltages before perform-

ing installation or maintenance.

Siemens Energy & Automation, Inc. 20

Notes

Siemens Energy & Automation, Inc. 21

Notes

Siemens Energy & Automation, Inc.

Publication No. SFIM-14000-0402

Subject to change without prior notice

Printed in the U.S.A.

Siemens Energy & Automation, Inc.

1000 McKee Street

Batavia, IL 60510

http://www.sea.siemens.com

2001 Siemens Energy & Automation, Inc.

Siemens is a registered trademark of Siemens AG.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Isuzu TF Series Electrical Body and ChasysDokument357 SeitenIsuzu TF Series Electrical Body and ChasysAlbert Briceño88% (16)

- CT & PT CalculationsDokument10 SeitenCT & PT Calculationssrigirisetty208100% (4)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 16-75 BWE, Bodywork Electrical System: Overview - Sheet 1Dokument13 Seiten16-75 BWE, Bodywork Electrical System: Overview - Sheet 1lilik sukristianto100% (1)

- Shipboard High VoltageDokument62 SeitenShipboard High VoltageArun SNoch keine Bewertungen

- Relay Coordination-SampleDokument5 SeitenRelay Coordination-SampleCatrina FedericoNoch keine Bewertungen

- Power ElectronicsDokument276 SeitenPower ElectronicsBikrant PoudelNoch keine Bewertungen

- Preparing To Synchronize A Generator To The GridDokument3 SeitenPreparing To Synchronize A Generator To The GridVarun KumarNoch keine Bewertungen

- Avk DSGDokument24 SeitenAvk DSGOwais Malik100% (1)

- 5855292-Avr Users Manual Ea63-5 CDokument8 Seiten5855292-Avr Users Manual Ea63-5 CAbhoe StankNoch keine Bewertungen

- 5855292-Avr Users Manual Ea63-5 CDokument8 Seiten5855292-Avr Users Manual Ea63-5 CAbhoe StankNoch keine Bewertungen

- TLE-Grade 12 MELCDokument8 SeitenTLE-Grade 12 MELCRex Chambers Ladao91% (11)

- Transformer Design PDFDokument72 SeitenTransformer Design PDFSujon MiaNoch keine Bewertungen

- STRIKER ClearVu OM EN PDFDokument16 SeitenSTRIKER ClearVu OM EN PDFRicky Ocktavi RizkyNoch keine Bewertungen

- Voltage Drop CalculatorDokument29 SeitenVoltage Drop Calculator7esabat7033Noch keine Bewertungen

- Calculated Motor Pump SizeDokument6 SeitenCalculated Motor Pump SizeRicky Ocktavi RizkyNoch keine Bewertungen

- Selecting An Automatic Capacitor Size 480V System To ADokument5 SeitenSelecting An Automatic Capacitor Size 480V System To Arafe788Noch keine Bewertungen

- Iso 9001 Supply ChainDokument20 SeitenIso 9001 Supply ChainRichard More LeonNoch keine Bewertungen

- Calculation Based On Motor HPDokument4 SeitenCalculation Based On Motor HPRicky Ocktavi RizkyNoch keine Bewertungen

- Cyscan Operator PDFDokument45 SeitenCyscan Operator PDFNayo Sanchez CrespoNoch keine Bewertungen

- Electronics Catalogue 2014 March 2014 PDFDokument44 SeitenElectronics Catalogue 2014 March 2014 PDFRicky Ocktavi RizkyNoch keine Bewertungen

- Volvo 8000 OM ENDokument60 SeitenVolvo 8000 OM ENRicky Ocktavi RizkyNoch keine Bewertungen

- WN 701 WDokument43 SeitenWN 701 WRicky Ocktavi RizkyNoch keine Bewertungen

- AD-100 Operator's Manual Ver U 8-20-04Dokument32 SeitenAD-100 Operator's Manual Ver U 8-20-04BeneDict Ben DNoch keine Bewertungen

- Port of Vancouver Port Information GuideDokument264 SeitenPort of Vancouver Port Information GuideRicky Ocktavi Rizky100% (1)

- STRIKER ClearVu OM ENDokument16 SeitenSTRIKER ClearVu OM ENRicky Ocktavi RizkyNoch keine Bewertungen

- YS5600 InstallManualDokument14 SeitenYS5600 InstallManualRicky Ocktavi RizkyNoch keine Bewertungen

- Loctite PDFDokument24 SeitenLoctite PDFbonifaciusNoch keine Bewertungen

- XD2PA22Dokument26 SeitenXD2PA22Ricky Ocktavi RizkyNoch keine Bewertungen

- GD-K88Ai ManualDokument38 SeitenGD-K88Ai ManualRicky Ocktavi RizkyNoch keine Bewertungen

- Presentation - Company Products - Eng (June 2012)Dokument11 SeitenPresentation - Company Products - Eng (June 2012)Ricky Ocktavi RizkyNoch keine Bewertungen

- Presentation - Company Products - Eng (June 2012)Dokument11 SeitenPresentation - Company Products - Eng (June 2012)Ricky Ocktavi RizkyNoch keine Bewertungen

- YS5600 InstallManualDokument14 SeitenYS5600 InstallManualRicky Ocktavi RizkyNoch keine Bewertungen

- Threebond 1215 RTV HIGH TEMP SILICONDokument2 SeitenThreebond 1215 RTV HIGH TEMP SILICONRicky Ocktavi RizkyNoch keine Bewertungen

- PRD0008292 GSpecDokument2 SeitenPRD0008292 GSpecRicky Ocktavi RizkyNoch keine Bewertungen

- New ProductDokument5 SeitenNew ProductRicky Ocktavi RizkyNoch keine Bewertungen

- LT3355v5 FullCatalogDokument152 SeitenLT3355v5 FullCatalogAhmed Emad AhmedNoch keine Bewertungen

- TC 69-3 (A) - Annual Report For 2018Dokument59 SeitenTC 69-3 (A) - Annual Report For 2018Ricky Ocktavi RizkyNoch keine Bewertungen

- TP 14710 eDokument72 SeitenTP 14710 eRicky Ocktavi RizkyNoch keine Bewertungen

- 63 Inf6Dokument4 Seiten63 Inf6Ricky Ocktavi RizkyNoch keine Bewertungen

- Automatic Control of Street LightDokument24 SeitenAutomatic Control of Street LightAbhinandan GogoiNoch keine Bewertungen

- Ele432 Report LedDokument2 SeitenEle432 Report LedRAJANoch keine Bewertungen

- Catalog Lampu PijarDokument32 SeitenCatalog Lampu PijarMuhammad Nuryaqin Pratama PutraNoch keine Bewertungen

- Philips CD 650 ModsDokument10 SeitenPhilips CD 650 ModsspikebitNoch keine Bewertungen

- Stp5Nc50 - Stp5Nc50Fp Stb5Nc50 - Stb5Nc50-1: N-Channel 500V - 1.3 - 5.5A To-220/Fp/D Pak/I Pak Powermesh Ii MosfetDokument12 SeitenStp5Nc50 - Stp5Nc50Fp Stb5Nc50 - Stb5Nc50-1: N-Channel 500V - 1.3 - 5.5A To-220/Fp/D Pak/I Pak Powermesh Ii MosfetJavier55Noch keine Bewertungen

- Ed Ail: Voltage Loss Compensator (VLC) Three-Phase 125 - 500 kVADokument7 SeitenEd Ail: Voltage Loss Compensator (VLC) Three-Phase 125 - 500 kVAwempy kurniawanNoch keine Bewertungen

- Exam Electrical Machines and Drives (ET4117) : Grid Back EMF Time (S)Dokument10 SeitenExam Electrical Machines and Drives (ET4117) : Grid Back EMF Time (S)chidoNoch keine Bewertungen

- Reles EuropeoDokument450 SeitenReles EuropeojuanNoch keine Bewertungen

- Revere 1100 Wide Beam Mercury Floodlight Bulletin 1966Dokument2 SeitenRevere 1100 Wide Beam Mercury Floodlight Bulletin 1966Alan MastersNoch keine Bewertungen

- ABB - Ma and V Signal Converter and IsolatorDokument2 SeitenABB - Ma and V Signal Converter and IsolatorKmj KmjNoch keine Bewertungen

- Codigos de Error LG InverterDokument2 SeitenCodigos de Error LG InvertercipaarzuNoch keine Bewertungen

- Service Manual: Modular Crescent CuberDokument74 SeitenService Manual: Modular Crescent CuberAgapito labiagaNoch keine Bewertungen

- Brochure Medium Voltage AssembliesDokument98 SeitenBrochure Medium Voltage AssembliesfranNoch keine Bewertungen

- Fluorescent Magic Eye Tubes: Forrest Cook 2008-2015Dokument8 SeitenFluorescent Magic Eye Tubes: Forrest Cook 2008-2015josue otonielNoch keine Bewertungen

- (Codientu - Org) - 29M41-CHASSIS TB97-VN (CRT CHUNGHWA)Dokument1 Seite(Codientu - Org) - 29M41-CHASSIS TB97-VN (CRT CHUNGHWA)GioVoTamNoch keine Bewertungen

- Ag en Technologies: 08903-90062 Volume 1Dokument240 SeitenAg en Technologies: 08903-90062 Volume 1João MendesNoch keine Bewertungen

- ElectropeneumaticsDokument164 SeitenElectropeneumaticstharindu100% (1)

- AVLIS Final MergeDokument454 SeitenAVLIS Final MergeSrinu BoddulaNoch keine Bewertungen

- Ec1461 Vlsi DesignDokument17 SeitenEc1461 Vlsi DesignArunkumarNoch keine Bewertungen

- Cobra ODE Installation Manual (English) v1.4Dokument49 SeitenCobra ODE Installation Manual (English) v1.4sasa097100% (1)

- Amercable - VFDDokument16 SeitenAmercable - VFDmgentry128Noch keine Bewertungen