Beruflich Dokumente

Kultur Dokumente

Akzo-3039 Akzo-3034 Acid Corrosion English Importante Stimolazione

Hochgeladen von

Fra Fra100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

133 Ansichten4 SeitenAcid corrosion inhibitor for acid stimulation

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAcid corrosion inhibitor for acid stimulation

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

133 Ansichten4 SeitenAkzo-3039 Akzo-3034 Acid Corrosion English Importante Stimolazione

Hochgeladen von

Fra FraAcid corrosion inhibitor for acid stimulation

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

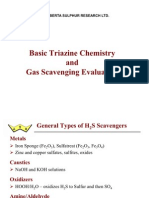

Products for the petroleum industry

Fig. 1 Schematic illustration of acid corrosion of

carbon steel.

1. Acid corrosion

Acid corrosion is the corrosion of materials in

acidic environments. Many metallic materials

are susceptible to acid corrosion. One of the

most widely used industrial materials, carbon

steel, suffers serious acid corrosion. Corrosion

protection, such as the use of corrosion inhibitors,

is often required for the use of carbon steel in

acidic media.

The mechanism of acid corrosion is straightforward.

In the case of carbon steel, the iron will react with

hydrogen ions to form iron ions and hydrogen gas

(Fig. 1). The reaction is shown below.

Fe + 2H

+

Fe

++

+ H

2

During the process steel is essentially dissolved

away. Weight loss, therefore, is a good measure

of the severity of the acid corrosion.

The corrosion rate of materials in acid is dependent

on parameters such as concentration of pH of

the acidity solution, temperature and the use

of corrosion inhibitors. As acid concentration

i ncreases, the corrosi on rate goes up

correspondingly. At a constant acid concentration,

the corrosion react increases exponentially with

rising temperatures The presence of an acid

corrosion inhibitor will have a profound effect on

the corrosion rate. The addition of 0.1 to 2.0% of

acid corrosion inhibitors can reduce the corrosion

rate up to 95%.

AKZO-3039 AKZO-3034 Acid Corrosion ENGLISH.indd 1 6/6/11 4:48 PM

2. Armohib

acid corrosion

inhibitors from AkzoNobel

Armohib is the trade name for corrosion inhibitors developed by AkzoNobel.

These aliphatic nitrogen inhibitors effectively retard acid corrosion during oil

well acidizing operations, pickling and acid cleaning. AkzoNobel carries two

types of acid corrosion inhibitors: Armohib CI-28 and Armohib CI-31. They are

specially formulated to inhibit corrosion of different acids as listed in Table 1.

Table 1. Application of Armohib corrosion inhibitors in different acids.

Armohib CI-28 Hydrochloric

Hydrochloric-Hydrouoric acid mixtures

Armohib CI-31 Sulfuric

Sulfamic

Citric

Phosphoric

Fig. 2 Schematic illustration of acid corrosion

inhibition by Armohib corrosion inhibitors.

Although the exact mechanism of nitrogen corrosion inhibitors is not fully

understood, it is generally agreed that the positive hydrophilic nitrogen

headgroup absorbs on the metal surface and the aliphatic chains form a

hydrophobic flm, which block the attack of hydrogen ions (Fig. 2). Higher

coverage of the surface with the impervious flm leads to higher acid

corrosion inhibition.

2.1 General properties

of Armohib CI-28 and

Armohib CI-31

The typical properties of Armohib corrosion

inhibitors are listed in Table 2. These inhibitors

are easy to use in the feld. They are available in

liquid form and are soluble in acid. They are non-

staining to metal surfaces and do not precipitate

when standing for a prolonged period of time.

The application of these inhibitors provides low-

cost, dependable protection over a wide range

of temperatures, since only a small quantity of

Armohib inhibitor mixed with the acids will deliver

the desired cleaning effect, while retarding the

acid attack on metals. For example, 0.25%

Armohib CI-28 in 15% hydrochloric acid at 200F

leads to less than 0.022 lb/ft

2

/day corrosion

rate of mild steel. In another example, 0.06%

Armohib CI-31 in 15% sulfuric acid at 200F

leads to less than 0.027 lb/ft

2

/day corrosion rate

of mild steel.

Table 2. Typical properties of Armohib corrosion inhibitors.

Armohib Specifc Pounds per gallons Appearance at 25C Pour point F Flash point F Cloud point F

gravity at 25C

28 0.925 7.69 Amber Liquid 52 90

31 1.042 8.66 Amber Liquid 24 340 28

2.2 Applications of

Armohib CI-28 and

Armohib CI-31

There are three major applications for Armohib

inhibitors: oil well acidizing, acid pickling and plant

cleaning.

Fig. 3 Corrosion

data of mild steel in

hydrochloric acid with

Armohib CI-28.

MILD STEEL IN

HYDROCHLORIC ACID

WITH Armohib CI-28

6 HOURS AT 200F

C

o

r

r

o

s

i

o

n

r

a

t

e

I

b

/

f

t

2

/

d

i

a

Percent inhibitor concentration based on total solution

2.2.1 Oil well acidizing

In the fracturing and acidizing of compact oil

formations, various concentrations of hydrochloric

acid are used to dissolve the undesirable carbonate

deposits of scales, which interfere with the passage

of oil, in tubing or in the formation itself.

The lines and tubing must be protected during this

operation, from corrosive attack by the acid, by

the high temperatures and pressures, and by the

potential for a "sour" environment resulting from

the high hydrogen sulfde and carbon dioxide

contents. Armohib CI-28 used at a concentration

of 0.25%, based on the total hydrochloric acid

solution, is highly recommended for this purpose

(see Fig. 3). It provides effective protection at

temperatures in excess of 230F (110C), for at

least six hours.

AKZO-3039 AKZO-3034 Acid Corrosion ENGLISH.indd 2 6/6/11 4:48 PM

2.2.2 Acid pickling

Pickling is the removal of oxide scales formed

during metal working operations by mineral

acids. Hydrochloric, phosphoric and sulfuric acids

are commonly used. These scales must be

removed without undue acid attack on the base

metal surface.

Armohib

CI-28: Hydrochloric acid is used for

pickling very high carbon alloy steels and for

wire pickling. Hydrogen embrittlement is a major

problem during the pickling of mild steel wire.

The addition of Armohib

CI-28 to the hydrochloric

acid eliminates or reduces embrittlement. The use

of Armohib

CI-28 as an inhibitor, in hydrochloric

acid pickling of steel, has no adverse effect on

the quality of the metal in subsequent hot dip

galvanizing.

Armohib CI-31: Phosphoric acid is used in

the surface preparation of structural steel to

remove mill scale, rust and contaminants, prior

to protective surface coating. Phosphoric acid is

of particular value in pickling operations where the

scale flm is thin, or if the flm is a hydrate oxide

of iron. Sulfuric acid is used extensively in metal

cleaning because of its low cost. In the absence

of inhibitor, up to 80% of the acid may be wasted

in dissolving metal under the scale. The use of

Armohib CI-31 as an inhibitor, regulates the scale

dissolution reactions and minimizes the amount

of surface material that is dissolved.

2.2.3 Plant cleaning

Inhibited acids are used extensively in plant

cleaning; both in pre-commissioning and periodic

planned service cleaning. In all applications,

the use of a corrosion inhibitor is necessary to

maximize the cleaning effect, while minimizing

any unwanted corrosion.

Hydrochloric acid is the acid most often used

for plant cleaning, although sulfamic, sulfuric,

citric and phosphoric acids are also used. The

appropriate Armohib CI-28 or CI-31 product will

serve the corrosion inhibiting needs of any of the

acid applications.

Armohib CI-28 is used to create efficiently

inhibited hydrochloric solutions for hydrochloric

applications for steels such as admiralty, carbon

steels, cast iron, copper and its alloys such as

monel, brass, bronze, cupro-nickel and chrome-

molybdenum.

Sulfamic acid is often used as an alternative

to hydrochloric acid. Sulfamic acid, inhibited

with Armohib CI-31, is used to clean deposits

from 300 and 400 series stainless steels, and

occasional cleaning of aluminum and its alloys.

Armohib corrosion inhibitors may be added to

either dilute or concentrated acid solutions. Never

dilute the Armohib concentrates with water, as

they will separate.

Dilute acid solutions: To obtain the inhibitor

concentrations listed in Table 3, add approximately

the indicated amounts of inhibitors to each 100

gallons of dilute acid solution.

For instructions on handling and storage, please

consult the MSDS sheets for these products.

Table 3. Preparing desired dosage of Armohib corrosion inhibitors

Concentration % total solution .01 .025 .05 .075 .10 .125 .15 .20 .25

Fluid ounces per 100 1.5 3.75 7.5 11.25 15.0 18.75 22.5 30.0 37.5

gallons of total solution

2.3 Applying Armohib CI-28 and Armohib CI-31

AKZO-3039 AKZO-3034 Acid Corrosion ENGLISH.indd 3 6/6/11 4:48 PM

For additional information, samples or assistance please

contact your local sales representative or AkzoNobel's

customer service department at:

Brazil & South America

AkzoNobel Ltda Diviso Quimica

Rodovia AkzoNobel 707

Bairro So Roque da Chave

Itupeva SP Brasil 13.295-000

Tel: +55.11.4591.8939

Email: Sc-southamerica@akzonobel.com

US, Canada & Mexico

AkzoNobel Surface Chemistry LLC

525 W. Van Buren Street

Chicago IL 60607-3823

(800) 906-9977

(312) 544-7000

Email: Csrusa@akzonobel.com

Asia-Pacfco

AkzoNobel Surface Chemistry Pte Ltd

41 Science Park Road

Singapore Science Park II

#03-03 The Gemini

Singapore 117610

Tel: + 55 6773 8488

Email: Surfacechemistry@ansc.com.sg

Europe, Africa & Middle East

AkzoNobel Surface Chemistry AB

Stenunge All 3

SE-444 85 Stenungsund

Sweden

Tel: + 46 303 8500

Email: Surfactants.Europe@sc.AkzoNobel.com

www.akzonobel.com/surface

AkzoNobel is the largest global paints and coatings

company and a major producer of specialty chemicals.

We supply industries and consumers worldwide with

innovative products and are passionate about developing

sustainable answers for our customers. Our portfolio

includes well known brands such as Dulux, Sikkens,

International and Eka. Headquartered in Amsterdam,

the Netherlands, we are a Global Fortune 500 company

and are consistently ranked as one of the leaders in

the area of sustainability. With operations in more than

80 countries, our 55,000 people around the world are

committed to excellence and delivering Tomorrows

Answers Today.

2011 AkzoNobel Surface Chemistry LLC,

all rights reserved.

All information concerning these products and/or all suggestions for handling and use contained herein are offered

in good faith and believed to be reliable. AkzoNobel Surface Chemistry LLC and its affliates, however, make

no warranty as to the accuracy and/or suffciency of such information and/or suggestions, as to the products'

merchantability or ftness for any particular purpose, or that any suggested use will not infringe any patent. Nothing

contained herein shall be construed as granting or extending any license under any patent. Buyer must determine

for himself, by preliminary tests or otherwise, the suitability of these products for his purposes. The information

contained herein supersedes all previously issued bulletins on the subject matter covered. The user may forward,

distribute and/or photocopy this document only if unaltered and complete, including all of its headers and footers,

and should refrain from any unauthorized use. You may not copy this document to a website.

AKZO-3039 AKZO-3034 Acid Corrosion ENGLISH.indd 4 6/6/11 4:48 PM

Das könnte Ihnen auch gefallen

- AkzoNobel TB ArmohibfinalDokument13 SeitenAkzoNobel TB ArmohibfinalMuhammad NaeemNoch keine Bewertungen

- Naphthenic Acid Corrosion in Synthetic FuelsDokument15 SeitenNaphthenic Acid Corrosion in Synthetic FuelsNXVNNoch keine Bewertungen

- HPHT AcidizingDokument8 SeitenHPHT AcidizingRamanamurthy PalliNoch keine Bewertungen

- Advanced Technique Inhibition-Removal Paraffin Deposition in Oil Wells PDFDokument69 SeitenAdvanced Technique Inhibition-Removal Paraffin Deposition in Oil Wells PDFTuan YusoffNoch keine Bewertungen

- The Effect of Norust 720 and CH1377A Inhibitors On N80 Steel Corroded by Bacterial CorrosionDokument5 SeitenThe Effect of Norust 720 and CH1377A Inhibitors On N80 Steel Corroded by Bacterial CorrosionInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- DNP 8000 - Corrosion Inhibitor Series - InformationDokument27 SeitenDNP 8000 - Corrosion Inhibitor Series - InformationMehman NasibovNoch keine Bewertungen

- AADE-11-NTCE-06 New Surfactant Allows For Higher Internal Phase in Non-Aqueous SystemsDokument11 SeitenAADE-11-NTCE-06 New Surfactant Allows For Higher Internal Phase in Non-Aqueous Systemsjangri1098Noch keine Bewertungen

- Riopipeline2019 1014 Rio 2019 Paper v4Dokument10 SeitenRiopipeline2019 1014 Rio 2019 Paper v4Marcelo Varejão CasarinNoch keine Bewertungen

- Armohib CI 28Dokument6 SeitenArmohib CI 28Wilson WanNoch keine Bewertungen

- Handling Silica in Cooling WaterDokument17 SeitenHandling Silica in Cooling WaterLekhamani YadavNoch keine Bewertungen

- Cooling Water y AditivesDokument8 SeitenCooling Water y AditivesNuryNoch keine Bewertungen

- Corrosion Inhibitors OrganicDokument33 SeitenCorrosion Inhibitors Organicprakash100% (1)

- Crude Oil Emulsions A State-Of-The-Art ReviewDokument11 SeitenCrude Oil Emulsions A State-Of-The-Art Reviewmalyari2002255100% (3)

- BASF Glyoxal As An H2S ScavengerDokument8 SeitenBASF Glyoxal As An H2S ScavengerMo OsNoch keine Bewertungen

- AKZO Oilfield Brochure 2011 CompactDokument32 SeitenAKZO Oilfield Brochure 2011 CompactLê Công100% (1)

- Oxygen Scavenger in OilfieldDokument27 SeitenOxygen Scavenger in Oilfieldguruhnurizal100% (1)

- 00-Cálculo de Dosis H2S PDFDokument23 Seiten00-Cálculo de Dosis H2S PDFamazo_14Noch keine Bewertungen

- Substituted Alkylamine IDokument3 SeitenSubstituted Alkylamine IFranklin Crespo AmoresNoch keine Bewertungen

- Specialty Oilfield Chemicals - Demulsifiers, Corrosion Inhibitors From Rimpro IndiaDokument12 SeitenSpecialty Oilfield Chemicals - Demulsifiers, Corrosion Inhibitors From Rimpro IndiaGovind PatelNoch keine Bewertungen

- Wax Deposition ProblemDokument2 SeitenWax Deposition ProblemDhea SamanthaNoch keine Bewertungen

- FSA-1 Fines Stabilization AgentDokument1 SeiteFSA-1 Fines Stabilization Agentpedro taquichiriNoch keine Bewertungen

- Well Stimulation - AcidizingDokument22 SeitenWell Stimulation - AcidizingJudy ann silvaNoch keine Bewertungen

- Brochure Oilfield Corrosion Inhibitors GlobalDokument5 SeitenBrochure Oilfield Corrosion Inhibitors GlobalAlfonso Dominguez Gonzalez100% (1)

- Driscal-D Polymer QMAXDokument1 SeiteDriscal-D Polymer QMAXAnonymous vSLFJCNNoch keine Bewertungen

- Review On Chemical Stimulation Techniques in Oil IDokument35 SeitenReview On Chemical Stimulation Techniques in Oil IJesseNoch keine Bewertungen

- Oilfield Chemicals - Blended1Dokument3 SeitenOilfield Chemicals - Blended1Wilson TanNoch keine Bewertungen

- 2010 Effect of PH and Scale Inhibitor Concentration On Phosphonate-Carbonate InteractionDokument18 Seiten2010 Effect of PH and Scale Inhibitor Concentration On Phosphonate-Carbonate Interactionandrea cunhaNoch keine Bewertungen

- Preventing Coil Tubing CorrosionDokument6 SeitenPreventing Coil Tubing Corrosionktjayakumar3878Noch keine Bewertungen

- PDFDokument23 SeitenPDFDharmaraaj RajalinggamNoch keine Bewertungen

- Options For High Temperature Well StimulationDokument11 SeitenOptions For High Temperature Well StimulationFra FraNoch keine Bewertungen

- Dukhan Field (Onshore Qatar) Uwainat Reservoir Optimum Development Scheme PDFDokument31 SeitenDukhan Field (Onshore Qatar) Uwainat Reservoir Optimum Development Scheme PDFsddNoch keine Bewertungen

- Filming Corrosion Inhibitor For Oil and Gas Field PDFDokument20 SeitenFilming Corrosion Inhibitor For Oil and Gas Field PDFPabel Lema100% (1)

- ClayGuard NPH TDS PDFDokument1 SeiteClayGuard NPH TDS PDFAlejandra RodriguezNoch keine Bewertungen

- Protective - Tank Coating Resistance GuideDokument7 SeitenProtective - Tank Coating Resistance Guideenrico100% (1)

- 00-Corrosión Inhibitor DOSES PDFDokument27 Seiten00-Corrosión Inhibitor DOSES PDFamazo_14Noch keine Bewertungen

- Coastal 1017-F: Process Defoamer/AntifoamDokument1 SeiteCoastal 1017-F: Process Defoamer/Antifoamfaradb100% (1)

- Sildril EplDokument4 SeitenSildril EpljelaapeNoch keine Bewertungen

- H2S Scavengers For The Oilfield ApplicationDokument6 SeitenH2S Scavengers For The Oilfield ApplicationMichael Medina100% (1)

- HAI-85M™ Acid-Corrosion Inhibitor: StimulationDokument2 SeitenHAI-85M™ Acid-Corrosion Inhibitor: Stimulationjangri1098Noch keine Bewertungen

- Ci-25 - MSDSDokument4 SeitenCi-25 - MSDSAtif Aslam100% (1)

- ENG101 FOAE - 08 Acid Design Fundamentals-Matrix Rev 2006-03-25Dokument12 SeitenENG101 FOAE - 08 Acid Design Fundamentals-Matrix Rev 2006-03-25danielmcaeNoch keine Bewertungen

- AKZO Brochure Oil FieldDokument35 SeitenAKZO Brochure Oil FieldFra Fra100% (2)

- What Are Corrosion Inhibitors.? Corrosion InhibitorsDokument3 SeitenWhat Are Corrosion Inhibitors.? Corrosion InhibitorsdiwakarngmNoch keine Bewertungen

- Baker Hughes: Material Safety Data SheetDokument4 SeitenBaker Hughes: Material Safety Data SheetLê CôngNoch keine Bewertungen

- 11 - Inhibitors 2007Dokument13 Seiten11 - Inhibitors 2007MattNoch keine Bewertungen

- Flowsolve™ 212Ln: Asphaltene DispersantDokument1 SeiteFlowsolve™ 212Ln: Asphaltene DispersantIrelena RomeroNoch keine Bewertungen

- Scavanger Injection RatesDokument6 SeitenScavanger Injection RatesAnonymous QSfDsVxjZNoch keine Bewertungen

- Bases Comerciales DowDokument4 SeitenBases Comerciales DowJulian GonzalezNoch keine Bewertungen

- Vapor Corrosion Inhibitors (Vcis) For Storage TanksDokument24 SeitenVapor Corrosion Inhibitors (Vcis) For Storage TanksMartin1973-03Noch keine Bewertungen

- About Polyacrylamide Fact SheetDokument2 SeitenAbout Polyacrylamide Fact SheetRodrigo da RochaNoch keine Bewertungen

- Canwell PresentationDokument12 SeitenCanwell PresentationA.J. MacDonaldNoch keine Bewertungen

- Corrosion Mechanisms of Mild Steel in Weak Acids - T. Tran - 2014 - PHD PDFDokument156 SeitenCorrosion Mechanisms of Mild Steel in Weak Acids - T. Tran - 2014 - PHD PDFAsep Ridwan SetiawanNoch keine Bewertungen

- ColaLube 3407Dokument2 SeitenColaLube 3407mndmattNoch keine Bewertungen

- Ne CADDDokument4 SeitenNe CADDLoganBohannon100% (1)

- Oilfield Chemistry: ProgramDokument36 SeitenOilfield Chemistry: ProgramMohamed HassanNoch keine Bewertungen

- Dow Corning Oil & Gas BrochureDokument20 SeitenDow Corning Oil & Gas BrochureProject Sales Corp100% (1)

- Brochure Biocides Oil and GasDokument12 SeitenBrochure Biocides Oil and GasAlfonso Dominguez GonzalezNoch keine Bewertungen

- Alcomer 750 Types: Technical InformationDokument2 SeitenAlcomer 750 Types: Technical InformationPrototypeNoch keine Bewertungen

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsVon EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNoch keine Bewertungen

- Corrosion Notes 1Dokument13 SeitenCorrosion Notes 1Anonymous PHoJKwhkMNoch keine Bewertungen

- Method For Measuring Degreasing On Different SubstratesDokument42 SeitenMethod For Measuring Degreasing On Different SubstratesFra FraNoch keine Bewertungen

- Options For High Temperature Well StimulationDokument11 SeitenOptions For High Temperature Well StimulationFra FraNoch keine Bewertungen

- Diesel FuelDokument70 SeitenDiesel FuelFra Fra100% (2)

- Friction Properties of Triazine Containing Hybrid CompositesDokument8 SeitenFriction Properties of Triazine Containing Hybrid CompositesFra FraNoch keine Bewertungen

- AKZO Brochure Oil FieldDokument35 SeitenAKZO Brochure Oil FieldFra Fra100% (2)

- 327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupDokument1 Seite327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupGokulprabhuNoch keine Bewertungen

- WAM-The Weighted Average Method or Predicting The Performance of Systems With Bursts of Customer SessionsDokument10 SeitenWAM-The Weighted Average Method or Predicting The Performance of Systems With Bursts of Customer SessionsArunNoch keine Bewertungen

- (Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateDokument5 Seiten(Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateRavi Shankar TurlapatiNoch keine Bewertungen

- FB131Dokument7 SeitenFB131Hoangvinh DuongNoch keine Bewertungen

- 14 Fine Tuned Assembly LineDokument4 Seiten14 Fine Tuned Assembly LineSadhish KannanNoch keine Bewertungen

- Radio Link Analysis and Data Collection-20120110-ADokument23 SeitenRadio Link Analysis and Data Collection-20120110-AHICHAMNoch keine Bewertungen

- Aerocore PropertiesDokument2 SeitenAerocore PropertieskflimNoch keine Bewertungen

- Quadrosense - ManualDokument22 SeitenQuadrosense - ManualdannraduNoch keine Bewertungen

- Reference Jica-Chodai Scouring Manual in ThailandDokument175 SeitenReference Jica-Chodai Scouring Manual in ThailandSeptinurriandianiNoch keine Bewertungen

- MZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalDokument59 SeitenMZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalFaiyazsulthanNoch keine Bewertungen

- Layanan Dan Pelayanan Perpustakaan: Menjawab Tantangan Era Teknologi InformasiDokument6 SeitenLayanan Dan Pelayanan Perpustakaan: Menjawab Tantangan Era Teknologi InformasiLailatur RahmiNoch keine Bewertungen

- Is 13134Dokument14 SeitenIs 13134Sowjanya ChNoch keine Bewertungen

- Zeal High Precision Wet Test Gas Flow Meters 2022Dokument5 SeitenZeal High Precision Wet Test Gas Flow Meters 2022Hiran ChathurangaNoch keine Bewertungen

- Anandarup Ray CVDokument4 SeitenAnandarup Ray CVsrihariNoch keine Bewertungen

- Manesar AutomotiveDokument101 SeitenManesar Automotiveshriya shettiwarNoch keine Bewertungen

- COMPRESOR KAESER Ask - T - SeriesDokument136 SeitenCOMPRESOR KAESER Ask - T - SeriesTALLER NUEVEDEJULIO SATNoch keine Bewertungen

- Python ScriptingDokument2 SeitenPython ScriptingRavikumar TumuluriNoch keine Bewertungen

- 3 Drill StringDokument43 Seiten3 Drill StringShabaz HazharNoch keine Bewertungen

- NS200 - Major Substations Ventilation Design Standard (2010)Dokument25 SeitenNS200 - Major Substations Ventilation Design Standard (2010)vince aquinoNoch keine Bewertungen

- Print PDFDokument11 SeitenPrint PDFFe CasarolliNoch keine Bewertungen

- Machine Drawing Question Bank PDFDokument22 SeitenMachine Drawing Question Bank PDFNééråj SmårtNoch keine Bewertungen

- Outline Spesifikasi BPKPDokument44 SeitenOutline Spesifikasi BPKPnadyaNoch keine Bewertungen

- Harsh's ResumeDokument1 SeiteHarsh's ResumeNavin J PomsonNoch keine Bewertungen

- Simple DistillationDokument2 SeitenSimple DistillationHarvey A. JuicoNoch keine Bewertungen

- Synchronous ManufacturingDokument18 SeitenSynchronous ManufacturingPatricia Romero100% (1)

- CPCCSF2003A Cut and Bend Materials Using Oxy LPG Equipment LR V1Dokument141 SeitenCPCCSF2003A Cut and Bend Materials Using Oxy LPG Equipment LR V1FfdsfdsNoch keine Bewertungen

- Project Management Resume ExampleDokument2 SeitenProject Management Resume ExampleGuino VargasNoch keine Bewertungen

- Hoses & AppliancesDokument92 SeitenHoses & Appliancestheguy 21100% (1)

- References:: 111 Richard Valantine, "Motor Control Electronics Handbook", 1998, ISBN 0-07-066810-8Dokument30 SeitenReferences:: 111 Richard Valantine, "Motor Control Electronics Handbook", 1998, ISBN 0-07-066810-8rajeevNoch keine Bewertungen

- Brl-Arpa Doploc Satellite Detection Complex PDFDokument226 SeitenBrl-Arpa Doploc Satellite Detection Complex PDFClifford StoneNoch keine Bewertungen