Beruflich Dokumente

Kultur Dokumente

EN21004243A Roller Stations

Hochgeladen von

bulentbulutCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EN21004243A Roller Stations

Hochgeladen von

bulentbulutCopyright:

Verfügbare Formate

Machine manual

en-21004.243-A

POLRO

r

selfaligning roller station

for mechanical direct drive

(2 roller drive)

Code word

Order No.

AAT items

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive)

Contents

en-21004.243-A

Contents

1 Technical data 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Components and mode of functioning 31 . . . . . . . . . . . . . . . . . . . . .

3.1 Components 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Mode of functioning 318 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Transport and assembly 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Transport and storage instructions 41 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Assembly 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Lubrication 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Preparation for test run 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Checks prior to the test run 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Setting and adjustment 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Maintenance 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Servicing 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Trouble shooting 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Repair 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Spare parts 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Appendix 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Technical drawings 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Subsuppliers documentation 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 11

Technical data

en-21004.243-A

1 Technical data

NOTE

Information concerning the electrical equipment is contained in the separate

electrical documentation or in the subsuppliers documentation.

Specification of the intended use

see machine manual of the rotary kiln No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic data

Year of manufacture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Station I

AAT item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diameter of the ollers mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width of the rollers mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diameter of the bearing mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Total clearance between thrust discs and thrust ring mm . . . . . . . . . . . . . . . . . . . . .

Gap s at the set screws mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight of the roller with axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature sensor (optional extra) yes/no . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type PT 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diameter 8 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation length (L + L1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 12

Technical data

en-21004.243-A

Station II

AAT item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diameter of the rollers mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width of the rollers mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diameter of the bearing mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Total clearance between thrust discs and thrust ring mm . . . . . . . . . . . . . . . . . . . . .

Gap s at the set screws mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight of the roller with axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature sensor (optional extra) yes/no . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type PT 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diameter 8 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation length (L + L1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil circulation lubricating system

Quantity 1 pump per bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type of oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 21

Safety

en-21004.243-A

2 Safety

NOTE

Be sure to comply with the general safety instructions in the supplement Important

notes on the documentation.

Use

D The supporting roller station is a component of the rotary kiln.

Be sure to comply with the specification of the intended use in section Technical

data.

D Any use other than the intended use is forbidden. POLYSIUS AG is not

responsible for damage resulting from any use other than the intended use. All

other use is at the owners own risk.

D The intended use also includes the observance of the instructions in the machine

manual and the compliance with the maintenance instructions.

Transport and assembly

D All transportation instructions in this machine manual refer exclusively to

transportation of the machine at the plant site.

D Only use suitable hoisting and lifting equipment which is in serviceable order and

has a sufficient load bearing capacity.

D Never work under a suspended load.

Operation

D Any safety checks before or during operation depend on the relevant national

regulations. The plant management is responsible for the performance and

recording of such checks.

D If changes in the machine or its operating behaviour relevant to safety occur, shut

it down immediately.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 22

Safety

en-21004.243-A

Maintenance

D Ensure that all machines and motors whose operation might endanger persons

or equipment are switched off and safeguarded against restarting for the entire

duration of the maintenance work.

D Ensure that all rotating parts of the machine have come to a complete standstill

before you remove any protection devices or open any flaps.

D Before performing any work on the machine, make sure there is no risk of burns

when touching the machine.

D After opening the top cover of the bearing, do not insert fingers or hands into the

bearing: danger of crushing or tearing off due to rotating oil scoops.

D Keep the machine free of oily and combustible substances and materials. Never

use gasoline or other easily inflammable substances for cleaning the machine.

D Switch off the power supply to the electrical components before commencing any

maintenance work.

D The plant management has to ensure that the whole area of the rotary kiln is

cordoned off, so that it is impossible for persons to come into contact with rotating

parts.

D It is forbidden to carry out work at the rotating kiln.

D Before beginning any repair work, make absolutely sure that the rotary kiln has

swung to a complete stop in its centre of gravity position and has been secured

by means of the holding brake!

D Strictly observe the welding instructions when performing any welding work.

D If you carry out electrical welding on any part of the machine, never conduct the

welding current through plain or antifriction bearings, other movable connections

or measuring devices. Always directly connect the welding current return lead to

the part being welded.

D Remount all protection devices when maintenance work has been finished. Make

absolutely sure that no persons are inside the plant component before you

properly close the inspection and service covers.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 31

Components and mode of functioning

en-21004.243-A

3 Components and mode of functioning

The rotary kiln is supported on the supporting roller stations I and II of the two

tyres; the occurring forces are transmitted into the foundations.

The roller stations are mounted on selfaligning bedplates that are fixed onto the

foundations.

The rollers of supporting roller station I are directly driven via the adapters.

3.1 Components

NOTE

Some details of the drawings in this manual may not be identical with the drawings

supplied under the contract as listed in section 9.1 Technical drawings.

Each supporting roller station essentially consists of the following components:

D the selfaligning bed plate units

D the tyre saddle

D the rollers

D the supporting roller bearings

D the adapters for receiving the direct drive

D the direct drive (see separate machine manual)

D the protection devices

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 32

Components and mode of functioning

en-21004.243-A

The selfaligning supporting roller stations consist of the following subassemblies:

1.0 Supporting roller with axle

2.1 Supporting roller bearings for roller station I

2.2 Supporting roller bearings for roller station II

2.40 Temperature sensor (optional extra)

3.0.1 Selfaligning bed plate unit for roller station I

3.0.2 Selfaligning bed plate unit for roller station II

4.0 Drive

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 33

Components and mode of functioning

en-21004.243-A

Figure 1

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 34

Components and mode of functioning

en-21004.243-A

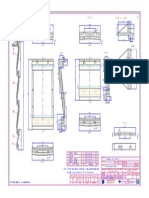

Roller station I

Items shown in the drawing of the selfaligning bed plate unit (3.0.1)

3.1.1 Bedplate I

3.2 Bedplate II

3.3 Bedplate III

3.4 Bedplate IV

3.5 Central bed plate

3.8 Bedplate anchorage

3.10 Elastomer bearing for motion absorption

3.11 Adjusting spindle with position sensor

1.0 Supporting roller with axle

1.1 Graphite block lubrication

4.0 Drive

7.0 Stabiliser

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 35

Components and mode of functioning

en-21004.243-A

Figure 2

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 36

Components and mode of functioning

en-21004.243-A

Roller station I

Items shown in the drawing of the selfaligning bed plate unit (3.0.1)

3.9 Elastomer bearing for motion absorption

3.11 Adjusting spindle

3.14 Set screws

1.0 Supporting roller with axle

2.1 Supporting roller bearing for roller station I

2.40 Temperature sensor (optional extra)

6.0 Balance weight

7.0 Stabiliser

NOTE

The dimension of the gap s at the set screws is described in section Technical data.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 37

Components and mode of functioning

en-21004.243-A

Figure 3

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 38

Components and mode of functioning

en-21004.243-A

Roller station I

Items shown in the drawing of the selfaligning bed plate unit (3.0.1)

3.6 Tyre saddle

3.7 Tension rod

3.9 Elastomer bearing for motion absorption

3.10 Elastomer bearing for motion absorption

3.12 Distance sensor, tyre

3.13 Distance sensor, roller

1.0 Supporting roller with axle

4.0 Drive

5.0 Radiant heat protection

6.0 Balance weight

7.0 Stabiliser

Figure 4

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 39

Components and mode of functioning

en-21004.243-A

Figure 5

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 310

Components and mode of functioning

en-21004.243-A

Items shown in the drawing of the supporting roller bearing (2.1) for roller station I

2.3 Bearing housing

2.4 Bearing bush

2.5 Half thrust ring

2.6 Oil scoop

2.7 Inspection cover

2.8 Inspection cover

2.9 Venting connection

2.10 Splash ring

2.11 Centering ring

2.11.1 Tensioning screw for the centering ring

2.11.2 Guide strip

2.12 Oring

2.13 Stuffing box gland

2.13.1 Tensioning screw for the stuffing box gland

2.13.2 Packing

2.13.3 Scraper ring

2.14 Lubricant inspection glass

2.15 Oil pump

2.16 Bearing cover

2.17 Centering ring

2.17.1 Tensioning screw for the centering ring

2.17.2 Guide strip

2.18 Oring

2.19 Stuffing box gland

2.19.1 Tensioning screw for the stuffing box gland

2.19.2 Packing

2.19.3 Scraper ring

2.20 Transverse key

2.21 Adapter for receiving the drive motors

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 311

Components and mode of functioning

en-21004.243-A

Figure 6

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 312

Components and mode of functioning

en-21004.243-A

Roller station II

items shown in the drawing of the selfaligning bed plate unit (3.0.2)

3.1.2 Bedplate I

3.2 Bedplate II

3.3 Bedplate III

3.4 Bedplate IV

3.5 Central bed plate

3.6 Tyre saddle

3.7 Tension rod

3.8 Bedplate anchorage

3.9 Elastomer bearing for motion absorption

3.10 Elastomer bearing for motion absorption

1.1 Graphite block lubrication

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 313

Components and mode of functioning

en-21004.243-A

Figure 7

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 314

Components and mode of functioning

en-21004.243-A

Roller station II

items shown in the drawing of the selfaligning bed plate unit (3.0.2)

3.6 Tyre saddle

3.11 Adjusting spindle with position sensor

3.13 Distance sensor, roller

1.0 Supporting roller with axle

NOTE

The dimension of the gap s at the set screws is described in section Technical data.

Figure 8

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 315

Components and mode of functioning

en-21004.243-A

Figure 9

Figure 10

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 316

Components and mode of functioning

en-21004.243-A

Items shown in the drawing of the supporting roller bearing (2.2) for roller station II

2.3 Bearing housing

2.4 Bearing bush

2.5 Half thrust ring

2.6 Oil scoop

2.7 Inspection cover

2.8 Inspection cover

2.9 Venting connection

2.10 Splash ring

2.11 Centering ring

2.11.1 Tensioning screw for the centering ring

2.11.2 Guide strip

2.12 Oring

2.13 Stuffing box gland

2.13.1 Tensioning screw for the stuffing box gland

2.13.2 Packing

2.13.3 Scraper ring

2.14 Lubricant inspection glass

2.15 Oil pump

2.30 Bearing cover

2.31 Thrust disc

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 317

Components and mode of functioning

en-21004.243-A

Figure 11

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 318

Components and mode of functioning

en-21004.243-A

3.2 Mode of functioning

For supporting the rotary kiln, each roller station requires two rollers with one pair

of bearings each, plus the associated bed plate units.

As a rule, the rollers are so arranged that the connecting lines from the centre of the

roller to the centre of the tyre form an isosceles triangle with an apex angle of 60.

The forces caused by the supported load are received by the roller stations and

transferred into the foundation.

The dimensions of the kiln tyre and the supporting rollers, as well as those of all roller

station components are selected to suit the expected operating conditions of the

respective rotary kiln.

To ensure a good contact pattern and avoid impermissibly high local Hertzian

pressures between a wobbling tyre and the supporting rollers, the rollers have a

selfaligning supporting system.

In combination with a direct drive system, the rollers also transmit the driving torque

to the kiln tyre. The drive acts on one or two rollers of one station.

Supporting rollers and axles

The cast or forged solid section rollers are nondetachably connected to the forged

supporting roller axles and have drill holes for transportation purposes.

The axle ends have been prepared for receiving the adapter of the direct drive

system.

Supportingroller bearings

The bearings consist of a cast housing with integrated coolant compartments and

of the bearing bush halves and the collar ring halves made of a special bearing metal

with very good emergency running characteristics.

The supportingroller bearings are so designed that PT 100 temperature sensors

can be installed.

The axle ends are mounted in the bearing bushes. Axial forces are transmitted via

the thrust rings bolted onto the axle to the collar of the bearing bushes and the half

thrust rings.

The plain bearings are lubricated with mineral oil (see section Lubrication). Oil

scoops mounted on the axle take oil from the sump and pour it onto the upper

(free)area of the shaft journal.

The lubricant enters through a wedgeshaped inlet gap on the inwardturning side

of the bearing bush, is distributed over the entire length of the bearing bush and

passes into the lubrication gap.

This type of bearing and lubrication provides high operating reliability.

Specially for the starting phase of the rotary kiln and operation with low rotation

speeds, the supportingroller bearings are equipped with oil pumps. It is wise to

observe a prelubrication period of approx. 25 minutes before starting to turn the kiln.

However, for safety reasons the lubrication during operation is performed by the oil

scoops.

The coolant for the supportingroller bearings (generally cooling water) flows

through cooling compartments in the bearing base.

In order to correct the position of the rotary kiln, you can shift the supportingroller

bearings (and thus the rollers) transverse to the rotary kiln axis by using the bearing

positioning units.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 319

Components and mode of functioning

en-21004.243-A

You can perform this adjustment under operating load, as the bearing positioning

units are designed to accept a hydraulic bearing adjustment device. You have to

adjust both bearings of one supportingroller simultaneously in steps of approx.

0.2mm. Check this by means of a dial gauge.

After relieving the spindle by means of the hydraulic press, perform the adjustment

as described above. Then remove the hydraulic press.

When readjusting the supportingroller bearings pay attention that no impermissible

heating up of the thrust disks and collar rings occurs, as this is a sign of skewing of

the supporting roller axis relative to the rotary kiln axis, which can cause

impermissibly high axial forces.

The supportingroller bearings are axially secured by lateral sliders.

Special seals are installed in the shaft passages to prevent oil losses.

Elastomer bearings for motion absorption

The elastomer bearings for motion absorption are made of special materials suited

to the rotary kiln operation and are pressureresistant and thrustresilient. These

bearings permit deflection in the case of a wobbling kiln tyre in spite of great

operating loads.

The elastomer bearings for motion absorption must be protected against oils,

greases, chemicals etc. as this considerably reduces serviceability.

Selfaligning bed plate unit

The pair of bearings belonging to each supporting roller is movably mounted on the

bedplates I (3.1.1 and 3.1.2) and is only secured by the bearing positioning units.

This provides the possibility to preset the supportingroller bearing relative to the

rotary kiln axis.

The spreading forces are transmitted via the tension rods (3.7) and the central bed

plate (3.5).

At supporting roller stations I and II, the bedplates I (3.1.1 and 3.1.2) are

movable via an elastomer bearing for motion absorption (3.9) relative to bedplate II

(3.2). This permits in combination with the adjusting spindle (3.11) fine alignment of

the supporting roller relative to the rotary kiln axis during normal kiln operation.

Selfalignment of the supporting roller station is ensured by means of thrustresil-

ient elastomer bearings for motion absorption between bedplate II (3.2) and

bedplate III (3.3). Bedplate IV (3.4) is permanently connected with the rotarykiln

foundation.

Bearing corrections (e.g. for compensating foundation settlements) are carried out

by means of correcting plates between bedplate III (3.3) and bedplate IV (3.4).

To avoid impermissibly high temperatures at the elastomer bearings for motion

absorption (3.10), bedplate II (3.2) is cooled with cooling water from the supporting

roller bearings.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 320

Components and mode of functioning

en-21004.243-A

Supporting roller centering device

The rollers (1.0) of supporting roller station I and the outwardrunning supporting

roller of roller station II are equipped with a position control system. The supporting

rollers are therefore held in an approximately central position. The position sensing

is performed via the distance sensors (3.13). The rollers are adjusted via the control

system by means of the adjusting spindles (3.11).

Central bed plate

The rotary kiln axial thrust system is bolted onto the central bed plate.

The tyre saddle (3.6) is bolted onto the central bed plate (3.5) and secures the rotary

kiln if components of the selfaligning roller station fail.

To facilitate repair work (e.g. replacement of a supporting roller), you can set the kiln

tyre down on the tyre saddle. You can also fit hydraulic jacks into the tyre saddle in

order to lift the kiln tyre station independently of the supporting rollers after

unscrewing the fixing bolts.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 41

Transport and assembly

en-21004.243-A

4 Transport and assembly

4.1 Transport and storage instructions

The supporting roller station is delivered in individual component parts. It must be

ensured that suitable lifting equipment is employed for lifting the parts from the

transport vehicles and transferring them to the storage area.

When they arrive at the site, all parts must be inspected for transport damage and

placed on wooden beams with the provision of suitable protection against moisture,

soiling and damage. Never place the parts directly on the ground.

Check the corrosion proofing and renew it if necessary.

Measurement and control equipment must be stored in wellventilated buildings and

must be protected against moisture.

4.2 Assembly

General notes

The following assembly instructions do not detail the individual steps for assembling

the machine units but rather give an overview of the work to be performed.

Changes in the planning of the plant during the processing of the contract may lead

to deviations from these assembly instructions.

NOTE

It is a prerequisite of our warranty that assembly and assembly inspection are

undertaken by an assembly specialist from POLYSIUS AG

A careful selection of the tools and appliances as well as the assembly personnel

to be employed is important for the correct performance of the work.

CAUTION

If you carry out electrical welding on any part of the machine, never conduct

the welding current through plain or antifriction bearings, other moving

connecting elements or measuring devices, in order to prevent damage to

these parts.

Always directly connect the welding current return lead to the part being

welded.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 42

Transport and assembly

en-21004.243-A

Measuring work

Elevation reference point

The starting point of all measuring work is the elevation reference point which applies

to the entire plant and which has a fixed relationship to the zero datum line shown

in the general arrangement drawing. The companies responsible for construction of

the foundations and buildings determine the elevation reference point and inform our

erection superintendent accordingly.

To facilitate the measurements of axes and heights for the purpose of assembling

the machine components, inscribe a benchmark of, for instance, 1000 mm above

zero datum line on every rotarykiln foundation. For this purpose, the construction

firm anchored steel plates sized 200 x 200 mm on 4 corners of each foundation.

Determine the height by levelling instrument or rubber tube level and permanently

chisel it as benchmark into the steel plates.

Figure 12

A = datum mark B = steel plate

C = anchorage D = concrete

E = drilled hole for nailed connection to formwork

This 1 metre mark enables any foundation subsidences to be determined by

means of subsequent check measurements. For this reason, the same benchmarks

must also be attached to the preheater and cooler buildings.

The bedplates of the supporting roller stations are provided with measuring marks

by the manufacturer.

The check measurements must be written into a measurement record (with sketch)

and their correctness must be confirmed by the customer.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 43

Transport and assembly

en-21004.243-A

Sequence of assembly

Laying base girders

After concluding the measuring work, first align bedplates IV (3.4) and then

grout in with nonshrink grout.

Mounting and aligning the bedplates

Place bedplates I, II, III onto the bedplates IV grouted in and align. Replace

the elastomer bearings for motion absorption during this work with steel auxiliary

devices of equal size, i.e. the roller station is not selfaligning in this condition.

For the alignment, packing plates can be inserted between the bedplates III

and IV.

After concluding the aligning work, lock bedplate III on bedplate IV by means

of the lateral keys. Secure the keys by means of a weld seam.

Then place the bearings onto the bedplates.

Mount the roller station with plain bearings (if not already mounted)

Remove the corrosion proofing from the roller shaft ends.

Clean the bearing housing, remove the bearing cover and check that the bearing

bushes with thrust ring are correctly installed.

Slip the bearing onto the roller shaft end, mount the thrust disks (2.31) and

adapter (2.21) and tighten and secure the bolts and locking washers with the

stipulated torque.

Mount and secure the oil scoops. Seal and mount the bearing cover.

Install the shaft seals.

Clean the contact surfaces of the bearing and coat with graphite paste or similar.

Insert the sliders and place the rollers and readymounted bearings on

bedplates I.

CAUTION

To prevent damage to the top side of the axle journal while transporting the

track roller with axle and bearing as a unit, insert a suitable wooden block

between the axle journal and the inner side of bearing. After setting the unit

(roller, axle and bearing) down on bedplate I, remove the wooden block

immediately.

Insert the bearing positioning units with thrust elements.

Adjust the supporting roller axle to the dimensions stipulated in the general

arrangement drawing and the measurement record.

Check the angles of inclination of foundations, bedplates and supporting roller

axes relative to the kiln inlet housing and cooler using POLSCAN

r

.

Permanently mark the set dimensions on the seat of the bedplates and at the

bearing base.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 44

Transport and assembly

en-21004.243-A

Protect the bearing positioning units against damage and dirtying of the threaded

spindle by means of protective boxes.

Mount and align the heat shields, guard plates and graphite lubrication devices

on the supportingroller bearing.

Fill with oil in accordance with the lubrication instructions (section Lubrication).

Before commissioning the rotary kiln, remove the steel auxiliary devices and

replace the elastomer bearings for motion absorption.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 51

Lubrication

en-21004.243-A

5 Lubrication

NOTE

The POLYSIUS table of lubricants with the lubricant reference numbers is

contained in the supplement Important notes on the documentation. The

supplement is contained in this folder or at the beginning of the overall

documentation. Each lubricant has a clear reference number to which the lubrication

instructions in this section relate. The table gives a complete list of all suppliers and

products approved by POLYSIUS AG.

It is the responsibility of the lubricant supplier to select appropriate lubricants

corresponding to the lubricant reference numbers. POLYSIUS AG accepts no

liability for the correctness of this data.

If you wish to use a lubricant that is not included in the Table of lubricants, you have

to first obtain the express permission of POLYSIUS AG.

The supplement Important notes on the documentation also contains the generally

valid Notes on lubrication.

Ensure that the environment is not polluted when lubricants are stored, used

and disposed of and carefully observe the relevant national legislation for the

protection of the environment when handling lubricants..

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 52

Lubrication

en-21004.243-A

Lubrication chart

A

b

Figure 13

oil level mark at the oil sight glass.

An excessive oil level in the supporting roller bearing causes

leaks.

Figure 14

CAUTION

Synthetic oils on polyethylene glycol basis attack the material of the bearing

bushes in the supporting roller bearings. (Lubrication points No. 11 and 12)

Never use synthetic oils on a polyethylene glycol basis for lubricating the

bearings of the roller stations.

Be sure to regularly check the oil levels in the oil sight glasses of all thesup-

portingroller bearings.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 53

Lubrication

en-21004.243-A

Lubrication points Quantity (ltr, kg)

per lubrication

point

Lubrication intervals

(weeks)

No. Qty. Designation Lubricant ref.

no.

Initial fill-

ing

Topping up Topping

up

First

change

Further

changes

11 4 Supporting roller bearing

station I

26 4 24

12 4 Supporting roller bearing

station II

26 4 24

13a 1 Graphite lubrication device

station I

Check the graphite blocks daily for wear.

Only the two outer fields may be filled with 100 mm wide graphite blocks.

13B 1 Graphite lubrication device

station II

Check the graphite blocks daily for wear.

Apply graphite blocks over the entire supporting roller width.

14 Hydraulic direct drive Acc. to manufacturers instructions

The different makes of lubricant corresponding to the lubricant reference numbers are shown in the Table of lubricants in the

supplement Important notes on the documentation. The supplement is contained in this folder or at the beginning of the overall

documentation.

Explanation of the numbers

Check the oil level at the oil sight glass of the downhill and uphill supporting roller bearings every week,

see Figure 14.

CAUTION

at the supporting roller bearings.

When the rotary kiln is starting up and when the kiln rotation speed is n < 1

min

1

the oil pumps of the supportingroller bearings have to be in operation.

When the rotary kiln is starting up the axles in the supportingroller bearings (2) have

to be covered with a film of lubricating oil. The selflubrication by means of the oil

scoops does not begin until after about a half rotation of the rollers.

The supportingroller bearings must therefore be prelubricated for 2 to 5 minutes by

means of the oil pumps (2.15).

Lubricant supply to the supportingroller bearings when the kiln rotation-

speed is below one rotation per minute

During operation with kiln rotation speeds of n < 1 min

1

the axles in

thesupportingroller bearings (2) have to be supplied with sufficient lubricating oil.

This is done by means of the oil pumps (2.15).

NOTE

If one oil pump fails at operating speed, a warning is issued.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 54

Lubrication

en-21004.243-A

At this speed of rotation the oil scoops assure that sufficient lubricant is supplied to

the supportingroller bearing.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 61

Preparation for test run

en-21004.243-A

6 Preparation for test run

NOTE

It is a prerequisite of our warranty that the first test run is carried out in the presence

of and according to the instructions of specialists from POLYSIUS AG.

6.1 Checks prior to the test run

After completing the assembly work and prior to the first test run, check all parts of

the plant in accordance with the list below. Make absolutely sure that any material

remnants, tools and assembly implements have been carefully removed.

Are all inspection ports in the bearings closed?

Are all stations correctly aligned?

Is the control system for supporting roller adjustment at stations I and II

ready for operation?

Are the supporting roller centering devices with distance sensors (3.13) ready

for operation?

Have all transportation aids and securing devices been removed?

Are the rollers of station I and II in nonangled position?

Is the bearing temperature monitoring system (option) ready for operation?

Is the total clearance between the thrust disks and the half thrust rings in

accordance with the dimensions stipulated in the data sheet?

Is the cooling device at the supportingroller bearings and bedplate II in

operation?

Is the coolant pressure of the closed cooling circuit less than 2 bar?

Is the feed flow coolant temperature below 30 C?

Are the graphite slabs for supportingroller lubrication installed at stations I

and II?

Have the components been filled with the correct lubricant in accordance with

thelubrication instructions?

Does the lubricant level correspond to the stipulated height in the bearing

inspection glass?

Is the circulation lubrication system for the bearings in operation (prelubrication

period 2 to 5 minutes)?

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 62

Preparation for test run

en-21004.243-A

6.2 Setting and adjustment

In the initial phase of commissioning you have to constantly check the setting and

temperature development of the supportingroller bearings. If necessary, you will

have to carry out fine adjustments to the bearing alignment while the rotary kiln is

running.

When carrying out fine alignment of the inwardturning supporting roller of station

II, pay attention to the oil film on the shaft journal and check the temperature

development of the thrust disks.

This work demands considerable special knowledge and may only be carried out

under the direction of specialists from POLYSIUS AG.

At the driven roller station I, a control system ensures the correct adjustment of

the rollers.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 71

Maintenance

en-21004.243-A

7 Maintenance

DANGER

The rotary kiln is hot.

You may suffer very severe burns!

Always use the required protective clothing.

No. Work to be performed Frequency Comments

1 Check the lubricant level in the

supportingroller bearings.

Weekly You can see the

lubricant filling level in

the oil sight glass on

the outer bearing face.

2 Check the bearing temperature

Permissible value:

60 C at the bearing bush

(can only be determined with bearing

temperature measuring system [option]) and

50 C at the bearing housing.

Daily

3 Check the inlet temperature of the coolant. weekly Required value < 30 C

4 Check the outlet temperature of the coolant. Weekly Required value < 45 C

5 Check the coolant pressure

(only in the case of closed systems)

Weekly Required value < 2 bar

6 Check the axial play between the thrust

disks and half thrust rings.

Every 6 months

7 Check the contact pattern of the rollers. Daily

8 Check the graphite lubrication device for

wear at stations I and II.

Daily

9 Check the supportingroller bearings for

leaks.

Weekly

10 Check the foundations for settlement or

tilting.

Measure the reference marks on the

foundations.

Every 3 months If only slight move-

ments are measured-

within one period, you

can increase the

intervals to 1 x per

year.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 72

Maintenance

en-21004.243-A

7.1 Servicing

DANGER

The rotary kiln is hot.

You may suffer very severe burns!

Always use the required protective clothing.

No. Work to be performed Frequency Comments

1 Change the bearing lubricant. See section Lubrica-

tion

2 Replace the graphite slabs of the

supportingroller lubrication system.

Depending on

wear condition

7.2 Trouble shooting

Fault Cause Elimination

Foundation movements of

w 5 mm since the last

check (adjustment).

Foundation subsidence POLSCAN

r

personnel measure

and, if necessary, readjust the

supporting rollers and the rotary kiln

axis with the POLYSIUS AG

measuring system by order and for

account of the customer.

Foundation tilting POLYSIUS AG personnel measure

and, if necessary, readjust the sup-

porting rollers and the rotary kiln

axis by underlaying bedplate III

with the aid of the POLSCAN

r

measuring system by order and for

account of the customer.

Leaks at the shaftpassa-

ges.

Mismatch of centres due

to wear of the bearing

bushes

Retension the stuffing box gland.

Loosen the tensioning bolts of

therespective centering ring.

This measure will recentre the seals.

Then retighten the tensioning bolts.

Worn seals Replace the seals and packings.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 73

Maintenance

en-21004.243-A

Elimination Cause Fault

Overheating of the

supporting roller bearing.

Lack of lubricant Open the upper bearing cover and

fill in lubricant.

The lubricant does not

comply with the lubricant

recommendation

Change the lubricant.

Attention:

When changing the lubricant ensure

that no foreign bodies get into the

supporting roller bearing.

Lack of coolant Ensure that the supply of coolant is

adequate.

Angling of the supporting

roller bearing (the contact

pressure between the

thrust ring and the thrust

disks is too high)

(only station II)

Readjust the supporting roller

bearing until there is only slight

contact.

Attention:

This work may only be performed by

experts.

Lack of lubricant due to

excessive axial clearance

between the thrust disks

and the half thrust rings

Check the clearance in accordance

with the dimensions stated in section

Technical data. Reduce the

clearance by underlaying the sliders

(5) with packing plates.

Lack of lubricant due to

insufficient delivery by the

oil scoops

D Oil scoops are not filling

adequately

Check the lubricant level.

Check the oil scoops to see if the

vent in the partition is clogged up.

(the scoops are possibly not filled

adequately because the air cushion-

cannot escape.)

D Low kiln rotation speed

(< 1 min

1

) over a

lengthy period of time

Check the functioning of the oil

pumps (2.15).

Failure of the position

control system at station

I or II

Check and repair the control loop

from the distance sensors to thead-

justing spindles.

If any faults occur which are not described above, consult the additional information

about faults, their causes and their elimination in the subsuppliers documentation.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 74

Maintenance

en-21004.243-A

7.3 Repair

Before beginning any repair work, switch off the power supply to all electrical

components.

Ensure absolute cleanliness at all times during repair work in order to prevent dirt

from entering the bearings, the drive units or other sensitive parts of the machine or

plant.

Do not remove or open any covers or protection devices before all rotating parts have

stopped.

DANGER

You may burn yourself!

It is forbidden to carry out work at the rotating kiln.

Before beginning any repair work, make absolutely sure that the rotary kiln

has swung to a complete stop in its centre of gravity position and has been

secured by means of the holding brake!

Always use the required protective clothing.

As a rule, it is only possible to carry out repair work on the supporting roller

stationsafter dismounting the supportingroller bearing or the rollers.

Mark the position of the supportingroller bearings relative to the bedplate by,for

example, chisel or punch marks.

Unscrew the frontside bearing cover.

Detach the bolted connections at the thrust disk.

Remove the thrust disk.

Withdraw the supportingroller bearing in axial direction of kiln.

Assemble in reverse order

Be sure to observe the tightening torque of the bolts at the thrust disks.

Bolt diameter (mm) Tightening torque (Nm)

M 30 1200

M 33 1700

M 36 2150

M 39 2850

M 42 3500

M 48 5300

M 52 6950

M 56 8600

M 60 10900

M 64 13100

After tightening these bolts, secure them against loosening by means of suitable

locking wire.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 75

Maintenance

en-21004.243-A

Check the condition of the bearing bushes and the shaft ends every time.

If you find scoring on the shaft ends, replace the bearing bushes in pairs and then

smooth out the grooves.

Subsequently, clean the supportingroller bearings and fill with new lubricant.

In order to improve the contact pattern, it is possible to grind the surfaces of the

rollers and tyres with a special roller / tyre grinder during normal kiln operation.

CAUTION

After you have completed the repair work, you must check the machine/plant

again according to section Preparation for test run.

Tools and implements

No special tools are required for repair work on the machine. However, you may need

torque wrenches of a bigger size than normal.

Whether or not you need auxiliary equipment, such as scaffolds or hoists, depends

on the conditions in your plant.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 81

Spare parts

en-21004.243-A

8 Spare parts

Notes for enquiring about and ordering spare parts

Dear Customer,

POLYSIUS AG strive to render your enquiring about and ordering of spare parts as

easy, and as a consequence, as efficient as possible. For this purpose we have

prepared a table containing all data required by our spare parts department to ensure

optimum processing in the most speedy and troublefree manner.

Please copy the page with the respective table and mark those parts which you

require with a cross in the column Order or Enquiry.

If the table relates to more than one machine, please also inform us of the AAT item

of the machine for which you require the spare parts.

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 82

Spare parts

en-21004.243-A

Spare parts for supporting roller station I

Figure 15

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 83

Spare parts

en-21004.243-A

Code word: Order No.: AAT-item:

Item Designation Qty. Unit Order Enquiry

1.0 Supporting roller with axle 1 Piece

1.1 Graphite block lubrication 1 Set

3.1.1 Bedplate I 1 Piece

3.2 Bedplate II 1 Piece

3.3 Bedplate III 1 Piece

3.4 Bedplate IV 1 Piece

3.9

Elastomer bearing for motion

absorption

1 Set

3.10

Elastomer bearing for motion

absorption

1 Set

3.11 Adjusting spindle 2 Piece

3.13 Distance sensor 2 Piece

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 84

Spare parts

en-21004.243-A

Spare parts for the supportingroller bearing (2.1) in roller station I

Figure 16

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 85

Spare parts

en-21004.243-A

Code word: Order No.: AAT-item:

Item Designation Qty. Unit Order Enquiry

2.1

Supporting roller bearing, com-

plete

1 Piece

2.3 Bearing housing 1 Piece

2.4 Bearing bush 1 Piece

2.5 Half thrust ring 1 Piece

2.6 Oil scoop 1 Piece

2.7 Inspection cover 1 Piece

2.7.1 Seal 1 Piece

2.8 Inspection cover 1 Piece

2.8.1 Seal 1 Piece

2.9 Venting connection 1 Piece

2.10 Splash ring 1 Piece

2.11 Centering ring 1 Piece

2.11.1 Tensioning screw 1 Piece

2.11.2 Guide strip 1 Piece

2.12 O ring 1 Piece

2.13 Stuffing box gland 1 Piece

2.13.1 Tensioning screw 1 Piece

2.13.2 Packing 1 Set

2.13.3 Scraper ring 1 Piece

2.14 Lubricant inspection glass 1 Piece

2.15 Oil pump 1 Piece

2.16 Bearing cover 1 Piece

2.17 Centering ring 1 Piece

2.17.1 Tensioning screw 1 Piece

2.17.2 Guide strip 1 Piece

2.18 O ring 1 Piece

2.19 Stuffing box gland 1 Piece

2.19.1 Tensioning screw 1 Piece

2.19.2 Packing 1 Set

2.19.3 Scraper ring 1 Piece

2.20 Transverse key 1 Piece

2.21 Adapter 1 Piece

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 86

Spare parts

en-21004.243-A

Spare parts for supporting roller station II

Figure 17

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 87

Spare parts

en-21004.243-A

Code word: Order No.: AAT-item:

Item Designation Qty. Unit Order Enquiry

1.0 Supporting roller with axle 1 Piece

1.2 Graphite block lubrication 1 Set

3.1.2 Bedplate I 1 Piece

3.2 Bedplate II 1 Piece

3.3 Bedplate III 1 Piece

3.4 Bedplate IV 1 Piece

3.9

Elastomer bearing for motion

absorption

1 Set

3.10

Elastomer bearing for motion

absorption

1 Set

3.11 Adjusting spindle 1 Piece

3.12 Distance sensor, tyre 1 Piece

3.13 Distance sensor, roller 1 Piece

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 88

Spare parts

en-21004.243-A

Spare parts for the supportingroller bearing (2.2) in roller station II

Figure 18

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 89

Spare parts

en-21004.243-A

Code word: Order No.: AAT-item:

Item Designation Qty. Unit Order Enquiry

2.2

Supporting roller bearing, com-

plete

1 Piece

2.3 Bearing housing 1 Piece

2.4 Bearing bush 1 Piece

2.5 Half thrust ring 1 Piece

2.6 Oil scoop 1 Piece

2.7 Inspection cover 1 Piece

2.7.1 Seal 1 Piece

2.8 Inspection cover 1 Piece

2.8.1 Seal 1 Piece

2.9 Venting connection 1 Piece

2.10 Splash ring 1 Piece

2.11 Centering ring 1 Piece

2.11.1 Tensioning screw 1 Piece

2.11.2 Guide strip 1 Piece

2.12 O ring 1 Piece

2.13 Stuffing box gland 1 Piece

2.13.1 Tensioning screw 1 Piece

2.13.2 Packing 1 Set

2.13.3 Scraper ring 1 Piece

2.14 Lubricant inspection glass 1 Piece

2.15 Oil pump 1 Piece

2.30 Bearing cover 1 Piece

2.31 Thrust disc 1 Piece

Machine manual

POLRO

r

selfaligning roller station for mechanical direct drive (2 roller drive) 91

Appendix

en-21004.243-A

9 Appendix

9.1 Technical drawings

Designation Drawing no.

Assembly drawing

Oil circulation lubricating system

9.2 Subsuppliers documentation

Oil pump

Das könnte Ihnen auch gefallen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- 01.0 - 22146.002E - Hydraulic SystemDokument126 Seiten01.0 - 22146.002E - Hydraulic SystemShariq Khan100% (1)

- Rotary Kilns: Transport Phenomena and Transport ProcessesVon EverandRotary Kilns: Transport Phenomena and Transport ProcessesBewertung: 4.5 von 5 Sternen4.5/5 (4)

- FK PumpDokument29 SeitenFK PumpPP2 Common ID/OperationNoch keine Bewertungen

- 36 KGD Presentation en APCAC2011Dokument20 Seiten36 KGD Presentation en APCAC2011Gonzalo Ale Olave A.Noch keine Bewertungen

- Axial Positioning System of Rotary KilnDokument32 SeitenAxial Positioning System of Rotary KilnRahmat Hidayat100% (1)

- PFC - The Great CoolerDokument47 SeitenPFC - The Great CoolerM.IBRAHEEM100% (1)

- 08 Polycom InspectionDokument33 Seiten08 Polycom InspectionAnita Fernandez C.100% (3)

- Fons Technology PDFDokument28 SeitenFons Technology PDFBulent BULUTNoch keine Bewertungen

- Roller Mill FundamentalsDokument11 SeitenRoller Mill Fundamentalshidrastar123100% (1)

- Fuller-Kinyon Kompact Pumps Pneumatic ConveyingDokument4 SeitenFuller-Kinyon Kompact Pumps Pneumatic ConveyingAnoop Tiwari0% (1)

- Rotary Kiln Reconditioning Tyre and Roller GrindingDokument8 SeitenRotary Kiln Reconditioning Tyre and Roller GrindingTiago CamposNoch keine Bewertungen

- Mini Plant Training Material: Air SlidesDokument28 SeitenMini Plant Training Material: Air Slidesbulentbulut100% (2)

- A4-P 1.0 enDokument53 SeitenA4-P 1.0 enmkpq100% (1)

- 1 Exemplary Technical Report 2012Dokument99 Seiten1 Exemplary Technical Report 2012MKPashaPashaNoch keine Bewertungen

- Main Bearing Mounting and Maintenance GuideDokument16 SeitenMain Bearing Mounting and Maintenance Guidezementhead100% (1)

- Slide Shoue BRG RemovingDokument8 SeitenSlide Shoue BRG Removingsivareddy143100% (1)

- 04 Vertical Roller MillsDokument12 Seiten04 Vertical Roller MillsVishnu Vardhan . C100% (4)

- A4-P 1.0 enDokument27 SeitenA4-P 1.0 enmkpqNoch keine Bewertungen

- Kiln Mechanics PDFDokument59 SeitenKiln Mechanics PDFAndrei Diacu100% (1)

- Heat correction of kiln cranks is cost effectiveDokument4 SeitenHeat correction of kiln cranks is cost effectiveMohamed Shehata100% (2)

- 23 HaverDokument36 Seiten23 HaverkonstantasNoch keine Bewertungen

- Vertical Mill PresesntationDokument54 SeitenVertical Mill PresesntationrecaiNoch keine Bewertungen

- 02 Plant OverviewDokument15 Seiten02 Plant OverviewErnestoAlonsoCornejoChambi100% (1)

- A4-P 1.0 enDokument21 SeitenA4-P 1.0 enmkpqNoch keine Bewertungen

- R A R F U: % Passing Size, M Feed Coarse FinesDokument3 SeitenR A R F U: % Passing Size, M Feed Coarse FinesAli HüthütNoch keine Bewertungen

- G-B: Understanding the FK PumpDokument9 SeitenG-B: Understanding the FK PumpMehmet CNoch keine Bewertungen

- Discrepancies: Shell Linear Trueness For 4 & 5Dokument7 SeitenDiscrepancies: Shell Linear Trueness For 4 & 5sreeganeshrNoch keine Bewertungen

- Loesche Round Table VICATDokument20 SeitenLoesche Round Table VICATrecaiNoch keine Bewertungen

- 2010 10 SMP - Grinding of Kiln Tyre and Roller Surface - Final - V1Dokument19 Seiten2010 10 SMP - Grinding of Kiln Tyre and Roller Surface - Final - V1Wisnu IndriyantoNoch keine Bewertungen

- Atox 20 Coal Mill Critical Interlock SheetDokument6 SeitenAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunNoch keine Bewertungen

- Hydraulic Cylinder Maintenance ChecklistDokument10 SeitenHydraulic Cylinder Maintenance Checklisthaziq100% (1)

- A4-P 1.0 enDokument45 SeitenA4-P 1.0 enmkpqNoch keine Bewertungen

- Bucket Elevators: Installation and Operation ManualDokument20 SeitenBucket Elevators: Installation and Operation Manualboyka yuriNoch keine Bewertungen

- Kiln Producers: UkashmDokument2 SeitenKiln Producers: UkashmDurga PrasadNoch keine Bewertungen

- Operation and Maint.70000056 - A4-P - 2.0 - enDokument53 SeitenOperation and Maint.70000056 - A4-P - 2.0 - enmkpq100% (2)

- Overview of plant equipment trainingDokument31 SeitenOverview of plant equipment trainingДен СтаднікNoch keine Bewertungen

- Kiln Girth Gear Force CalculationDokument7 SeitenKiln Girth Gear Force Calculationvikubhardwaj9224Noch keine Bewertungen

- AUMUND Pan Conveyors Fd0a10Dokument24 SeitenAUMUND Pan Conveyors Fd0a10Bruno100% (1)

- Cooler ETA Vs Grate JG (Dokument39 SeitenCooler ETA Vs Grate JG (NaelNoch keine Bewertungen

- Gap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Dokument8 SeitenGap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Javier Gutierrez100% (1)

- Precalciner Systems Cement IndustryDokument22 SeitenPrecalciner Systems Cement IndustryfaheemqcNoch keine Bewertungen

- Tires and Tire ElementsDokument20 SeitenTires and Tire ElementsRamsai ChigurupatiNoch keine Bewertungen

- Loesche - Loesche Cement Mills Concept Large CapacityDokument26 SeitenLoesche - Loesche Cement Mills Concept Large Capacityphucdc095041Noch keine Bewertungen

- Maintain central chain bucket elevatorDokument8 SeitenMaintain central chain bucket elevatorGarfang RattanapunNoch keine Bewertungen

- Course Polycom Hydraulic Functionality Specification Components PDFDokument30 SeitenCourse Polycom Hydraulic Functionality Specification Components PDFBruno Cecatto100% (2)

- Raw Mill Vertical Roller Mill PDFDokument58 SeitenRaw Mill Vertical Roller Mill PDFganong itbNoch keine Bewertungen

- 04 General Frames Pedestals Lower HousingDokument13 Seiten04 General Frames Pedestals Lower HousingDavid Vilca MamaniNoch keine Bewertungen

- Rex High Performance Chain Bucket Elevator ManualDokument170 SeitenRex High Performance Chain Bucket Elevator ManualJohnNoch keine Bewertungen

- 2020 - 07 - SZS WPU 274Dokument12 Seiten2020 - 07 - SZS WPU 274pinion gearNoch keine Bewertungen

- 08 M Roller Lube Mill Greas SysDokument16 Seiten08 M Roller Lube Mill Greas SysDavid Vilca MamaniNoch keine Bewertungen

- Atox 45 Raw Mill Critical Interlock SheetDokument6 SeitenAtox 45 Raw Mill Critical Interlock SheetValipireddy NagarjunNoch keine Bewertungen

- Loesche-Mills: For Cement Raw MaterialDokument28 SeitenLoesche-Mills: For Cement Raw Materialboyka yuriNoch keine Bewertungen

- Roller Mills MaintenanceDokument109 SeitenRoller Mills MaintenanceTiến Lê MinhNoch keine Bewertungen

- Size:: Every Kiln Has The Following ComponentsDokument10 SeitenSize:: Every Kiln Has The Following ComponentsShehabul Hasan MamunNoch keine Bewertungen

- 08 Rp-Trouble ShootingDokument26 Seiten08 Rp-Trouble Shootingaff bearNoch keine Bewertungen

- Bag House Differential Pressure: Key Indicator of Operation and TroubleshootingDokument8 SeitenBag House Differential Pressure: Key Indicator of Operation and TroubleshootingZegera Mgendi100% (2)

- Iron Roughneck ST-80CDokument145 SeitenIron Roughneck ST-80CFlorin Stoica75% (8)

- Use and Maintenance ManualDokument152 SeitenUse and Maintenance ManualArnaldo OviedoNoch keine Bewertungen

- Manual Fierastrau Panglica Shark 280 SXDokument152 SeitenManual Fierastrau Panglica Shark 280 SXnicuciuca0% (1)

- Fertilizer Guide 170418 508Dokument162 SeitenFertilizer Guide 170418 508Job MateusNoch keine Bewertungen

- SS20 All Films CarliDokument4 SeitenSS20 All Films CarlibulentbulutNoch keine Bewertungen

- Brochure - Mecontrol AirDokument2 SeitenBrochure - Mecontrol AirKenny RuizNoch keine Bewertungen

- SUPER THERM Weather Resistive Barrier Solves Building ChallengesDokument1 SeiteSUPER THERM Weather Resistive Barrier Solves Building ChallengesbulentbulutNoch keine Bewertungen

- Nansulate For Energy Efficient WindowsDokument5 SeitenNansulate For Energy Efficient WindowsbulentbulutNoch keine Bewertungen

- Pump AuditDokument1 SeitePump AuditbulentbulutNoch keine Bewertungen

- Flo Way PresentationDokument33 SeitenFlo Way PresentationbbulutmmNoch keine Bewertungen

- Light Bulb CalculatorDokument7 SeitenLight Bulb CalculatorbulentbulutNoch keine Bewertungen

- SS20 All Films CarliDokument4 SeitenSS20 All Films CarlibulentbulutNoch keine Bewertungen

- Bu Coalpsa en v011Dokument2 SeitenBu Coalpsa en v011bulentbulutNoch keine Bewertungen

- Open Gears: Lubrication + Maintenance + ServiceDokument16 SeitenOpen Gears: Lubrication + Maintenance + ServicebulentbulutNoch keine Bewertungen

- Loesche Classifiers Modification Report at MCLDokument42 SeitenLoesche Classifiers Modification Report at MCLnsprasad88Noch keine Bewertungen

- SUPER THERM Weather Resistive Barrier Solves Building ChallengesDokument1 SeiteSUPER THERM Weather Resistive Barrier Solves Building ChallengesbulentbulutNoch keine Bewertungen

- WEBBH009 - Baghouse Maintenance GuideDokument1 SeiteWEBBH009 - Baghouse Maintenance GuidebulentbulutNoch keine Bewertungen

- Çap3668 X L 1777-ModelDokument1 SeiteÇap3668 X L 1777-ModelbulentbulutNoch keine Bewertungen

- SUPERTHERM Over Tanks JapanDokument2 SeitenSUPERTHERM Over Tanks JapanbulentbulutNoch keine Bewertungen

- WEBBH009 - Baghouse Maintenance GuideDokument1 SeiteWEBBH009 - Baghouse Maintenance GuidebulentbulutNoch keine Bewertungen

- Nansulate Translucent PT DataSheetDokument2 SeitenNansulate Translucent PT DataSheetbulentbulutNoch keine Bewertungen

- SUPERTHERM Over Tanks JapanDokument2 SeitenSUPERTHERM Over Tanks JapanbulentbulutNoch keine Bewertungen

- Dustex Turkey - Cement Industry 11-27-13Dokument37 SeitenDustex Turkey - Cement Industry 11-27-13bulentbulutNoch keine Bewertungen

- Dustex Overview For DustexTurkey TrainingDokument69 SeitenDustex Overview For DustexTurkey TrainingbulentbulutNoch keine Bewertungen

- CompAir L23 - L29 - RS Compressor Brochure PDFDokument8 SeitenCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutNoch keine Bewertungen

- Filter Media Selection GuideDokument29 SeitenFilter Media Selection GuidebulentbulutNoch keine Bewertungen

- Stroboskop RT LED TR PDFDokument2 SeitenStroboskop RT LED TR PDFbulentbulutNoch keine Bewertungen

- Chap 2 3 PDFDokument56 SeitenChap 2 3 PDFbulentbulut100% (1)

- Dustex Turkey - Power Industry 12-16-13Dokument37 SeitenDustex Turkey - Power Industry 12-16-13bulentbulutNoch keine Bewertungen

- High-Pressure Grinding 2MB PDFDokument0 SeitenHigh-Pressure Grinding 2MB PDFbulentbulutNoch keine Bewertungen

- Without ATEX Permission: LED-cap Lamp With 2-Step Illumination (Emergency Light, Main Light)Dokument29 SeitenWithout ATEX Permission: LED-cap Lamp With 2-Step Illumination (Emergency Light, Main Light)bulentbulutNoch keine Bewertungen

- 4D - Yulianti Viviana - Exercise 9Dokument7 Seiten4D - Yulianti Viviana - Exercise 9Uli JennerNoch keine Bewertungen

- Food Science, Technology & Nutitions - Woodhead - FoodDokument64 SeitenFood Science, Technology & Nutitions - Woodhead - FoodEduardo EstradaNoch keine Bewertungen

- Joel Werner ResumeDokument2 SeitenJoel Werner Resumeapi-546810653Noch keine Bewertungen

- Rock Type Identification Flow Chart: Sedimentary SedimentaryDokument8 SeitenRock Type Identification Flow Chart: Sedimentary Sedimentarymeletiou stamatiosNoch keine Bewertungen

- E.sybox - Esybox All Information PDFDokument56 SeitenE.sybox - Esybox All Information PDFnle_16948Noch keine Bewertungen

- Psalms Magick of The Old Testament PDFDokument129 SeitenPsalms Magick of The Old Testament PDFirrrs100% (1)

- Ir Pc-1: Pre-Check (PC) Design Criteria For Freestanding Signs and Scoreboards: 2019 CBCDokument15 SeitenIr Pc-1: Pre-Check (PC) Design Criteria For Freestanding Signs and Scoreboards: 2019 CBCAbrar AhmadNoch keine Bewertungen

- Cefoxitin and Ketorolac Edited!!Dokument3 SeitenCefoxitin and Ketorolac Edited!!Bryan Cruz VisarraNoch keine Bewertungen

- Moment Influence Line LabsheetDokument12 SeitenMoment Influence Line LabsheetZAXNoch keine Bewertungen

- PE and Health 12 - Module 7Dokument19 SeitenPE and Health 12 - Module 7Stephen Lorenzo A. DoriaNoch keine Bewertungen

- HUMAN RIGHTS, RATIONALITY, AND SENTIMENTALITYDokument13 SeitenHUMAN RIGHTS, RATIONALITY, AND SENTIMENTALITYJohn HunterNoch keine Bewertungen

- Project Planning and Management Unit 1Dokument13 SeitenProject Planning and Management Unit 1Savant100% (1)

- Intelligent Transportation System SolutionsDokument38 SeitenIntelligent Transportation System SolutionsWisnu AjiNoch keine Bewertungen

- Youre The Inspiration CRDDokument3 SeitenYoure The Inspiration CRDjonjammyNoch keine Bewertungen

- Reasons Why Coca Cola Has A Large Market Share in Kenya and The WorldDokument9 SeitenReasons Why Coca Cola Has A Large Market Share in Kenya and The WorldAludahNoch keine Bewertungen

- HCCM System Technical Specification v1Dokument12 SeitenHCCM System Technical Specification v1Ankita ChowdhuryNoch keine Bewertungen

- Ownership and Governance of State Owned Enterprises A Compendium of National Practices 2021Dokument104 SeitenOwnership and Governance of State Owned Enterprises A Compendium of National Practices 2021Ary Surya PurnamaNoch keine Bewertungen

- Electronics HubDokument9 SeitenElectronics HubKumaran SgNoch keine Bewertungen

- Surface water drainage infiltration testingDokument8 SeitenSurface water drainage infiltration testingRay CooperNoch keine Bewertungen

- Silicone Bonding BrochureDokument4 SeitenSilicone Bonding BrochureAmir ShahzadNoch keine Bewertungen

- Trishasti Shalaka Purusa Caritra 4 PDFDokument448 SeitenTrishasti Shalaka Purusa Caritra 4 PDFPratik ChhedaNoch keine Bewertungen

- PA2 Value and PD2 ValueDokument4 SeitenPA2 Value and PD2 Valueguddu1680Noch keine Bewertungen

- Primavera Inspire For Sap: Increased Profitability Through Superior TransparencyDokument4 SeitenPrimavera Inspire For Sap: Increased Profitability Through Superior TransparencyAnbu ManoNoch keine Bewertungen

- How 50 Million People Are Changing the WorldDokument5 SeitenHow 50 Million People Are Changing the WorldCTRCTR0% (1)

- 740 (Q50, V40, Awa 4Dokument10 Seiten740 (Q50, V40, Awa 4rawat2583Noch keine Bewertungen

- Italian Painters 02 MoreDokument450 SeitenItalian Painters 02 Moregkavvadias2010Noch keine Bewertungen

- Assessment in Southeast AsiaDokument17 SeitenAssessment in Southeast AsiathuckhuyaNoch keine Bewertungen

- Echt Er Nacht 2014Dokument8 SeitenEcht Er Nacht 2014JamesNoch keine Bewertungen

- S4 - SD - HOTS in Practice - EnglishDokument65 SeitenS4 - SD - HOTS in Practice - EnglishIries DanoNoch keine Bewertungen

- The Transformation of Metaphysical ScienceDokument7 SeitenThe Transformation of Metaphysical ScienceblavskaNoch keine Bewertungen